-

xs10shl started following MZR , The Development Story & Specification Of The European Spec Datsun 240Z and Advice on selling Mikunis

-

The Development Story & Specification Of The European Spec Datsun 240Z

Those are some really nice upgrades to the base model examples. Were there "pre-package" Euro deliveries which did not have some of these package features, or were they pretty much all grey market from Australia & elsewhere? Also, which of the described features were on all of the Euro deliveries, or were things like spoilers an extra cost option?

-

1970 240Z Works Rally - the road to restoration

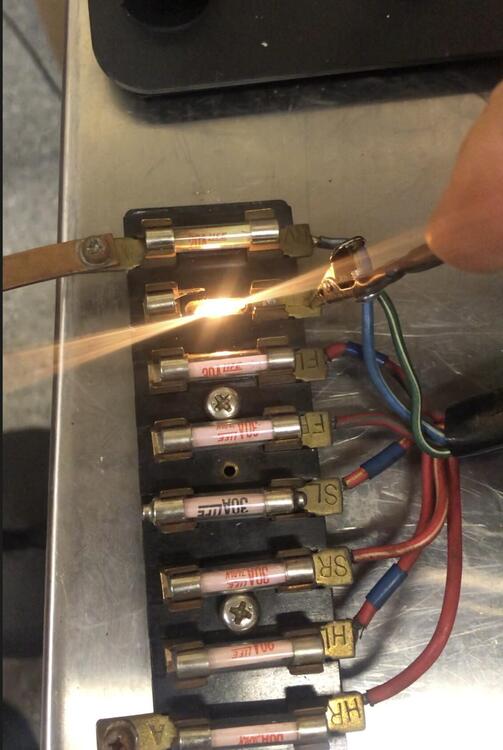

Things are moving quicker on the body front, so I've turned my attention to long-pull items which need to be ready in time for the shell's return. Tops on the list is the wiring harness, which I typically install first when a car is rebuilt. The harness itself thankfully needs limited work - it was in decent shape coming out of the car, although I suspect there are a few breaks I need to trace and take care of. I'm also planning on replacing all the connectors, as they tend to get corroded through exposure. I wont go into that process, as it's is fairly well understood by the community. The fuse boxes require a bit of TLC, however (picture 1). On my car, they are comprised of a pair of modified Niles 8-position boxes, possibly hand-made from a Niles FB87A box (or similar). Pigtail wires were soldered in place, terminating in a connector to the main harness. Some of these connectors show signs of maintenance over the many years. The lids are also showing signs of age (picture 2), so I'll put them on the 3D scan list as well. It's worth noting that someone took the time to scribe the lids with appropriate fuse sizes, which is likely unique to only a handful of early rally cars. On close examination of the boxes themselves, I found that each of the fuse locations had a pre-wired axial 12v bulb bridging the fuse terminals from the back (picture 3). Much like how a dead short blows a fuse, this outrageous modification really blew my mind - the Works team had considered the potential difficulty in tracing blown circuits and identifying shorts in dark foot wells in the dead of night. So they designed a novel solution: a blown fuse allows current to instead flow through the bulb, causing the specific fuse location to glow (picture 4). I can't speak to how well it worked in competition, but it probably only needed to work a single time during a race for the modification to be worth doing!

-

1970 240Z Works Rally - the road to restoration

Time flies, and it's been a while since my last update. Fear not - much has been happening in the background! The shell is nearing the point where panels are being welded back on, and I'll post an update when that process is a little further down the line. Today I'll give a preliminary update on my efforts to memorialize some unique Works pieces. I've begun the process of scanning in some unique or hard-to-find parts. in some cases, this will be the only way I'll be able to rebuild the car "as original", because the original piece is so far gone that it's unusable. Such is the case of the bespoke Works exhaust header, which is a rusted metal hulk (picture 1). Thankfully, it retains almost all of its original shape, so recreating it will hopefully be a fairly straightforward process. My plan is to have the custom pieces 3D printed out of metal (such as the expansion chambers and collectors), have the flanges cut at a metal cutter, and then use relatively standard piping to recreate a near-exact look of the piece. The whole thing is likely to be made out of stainless, which I can then ceramic coat to provide a more matte period-looking finish. Stay tuned. In other cases, I'm scanning in some parts which have limited value for anyone who doesn't happen to have a 1970 MY Works car- the pieces in this category are fairly unique to the early cars, and my interest in scanning them are primarily to teach myself about the state of parts reproduction, and be able to refer to them should something go amiss, and I lose or damage the original piece. An example of this is the side jack points (picture 2). In still other cases, there are some pieces I am scanning that are actually stock Nissan Competition parts. The oil catch (picture 3) falls into this category. Although the function of this part is easily reproduced by other modern replacement parts, creating a few samples that look original might be of interest to the larger community, as even authentic competition oil catches are quite rare and expensive. Then there are the most difficult cases, free-hand creation of parts which just don't exist in the market. A good example of this are the spotlights. These Koito housings are just not obtainable- let alone trying to obtain the four required for each car- it's to the point where I openly wonder if they were ever sold to the general public at all, or perhaps just some special-order pieces supplied by a trusted vendor. Thanks to friends we all know, I have a fairly good notion of what they look like, and I've assembled a series of parts which I think I'll be able to fashion into a reasonably correct-looking "tribute" spotlight compete with "Koito" glass lens (picture 4), but without the special protective covers, which I don't think anyone has an example of. To make these tribute lights look reasonably accurate, they will require the 3-D printing of a special front bezel, which has a unique flat-face design, to replace the more conventional rounded bezels more typically seen on spotlights of the day.

-

Z's on BAT and other places collection

From an SNL comedy skit, covering the birth of our nation. Washington rallies the troops by highlighting our freedom to choose our own systems of weights and measures-- Washington: "We are free men, and we shall be free to measure liquids in liters and milliliters. But not all liquids - only soda, wine and alcohol." Soldier: "Only those, sir?" Washington: "Yes. Because for milk and paint, we will use gallons, pints, and quarts, God willing!" Soldier: "And how many liters are in a gallon, sir?" Washington: " . . . Nobody knows."

-

Z's on BAT and other places collection

Mixed emotions on this particular example. To your point, it was clearly done to a high level during a time where few (if any) 240Z's were restored to this level at all - and for that, it certainly commands the accolades it has garnered over the years. I'd guess it will match it's previous sale point +/- a few thousand. Whether or not the seller will let it go for that price point remains to be seen. The early 240Zs are special to me precisely because they have so many special first-year-only parts- parts which may appear the same to most enthusiasts, but on close inspection have their own unique characteristics. Unfortunately for this car, much of it's "early car-ness" has been replaced with s30-correct, but later MY replacement parts. So for me, much of what makes the MY1970 so collectable is no longer present here. That said, I'd say that 99% of the Z community probably wont notice or care. Even taking your post on judging guidelines into account, I could foresee a non-zero possibility where this car would show up to a concours where there was another top MY1970 car, with all it's MY1970 parts still attached, and a really knowledgeable Judge may rightly place this Franklin Mint example below it in a tie-breaker because of it. An additional $10-$15K spent on sourcing many of the correct MY bits would go a long way to alleviating that worry. Even with my own nitpicky standards, I think if I purchased this car, I'd probably leave the hood as-is, and just replace all the newer parts with as many MY1970 parts as I could source. It appears to be a fantastic example, and worth this exercise, IMHO. Such is the challenge- and potential reward- of properly restoring an early car to the highest level.

-

Z's on BAT and other places collection

it seems to me like the supply of decent cars is rising. You really cant get a decent 240z for under $20k anymore, but $25-30K will get you your choice of a really nice one. There appears to be enough good examples out there to meet demand at that price point, with the occasional true collectable eye-popper that reaches well above the average. BaT's own graph of 240Z sales shows that since 2016, most examples are entrenched in the "Under 50K" range, with occasional outliers for exceptional cars. To my eye, the trend has looked flat for several years.

-

Z's on BAT and other places collection

It appears that the Seller perhaps just didn't understand that BaT has the option to make up any difference between the final bid price and the reserve to make the seller whole, which IMHO is a completely understandable reaction on the part of any novice Seller (who probably would feel cheated, not knowing that he was going to be made whole by BaT). If I'm correct in my assessment, then this is just a simple and easily resolved issue, making BaT's slightly unfriendly public notice unwarranted-- and I personally feel, a case of needless badgering of the Seller. There is no reason to publicly threaten a seller for nonperformance if indeed it's a simple misunderstanding. [EDIT] Ok, I've re-read the thread, and it does appear that the seller was aware of what happened prior to posting "No Deal". I'd still venture to say that BaT would have been smarter to write an educational post about the mechanism of covering the spread, vs what they posted.

-

Advice on selling Mikunis

From my limited knowledge, these appear to be Type-R Mikuni bodies, which are typical later castings, AFAIK. Looks like you have some nice linkage, but everything needs to be rebuilt by the eventual purchaser, as "lightly used" is still "used" when it comes to old gas. My initial guess is you could get $600-$900 as-is for everything pictured if you put it on eBay. I'd suggest you do some snooping on eBay's "completed items" listings for historical pricing data. Hope this helps!

-

MZR

I for one am glad that a company like MZR exists, and I can appreciate the work and effort they are putting into their offerings. It's also great to know that there's enough demand out there for them to keep at it.

-

My two swiss S30Z Fairlady Restoration build thread

Great info, thx. Also of note, the original examples shown have a trunkbed plate with welded nuts in place of the provided plate, with welded studs- likely also for ease of installation. The original nut-plate solution is also how the roll bar was installed on my Works car. i can certainly understand why Mizukami went with the latter stud system, as the original welded-nut-plate solution requires 4 large holes to be drilled into the floorboard. A very subtle difference that 99.5% of enthusiasts would probably not recognize. (thatsa lotta nuts & studs talk)

-

My two swiss S30Z Fairlady Restoration build thread

That is a really nice replica comp roll bar. I have one myself, and it is very true to original, as far as I can tell. Just for the sake of discussion: I have not seen the three through-bolts on the wheel well actually appearing on original units. Of the few pictures that I have, I don't see any with this particular feature. That said, I'm confident it will improve safety and utility that way. The hardware is also a bit different from original on the kit I have - I believe the original units were fastened using JIS bolts labeled "9". I'll defer to others with better knowledge.

-

1970 240Z Works Rally - the road to restoration

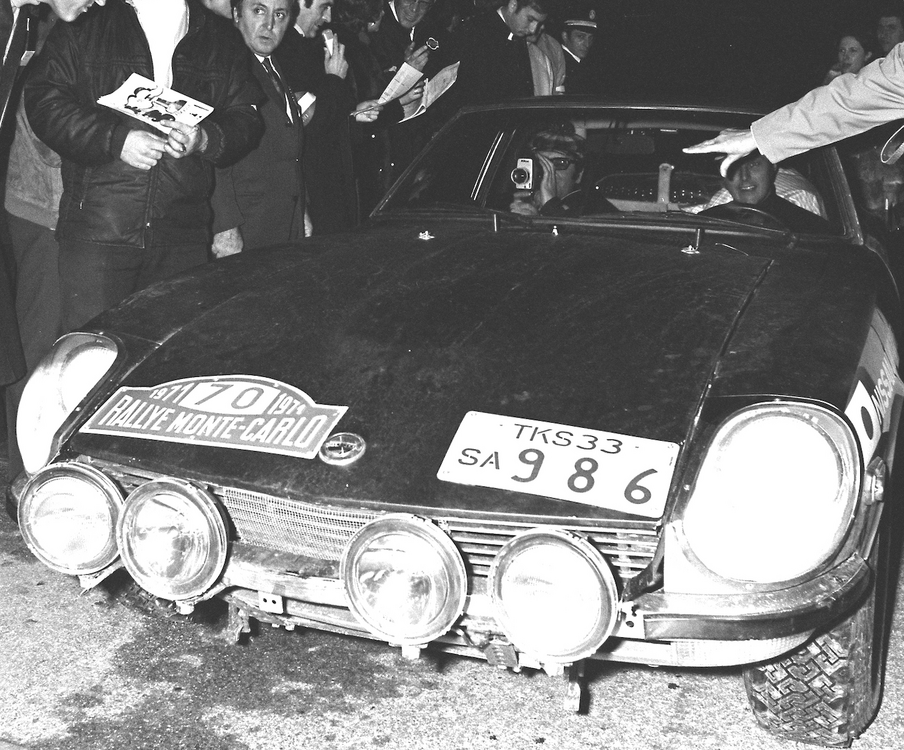

The next video in the Mike Wood rallying days is available - this one from the 1971 East African Safari. Although Mike was with the Lancia team for this event, there is a great deal of fabulous 240Z footage, both pre and post race. Keen eyes will spot several well known Datsun drivers from the Works days. TKS33-SA-1223, 1224, and 1228 are all featured.

-

Datsun-240z Vs Fairlady-z432

Oddly enough, in the US, a stock Fairlady Z will trade at a considerable premium to a 240Z of similar condition.

-

1970 240Z Works Rally - the road to restoration

-

1970 240Z Works Rally - the road to restoration

I'd go so far as to say that there's nothing in the blurred text that rules out "8D-424" as an option, mostly based on what appears to my eye to be two "4"s. This is the "wishful thinking" component of my reasoning. I can only hope to retrieve a clearer photo at some point in the future.

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.