Everything posted by HS30-H

-

'69 through '73 Steering Wheels - Wood, or Plastic?

There are several world-class research universities in my home city. In the new 2023 term I will ask about the possibility of testing. I doubt they would do it "for free", but I will approach them nonetheless.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

I invite you to take another look at the photos I posted at the beginning of this thread. Does that look like "stone powder" to you? How about "wood powder"? It's almost like you're talking about a different substance completely. Mine has a clearly-visible structure of oriented strands and what might fairly be described as 'grain'. I'm pretty sure that if I showed it to anyone on the street in a blind tasting experiment they would say 'wood'. Why still this push-back on the nature of the majority component?

-

Factory fog light relocated horn mounts

Kind words. Thank you.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

Yes! And don't forget the "...For The USA!" part... Tell that - just a few days after Christmas - to Frankincense and Myrrh. They'll Shellac you for it. Seriously, we don't know what kind of 'resin' was used as a binding/curing agent here. We are guessing. But given Japan's long history with lacquerware ('Shikki') I would not necessarily bet against the binding/curing agent being plant-derived. Another guess yes, but one with some supporting evidence. Incidentally, there's an old Japanese technique called 'Harinuki'/'Ikkan Bari' which is - in effect - paper composite. Japanese 'washi' paper was put into a mould or former and lacquer was applied in layers to 'cure' it into the desired shape. There was also a process called 'Shunkei Nuri' where wood was stained to bring out the grain and then lacquer applied in layers - sometimes with added metal flakes or shell fragments for decoration - to preserve the effect and make it water (or tea) proof. The artisans involved would probably find Izumi's wood composite work somewhat familiar, I should think. I would respectfully add that we are missing two key points here. Volume production and cost. Nissan specifically wanted wood steering wheels (they already had true 'Plastic' steering wheels for their more basic models, and they were made by a company called - wait for it - 'Nihon Plastics') but it was at that point fairly hard to mass-produce them. The traditional wooden steering wheel of the 50s and 60s was predominantly a low volume/hand made type of item attached to higher status/more sporting cars, or sold as a comparatively expensive aftermarket accessory with a brand name attached. Izumi's techniques allowed wood steering wheels to be mass produced (hundreds a day at least), and at a cost that made them viable for fitment as standard equipment. This is important.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

I'm here all week, by the way.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

Ironically enough, with a couple of coats of 'restoration' varnish/gloss coat on top of the wood composite of an original wheel, 'plastic' is pretty much what you *are* touching and feeling...

-

Factory fog light relocated horn mounts

432-R got an oil cooler as standard equipment (it was a Sports Option extra for the 'ordinary' 432) but that sat on the core support in front of the radiator, offset to the left of the car, with two 'feet' that bolted to pre-drilled holes in the core support. There were two tab fixings at the top which were screwed into pre-drilled holes underneath the top lip of the core support. There was also a factory oil cooler option for the L-series engined cars, but that was longitudinally mounted in the centre of the core support and sat on two inverted L-shaped brackets which bolted through (again) pre-drilled holes in the core support crossmember. However, the brackets you are asking about are not oil-cooler related, or fog lamp related either. They are definitely the mounts for a nascent aircon condenser radiator which doubled as re-locators for the horn units.

-

Factory fog light relocated horn mounts

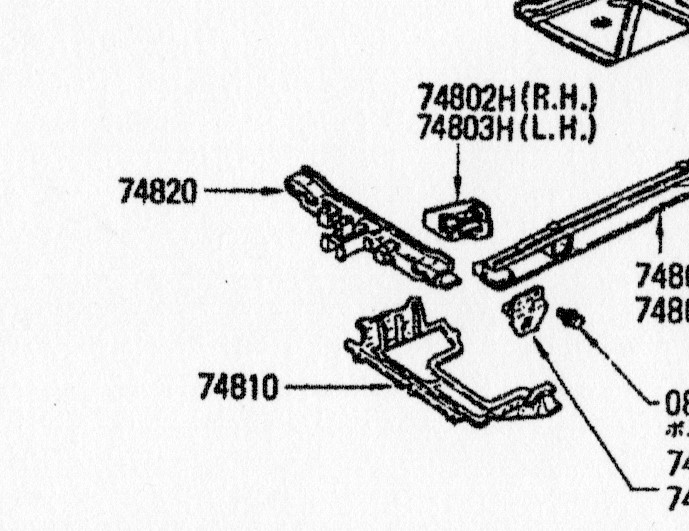

There are two 'fingers' protruding from the bottom of the 432's air filter box, and they slip into the double recess tab. The upper fixings are captive studs which pass through pre-drilled holes on the RH core support. This is what the 'fingers' look like without the double recess tab they fit into:

-

Factory fog light relocated horn mounts

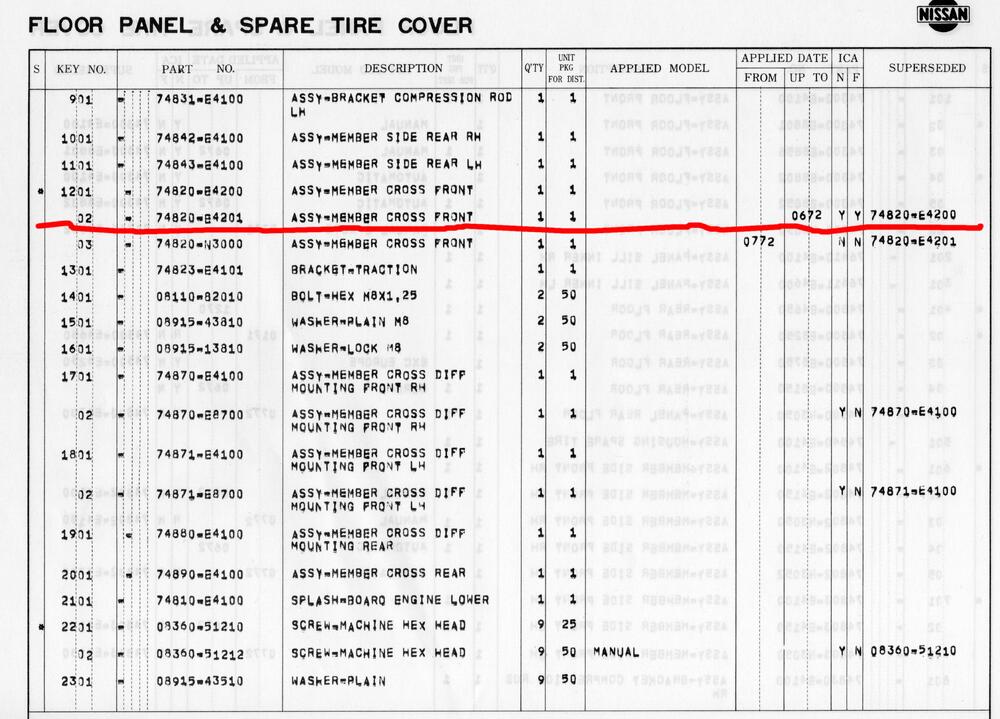

The extended horn mount brackets were a short-lived phenomenon related to the nascent factory fitment of an air conditioning condenser. The mounts moved the horns further away from the radiator and also acted as the lower mounts for a condenser. The 74820-E4201 front (radiator support) crossmember was supplied as a 'universal' replacement part for a period, and it carried a couple of hermaphroditic details that were not usually required on the cars they were being fitted to. If you look to the left on your above photo you can see a double recess tab spotwelded to the front face of the crossmember. This was the mount point for the bottom of the 432's air filter box, included on the E4201 crossmember because of its 'universal' nature.

-

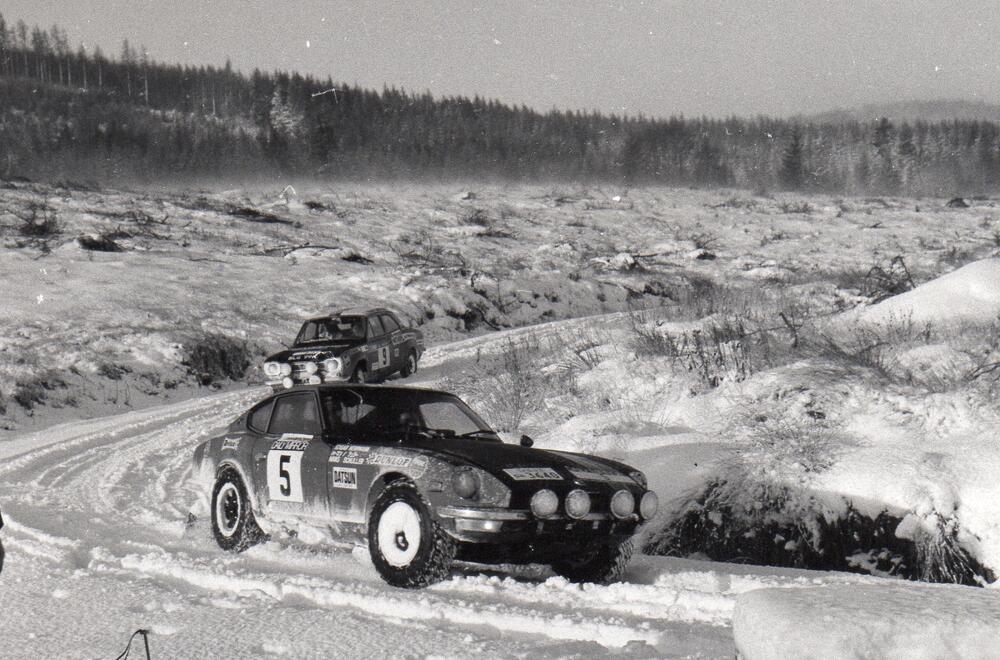

1970 240Z Works Rally - the road to restoration

I was told that the diff cooler setup on '8D-433' (the '71 Safari winner) was removed when the car went back to Japan and began to be used as a display exhibit to celebrate the Safari win at shows and regional dealerships. Probably part of an effort to make the car a little more practical (and less smelly...) and for sure some effort was made to tidy the car up a little at that time. Back in Japan the car became visibly more complete than when it finished the Safari. Then, a few years ago, Nissan's team of volunteer restorers at Atsugi 'refreshed' the car once again as part of a program intended to make the car 'safer' and more presentable for public display (liability insurance concerns part of the deal) and - in my opinion anyway - they got a bit too close to throwing the baby out with the bath water. For example, they re-upholstered the seats (in the wrong shade of fabric, grrrrr...) and touched up paintwork that didn't need touching up. They even replaced the rear license plate with a new one (grrrrr...). They had done the same with the '72 Monte Carlo 3rd place finisher some years earlier, with similar baby-down-the-plug-hole results. Its hard to photograph the diff cooler in situ unless you can get the car on a ramp or lift, but - I think - in the '71 Safari winner's case it is no longer there to be photographed.

-

1970 240Z Works Rally - the road to restoration

I can't recall having seen a Works 240Z rally car *without* the Japanese market style extended seat mount brackets. As far as I am aware they all had them. Certainly all the cars that still exist have them. They would not normally be seen on any Export market cars. This seems to be another built-for-purpose quirk of the Works rally cars.

-

1970 240Z Works Rally - the road to restoration

-

1970 240Z Works Rally - the road to restoration

I was told that the advantage of the oil/fuel heat exchanger diff cooler was that - on a rally car - it was not so vulnerable to damage and/or blockage in the way that a traditional air-cooled 'radiator' would be. It gets pretty messy underneath the car in rally conditions. Nissan's Works team used traditional type coolers on their diffs for circuit racing duties. The parts were available to buy from the Sports/Race Options list and the Nissan Sports 'Yellow Books' gave advice on fitting:

-

1970 240Z Works Rally - the road to restoration

Nissan had used the little fuel/oil heat exchanger (its actually a 130-series Cedric/Gloria part) as a diff cooler on the 510-series Bluebird Works rally cars (winning the East African Safari Rally with them in 1970) and engineered a similar system for the first batch of 240Z Works rally cars (entered in the 1970 RAC Rally). However, there was some debate over whether diff cooling would be an issue given that the RAC Rally was traditionally held in the depths of the British winter, and before the rally the team mechanics removed the heat exchangers and pumps from the cars in a quest to save weight and simplify. Cue trouble. Without the coolers the diffs got very hot indeed and that extreme heat weakened the thread locking compound on the crownwheels, causing bolts to loosen, back out and catch on the housing. Spare diffs were carried on the team service cars, but they used them all up. The replacements - of course - failed in the same way. Aaltonen and Easter managed to nurse their car to a 7th place finish, but Fall/Phillips, Herrmann/Schuller and Bloxham/Salt all retired with differential failures. Seems the diff coolers would have been beneficial after all.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

The raw wood was first processed into wood fibre (so, the grain was preserved) which could then be impregnated with the bonding agent and laid into the two halves of the former in continuous rings. There's a surprising amount of push-back on all this. It's a known and understood process, but the whole "they are plastic!" thing is ingrained and deep rooted in a particular branch of the community...

-

1970 240Z Works Rally - the road to restoration

Although Uemura san's stories are always very interesting, I somehow doubt he would pitch them into a conversation around the diffs on the Works 240Z rally cars. Nissan's Works rally team already had the experience and data accumulated from the use of the R160, R180 and R190 Fuji Heavy Industries differentials that had been used in competition before the 'Kaku U' 240Z team had pitched up in North America, and there will have been very little transferable/comparable data between the (3.3:1 ratio) 2-pinion 'open' R180 used in the North American 240Z and the 4.375~5.1 ratio 4-pinion plate LSD-equipped R180s used in the Works rally cars.

-

1970 240Z Works Rally - the road to restoration

The gas struts certainly overpowered the tailgates on the lightweight Works cars, giving them a characteristic twist on the LH side: I can't recall a good photo of a 432-R Sports Option style prop rod setup on a Works rally Z, but I'll have a look for one. For my own FRP tailgate with acrylic window, I'm using a gas strut but discharged it by drilling a hole in the body (its a mixture of gas and oil in there, so be careful if you drill...) and then drilled a hole in the rod so that I can insert a big R pin in it to hold it up. I know a couple of cars which used the same solution in period. Seems to have eliminated the 'twist':

-

Datsun-240z Vs Fairlady-z432

Looks spot-on to me, Kats. Great colour choice too. FRP bonnet has to fit imperfectly to be perfectly authentic-feeling. That's what they were like!

-

Ask the eZperts

At some point (it may have already passed...) it will become necessary to define what market sub-variant is being referred to. Production date will also be a factor with regard to detail changes. For example: I have a no-hole 'splash pan' hanging up on the wall of one of my garages. Obviously the splash pans were part of the original design for the L-Series engined cars across the board (because the fixing points are there on each car and we see them in the early factory literature) so the question then becomes whether they were being fitted consistently across all markets and models. USA/Canada may have been an outlier here considering the other examples of de-contenting in those markets. I can't imagine why dealers would go to the trouble of removing them from new cars? Here in the UK the splash pans had a reputation for not being re-fitted after servicing (especially after an oil change) but that was typically laziness rather than any kind of policy. I remember we had several conversations on here about the splash pans in the past. The finish question (as far as I remember) concluded that the photos in the service manuals may have used unpainted (Zinc plated?) pans to allow them to be seen more clearly, but there were anecdotes of silver (?) pans being sighted on production cars too. My experience is that all of the 'early' style (no holes) pans I have come across were painted black and I have certainly seen black painted pans supplied as replacement parts, complete with Nissan parts sticker. So - in reference to this "eZperts" thread - I don't think it will be possible to make a definitive conclusion as to whether a particular car would have had a splash pan or not, apart from pointing out that it was part of the original design...

-

240Z restorations, what's right and what's not

So I don't want them. I'd rather see a broken original.

-

240Z restorations, what's right and what's not

I still think we are applying a slightly unfair level of scrutiny to it, and you yourself imply it was 'done wrong'. There's a big yawning gap between the new owner's comments on BaT and our nitpicking here. Where's the pragmatism? Winning bidder said: "I am convinced there isn’t another one in the world in this condition! I’ve waited a long time for the right one and I know I’m getting the best one!". I think BaT is something of an echo chamber in cases like this. This is why I still feel a patinated and lived-in unrestored car pleases me more than the average 'restored' car, in the same way that a lived-in human face - without surgery, 'fillers' and veneers - makes me feel. Done right? Only the original cars were "done right". Anything else is just simulation.

-

1970 240Z Works Rally - the road to restoration

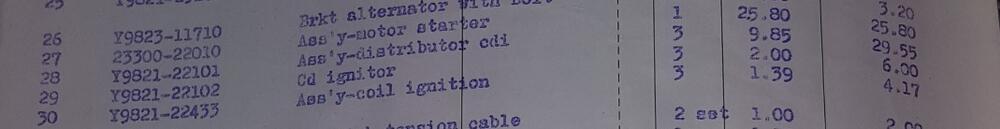

My own view is that the fitting of CDI is possibly one of those 'evolutionary' differences in the different batches of Works rally cars. The two earliest batches of cars (1970 RAC Rally batch and 1971 Monte Carlo Rallye batch) may or may not have had CDI ignition modules, but the 1971 Safari and 1971 RAC Rally batches certainly had them. Both were RHD batches and (most probably) used the E72 'Cowl Top Inner' 432-R type panel with the CDI mount bracket already in situ, but - apparently - without the heater inlet duct brackets (because full heater was fitted). The import carnet spare parts list for the Works team's entry on the 1971 RAC Rally included the following:

-

1970 240Z Works Rally - the road to restoration

Perhaps it is not so surprising that the heater inlet duct 'chimney' doesn't have 432-R style captive nuts? After all, this is an LHD car and there were no LHD versions of the 432-R's E72 'Cowl Top Inner' to use. Additionally, a Works rally car would most definitely need a fully operating heating and ventilation system (and more!). All the roadgoing 432-Rs I've seen had the fresh air ducts, flaps and cables. There's not much weight in them and they would certainly be a welcome presence on a road car driven in Summer. I don't know if it will have been done on xs10shl's car, but other (later) Works rally 240Zs had 'overclocked' fan motors with extra windings, allowing them to push more air. They also enlarged the ducts under the windscreen and put wire mesh in them to stop them swallowing up anything important... There's some evidence of Namba san's mentioned ventilation system mods on cars later than the '71 Safari winner. '7924' is the '73 Safari winning car of Shekhar Mehta. LHD, but it was originally built in order to take part in the 1972 RAC Rally (driven by Rauno Aaltonen) and it shows the much-modified heater box and blower motor mounting position they used. This Works rally-specific mod hides its light under a bushel, and its full splendour would only be revealed if the dash was removed...

-

1970 240Z Works Rally - the road to restoration

Stock (roadgoing) 432-R tailgate was steel, of course. It had the acrylic window and used the stock window rubber (sans stainless trim) to hold it in. Nissan Sports/Race Option tailgate was FRP and had the standard shape lip, so could accept the stock window rubber and either stock glass or acrylic window. That matches what I've seen too. The FRP tailgate used by the early Works rally cars must have been a dedicated moulding because of that different window-mounting lip. It allows the bonded acrylic window to sit pretty much flush with the outer surface of the tailgate. Somewhere I've got photos of a Works lightweight car with a bonded window that has very small screws embedded (covered) in the bonding material for a belt-and-braces solution.

-

1970 240Z Works Rally - the road to restoration

Did it have any of the venting/draining gubbins inside it. Other Works FRP tailgates I have seen had the vents blocked off and therefore didn't have any of the usual internals.