Everything posted by DC871F

-

Z's on BAT and other places collection

Im just up the road (30 miles) from this car for work, I'll be here all day tomorrow and leave early Thursday morning. If someone is serious I can scope it out. I have no wheels, so uber or rental car is the only way. Uber says $70 one way.

-

73 240z restoration 904 White

-

73 240z restoration 904 White

-

Restoration of BringaTrailer 240z - HLS30-35883

I did a while ago and forgot about this. I'll be adding these to my build. Thanks for sharing.

-

Restoration of BringaTrailer 240z - HLS30-35883

Ok, that's awesome. I may have to do this on my project.

-

73 240z restoration 904 White

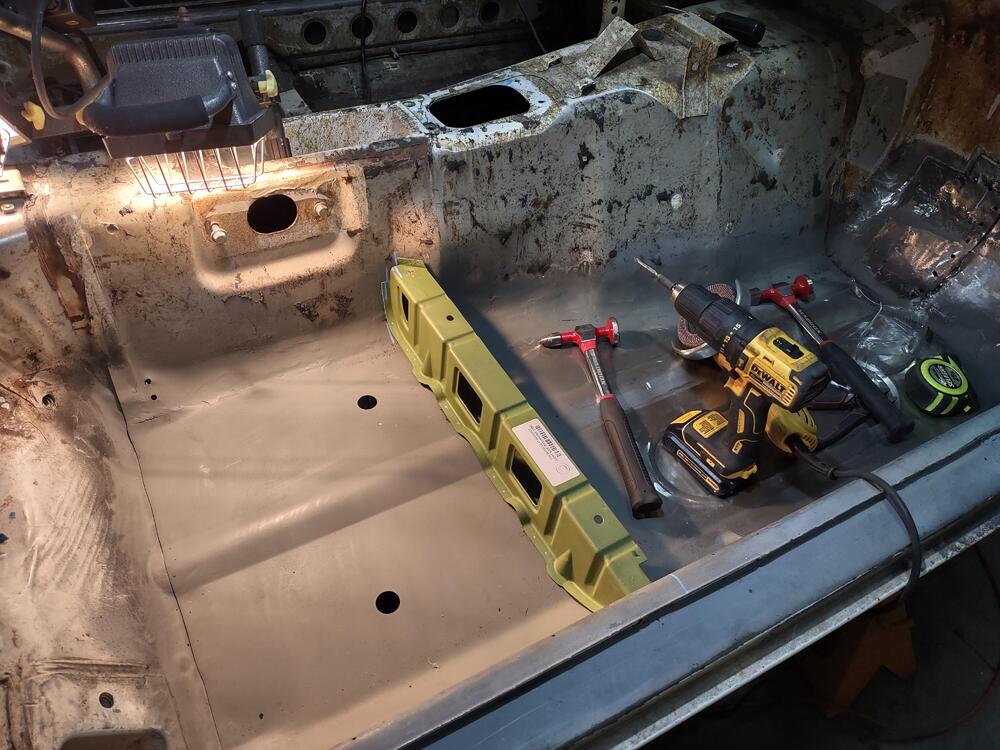

Yes, I'm excited to have these parts. I really think they are worth the money.

-

73 240z restoration 904 White

-

For us who appreciate making metal do what we ask of it

Stumbled on this youtube channel. Amazing stuff.

-

Restoration of BringaTrailer 240z - HLS30-35883

Very nice. I did this on a set of JDM chromed bezel headlight lenses. I used MicroMesh system.

-

Z's on BAT and other places collection

I'll let my imagination run wild on the interior condition, and frame rails. But in the current market, it probably doesnt matter for 5K

-

Classic Tube Brake Line Kits. OE or Stainless?

Wow, almost $500 for both sets of clips and rubbers from 240zrubber. I knew I was in the wrong business.

-

Classic Tube Brake Line Kits. OE or Stainless?

Well I'm really liking these. More labor........ I'm not counting my hours so theres that.

-

Classic Tube Brake Line Kits. OE or Stainless?

This has been in the back my head ever since starting my project. I've been trying to figure out how I was going to make all the hydraulic lines look new. Cost comparison between kits and making your own, I wonder? (Time and hassle)

- Inflatable Paint Booth

-

73 240z restoration 904 White

I see a little modification coming. Thanks for the pics. When I first noticed this, I called Charlie at ZF and he didnt really understand what I was referring to. I wonder what the cutoff year was for this.

-

Inflatable Paint Booth

Anyone have any experience, comments on inflatable paint booths? Youtube sure has people that both love and hate them.

-

73 240z restoration 904 White

I see the waviness, at least its on the bottom where it will be plug welded. When it dawned on me that the ZF rails were missing the step down by the radiator support, it kind of concerned me about originality, but I may be getting over it. If not, I'll have to order the two rails from KF. Another note as well. The tow hook mounts on both rails are wrong for 240z. I think they are supposed to be parallel to the rail, not perpendicular. Maybe 280z had it perpendicular. Anyone have a pic of their front hooks on the 240? If you look at mine on the rotisserie, my mounting holes are parallel.

-

73 240z restoration 904 White

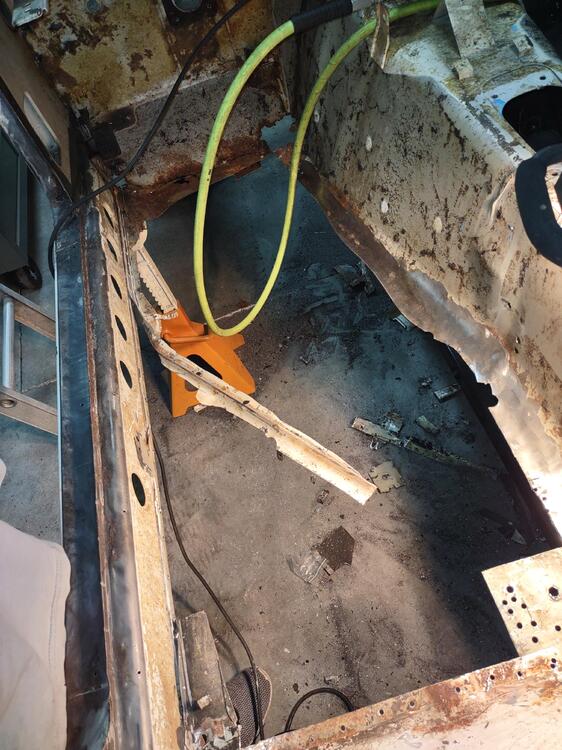

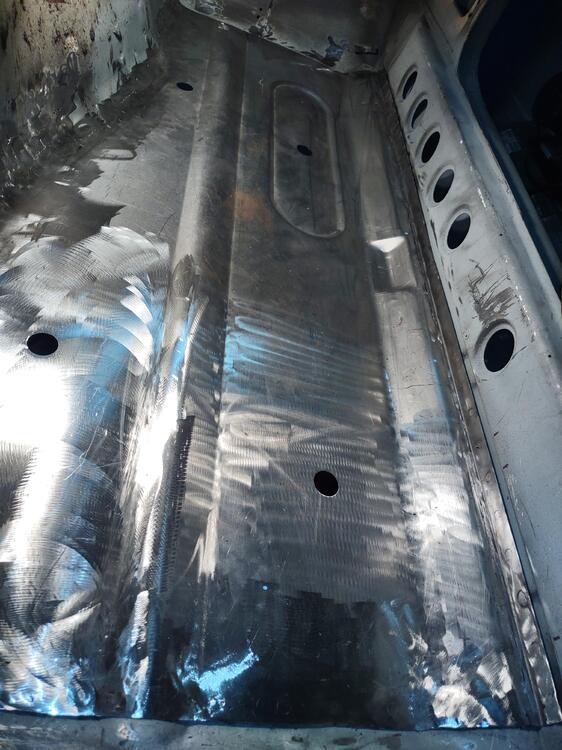

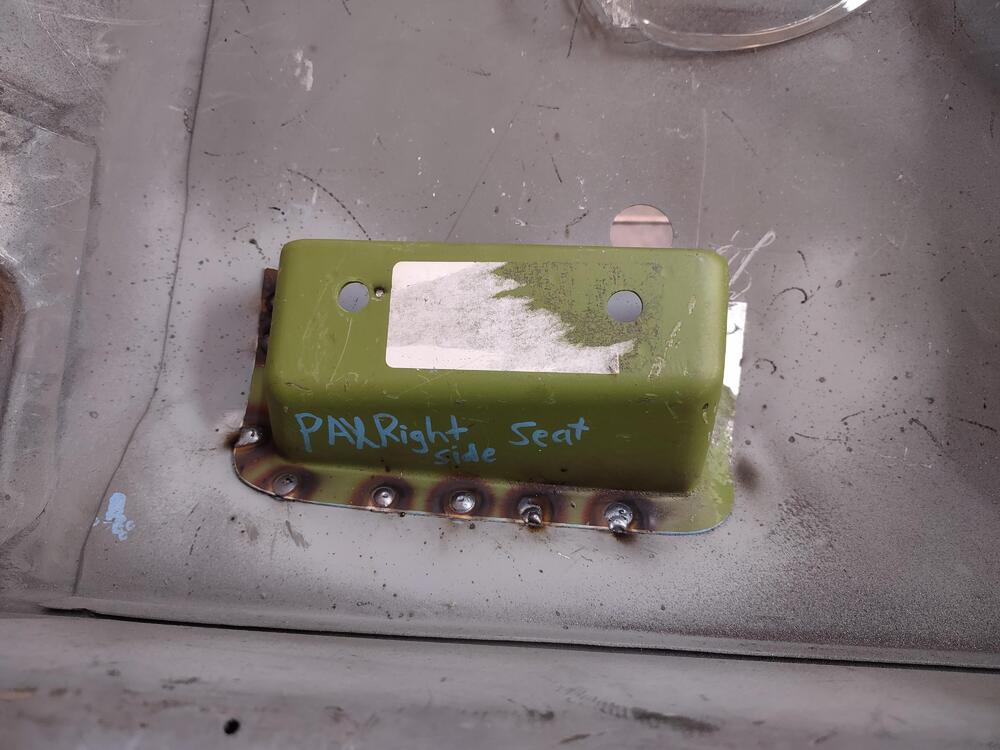

Working on seat mounts for passenger side and since I just ran out of welding gas, I went ahead and cut out the driver's side floor and got it cleaned up. Started the patch panel for the forward foot well to fix up the rust where the floor pan welds up to. Smoked turkey for Christmas dinner. Had to share

-

73 240z restoration 904 White

I have to say those rails look a little better than Zedd Findings. They have the correct shape up by the radiator support. May have to order some. Not sure yet but I believe one of my rails just needs patch work, but the other needs to be replaced, so one would look different than the other if I just used one of ZF's.

-

73 240z restoration 904 White

Thank you! Welding new metal onto old Datsun metal was quite a task, especially for a novice. Several pin holes. Has to be a better way of doing it. One thing I would do different is to make the cut onto the tunnel at one level. I adjusted each strip to where there was clean metal. I should have just went up the tunnel level.

-

73 240z restoration 904 White

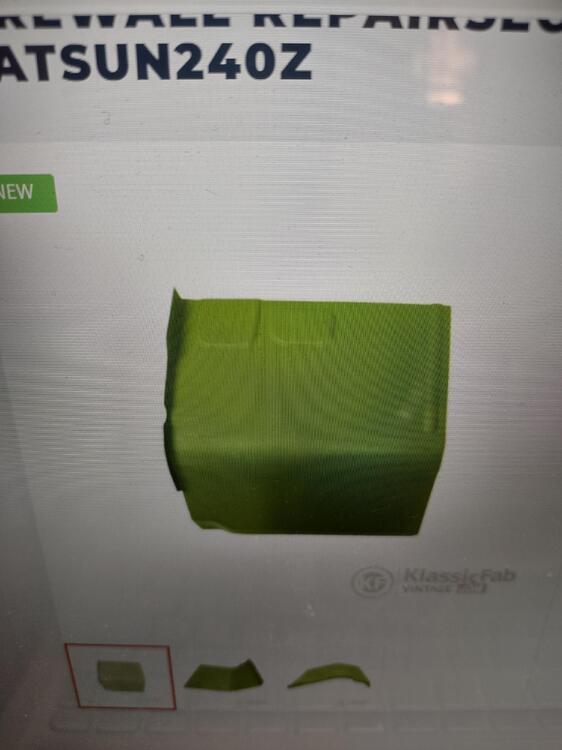

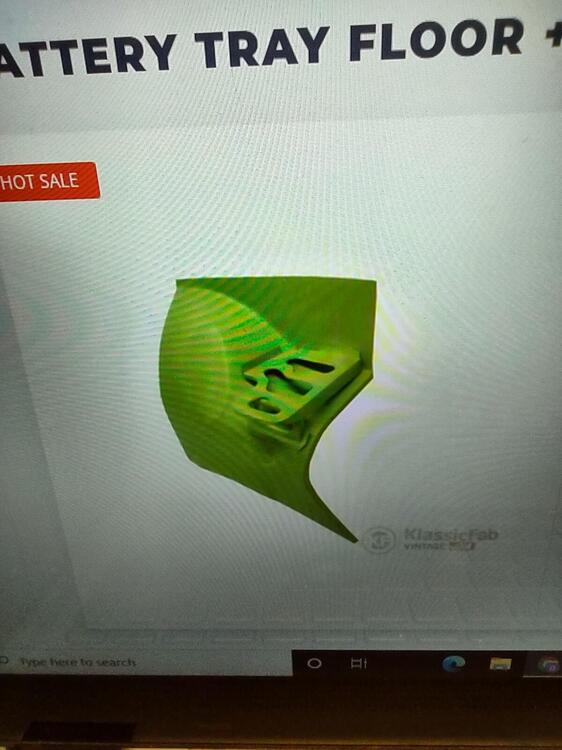

Just ordered these. It had been a while since I've been on their site, they have added some nice panels to their list.

-

73 240z restoration 904 White

-

Z's on BAT and other places collection

It would be fun to see someone hook onto them to move them.

-

Z's on BAT and other places collection

https://daytona.craigslist.org/pts/d/daytona-beach-datsun-280z/7422784491.html Generational rust. These must have fallen off the boat and dredged up.

-

73 240z restoration 904 White

.thumb.jpg.232af85c716181c5358db8cd42eb530e.jpg)