Everything posted by HS30-H

-

Z's on BAT and other places collection

You've got at least some of that the wrong way around. BMW '3-series' (like '5-series' and '7-series' etc) is used in the same way that (for example) Mopar used 'A-body' and 'B-body' to denote platform type/size. Hence they carry it across different generations of Series (E21, E30, E36, E46, E90/91/92/93 etc). Similarly, W201 is a Mercedes generation for a particular class of product. The sequence was W121, W110, W201, W202 etc. The whole point about Nissan's S30-series is that it was a series from launch, but people use variant names from within that series as though they are a series themselves. Hence '240Z' instead of HLS30/HS30 and their sub-variants, '260Z' instead of RLS30/RS30/GRLS30/GS30 and their sub-variants, and not even a thought to S30/PS30. Nissan's system made sense and was used across its whole range. The 'base' model in a series was usually the series denominator, hence C10-series Skyline and C10 model, S30-series Z and S30 model.

-

Z's on BAT and other places collection

I can see why the vernacular 'Series 1' etc thing came about, but I think the word 'Series' was probably not a good choice seeing as 'Series' was already defined by NIssan with 'S30 Series'. Additionally, the 'Series 1' etc nomenclature seems to be a moveable feast open to misuse, mistake and misnomer. The Human Element, I guess. It also does not apply neatly (to say the least...) to market variants that are not USA/Canada models. On the contrary. They do. It's the American 'Model Year' thing that doesn't work very well elsewhere. I'm also wary of applying such nomenclature to Japanese cars in general. Sure, Nissan and the other Japanese manufacturers made great efforts to comply with the American 'Model Year' system and apply/inform of certain changes in line with that, but that doesn't mean that their non-USA market output follows suit. The whole thing seems to have been badly applied and open to misuse. Look at how much talk there is on here and Bring A Trailer about the anomalies and inconsistencies in (stated) Model Years vs (stated) Production Dates. It seems like there was a huge gulf of intent between a car rolling off the line at the Hiratsuka plant and it being sold by a dealer in the USA and, despite the best efforts of everyone at Nissan Japan, the dealers were almost free to do what they liked. There are parallels with showroom sales of the new RZ34... Personally speaking, most of what I need to know about a particular car will probably be contained in the combination of its chassis designation and prefix (full 'Katashiki would be nice), production date and its destination market. Anything over and above that comes from looking at the fabric of the car itself. 'Model Year' and 'Series X' are tits on a bull to me. We touched on this several pages back on this thread.

-

Z's on BAT and other places collection

Sorry but I'm definitely the wrong guy to pose that question to. I find the seemingly arbitrary nature of 'Model Year' application to be a USA-specific nonsense open to all sorts of shenanigans. A real chimpanzees tea party. Thanks for the hat-tip though. I wish you good luck...

-

Z's on BAT and other places collection

-

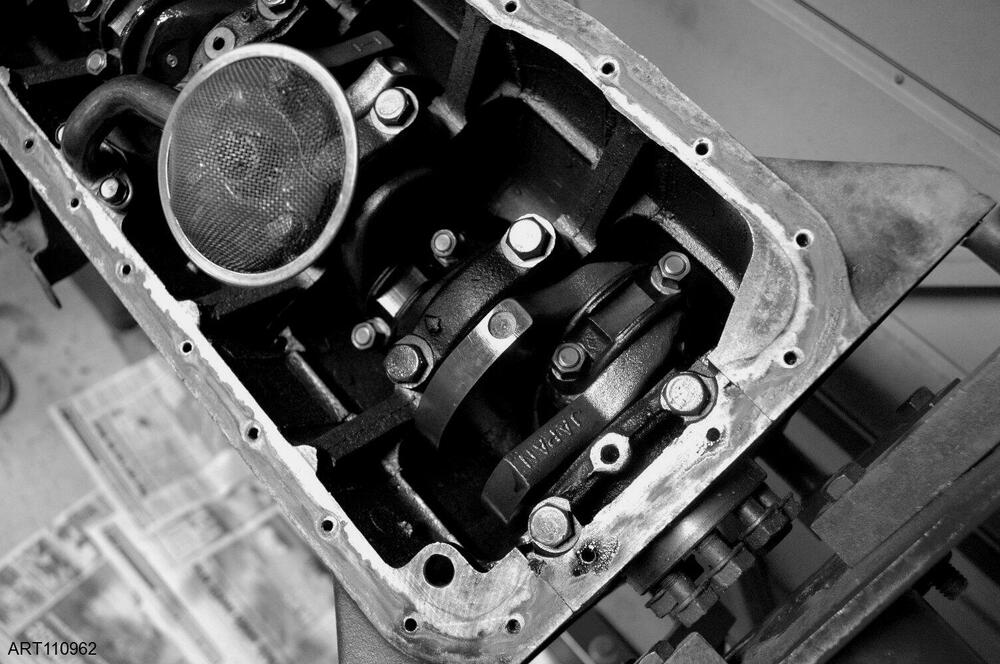

1970 240Z Works Rally - the road to restoration

More specifically, NMC USA - either officially or semi-officially ("come and take this damaged car away...") - provided a handful of HLS30Us to race teams in the USA. Bob Sharp's first car appears to have been a personal deal between Kawazoe san, via Usami san, and Sharp. A damaged show car, no less. You're projecting quite a lot here. Your "...not fit for the purpose" is doing a lot of heavy lifting (some understatement here...). Says who? The cars in question were not provided or sold as race cars. You might as well point out that the fuel tanks, suspension, brakes, transmissions, differentials, wheels, tyres and cigarette lighters were also "...not fit for purpose" in race cars. These were road cars and they required preparation even for production-class racing. The other cars they were competing with often had their own weak spots and requirements for evolutionary parts, even the Porsches. As far as I understand it, the crankshafts suffered from a harmonic (something very common in straight sixes) which caused damage to flywheel bolts, flywheels and clutches under prolonged high rpm use. The crankshafts themselves did not "break" and they were - clearly - being expected to perform far beyond their original design parameters. So, yes. Hardly Nissan Japan's fault. Without knowing what was going on between NMC USA and NMC Japan - remembering that we are constantly told that the L24 was specified "for the USA" in a car that was "designed for the USA" and that the engine was the personal choice of Yutaka Katayama, which is of course nonsense - I'd say it is jumping to conclusions to blame the engineers back in Japan. That's a fairly simplistic - if not bowdlerised - version of events. Plenty of details on these cars were subject to evolution, improvement and supersession. Mr Brock and his followers may well believe that his employees 'discovered' a design fault and were part of the cure, but Nissan were already on the case - just as they were with many other details on the cars. If you follow the part numbers, the homologations and supersessions they give a good picture of what was going on crankshaft-wise, particularly when you look at homologated crankshaft weights. You seem to want to paint the early L24 crankshafts as some kind of mistake, but I believe you need to take other factors - not least production costings, late specification of a sedan engine for a sports car due to the need to mitigate power-sapping anti-pollution devices and the whole question of who was in charge/responsible for the specifications in the first place. Apparently NMC USA and their president get to collect plaudits for success but dodge any finger of blame for perceived problems? Meanwhile, those same engineers at Nissan were planning and developing their Works race and rally LR24 engines... E3141 8-bolt crankshafts with sufficient counterweighting for competition use, made from higher strength steel (NCM45) than the stock L24 crankshafts:

-

1970 240Z Works Rally - the road to restoration

That's why I posted it!

-

1970 240Z Works Rally - the road to restoration

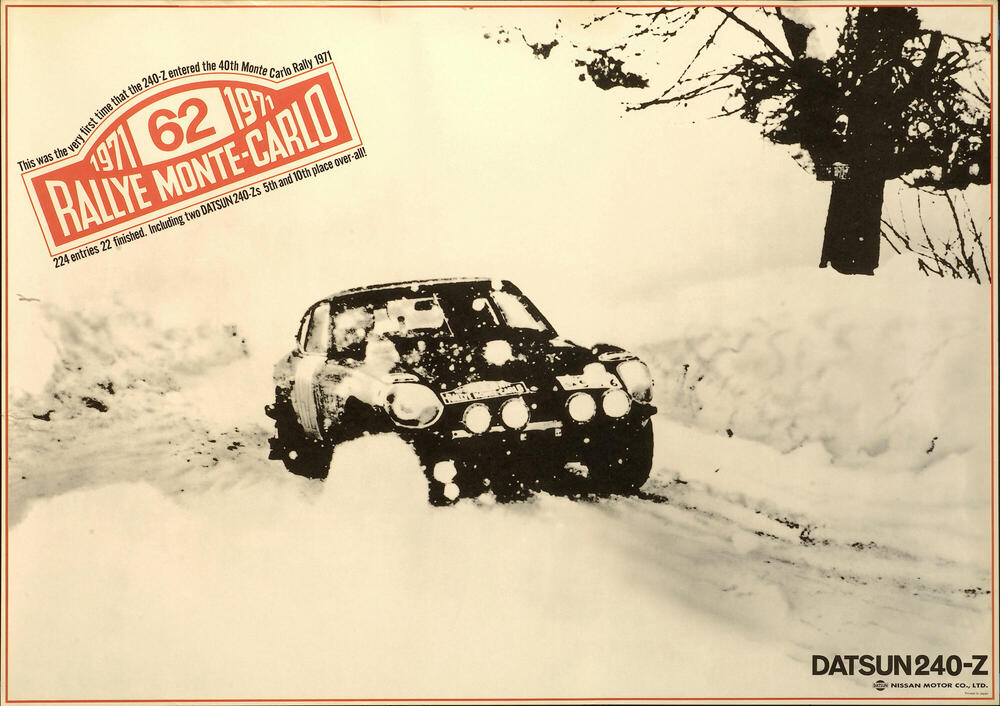

It might actually be beneficial to hear views from people like SpeedRoo, however half-baked they may be. Maybe we can help him straighten it out a little? "Faulty"? How many early L24 crankshafts failed in normal - road - use? The use for which they were designed? Why was the early L24 crankshaft designed and manufactured in the way that it was? You might think different, but I have a hunch that Nissan knew how to design and manufacture a crankshaft properly. We already know that there were problems meeting the required kerb weight and costing of the HLS30U variants (that costing due to an unusually low retail pricing target set by NMC USA) so where to pinch? Personally I'd say that whole subject is a lot less black and white than you want to paint it. And the story of BRE having "discovered" the counterweighting issue and given feedback "to Japan" and therefore solving the issue is for the birds. Happier, thanks (tee hee). You get the point though, right? Nissan - like any Japanese company - takes its home market very seriously. Sometimes people make it sound as though they only existed to feed the USA with cheap cars and trucks, but Nissan's aims were global. Hence we are talking here about a car they built to compete in a world championship European rally, a factor that was taken into account on the drawing board, indeed. On the contrary. Of course they thought it important. That's why NMC USA supported racing in the way it did. How would you have proposed they took part more directly? Factory-built race cars shipped from Japan to take part in local SCCA C-Production races in the different divisions? Or maybe setting up a satellite factory race shop in the USA (or maybe one for the East Coast and one for the West, maybe more...)? It becomes increasingly unlikely the more you think about it. No, the way they went about racing in the USA made perfect sense. Private race teams and private individual racers benefitting from national distributor support was the way to do it. Direct factory team presence would have been disruptive and counter-productive even if there was any possibility of it being logistically feasible, which there wasn't. For Japanese domestic racing and selected international events Nissan could of course take a more direct approach. The car we are discussing here is an example of that. As I've mentioned, Nissan was taking a world view for its activities. That's why it was in Australia before it was in the USA and Canada. That's why it was in Africa. That's why it was in Europe. This wasn't just about selling a few hundred thousand sports cars. I don't know why you find it so difficult to understand how important those 'Big Three' international events - the East African Safari Rally, the Rallye Monte Carlo and the RAC Rally - were to Nissan. It might be possible that one or two people got out of bed and went to work at Nissan Japan whilst dreaming of Bob Sharp winning Sunday's SCCA C-production race at Cumberland, but I somehow doubt it. The farmer in Angola didn't buy his little Datsun truck because he was swayed by the result of a race at Bridgehampton. That's not my view at all. However, there's certainly the occasional whiff of the opposite view from yourself here and there. This recent exchange was prompted by your reaction to the assertion that Nissan's international rallying activities are underappreciated in the USA but, ironically, your reaction serves to prove the point. Why would Nissan have to compete in a USA-based road rally event (not that there was one...) in order for people in the USA to take notice? Are you saying that results of the Safari, Monte and RAC are not of any interest or relevance in the USA? If so, maybe we need to check who is wearing those blinkers you mentioned? Personally, I'd like to give a little more benefit of the doubt. There has always been a hard core of world motorsports enthusiasts in the USA who know what's what, and it is reciprocated. This weekend the subject of this thread was on display at the show in Long Beach. I feel sure it will pique the interest and curiosity of many attendees. The owner is certainly dedicated to the task of helping us all to understand the car and its context more fully, and I am cheering him on with that.

-

1970 240Z Works Rally - the road to restoration

Nissan's most important market was then - as it still is - the Japanese market. Do you honestly think that Nissan were "not good enough to compete" in the USA's local, SCCA-sanctioned events? How about the possibility that they didn't even consider it as necessary? What other actual manufacturer team was directly involved in C-Production at the time? As far as I'm aware, none. All the manufacturers were represented/supported by distributor-supported local teams. Nothing wrong with that, and it makes total sense. Like I said, why have a dog and bark yourself? Oh, you mean the crankshafts that were penny-pinched to meet the "Thanks Mr K!" recommended retail price? Good job that BRE "discovered" that and "told Japan", huh? I have a very nice bridge here that you really should buy.

-

1970 240Z Works Rally - the road to restoration

'Planet USA' thinking. By inference, nobody outside the USA would need to take any notice of what BRE and Sharp were doing locally then? Nissan's Works team rally activities were undertaken on the WORLD stage in competition with the other manufacturer Works teams. Anybody with an interest in world-level motorsport would understand this as significant. Ben is saying that this is largely unrecognised in the USA, especially with regard to the content and specs of the cars involved, and I concur. Nissan never rallied a car in the USA because there was no World class rallying event in the USA to take part in. Not exactly a shining success, was it? And I'd dispute the 'for them' part too. The attention BRE gave to the Baja style events was purely its own. Nissan was concentrating its Works efforts on the Big Three world-class events - the E.A. Safari Rally, The Rallye Monte Carlo and the RAC Rally - through the 1960s, 70s and 80s as standalone events and also - from 1970 - as part of the FIA International Championship of Makes. Manufacturer-backed local activities in the USA were best undertaken by locally-based teams. Why have a dog and bark yourself?

-

1970 240Z Works Rally - the road to restoration

One of those Hollywood snow-making machines would be appropriate at this point. Maybe sprinkle some ice cubes from a local convenience store? Good luck!

-

1970 240Z Works Rally - the road to restoration

I agree about the period Japanese magazines. They are very technical and the access to major players such as Namba san and Takashi 'Waka' Wakabayashi san gave a great behind-the-scenes insight. I still think they held back on some of their activities though. Always lots of secrets! Auto Technic magazine's 'Rally & Rally' special editions were superb. See if you can seek out the 74-11 edition. The European magazines did get hold of some cars to test. Autocar magazine (UK) were allowed to borrow Rauno Aaltonen's 1970 RAC Rally car '695' after the event, and clearly it was very tired. Not surprising really. The journalists didn't seem to know too much about the spec of the car and the team probably didn't tell them much either. There are some mistakes and misapprehensions in the article. Echappement magazine (France) tested Aaltonen's 1971 Monte Carlo Rallye car '985' and it is a little light on detail and spec but has some great photos. Autorevue magazine (Holland) got hold of '988' (just after it had been used as a Recce/Fast Service chase car on the 1971 Monte) and similarly it is a little light on detail, with some nice photos. I think the team staff were playing their cards close to their chests with regard to some of the details of the cars. Perhaps understandably.

-

1970 240Z Works Rally - the road to restoration

That period of Japanese Dunlop radials - especially the 'SP Radial' series, which was a key branding product for Dunlop Japan on road cars - was designed to run either with and without tubes. There are some good technical articles covering them in the period Japanese specialist press (especially Auto Technic and Auto Sport magazines) and they were certainly pushing the 'Tubeless' philosophy. However, for sure the Works team were running with tubes some of the time. It probably made puncture repair turnaround faster at remote servicing. I use tubes in my original Kobe Seikos when fitted with Dunlop CR65s, but it is the tyres themselves which let the air out! They are supposedly a Tubeless design, but I see no harm in using tubes. Old Magnesium wheels can become quite porous, so best to inspect and treat on a case-by-case basis. Generally speaking I tend to suspect the rubber is at fault rather than the wheel unless the wheel is a repeat offender. The Japanese Dunlops had a really good reputation in period. Nissan's Works team manager said they could not have done so well on the Monte (against rear-engine, rear-drive/front-engine, front-drive cars with their inherent traction advantage) or won the Safari without the Japanese Dunlops. In fact one or two of the UK-based drivers 'acquired' several sets for their own personal use...

-

1970 240Z Works Rally - the road to restoration

The BRE Baja 240Z and the Nissan Works rally 240Zs have no connection whatsoever. Two completely different things. The most commonly-used tyre on the Nissan Works rally 240Zs was the Dunlop (Japan) SP44, with the PW51 and PW72 also used for snow and ice stages, usually fitted with spikes.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

No doubt that's what was involved in making it, but both Izumi and Nissan called them 'Wood Rim Steering Wheels' so I think it fair to follow suit. So, high-pressure moulded, heat-cured, oriented strand wood fibre (quite a mouthful), but certainly 'wood'.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

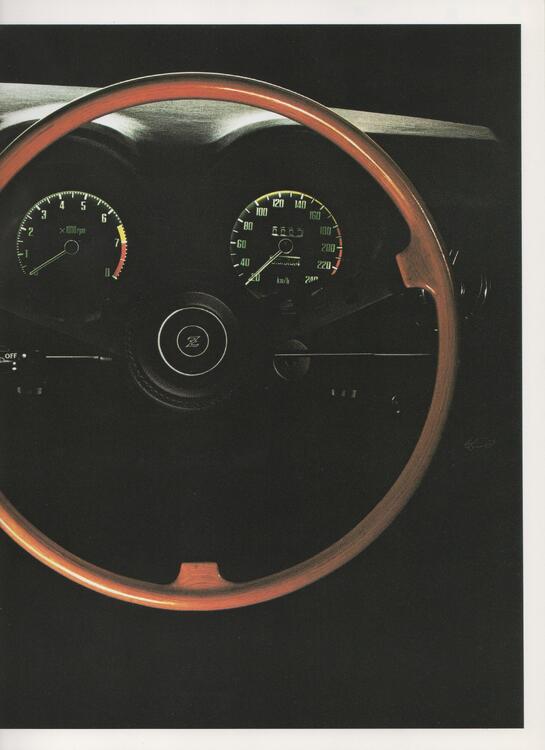

My 'autopsy' wheel is from a 4/70 production-dated car, and the hoop measures consistently at 7mm all the way around. Conjecture: I wonder if there was a production change where a smaller rod was specified. Could it have been related to safety, as was the change from solid to pierced spokes? Your customised wood rim wheel is based on a pierced-spoke wheel, right? Well we are going to have to agree to disagree then, because what I have in front of me has a readily-observable grain structure which follows the circular shape of the wheel. I don't see grain 'laying all over the place'. It seems to weave in an out of itself like rope, and where it hits surface layer after the glossy (varnish?) coating is worn away it has texture too. That texture is quite distinctive. Obviously the tooling required a split line between its two halves and if you look closely you can see that, but it is very well disguised. See the tooling split line in the RH side piece above? Here:

-

'69 through '73 Steering Wheels - Wood, or Plastic?

The 'hoop' on my 4/70 steering wheel - as seen in the photos on the first post of this thread - is mild steel bar and measures at 7mm. 6.3mm seems a strange - non-standard - size? I would imagine it being far more likely that they would use a readily available standard size, no? I don't know where this talk about wood "powder" and even "sawdust" comes from. There is an easily-observed grain and structure to the wood material used. That grain follows the shape of the wheel circumferentially. There are no readily-seen end joins. In a way it is rather like wool, where short strands of carded wool are spun together to make a continuous thread. The wood fibre used here seems to have been processed in something of that nature. Yes, it is not a traditional wood-rim wheel in the way that your custom-made version is (we have already covered that) but it IS wood.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

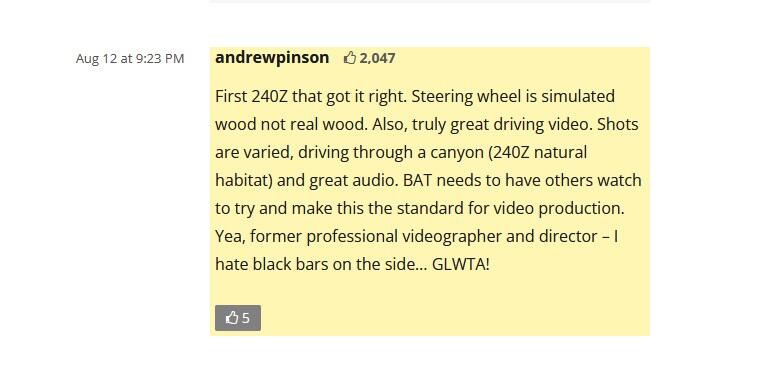

A couple of extra comments from the Bring-a-Trailer auction that I think are worth saving with a screenshot. "...simulated wood, not real wood." As the old saying goes, 'You can lead a horse to water, but you can't make it drink'...

-

'69 through '73 Steering Wheels - Wood, or Plastic?

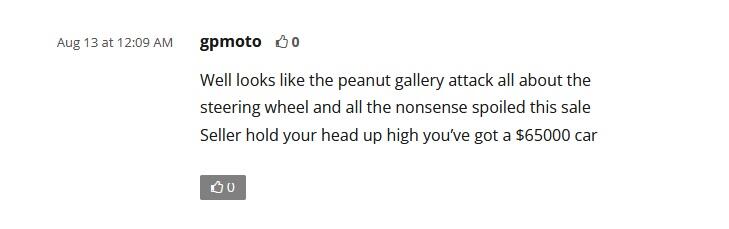

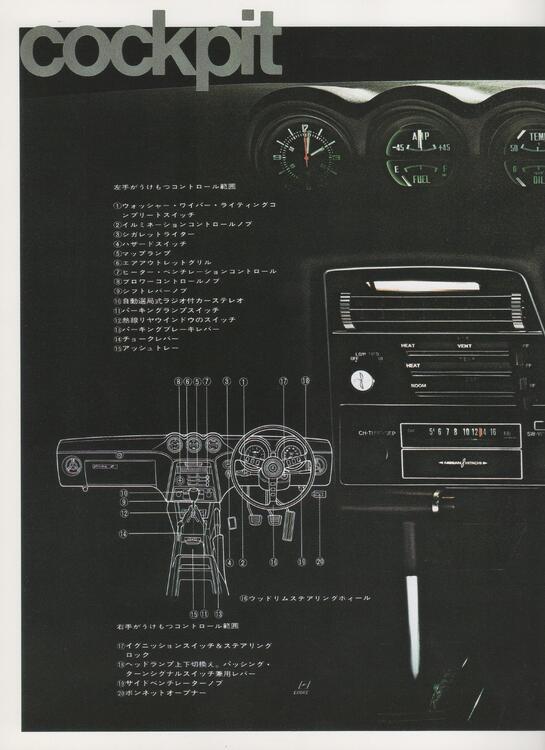

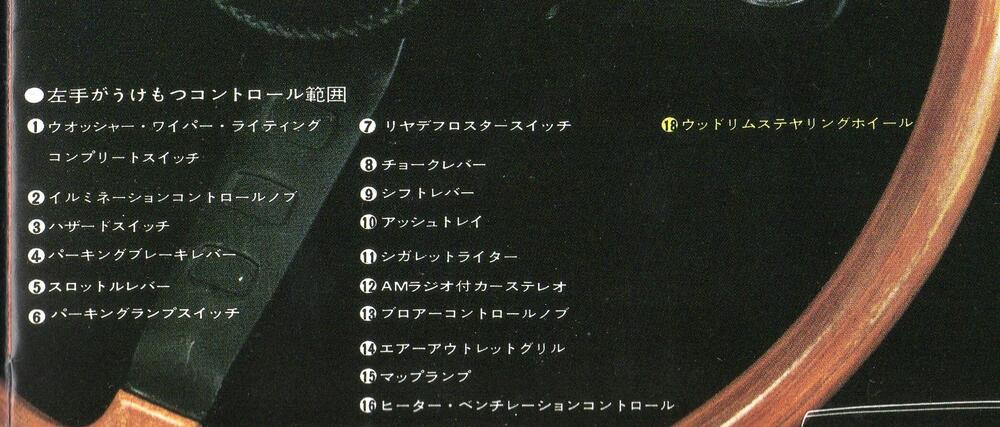

Yes Kats, you beat me to it. The Z-1 Service Shuho was my next card... Instead I'll show another Japanese market sales brochure, this time the late 1971 large format booklet that introduced the L24-engined HS30, HS30-S and HS30-H models alongside the already available L20A-engined S30 and S30-S models and the S20-engined PS30 and PS30-SB models, giving a seven model lineup at that time. Again, a light-coloured rim (better for photos?) and described (No.16) as 'WOOD RIM STEERING WHEEL'.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

From the 1970 Nissan S30-series Fairlady Z model range brochure. 'INSTRUMENT PANEL' double page picture and dash layout explanation. Item No.18: Written in Katakana: 'WOOD RIM STEERING WHEEL'.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

I suggested Indian Rosewood earlier, but Walnut seems very likely too. Izumi would surely have needed a good, uniform quality, supply. We have noted rim colour differences - lighter in the early factory publications - before on this forum. I'd consider giving a sample to a wood expert or scientist for identification/appraisal, if I can find one. Izumi themselves - of course! - could have answered just about every question we have here, but contact after the Autoliv takeover might make asking difficult.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

You might be advised to qualify who you're talking about with the "feels like plastic" thing. You left plenty of room for crossed wires. And sorry if I come off as "feeling superior". Don't want to step on your toes for that mantle.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

"...so good that the final product seems like plastic."

-

'69 through '73 Steering Wheels - Wood, or Plastic?

Are you sure about that?

-

'69 through '73 Steering Wheels - Wood, or Plastic?

No need for details in that context. I think pretty much everybody is familiar with bentwood furniture and the general concept of materials such as MDF. Part of my job involves sourcing and exporting vintage 20th Century modernist furniture, so I'm up to speed with the processes and materials that 26th-Z was referencing. I don't think I need to explain any tongue-in-cheek banter between myself and 26th-Z to you either. I agree with you about the art (or perhaps craft...) but if the final product really does seem like plastic to you, then I can't help you. I think it is bizarre for somebody to look closely at one of these wheels, look at the photos on this thread, and still talk about 'plastic'.

-

'69 through '73 Steering Wheels - Wood, or Plastic?

Already covered in post #6 of this thread, I'd say. Izumi - and Matsuo san - mentioned that the wood was processed in 'fibre' (conjoined strands, oriented lengthways) form. It is not a solid piece of wood in the way that traditional, mostly hand-made wood rim steering wheels used to be. The only hint (and it is only a hint....) of any seam or join I can detect is on the inside edge, where I think there is a faint line. It may be some sort of mould tooling joint line, which would make sense. Just such a view is visible from the photos in the first post. The final photo homes in on an imprinted 'negative' of the welded joint between a spoke and the outer steel hoop. There's still 'grain' visible, but the impression of the welded joint is pushed into it. You can also clearly see the dark and smooth area where the wood material was pressed around the main part of the steel hoop. I would expect the steel spokes and hoop to conduct more heat than the wood and the resin, and we know that the mould tooling itself was hot. That seems to be one of the things that affects the surfaces most in contact with the metal. I already did this, with two results. First I burned a section with the outer (shiny, dark) layer in situ and got grey smoke and a distinctive smell. Then I chipped off some of the more obvious wood inner and burned that on its own. Much lighter smoke and a very typical burning wood smell. The burned black wood can be used to write and draw, like a piece of charcoal. The material is incredibly tough. It was hard to remove from the steel rim (although it was not adhered to it) and difficult to split the material into smaller pieces. It wants to split with its circumferential grain and it is very resistant to breaking across it. It makes me think of some sort of hardwood, like Indian Rosewood.