Everything posted by HS30-H

-

Magazines: Perhaps the first German mention of Goertz in 1974

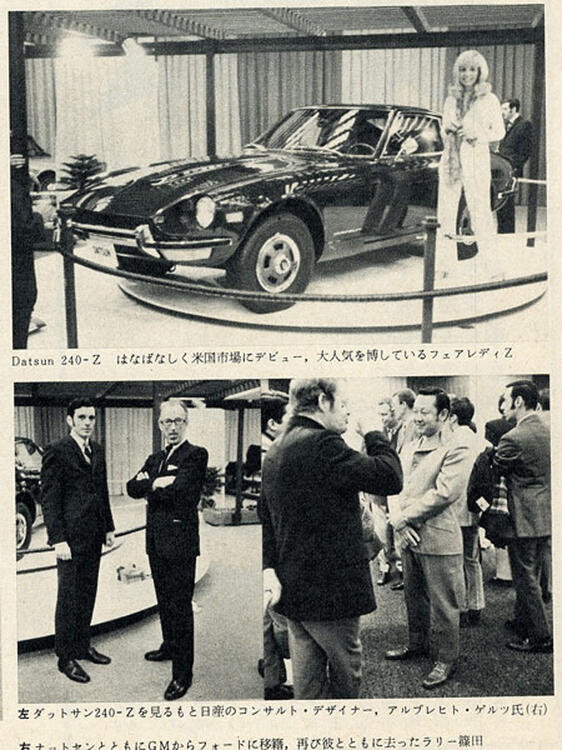

You've got the right show. Goertz was photographed there - hanging around the Datsun 240Z that was on display - by CAR GRAPHIC magazine of Japan. I think it goes without saying that Goertz would have been talking up his (non) connection to the new car as soon as it debuted and hit the media in October 1969, so your hunt for the first example of such story being actually published is probably going to be somewhat subjective. Car shows presented great opportunities for Goertz to meet with industry insiders as well as international journalists. This could be a 'Where's Wally' type hunt... I'm not sure what the exact lead time on CAR magazine (UK) was in 1970, but the cover date for UK magazines in that period was usually up to four weeks - possibly more - before publishing, so I would say it is likely the March 1970 cover-dated issue hit the news stands in early February 1970 and the Goertzlore pre-dated the 4/70 NY Intl. show. There are were several other shows in the USA that could be candidates for a Goertz sighting (we have discussed early USA and Canada shows on this forum), and - of course - he could easily have been spreading his story amongst personal contacts between-times. He would naturally have been surfing the buzz about the new car. Here's the photo from CAR GRAPHIC Japan relating to the 4/70 NY show at the Coliseum. The caption below calls Goertz "a consultant designer for Nissan", although - technically - Goertz was never engaged by Nissan as a 'designer'.

-

Magazines: Perhaps the first German mention of Goertz in 1974

Seems logical.

-

Magazines: Perhaps the first German mention of Goertz in 1974

I think the 507 looks OK until you see somebody sitting in (on) one. At that point, it turns into a kiddy's fairground ride. And here it is again. The bald and simplistic idea that the Japanese 'copy', as though its a one-way street. And from a Dutchman too. Maybe another tour around the van Gogh museum in Amsterdam might put it into context somewhat?

-

Magazines: Perhaps the first German mention of Goertz in 1974

Hi Florian, and welcome. Well, for sure it had to come out of Goertz' mouth first. Apparently he was telling anybody who would listen that *he* had 'designed' the Z as soon as it debuted. We can even see him hanging around the car in photos from the 4/70 New York International Auto Show. Networking and hustling... From the Feb '74 Rallye Racing article: "The creator of this entirely un-Japanese looking car is the German AIbrecht Graf Goertz, an industrial designer. He provided the body design for this sports car first introduced in 1969." Coincidentally, I came across a similar "un-Japanese" quote earlier this week in a YouTube clip. But what does it actually mean? If the styling of the S30-series Z is "un-Japanese", then what does a 'Japanese' car look like? There has to be a thesis for their stated anti-thesis. The quote I saw came from somebody who was convinced it was Goertz' creation. We know it wasn't, so I wonder if knowing that would make it any more - or less - "un-Japanese" to his eye? At the very least it is a stupid thing to say, at worst it verges on xenophobia. Underestimation of Japan and the Japanese can often be sniffed between the lines in that period, and that will - in my opinion - have bolstered Goertz and his rather tall stories. The inference is... the Japanese didn't do it. And not only that, the Japanese couldn't have done it even if they wanted to. Sorry, I don't think I can help with any earlier sightings of Goertzlore than the 1970 CAR Magazine example, but thanks for bringing the topic up again and allowing me to stick another pin into my Goertz voodoo doll.

-

Datsun-240z Vs Fairlady-z432

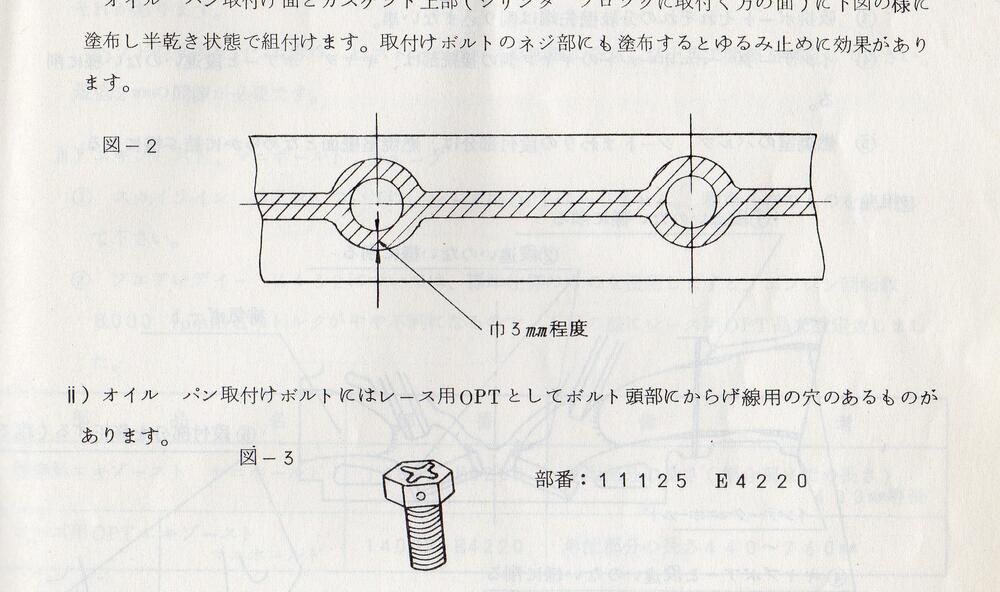

That's a nice purchase, Kats. I am jealous! Quite possible it did indeed come from SS KUBO. Kubo san acquired many parts from Tomei, Scuderia Nissan and the Works team over the years he was involved in racing and afterwards. He picked up a lot of rare parts. There's a small mention of lockwiring in the first Nissan Sports 'Yellow Book' from 1970. This was for the oil pan bolts, but - as Patcon mentions - this was common in aviation and specialist machinery preparation since the beginning of the industrial revolution (I've seen it used on steam pumps from the early 1800s...). Typically the bolts are locked against each other to stop loosening from vibration. Here's an example from a Works rally L24:

-

1970 240Z Works Rally - the road to restoration

That series of photos was taken by Rob Janssen's friend and navigator Jaap Dik, who carried a camera with him on the events they took part in. For sure a rock star move, but they had little to no option. No private jet home for them whilst others swept up the mess. Heroic privateers on a shoestring budget!

-

1970 240Z Works Rally - the road to restoration

Something we have discussed before, but is it not a possibility that OWSS simply supplied and fitted a set of the taller RAC type springs to use on the same Monte struts originally fitted to the car? I would think, what with Works parts being in short supply in-field (I am in possession of much period correspondence where OWSS, Datsun UK and various privateers were all trying to get hold of Works-specific spares in order to use Works cars that they had care of) that could have been a possibility. Have you got any intact part number alloy tags or painted numbers on the springs? Any legible Dymo tags on the rear strut tubes?

-

Datsun-240z Vs Fairlady-z432

Wow. Excellent!

-

Datsun-240z Vs Fairlady-z432

I have an earlier repro on my Pretend-R. Technically speaking I guess the genuine PZRs didn't need this part as they didn't have the air filter housing, air filter duct and airbox (running open trumpets) in the way, but I like it in any case.

-

Datsun-240z Vs Fairlady-z432

Attached some photos of a couple of rare original examples I have handled. Your repro example looks accurate, and even has the seam in the middle that was missed off in previous repros. Seems there was indeed a foam gasket on the inner fender flange, so you have done what the factory originally did:

-

Datsun-240z Vs Fairlady-z432

Hope that helps. Happy to take any other measurements/photos if required. Can't help with any identifications here I'm afraid, although I have seen brackets in that area on C10-series GTR-specific aftermarket manifolds in the past, bracing them to the bellhousing. Actually I have seen many, many aftermarket exhaust manifolds for these engines. Some of them were one-offs or made in really small batches. The ex manifold on my KPGC10 was made by a race car builder called 'Ito Racing' specifically for the car in the late 1970s, and was beautifully made in the old school sand-filled hand-bending method. It would have been almost impossible to identify without the knowledge passed-on by the previous owner, who commissioned it.

-

Datsun-240z Vs Fairlady-z432

Here's my early 1970 PS30-type S20 OEM exhaust manifold and the dimensions from the centre of the rearmost hole in the mounting flange horizontal to a 90 degree line from the mounting face of the 'binocular' flange and the centre of its innermost bolt hole (does that make sense?). Anyway, pictures saving words:

-

Datsun-240z Vs Fairlady-z432

I've got an OEM exhaust manifold from an early 1970 432 hanging on the wall in one of my garages. I can measure it for you tomorrow.

-

1970 240Z Works Rally - the road to restoration

Hopefully not too much of a digression, but here's a photo of another iteration of the Teikoku Dempa/Clarion intercom/interphone box. This is an original period photo from a small hand-made booklet of data and advice put together by Nissan's Works competitions department at Oppama, and sent to the de-facto competitions department here in the UK in May 1974 (by then based at Nissan UK's Worthing HQ) with the intention of informing the UK competitions staff about details of the new P710 'Violet' Works rally cars which were - at that point - being shipped to them. The intercom/interphone unit is very similar to the one seen on '7924', which was built in mid 1972. It has the same volume control (interestingly, for a 'new' and supposedly unused car, the control knob appears to be missing as it is on '7924', which makes me wonder if they were prone to falling off, or just not fitted...?) and it also has the external 'floating' jack boxes, but with some extra belt-and-braces suspension for them. So, an indication that the Works team carried on with the same basic design well into 1974. I guess that Teikoku Dempa must have made a fair few of them?

-

Albrecht Goertz and the 240Z

It's a pastiche of one of the original World Championship of Makes stickers. Porsche were serial - consecutive - winners in that period:

-

Albrecht Goertz and the 240Z

From a combination of ignorance, opportunism and pastiche (of an original Porsche badge). See some of this seller's other alternative reality fantasies here: Martini/Targa Florio/Datsun emblem

-

1970 240Z Works Rally - the road to restoration

I've dug out some photos of 'TKS 33 SA 7924', an LHD car originally built as part of a batch for the 1972 RAC Rally (driven by Rauno Aaltonen and navigated by Paul Easter, running number 6, finishing 11th overall and 3rd in the Group 4 class) which went on to win the 1973 East African Safari Rally, driven by Shekhar Mehta and navigated by 'Lofty' Drews running number 1. It has a later evolution of the 'Teikoku Dempa' intercom with external headphone jack units (which would appear to give more freedom of movement and less stress on the jack plugs) but it still gives a Model No. of 'Y-4009' and with a Serial No. of '066'. Volume control appears to be conventional 'pot' type dial knob rather than the rotary (I don't know what to call it?!) dial on your Serial No. '014' unit. Interesting that there is a 52 unit difference between serial numbers for a roughly two year production gap. It was powered by a battery pack mounted behind the RH rollover bar mounting bracket, carrying two batteries (one connected, one spare) and press-on old battery radio style blue vinyl-covered connectors:

-

1970 240Z Works Rally - the road to restoration

Great 'behind-the-scenes' photos there Kats. I have not seen those before. Excellent! Yes! Rauno Aaltonen was often seen wearing a red crash helmet around that time. In later years I have seen photos of him using a white one too. Aaltonen had a reputation for being fastidious and meticulous about his preparation, and whenever I see photos of him before rallies and at servicing that does seem to come across. He liked to put a '12 O'Clock' stripe on his steering wheels and he also preferred the blue WILLANS brand safety belts, which he would swap with the factory Works team's Takata belts. Here are a couple of colour shots from the '70 RAC and '71 Monte:

-

1970 240Z Works Rally - the road to restoration

Nissan's Works team called this system an 'Interphone' (the period English vernacular being 'Intercom') and they had already been using similar systems on previous Works rally cars. They were especially important/useful on the East African Safari Rally with its long and arduous road sections between special stages, where it was still necessary for the navigator to call the route to the driver, often at fairly high speeds (high noise). They would have been necessary on 'recce'/reconnaisance practice and ice note runs where the crew needed good communication to make accurate pace notes on events such as the Monte and RAC rallies. For the 1970 RAC Rally, the crews were using single-ear interphones that could be used also be used over specially-adapted Paddy Hopkirk crash helmets. Kind of unwieldy, and it is easy to see why the next step was to integrate the earphone on the inside of the helmet. Some photos of testing in the UK prior to the 1970 RAC Rally, where the crews were getting used to the new systems: Rauno Aaltonen, Hans Schuller and Tony Fall: Detail: Aaltonen and Fall: Tony Fall with Works team mechanics, team manager Takashi 'Waka' Wakabayashi on the left:

-

Center console date ?

'46' indicates Showa 46, which is 1971. Japanese calendar dates tend to follow USA format, which is Year-Month-Day, so '46-11-9' is November 9th 1971. This of course indicates manufacturing date and/or quality control check of the console, not of the car. It may even be for the FRP moulding of the console body and not the completed article. Consoles were made in another facility and then shipped in batches to Nissan Shatai's Hiratsuka plant for the build-up of the cars. The batches may well have been made up of consoles made over several days or even weeks, and it is doubtful that they were attached to cars in sequence according to the quality control date - although it is logical that they would normally have been attached to a car within a few weeks of production. I think it is fair to say that most quality control/production date stamps on the components of these cars tend to average out at within a month of the car being given its 'OK' completion check, although it is possible to observe the odd exception which tends to prove the rule...

-

1970 240Z Works Rally - the road to restoration

Seems logical. Our numbers are very close too.

-

1970 240Z Works Rally - the road to restoration

-

1970 240Z Works Rally - the road to restoration

I have a Works 240Z rally car alternator. It is a Hitachi L-X503. I was told by several people in Japan that this was a heavy duty type usually fitted to various trucks of the period. Works rally modification included adding a splash shield to protect it from ingesting road debris. This was spotwelded to the fan blades. Here's a period photo of a Works car engine bay where the same or similar Hitachi part number is visible:

-

240Z 5 speed transmission?

Datsun Competition in the USA used to supply a 'kit' to convert an FS5C71-A 'Roadster 5-speed' for use in the Z. The transmission you ask about may be an example of this. Datsun Competition supplied various close ratio gear kits for them too. However, the FS5C71-A Servo Synchro 5-speed overdrive transmission was fitted as standard equipment for the S30-series Z range everywhere except the North American market. They were also used on Skyline, Cedric and Gloria models in the Japanese market. Parts (especially the steel Servo-patent synchros) are now hard to find and therefore they can be expensive to refurbish. I have the FS5C71-A on three of my cars and I personally like them, but they have a somewhat undeserved bad reputation which mostly comes from worn out examples.

-

My two swiss S30Z Fairlady Restoration build thread

Yes! You've got it. Definitely 'Conversion & Tuning Centre Ltd' of Brixton, South London. I didn't see the 'C T' logo cast into the manifold in your previous post. Very distinctive. The only other big London-based specialist supplier of carburettors, inlet manifolds and conversion kits from that early 70s I can remember was Chris Montague Carburettor Co. in North London (my side of town), and which I am old enough to have been a customer of. Gone now. They really knew their stuff. I bought my John Passini-authored Weber 'bibles' from them in the late 1970s. My *guess* is that Mangoletsi may have cast some manifolds for C & T London with their logo on them. It probably would have been too expensive for C & T London to have commissioned their own castings with such a relatively small market already covered by Mangoletsi. I would say - judging from the photos - that the C & T London version looks like a neater casting than my '470' Mangoletsi, but that may have been down to batch quality differences? Having said that, other '470' manifolds that have passed through my hands in the past (often from period 'Samuri Conversions' cars) are equally poor castings, so they seem to have been pretty consistently poor. Could C & T London have insisted on a better casting, with their name on them? Seems feasible. Just as an aside for your friend; if he uses this 40DCOE-24 setup on an L24-based engine he might want to try changing to short (10mm) accelerator pump rods and 0.45 accelerator pump jets, as used on the 40DCOE-18. I have recommended this a few times for others with positive results. The Nissan L6 seems to 'like' a short, sharp accelerator pump action on the DCOEs. John Passini covered the topic in his books. Recommended.