Everything posted by alhbln

-

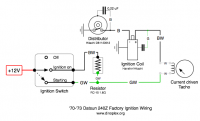

Converting a four wire tacho (current driven) to an electronic tacho

Sure, but please keep the reference to my website

-

Converting a four wire tacho (current driven) to an electronic tacho

I've set up a new project which contains a full replacement of the existing board. It is as simple to build as my previous conversion but is based on standard components and does not require an attiny programmer or programming software anymore. The old project is now deprecated, the new one can be found at the same link: http://www.dinoplex.org/tachoconversion/ Enjoy, Adrian

- Electronic ignition - Revisited after I gave up!

-

New here, need some help ie.. disrtibutor

This indicates a problem with the fuel supply, your carbs are running empty and then the engine dies. Check the fuel lines and filters and clean accordingly, if there is rust and gunk in the filters then your fuel tank will need a good cleaning too. Then check the fuel pressure at the fuel line feeding the carbs, your workshop manual will list the correct pressure for your carb setup (probably somewhere between 2.5-3.5 psi). Also make sure that the Napa pump is the correct size and delivers enough fuel and pressure.

- Electronic ignition - Revisited after I gave up!

-

New here, need some help ie.. disrtibutor

If you get a spark then i would expect that your pickup is ok. This sounds rather like mixed up spark wires or a too advanced or retarded ignition timing. Check your spark plug wiring to really make sure you didnt mix up one or two cylinders. If in doubt, start the engine and let it idle, now plug one spark plug at a time (don't get zapped) and listen to the engine, does it run a bit smoother? Then the spark plug in question was wired to the wrong cylinder. If it does not change, the corresponding wire or plug might be broken. Also check the ignition advance with a timing light (vacuum disconnected), is the advance correct at idle? This would indicate a too retarded ignition timing.

-

Electronic ignition - Revisited after I gave up!

That leaves the Ignitor, which seems to have gone bad, or the magnetic shim had a bit of play and started to vibrate at high speeds but i guessed you checked that already. I don't think its a problem with the supply wiring as your points setup is ok and the Ignitor is merely an electronic version of the mechanical switch, so your wiring seems to be fine.

-

Electronic ignition - Revisited after I gave up!

Sounds like the supply power wiring if its not temperature related, but then the symptoms would be the same when changing to a points ignition setup, as the supply wiring itself does not change. The symptoms you mentioned could indicate a defect Pertronix coil. If there is a broken wire or short in the secondary (output) winding of the coil, the output voltage would be quite low and barely sufficient to create a spark, especially at higher RPM. You could run the factory coil and resistor with the Pertronix ignitor as a test, the combination is equal to a 3.2 Ohm coil.

-

Electronic ignition - Revisited after I gave up!

This might be a problem with the Ignitor overheating, i had similar effects with an Ignitor installation where the engine would start to run rough above 5000 RPM, then gradually it got worse until i let the engine cool down, and everything would be fine until the engine heated up again. Did you notice the same issues with a cold engine? The overheating issue seems to be a design fault with the Ignitor. The Pertronix Ignitor uses an IGBT transistor for driving the coil, which lowers the coil current for circuit protection when the temperature rises considerably. Up to 150ºC internal temperature everything works nice, then the current drops progressively up to 175ºC where the available current is below 1A. The round mounting plate of the Ignitor is the heat sink of the IGBT, but as the engine (and thus the mounting plate) easily heats up to 80-90ºC, the IGBT can't cool down and warms up even further, up to a point where the coil current is so low the ignition starts to cut out. You could either use a points or Pertronix Ignitor setup to drive an external (robust) transistor ignition, as example a MSD 5900 or convert to an optical pickup and transistor ignition such as the Crane XR700. Good luck, Adrian

-

I think its time to take on the Webers

They look a tad melty indeed. These are DCOE 45 carbs? Webcon lists part number 69602.450 for the venturis: http://www.webcon.co.uk/weber/45dcoe.htm#17 Here are two shops who offer the venturis as a spare part for $24-$25 each: http://www.carburetion.com/weber/weberventuri.asp http://www.piercemanifolds.com/product_p/69602.450.htm

-

what is the purpose of the condenser on the zx ignition?

The current driven Z tach has a small coil below the wire loop to pick up the current spike, the spike is then amplified by a two stage germanium transistor (2SB189) circuit to drive the indicator needle coil. If you build a small circuit to convert the 200-400 Volt kickback pulse from the coil (-) terminal via a resistor feeding into a 5V zener diode and then trigger a standard BC547B transistor to put out 500 mV to the tach's pickup coil black wire, then you are all set I would add a schmitt trigger after the transistor to clean up the signal, but thats just me. Here is a small project i did to convert my current driven tach to interface with an electronic ignition (MegaJolt), which might help building a kickback triggered conversion: http://www.dinoplex.org/tachoconversion/index.html Best, Adrian

-

what is the purpose of the condenser on the zx ignition?

Condenser is the old technical term which is still used in the automotive area, but Walter is correct, the correct term is capacitor. Just don't try to order a capacitor at a parts store, they wouldnt now what you need Best, Adrian

-

IGN module thinks it's running at 2k when engine is off

I would recommend borrowing or purchasing a new battery first, the symptoms you have described could result from powering the car with the charger only. Can you post some photos of the ignition module and magnetic trigger, that would help with the identification of the parts Sorry, i don't know the 260Z wiring well enough to answer your question regarding the ground strap, but adding one is certainly a good idea.

-

IGN module thinks it's running at 2k when engine is off

The tacho just shows the ignition impulses received by the coil, those impulses also create the 'angry noises' which you normally won't hear because a running engine is louder than the coil. Question is why the coil receives ignition impulses at all. My wiring scheme for the '74 260Z indicates a point breaker setup, do you have a points setup or an ignition module/magnetic pickup fitted? If you have a points setup, check out your contacts and the capacitor, the contacts might be touching each other and create a partial connection due to the high current flowing, a defective condenser could have similar effects (simple test, what happens if you disconnect the condenser?) With an ignition module either the magnetic sensor/pickup is broken, or the ignition module is defective. Disconnect the pickup wire from the ignition module, do you still have the erratic ignition impulses? If so, the ignition module is most probably defective, otherwise the magnetic pickup might be the source of the problem. Did you encounter the problem with a fully charged battery or with the charger still connected? An electronic charger connected to a dead battery can create similar symptoms when you put a load (ignition circuit) on the circuit.

-

No spark out of coil

This would point to the contacts not doing their job. You may want to remove the distributor cap and give them a visual inspection to check if they are correctly in place and clean, check also the wire going to the outside screw terminal. If you need to clean the contacts/points, use brake cleaner or gasoline and a swab, but don't use sandpaper or anything abrasive. Now connect the test light to the distributor wire and +12V again. If the contacts are currently closed, open them and close them again, does the light now stay on/blink? If the contacts are currently opened, bridge them by (gently) introducing a screwdriver blade inbetween the points, the light should go on then. Good approach. You might ignore the condenser for now until the light tests indicate that the contacts are ok. If you get +12V to coil (+) both on starting and ignition on, your contacts switch coil (-) to ground and the capacitor and coil are good, then you should get a spark. You might also want to check you distributor cap and rotor as well as the spark wires and plugs, but that can wait until you get a spark from the coil. good luck, Adrian

-

No spark out of coil

You want to make sure that you also have power when the starter is turned, else your engine won't start. Pull the green/white wire from the resistor and measure the voltage or use a test light between green/white and ground, while turning the starter. If this test works out ok, then your problem is most probably the black wire to the distributor contacts or the contacts itself. As a simple test, remove the black and black/white wire from the coil and connect them to a +12V light bulb or test light. The lamp should flicker while you turn the starter. The coil must be grounded via the mounting bracket, as the spark energy is delivered via the HV cable and ground to close the circuit.

- Electronic ignition - Revisited after I gave up!

- Electronic ignition - Revisited after I gave up!

- Electronic ignition - Revisited after I gave up!

-

Ever blow a Freeze Plug while Driving?? I did....

8º is conservative, shouldnt give any issues. What is your maximum advance at 3200 RPM, should be 31º. Sputtering at the top end might also be mixture or air, as the distributor is already maxed out at 3K-4K RPM.

-

Ever blow a Freeze Plug while Driving?? I did....

Factory recommendation is 7º-8º, hope that helps.

-

Ever blow a Freeze Plug while Driving?? I did....

With an engine management system (Megajolt as example ) you can set idle independently of the rest of the advance curve, but with a mechanical advance setup i would rather focus on the max advance and let the idle follow. If you care for a smooth idle, turn the distributor to 10º with a warm engine, then start the engine and slowy turn the distributor in both directions and listen to the engine where the idling is smoothest. Might be anywhere between 6-15º depending on the engines condition, carbs and air supply.

-

HI-6 not recieving trigger signal from Unilite

Did a quick research, you seem to use a Mallory #609 type ignition module with a VR magnetic pickup (if you have a star shaped trigger ring, it is usually VR, a pot style trigger with rectangular gaps indicates a hall pickup). The Unilite documentation is not very clear about this setup, it recommends that you should use a ballast resistor between +12V and the ignition coil (+) to restrict the maximum current which could destroy the module. But since you are not driving a coil with the Unilite module but merely trigger an external ignition system (HI-6), this should not be an issue. In the Mallory wiring sheet, the red wire of the module is indeed directly wired to +12V. This is the excerpt from the Unilite magnetic pickup module installation manual: http://www.malloryperformance.com/pdf/609.pdf (Figure 4, Page 2) NOTE: The purpose of an ignition ballast resistor between the ignition switch (12V) and the ignition coil positive terminal is to restrict current flow through the ignition coil. Failure to use an ignition ballast resistor will eventually destroy the Ignition Module. From that perspective i would say that it is safe to run the Unilite module with a +12V feed if you only use it to trigger a HI-6 or MSD 6A CD unit. The Mallory Hyfire 6A (identical setup to a Hi-6 unit) also shows a direct wiring without ballast resistor, have a look at the wiring sheet on the bottom of page 6: http://www.malloryperformance.com/pdf/6852M_6853M.pdf Dave, what do you think?

-

HI-6 not recieving trigger signal from Unilite

Good info, thanks! I wonder why Mallory did not care to add an LM7810 then, car components should be able to handle 12-16 volts without any negative effects. Magnets don't usually wear out (if you dont cook them or hit them with a hammer) but the pickup could fail, both issues are not very likely with a new module though.

-

HI-6 not recieving trigger signal from Unilite

Tommy, quick question, are you sure that the Unilite gets +12V via the green wire or just a typo? Should be the red wire as in 1). You said that your extra module is not magnetic, but the one installed in your Unilite should be optical. Could you send both parts number so i can look up these? The test in 2) puts a load on the Unilite output to check if the output if functional and goes to ground, its a simple test to check the basic functionality.The green wire goes to one terminal of the bulb or test light, the red wire to the other terminal. Good luck, Adrian