Everything posted by Lazeum

-

F54 and P90

this is what I've measured. For my rebuild, I bought 4 different gaskets before giving up. I then torn down the bottom end again and milled pistons to match Felpro gasket. Compressed thickness on headgasket needs to be measured if we want to be 100% confident. I've done it with calibrated gauges so I know how reliable my measurement were (minus my skills). I advice everyone to build an engine to check those dimensions, it is not hard to do but some tools & time are required.

-

F54 and P90

I've measured mine - a new ishino gasket - at exactly 1.00mm compressed (while others said over the web it should be 1.25mm). link: http://www.amazon.com/gp/product/B001G7GT5G/ref=oh_details_o00_s00_i00

-

F54 and P90

You're right! I should have doublechecked

-

F54 and P90

"As far as you know" is already not a good sign better be safe than sorry, get some measurements done the clearance between pistons & head is a topic discussed on hybridZ with many different versions. I went with 0.8mm (0.032") and so far, so good. It was a direction given by Brian Blake (a.k.a "1 Tuff Z" who did the L28 DOHC DETT) Top rpm so far has been 5500rpm until I'd got bigger chokes or better: bigger carbs. Regarding head shaving, it is hard to tell. Some say 0.040" is good but I have less on my build and I'm above 200wph. Head builder (Braap on hbz) did not push comp ratio. There's little gain to get vs. ping safe conditions. I think you should focus on cam grind vs. comp ratio => meaning, talk to cam builder for proper setup - it should be a match. Surface treatment done on cam lobes are usually very thin (0.5mm deep - 0.020") so if you perform a regrind, a new hard layer made with some treatment is mandatory.

-

F54 and P90

As Diseazd say, pistons would be ok. The combustion chamber looks like a bean, there's a flat area that would end up in front of the piston anyhow. This zone will allow the engine to have a quench effect at TDC improving air/fuel mix (= efficiency + ping resistance). To make sure, you'll be ok, you will have to measure some parameters: piston top vs. deck for each pistons, head gasket thickness compressed. head gasket thickness is usually given by manufacturer. if nothing is written, don't trust Internet value. Felpro gasket for instance are given sometimes for 1.2mm or 1.0mm, I measured it at 1.0mm but Ishibo gasket (the stock unit) is given by internet users for 1.25mm, I measured it at 1.0mm also. The gap at TDC for each pistons should be min at 0.023" (0.6mm) & max at 0.032" (0.8mm). If you're too short, pistons will hit the head, if you're above max, you will lower quench effect. For your info, I was conservative with my build, I shoot for 0.8mm nominal; I'd rather loose some hp than an engine. In stock form, if nothing has been machined on your engine block, you should be right on. My block has been surfaced before rebuild, I had the milled the pistons by 0.3mm with Felpro gasket. Without measuring gasket thickness, I would have ended up using Ishibo gasket, I would have over-estimated quench gap that could have led to engine destruction...

-

Hood Alignment

The link above does not work To lower the hood, you have to tilt the hood. Get the hood wide open, loosen the 2x 2 bolts between the hinges & the hood. Then push gently with your knee on the bottom side, where the emblem is, and pull towards you the top. Clamp the bolts. That will create a rotation motion of the hood that will lower the front while it will be closed. Try to close it gently since hood might still rub against the fenders. To center it, you have to play with top/bottom position with a translation, still with the same bolts. If it is too far on the left, you have to lower the right side & to rise left side. I know how it works, I still fight each time I want to put everything back together. Good luck!

-

Idle Speed and Engine Performance

How do your spark plugs look like? you might want to check them and try new ones if you haven't done it in awhile. If it was running fine before and not now anymore, start looking for little stuffs instead of big tune-up moves. I'm the first to look for major issues but no later than Monday, I got stuck on the side of the road with the Z because plugs were bad (brought it to a shop who did a lot of cold starts to move the car around the parking lot). I put some new plugs, the power was back. it cost me 10-15$ to fix the issue. Before changing the plugs, of course I've tried to set up advance since the car was backfiring & pop at 3k rpm :/

-

Tuning 40 DCOE Weber 151 on an L24

Something else you could try to help pouring more fuel would be to close the bypass valve (spill valve) at the bottom of your fuel bowls. You have 1 per carb. On mines, previous owner has shut the holes with solder so 100% of the fuel from the accel pump system is going thru the throttle instead of having some getting back into fuel bowl. I don't have any flat spot at tip in, except if I try at 2000rpm to hit WOT super fast (something we never do that fast anyhow)

-

Triple Weber fuel pump switch-a roo

I believe pressure is important too to open up needle jets. low flow might lead to higher float height. No clue if a big difference could be observed but I do believe it has some effects.

-

Triple Weber fuel pump switch-a roo

My Mallory 4070lp pump is having a pressure of 2.5psi. I cannot get much more than that (whereas it is given for 4psi) I just remember that I've also changed my fuel filter with a inline glass unit I can disassemble, maybe the pressure limit comes from filters, flow anyhow is good.

-

L28+box

That's definitely some good news, thanks! Silvia's GB are readily available and cheap in Europe

-

Triple Weber fuel pump switch-a roo

it is the oil pressure sender that is having such feature. It is right next to your oil filter.

-

L28+box

that's interesting! have you had to make any modification to the casing as we should do when setting up a Silvia gearbox on L-engine?

-

Triple Weber fuel pump switch-a roo

you should install it close to your tank. In front of the tank fuel sender, you'll see 2 holes tapped on your car. You should use those 2 holes with M6 screws to install the pump. In the fuel sender harness, you'll find a green wire hidden you should use for the pump for +12V. It was a wire made for fuel pump from Datsun connected to ignition switch already. Other wire has to be grounded somewhere on the Z body. Support provided with Carter pump worked well with r180 mustache bar but I switched to r200, I had to custom build a new support. If you add a fuel pump, either add an inertia switch (found mine in junkyard) or a oil pressure cuttoff switch (280zx have one). You need to make sure your pump will stop working in case of accident. and while you're at it, change all the fuel hoses going from the tank to the pump and then from fuel hard line to carbs if it is not done already. This is how my inertia switch looks like - it can also be a thieft prevention device. Mine is behind passenger seat.

-

What main Jets?

I won't go off topic then on this post. I'll go on HBZ if I've got questions Looking forward for the tach to work since this is the little unknow for now (I took the tach adaptor with my kit)

-

What main Jets?

I'm wondering if I haven't heard stuff about extr lean AFR to run modern engine. I think direct injection fuel engine are working also with those kind of AFR. I'll have to look for some info but it would make sense. For your Edis system, I know that too well You've shared this picture with me already and I'm going to follow your steps towards EDIS & Megajolt also

-

What main Jets?

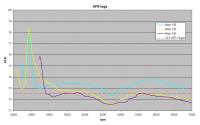

Usually on our cars with no programmable ignition (as far as I'm concerned, it won't be true anymore in some months ) or without depression in the dizzy, timing is way to low to provide good burn at low loads. To compensate for the deficiency, AFR needs to be richer than 14.7. Catalysis reaction only occurs at 14.7:1 AFR, that's why car with catalytic converter have always an O2 sensor; it is to allow the ECU to run in close loop mode to regular AFR to be as close as possible to 14.7 ratio. Running leaner than 14.7 on our car is creating more NOx & CO2 but less HC & CO but to a small step which makes it not so interesting. See the graph below.

-

Tuning 40 DCOE Weber 151 on an L24

To tune timing at idle, I start the engine (while already hot) with distributor loose so I can turn it by hand. Turn it and hear the difference from the engine, the rpm will increase or decrease. Best timing will be when the idle will be the highest. This is where you should setup your timing. Check with a light where you stand and record the value. Do a quick math to determine your dizzy advance based on targeted total advance wanted. With a Mallory Unilite, you can set up this advance. You don't need specific tools (even if it would be nice to get). To offset properly the dizzy, I measure the arc length vs. the radius from where I do the measurement. then I use drill bits with corrrect diameter as a gage for proper adjustment of the 2 plates inside.

-

What main Jets?

For what is worth, with the curves shown above, I was running around 14:1 to 14.5:1 at crusing speeds. I was running 45f9 if I'm not mistaken (or 50f9 if not 45f9)

-

What main Jets?

Rich at high rpm could very be your chokes being undersized also but 11.5:1 at 4000 is too rich, I would go down to 115 since you have a lot a fuel to restrict to get back to proper AFR at WOT. here is a graph with my previous setup with F54/N42, Schneider stg 2 cam & 40DCOE-18. You can see the difference in AFR between mains.

-

DCOE Documents

Thanks! Some are classics, some are new to me and very interesting!

-

Triple Weber fuel pump switch-a roo

Do you know how much GPH the pump is rated for? It could be a interesting alternative to after market pumps. I'm currently running a Mallory pump because of its supposely quiestness & flow rating. It is much quieter than my previous Carter pump I had before but I can still clearly hear it, only at idle though. [edit]: I found the answer on rockauto spec sheets: 30 GPH.

-

L28 is toasting my 240z clutch

The torque resistance for your drivetrain is much greater on higher gears. You always start to feel clutch slippage on 4th or 5th gear on highway while you go WOT because it is where the torque coming from the motor becomes much smaller than the torque to move the car fast (it's a so-so explanation but I hope you get the picture )

-

Tuning 40 DCOE Weber 151 on an L24

just to make sure, when I was referring to "idle screw", I was talking about the screws used to balance the carbs & RPM at idle, not the ones used to play with AFR.

-

L28 is toasting my 240z clutch

I've got a setup very close to yours: same trans/diff, L28 with flat tops just rebuilt, 225mm clutch but with 3xDCOE, Rebello cams, ported P79 head. The clutch for now holds power fine, I've never experienced slippage (but I was concerned as well during the rebuild). Not sure though if it is a stock clutch, there's nothing written on it letting me know if it would be a aftermarket unit. I got the clutch with the car.