Everything posted by xs10shl

-

Z's on BAT and other places collection

I'm quietly laughing and sobbing to myself a little bit as I contemplate the reality that the supply of Americans who need to or bother to get their license will dwindle with each passing generation. But even before that, Americans who can drive a manual are becoming an endangered species.

-

Z's on BAT and other places collection

It's worth noting that this incident is a different seller and ownership chain. I've edited my comment so as to prevent any confusion.

-

Z's on BAT and other places collection

[edit] - I decided I don't need to drag my own personal methods and beliefs into this thread - its really none of my business.

-

Z's on BAT and other places collection

I personally feel it's odd that Mecum chose to highlight this Z432 over some of the other cars from the collection. IMHO, there are some real gems on offer, which deserve the spotlight.

-

1970 240Z Works Rally - the road to restoration

S30 Works gearboxes: we weren't really sure what to expect as far as condition and composition of this particular box, given that the car was non-op when it was acquired, and the box had been used in competition 50 years ago, followed by several years of street use. Indeed- prior to cracking it open, we weren't even really sure what we'd find inside: a stock box with standard ratios, a hybrid solution, or perhaps something totally custom. Upon opening the box, it appeared to be something I'd label as an "iterative" upgrade from stock- the primary components were stock A-Box 5-speed, with a few internals that were modified from stock, and an "Option 1 Middle Close" gearset. Thankfully none of the unique pieces were damaged, but there were a few chipped teeth on the main shaft, likely due to several hard shifts. Although these chipped teeth may not have been noticed during regular driving, we elected to replace the main shaft with an identical spare from another A-box 5-speed anyways, as a precaution. What we learned about the composition of the box itself is probably not applicable to any other S30 Works gearbox, given that this example is probably one of the earliest surviving iterations built for the 240Z Works cars, and was likely followed by a series of improvements used in the later 240Z's as the technology developed. Included in the unique pieces we found were shift forks made using a different casting (picture 1), and shift rails with additional grooves cut into them to provide some feedback while shifting (picture 2). Also, as previously mentioned, the stick mount is different from stock (picture 3 & 4). So it appears that for this 1970 Works A-box iteration, the Works team made several modifications to improve reliability and gearbox feel, and utilized an available competition gearset, but otherwise kept things the same (apart from a few other small details which I won't dive into). When examined on a timeline, this makes some sense to me, as this car would have been assembled roughly in late summer of 1970, building on knowledge primarily obtained from the 1968 Monte Carlo, and the successful 1969-70 rallying season with the 1600SSS. During this era, I personally don't know of any earlier Works models (SRL311 or 1600SSS) that suffered gearbox failures- anyone know more details? After vapor honing the case, we've got it all back together, and ready for installation (picture 5). I'm definitely looking forward to trying it out, to see if I can feel the difference!

-

Datsun-240z Vs Fairlady-z432

Sure enough, a few weeks later on Y!.jp, up pops this piece for less than $200. Looks authentic enough. Now I have a spare.

-

1970 240Z Works Rally - the road to restoration

It’s an interesting question- one that I’ve given quite a bit of thought to over the past few years. here are some long-winded thoughts on the subject: When I previewed the car at JCCS in 2022 (see picture 4), by far the number one comment I got from onlookers was "Leave it as-is, and don't restore it”. I really appreciated these comments, because I myself had considered the very question “Can I leave the car as-found, and do just enough to get it running?” Short answer: I could probably make that work in some fashion, but not really in a way that makes much sense to me from a historical perspective. if I left the car as-is, I really wouldn’t be “preserving” much of any historic rallying patina. To explain: the interior appointments of the car was largely salvageable (and will be preserved, apart from the metal work) but most of the original exterior patina from its rallying days was already long gone, and any originality that was left was unlikely to be usable without a complete overhaul. The rally “patina" that was displayed in 2022 in the form of racing stickers and fog light mock-ups was largely applied by me to give event-goers an idea of what the car looked like in period. The car is REALLY rough (see picture 3, on the lift), and IMHO, beyond the sticker appliqué, there’s really almost no exterior patina that evokes its past as a Works Rally car. The damage on the dogleg and doors raises perhaps a slightly different question, but I personally feel it can also be considered in the same vein. Someone had already repaired this damage to the door and body in Spring 1971. Fast forward to today, we’re really only looking at their “fix”, and not the original hit. So. I pose the question: do I leave the fix as-is, re-damage it so it looks like the hit in the 1971 Monte, or fix it properly? I think if the car had any authentic “Post-Monte” patina, or even “Post-RAC” patina left, it would be much easier to re-create, preserve, or otherwise highlight damage such as this dogleg, and I’d have a much tougher time deciding which condition to restore the car to. However, In this case they’d already applied the fix by April 1971, and rallied it with the fix in-place. Further: apart from retaining its RAC ride height, and a few dents in the floorboards, IMHO the car really has no other external rally patina showing- it’s pretty much all gone. Given all this input, my current plan is to restore it to 1971 Monte Carlo “Pre-Race” condition (picture 1 below, credit unknown), while keeping as many of the original and period pieces as possible, restoring them to their pre-race state as best I can. This restoration target will likely include properly repairing the dogleg, and saving the original “repaired" piece for my wall. But I’m still open to hearing opinions, so I’d love to hear yours if you think differently after hearing my thoughts. Just to note, this restoration target is slightly different from an “As-New” condition, which I’m not really sure is even possible, given that these cars were hand-assembled and field-tested. IMHO “As-New” would probably yield a less interesting and inaccurate result.

-

1970 240Z Works Rally - the road to restoration

After months of delays, the car has finally been stripped of paint, and delivered to the body shop to start the lengthy process of returning the bodywork to pre-Monte Carlo condition. This point always feels like a milestone of sorts to me, because from here on, the car is coming back together. There were thankfully no real surprises (yet), which is always a good sign. Of course, there is rust in the usual spots , necessitating the retrieval of a few donor panels. Ive also included a picture of the seldom-seen fuel tank mounts, which appear to be identical to PZR stampings. Based on my understanding, these pieces were installed in place of the standard componentry as the four sequentially-numbered (I assume) Monte Carlo cars traveled down the assembly line. One thing I expected to see was the damaged passenger-side dogleg and right door, which occurred during the 71 Monte Carlo. This was hastily banged out, filled and painted.

-

1970 240Z Works Rally - the road to restoration

Just to circle back to this with some measurements: Dimension A and B match the front strut housings on my car, but the damper rod is thicker at 25mm, perhaps for off-road use? The only other difference of note is the TKH vs TKJ designation on the strut housing. At any rate, the identical sizes of the strut housings lends credence to the theory that at least some suspension setups used the same parts. So it seems reasonable that I may be able to re-use the strut housings with different dampers and shorter springs, and achieve a close result.

-

Differential front mount insulator for a 1970 S1 240Z - NLA?

Digging up an old thread. Anyone re-popping these exhaust hangers and associated exhaust hardware? They appear to the same as the early 240Z hangers.

-

1970 240Z Works Rally - the road to restoration

Yes, please! Knowing the spring perch height, and overall strut height of the Tarmac strut casings would be very useful. If they are identical measurements to mine, or even very close, that would lead credence towards re-using my casings with shorter springs to create the proper ride height.

-

1970 240Z Works Rally - the road to restoration

Agreed, sounds like they are all different. I had thought that perhaps 4150 was early enough to have fixed struts.

-

1970 240Z Works Rally - the road to restoration

Part three of the Works Rally Struts show-and-tell: Rear Struts I only have the L/H part number here, because the tape on the right strut has peeled off (or was removed): Y9821-55303. Rear springs are listed as Y9821-55020 2.98. Rear spring diameter is 12mm, and a height of 308mm. The Strut tube is slightly shorter than stock at 15.25", while stock tubes are approximately 16". The spring seat is also about 1/2" lower. In thinking about this - a lower spring seat means a slightly longer spring, but a shorter strut tube means less potential shock travel. As both the struts have the same construction and dimensions, I'd venture that the right strut p/n is Y9821-55302. The front tube spring seats are actually set about an inch higher than stock, with the strut tubes being approximately the same length.

-

1970 240Z Works Rally - the road to restoration

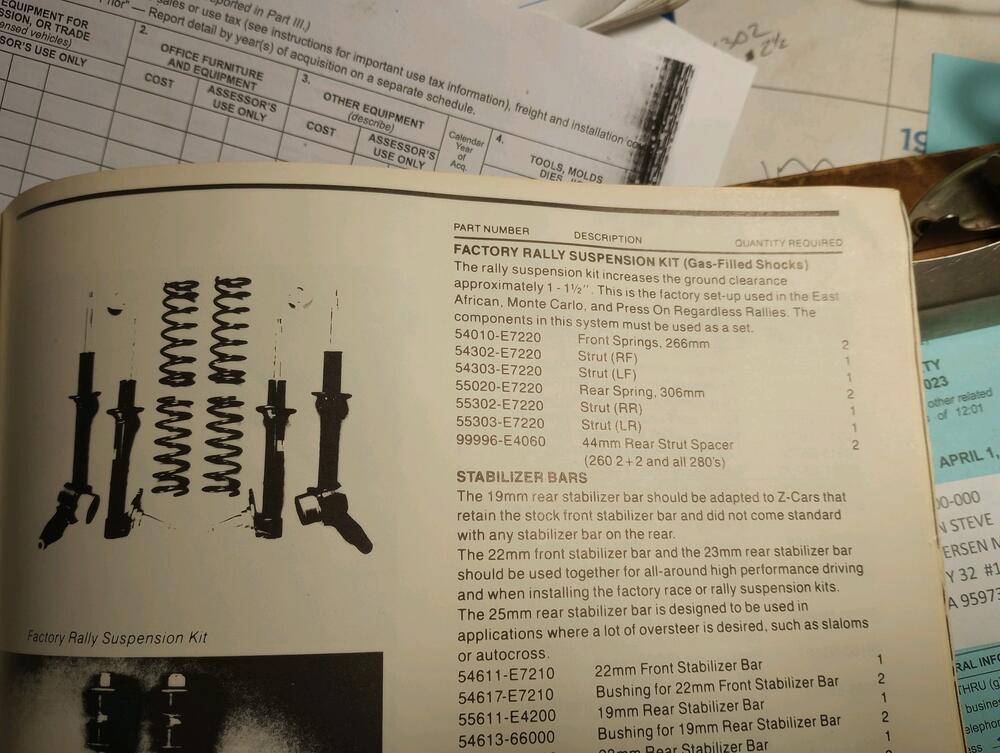

Just to follow this line of thinking you've proposed: It's indeed my hope that I can retain the Works strut assembly, and simply replace the spring with a shorter one, and have that work. This is a straightforward upgrade to many a stock S30 strut, with the substitution of Eibachs for the standard springs - something I've done myself on two S30s. That said, I do wonder whether there was an alternate Works fixed strut assembly akin to the racing 54302/3-E7212, perhaps used within the Works racing team. This is listed in my 1974 parts manual as lowering the car 2 inches. Did the Works team (and others) perhaps use the lowering spring 54010-E7210 with the rally struts to achieve the same effect? If it worked this way in period, it would reduce the need to modify several sets of struts for different ride heights. It would be helpful to know the height of these racing springs, as well as the height of the fixed spring seat on the racing strut itself. I don't know when the Works team switched to adjustable height struts. If it was after 1972, then It would be helpful if an enterprising individual crawled under #11 and #5 to take a look, and do a quick measurement of the spring seat height. [edit - 1974 Competition catalog page added for clarity]

-

1970 240Z Works Rally - the road to restoration

Part two of the Works Rally Struts show-and-tell: Front Struts @HS30-H requested a few specifics about the parts, which are shown below, for discussion. For starters, the RH/LH part numbers are Y9821-54302 and Y9821-54303, with a spring part number of Y9821-54010-1. There does not appear to be a part number on the strut shock absorber. All this seems to potentially coincide with a later parts-manual listing for competition rally parts 54302-E7220, 54303-E7220, and 54010-E7220. [edit: just for reference, stock strut components also have the 54302, 54303, and 54010 prefixes] Some observations: The strut housing and strut itself appears more substantial than a standard strut, although I don't have the parts in front of me to give accurate measurements - everything is out for analysis and rebuilding, so it might be awhile before I can have exact dimensions to share. One thing we did capture is the front spring height, which is 266mm. This matches the listed height of the competition rally spring 54010-E7220. That being said, the competition parts manual only lists a single ride height for the East African, Monte Carlo, and Press On rallies, instead of multiple ride heights. I'd venture to say that I've got what will likely become a "future-standard" rally ride height setup on the car presently, which I already have discerned is not the correct ride height for period Tarmac use (see above post for my thoughts on that). Also, I cant say whether the strut design I have is identical to the listed competition parts, but there is very likely an overlap. Another tidbit that keen observers may have spotted from the first photo is the rally odometer cable attachment point, located at the wheel hub. This served as the attachment point for the twin Halda Tripmasters (one per wheel), which I'll go over in more detail at a later time.

-

Datsun-240z Vs Fairlady-z432

Digging up an older post - My Z432 had a conventional spare tire hold-down in in it when I purchased it in 2010, so finding a more suitable hold-down for a mag spare was yet another item on my 10-year-old wish list. A cheap, rusty hold-down which looked the part popped up on Y!.yp a few months ago, and I paid something like $40 for it, with another $30 to have it shipped. I'm not entirely sure it is the exact S30 Z432 part, as it's been mentioned that it might be shared with another model, but it seems to do the trick regardless. I'll have to add a rubber cushion prior to using it. It cleaned up fairly decently (photos of bare metal part attached), and will be sent out for cad in my next batch. I'm assuming it was Yellow cad, and not originally silver cad?

-

Magazines: Perhaps the first German mention of Goertz in 1974

Indeed, he muses about "having tea" with some of the legends of Japanese automotive industry - Honda, Toyota, etc. All of whom apparently elected not to pursue furthering their business relationship.

-

Magazines: Perhaps the first German mention of Goertz in 1974

To add: I'd venture to say that most designers are influenced by other designs and designers. Take as an example Gandini/Guigaro and the Miura. There are only so many unique ideas out there, and if someone claims the S30 is a derivative work, they could at least acknowledge that the S30 designers picked some great designs to be influenced by. Imagine if they had picked a VW bus, or a Renault 2CV as their styling cues. Many enthusiasts who spot an S30Z seem to know exactly what it is, and don't say, "Hey, what is that- a Jaguar?" In that sense, I'd put forth that the S30 design can be categorized as having staying power on its own merit. A automotive journalist friend of mine has traced many such rumors back to a single article-of-origin. It's very common, and speaks mostly to the laziness of some writers, who perpetuate the rumors with their own "articles-from-a-prior-article" [EDIT: HA! - an even more clear-cut case of "derivative work"]. Even today, I see articles crediting Goertz with designing the Toyota 2000GT, long after stories of any "involvement" on his part have been debunked.

-

Datsun-240z Vs Fairlady-z432

Looks like a nice purchase. What A-box ratios are option 3? My rally car has option 1 (Mid-Close), and I'm aware of option 2 (Ultra-Close) from my reading materials. Sounds like there are more ratio options? Patcon's picture is a good illustration as to how they'd be wired together. I don't know that the bolts were drilled that way from the factory, but one can probably purchase them that way from a vendor.

-

1970 240Z Works Rally - the road to restoration

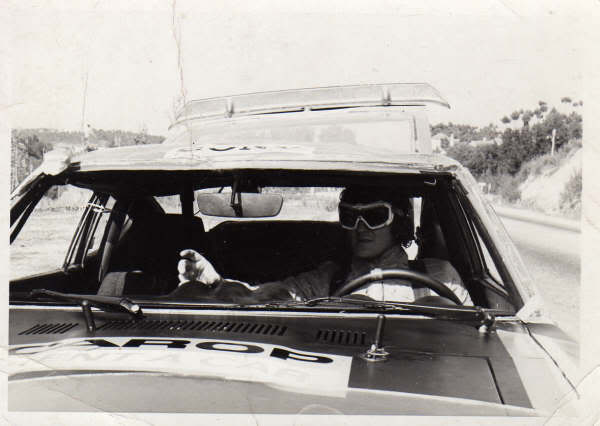

They banged out the roof, chucked the windshield, and he drove it home, apparently (don't know about the navigator). I can't tell whether this photo was staged, but if the story is at all true, then that is a rock star move. (photo credit unknown)

-

1970 240Z Works Rally - the road to restoration

S30 Works Rally Struts - this is a lengthy post because there's so much to unpack here, that I hardly know where to begin. For starters, it's worth noting that the Works team was constantly developing and improving their suspension technology, and what was employed for use on my car was a very early system in comparison to the later adjustable and (likely) more maintainable systems used on later cars. The system on my car was not ride height adjustable in the way later cars were, apart from swapping out entire systems for struts with different components. A preamble before I dive into the actual struts on my car - for the sake of simplicity, I've postulated in the past that there were probably at least three established ride heights for the early rally cars, which I've internally labelled "Tarmac, Forest, and Safari". Please note, this is just a visual way I've used to convey "Low, medium, and High", and are not in any way official designations. I can imagine that it's also possible that there may have been more gradients denoting other characteristics, like firmness, travel, etc., but this is outside my own knowledge-base, and I personally don't possess any evidence to support this line of thinking. Using the same terminology as above, here's a little flash-back to 1971, to gain some color: my car originally ran the 71 Monte Carlo using a Tarmac setup (picture 1, credit Nissan Global Media), thereby lowering the chassis by several inches. After it was sold to Janssen (along with 3 other Works cars), he ran it the 71 Paasraces (picture 2, unknown source) with the what looked to be the same Tarmac setup. What happened after that race is pure speculation by me, based on clues I've loosely pieced together. I can surmise he stripped the car of it's sump guard and a few other off-road parts, presumably with the intent on using it primarily for road use (something he was quoted as planning on doing in a 1971 AutoVisie article). Later in the season, when he rolled his OTHER off-road s30 in the 71 TAP rally (picture 3, unknown source - please note, this is a picture of the crunched SISTER car to my car, inserted here for narrative purposes only), my car was likely pressed back into off-road service for the upcoming 1971 RAC. The off-road rallying parts were re-fitted, along with the sump guard, additional protection for the fuel tank, and Forest struts. He ran an unsuccessful RAC, with a retirement (picture 4, unknown credit). Some time after the RAC (picture 5, unknown credit) he sold the car on to an enthusiast. Back to today, and the struts I have on the car - just about the only thing I can confidently say is that these struts on my car are Works parts - perhaps possibly the Forest struts used in the 71 RAC, given the car's use history - but almost certainly not the correct setup for Monte Carlo, as they make the car to sit too high (picture 6). What I'll need to do in the coming year is to determine if it's possible to easily alter the Forest struts to be used as Tarmac struts, hopefully by just swapping out some of the internals. More on the actual Works strut tower construction (picture 7) in an upcoming post.

-

Datsun-240z Vs Fairlady-z432

Yep. I was frankly happy to pay it, just so I could cross off a 13-year-old TBD item. I had access to an authentic piece about 11 years ago and didn't think to jump on it, so this was actually my second opportunity to rectify this omission. That said, now that I no longer am in need of one, my First Law of Acquisitions predicts that I'll stumble across an authentic piece within a month or two. There's not much that's inexpensive anymore. We've been living in a world of $500 used ash trays and $300 inspection lights for a while now, and we'll soon see how much people are going to offer for that NOS radio antenna on eBay - the one with the "pointy top."

-

Datsun-240z Vs Fairlady-z432

Knowing that the piece was constructed out of fiberglass, as opposed to more malleable plastic, I was naturally concerned that the fitment would not be great, and that the inflexibility of the duct might cause the mounts to stress crack while in-use. There are a few things which need to come off in order to test-fit it on the Z432, so I elected to bolt it onto my rally car, which has been stripped for body work. I was delighted when I saw how well it fit (picture 6)! Nonetheless, I thought Id take the opportunity to cut a set of foam gaskets for it, if only to give the mount a bit of a cushion, and to plug any imperfections with the fit on the Z432 (picture 7). A little fiddling here and there, and I had the piece installed (picture 8 )- That's one more thing I can cross off my mental to-do list. ... With one small caveat - I'm not sure what the proper finish is for the retaining screw. I used black because it blended in with the finish of the part, but I'd guess it's actually supposed to be yellow cad. Any inputs?

-

Datsun-240z Vs Fairlady-z432

Today's project comes courtesy a purchase from JDM Car Parts. I've purchased several of Jay Ataka's original and reproduction parts that he sources from Japan, and although they can be expensive (for good reason - they are typically hard-to-come-by!) he's always offered prompt service, and any parts that have 60-90 day lead times are delivered promptly when they arrive state-side. There may be one or two folks who have wondered why there are a few extra tiny holes around a large circular cut-out on the right-side of their front frame (picture 1). On a stock Z432, these serve to hold the air-cleaner, which is mounted outside the engine bay (picture 2 and picture 3). In addition, they also serve as mounting holes for a special plastic air duct, used specifically on the Z432, in order to clear the air intake. For some reason that I can't entirely fathom, this part is so-very-rarely still attached to most Z432 that I've seen in person, or have pictures for. Just based on what I've seen, I'd venture to say that maybe one out of two cars still retains this air duct. What probably happens most frequently is that owners converted their cars to velocity stacks, and took all the air cleaner-related parts off their car, and somehow the plastic air duct ended up in the trash, or in a box somewhere, never to be seen again. And as one might expect, one of these bespoke plastic pieces does not come up for sale all that often. In fact, I can't remember the last time I saw a real one available for sale. Regrettably, the plastic-air-duct-omission extends to my car, which was sold to me without it (picture 4). I've had it in my mental to-do list to find such a part for over a decade. I've always known that there were fiberglass reproductions out there, but I just haven't taken the time to track one down, as I've had much bigger things to upgrade on my Z432. Fast forward to a few days ago, when I was browsing jdm-car-parts for other stuff, and I spied that Jay now offers fiberglass reproductions of this part for sale. Perhaps he's noticed the same deficiencies I have on other Z432's! I jumped at the opportunity to order one, and it arrived just 3 days later (picture 5). (continued on next post)

-

Suspension rides too high - What are my options? ('72 240Z)

Just my own opinion here on Eibach - I've recently installed 2 sets of Eibach springs on 2 cars- one new set and one used set - and to my eye, the nose of both cars still sits too high relative to the rear ride height. I've heard that this happens to some folks and not to others. Upon examining the coils under load, the top 3 turns are fully compressed against each other, so it's probably a simple matter of cutting off a full coil turn to lower the car an additional 1/2" (the width of the coil itself), which would be a noticeable stance improvement. I'd venture to say that this shortening would likely yield minimal degradation of ride quality, given the full compression of the to 2-3 spring turns while under load already.