Everything posted by Lazeum

-

Weber DCOE 45 setting

You've missed the choke size. Without this info, it will be hard to tell anything. Are they 34mm or 36mm or something different? I can say that delta between main & air jet seems small but not unusual. Idle jet seems huge. If the engine runs well at idle this way, it shows choke size is probably very large. If you're engine is stock, they are probably too large. You're not telling us how your engine runs also. it could be a good info to comment your settings. You can go also to Hybridz, FAQ. There's a nice thread with tons of info about DCOE on L6.

-

Carb Tuning with IR thermometer?

Dad is always asking me: "why do you touch your car? it's running well" I'm not the only one here who can't stop improving & learning stuffs. I'm just (too) curious - like many others in this board & on hbz. For information, I've tuned mine with a wide band (Innovate LM2) & a synchrometer.

-

Carb Tuning with IR thermometer?

can't it be done for idle only though? I've been thinking about it somehow to finely tune my DCOE. My spark plugs look identical, carbs are well balanced but it would be cool & intereting to know, wouldn't it? Issue such as fan cooling header #1 has to be overcome as Jonh says

-

S30 fastener cataloging

Topic about suspension bolts has been already discussed, you can find all info in the following link or on the following one. On the other side, I've been recorded every bolt & size I've removed from my car. Since I've rebuilt the engine, here the list for my L28 engine. Most likely the same for L26 & L24. They are all normal pitch metric bolts. To replace eveything with brand new bolts, it cost me 20€ in Europe. It is probably more expensive to replate stock units. I did not include specific bolts/studs such as rod bolts, cranshaft bolts, head studs, etc. you should source them at Nissan dealer or ARP (--> what I did). Inventory - L28 Motor bolts.xls Once more, I'm not in favor of replating stock bolts. They have been stretched & stressed already. once they're removed, they should go to the bin, except eventually for the ones with no stress associated with them. Basically: Suspension/brake bolts ==> Trash, if one fails, you can die Motor component bolts (dizzy, water pump, etc.) ==> can be reused, if one fails, you might only end up on the side of the road. Motor critical bolts ==> Trash

-

Taking off the emblem on the rear quarter pillar

On 240z, you just need to pull them off nicely. I do it by only using my fingers. There're some spring loaded sleeves around the pins holding the emblem on the car.

-

slow drip of gas off air cleaners on webers

Mine are leaking as well. I talked to many people with Weber (guys with Alpine A110 mainly & also Alfa Romeo's), they all have weber leaking... So I figure it is "normal" (even if I'd like them to be sealed tight also)

-

steering column help

That's definitely very good information. I might not be the only one with shaft play in my steering column. Thanks!

-

Upgrading to Eurethane Bushings

I just don't. The Z is 30km away in the middle of a forest in my family house I just don't go to Paris with my car (Z or DD), such a pain.

-

Upgrading to Eurethane Bushings

you might be right. Mine were having a groove inside. NCdatsunZ, I believe you're mixing TC rod bushings and spindle pin bushings. To change TC rod bushings is a no brainer. It takes 20 minutes to change them.

-

Upgrading to Eurethane Bushings

I had a full discussion with MSA about this. They say they was no problem to be expected. As far as I'm concerned, I've changed everything but TC rod bushings where I've put new rubber bushings to avoid failure last spring. The drive was sluggish and not sharp. I then switched to poly since they came with the kit anyhow, the car is much more enjoyable to drive. Regarding the flex with poly bushings, I had to apply only 2 lbs on the tip of the TC rod where it's attached to the control arm to move it around way enough to reproduce suspension travel. Basically, I'm not convinced TC rod failure would occur because of poly bushings. Loads aren't high at all. I'm wondering if there wasn't any other special cause creating the failure: sway bar interference, wheel interference, etc. I'm running a fully poly set and everything goes well for now. To the OP, the major job is definitely the spindle pin bushings that are really small & stiff. Other parts are easy to do as long as you're using proper tools. If you want to do it right, do everything (that's better) but you might be fine leaving them alone.

-

Bench Testing Half Shaft U-joints

Been working in half shaft & steering company (Delphi), I can tell you the only good way to check is a bench with torque actuator to measure lash. In our garage, the only way is to check for lash by hand but it is not always easy to feel. If you had no noise before, there's no need for anything else. Anyhow, getting half shaft out of the car is a matter of lifting rear wheels, remove them, remove half shaft bolts & pull apart shaft. It's an 1h job if you take your time. Bottom line, don't spend time redoing them if they feel tight, you can do it easily whenever you'll need it. Make sure anyhow that boots on spiders are fine, if you have dirts going into needle bearings, they failed quite shortly. You might also be able to add some grease since you're at it. Wear on them will most likely be fatigue so no deflection might occur before they fail eventually. If you don't launch your car & you do not have crazy power, you should be fine otherwise they'll fail without any notice. Do I what I say, not what I do : I've replaced mine while I was working on them, you need a press (I used 25t), some fixtures to hold them up & some time. I have redone them also because I've shortened the driver side to avoid bottoming issue due to R200.

- Nuts and Bolts What to do?

-

multi-spark discharge (msd) systems

I had a L28, DCOE, Mallory Unilite dist. + Mallory Hyfire 6AL box. Last year, the 6AL box fried, most likely due to inappropriate primary coil resistance (1.6Ohm instead of 0.6Ohm). So I've ditched the box and run the car with only the Unilite. Guess what: No change at all in car behavior I could feel & mileage. I was in advanced break-in (600mi after rebuild) mode so I did not go above 5000rpm, maybe above I could have felt something but based on my experience, the box is not necessary. Since then, I've moved to Distributorless ignition with megajolt ecu + EDIS. I have yet to try it on roads with no salt - winter is long

-

Nuts and Bolts What to do?

Never use suspension bolts twice (ok, let say three times), they expand, you stressed them, you're brinelling the threads as a result the torque/tension relationship is becoming way out. You risk to get bolts to snap or to get loose while driving. Here's the link with data you need. => Thanks! Leon for the credits

-

Oil Pan Removal

I did it many times on my '72 240z with L28 with the front of the car lifted. You just need to get rid of all the bolts, carefully lower the pan, spin it a little to get some room around the pan (gearbox & cross member) and remove it. Never apply force during the process, you have the oil pick up in the way you do not want to bend or break.

-

Tuning 40 DCOE Weber 151 on an L24

Not sure about the equivalence of choke size with different carb sizes. Check the file attached below, given by Duragg on HBZ. The only exception would be at 32mm according to this chart so your comment may still apply

-

Tuning 40 DCOE Weber 151 on an L24

I would say bigger isn't always better but I would also agree. With my current setup: F54, flat top, p79 ported/polished, Rebello Cam, I'm a little bit short with my 40DCOE. Some 45DCOE with small chokes would probably work better.

- Hood Alignment

-

Tuning 40 DCOE Weber 151 on an L24

I guess my next move would be to measure mine and fine some stiffer. I'll keep this on top of my head for the future. My carbs are really well tuned for now.

-

Tuning 40 DCOE Weber 151 on an L24

I'm very curious about your new springs. I've understood they are stiffer but to which extend? It looks like it could be something to try out also on my side.

- 240 runs out of power under load, i.e. going up hills

-

280Z fan and fan clutch on 240Z?

To make the 240z tach to work, it seems you just have to plug the black/white wire used to power the stock coil as the power line for EDIS coils instead of using power from ECU like MJLJ. I have yet to give a try. For 280z, there's a tach adapter at $10 that exists, don't know if that would work... Regarding fans, I've noticed you just need to keep the hub in accordance with the fan. I've tried to put an unknown fan coming from a Z (also unknown) on my current hub/fan clutch, it did not work.

-

R&T, Datsun 510 BRE

I enjoyed this video, very well done & high def... and the sound of the L engine is just amazing!

-

F54 and P90

I'm running as well F54/P79 with head shaved only by 0.020", Rebello cam, 3x 40DCOE, Unilite dizzy. I'm very happy with the build so far. Engine/car is very nice to drive.

-

fastener woes.

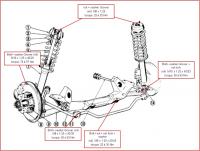

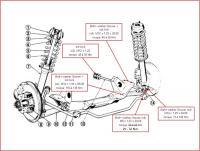

I believe the pictures below are what you're looking for Use only grade 10.9 bolts & grade 10 nuts. Those are not easy to get since they all have small pitch but this is what you need. Grower washers are the spring loaded washer type for your information.