Everything posted by Mikes Z car

-

240Zs on Craigslist in Idaho, an Orange one and a Black one

The orange 240Z craigslist ad I see listed intrigues me because I remember spotting this car repeatedly over the years heading down Broadway Ave here. It is orange like my first Z. I recognize the car because of the name on the license plate. There are some other Zs on craigslist now too. Orange 240Z: Black 240Z: Note that Bill Reagan has dropped the price on serial number #201, his ad is listed on this site in the Classifieds section. Orange car craigslist ad link: A SWEET LITTLE 240Z Black car craigslist ad link: Price Drop Nissan/Datsun 1972 240z

-

Parts car grab, starter, alt, windshield

Virto, Fortunately I spotted a wasp entering the crack at the front of the passenger door so I had a clue they were there. Investigating by opening that door brought a swarm out and I beat a hasty retreat. I was thinking about them as I crawled under the car from the driver's side to get the starter off but fortunately they weren't thinking about me. Bonzi Lon, I once threw what someone called mineral spirits on a wasp nest and was amazed that they dropped dead with no further wiggling, as you said faster than spray. Wade Nelson, Thanks for the windshield cut out info. I have to be careful at JY's so that I don't drag home stuff I don't actually need as I think they are fun.

-

BEHOLD! The NEW Datsun.

-

Parts car grab, starter, alt, windshield

The steering wheel(s) and seats were already gone but the 280Z turned out to be two 280ZX's and two 300ZX's but I got the starter and 2.2 ohm ignition coil off of one of the 280ZX's. I think the starter is a gear reduction type based on the output drive shaft appearing to be offset from the center of the rest of the starter. I believe I read that a 280ZX starter will work on a 240Z. Got a GEN YOU WINE Bridgestone 175X14 to check fitment in my 240Z spare tire well. Rubber is cracked a bit on the 175 though it is still holding air, won't be taking that out on the freeway. I wonder if that could be an original tire? Ran into two women in the JY, first time I saw any ladies there. Grabbed some connectors while avoiding a large paper wasp condo. Those guys thought they owned that car for some reason and me with no wasp spray to overrule their conviction. Also spotted a 73 Austin Healy, two MG midgets and a Porsche 928. My dad had a 928. I like to check out Porsche suspensions in a JY since they are supposed to handle well but didn't see anything unusual to my untrained eye.

-

Parts car grab, starter, alt, windshield

I don't actually have the two parts cars I just found out about them. I plan on getting parts off of them this weekend. I don't know what year they are. How are those covers removed, do they just pull off or have snaps?

-

Parts car grab, starter, alt, windshield

I found out about a 280Z parts car being parted out. Will grab starter, alternator and other parts for my 240Z if they are still on the car. What is the easiest way to grab the windshield, just cut the rubber with a knife? Any hope of cutting off the windshield rubber so it is reusable? Will the distributor work on my 240Z? It might be good to pull the head if it is for unleaded gas if the car used unleaded gas? Thanks for any heads up. Mike

-

70 Z on Baltimore Craigslist - Slipped Decimal Point(s)?

I bought my 1970 240Z that I saw listed on craigslist back in 2008. It was maybe 15 miles from me. There was another 240Z I looked at for half the price but it was a total rust bucket.

-

Gas filler hose leak fix?

Anyone know if seal all would work for this repair?

-

70 Z on Baltimore Craigslist - Slipped Decimal Point(s)?

For $300K I would want a picture too. Ad: rare 1970 240z - $300000 (annapolis) original owner since 1971 car is mint call for pics and questions wont last long Location: annapolis

-

Gas

I use only ethanol free gas from a station nearby. One day I asked another patron with a newer car if they bought gas there for the same reason I do to avoid ethanol. He said I will never use ethanol in my car. I understand there are at least two more ethanol free stations in the area but they aren't as convenient. I avoid ethanol due to concern about corrosion from ethanol on aluminum carburetor parts and steel fuel lines which I have read about. I read somewhere that premium gas doesn't have ethanol, that ethanol lowers mileage due to it having less energy. I don't know if flex fuel cars have different alloys in the fuel system. Have read about bad effects of ethanol on boat engines. Be your own guide and information resource. Google knows all, tells all.

-

Article: Honda Wiper Motor Upgrade for the 240Z

Dave, Thanks for the great writeup and pictures, nicely done! One advantage to using the Honda Civic motor you selected I think (as opposed to the '97 Honda Accord motor I used) is that due to the Civic's slotted drive shaft it is easier to have the park position work. To make the park work on the Accord motor the shaft has to be ground off at the right angle. Mike

-

Distributor question/issues

I THINK pictures get turned sideways in the upload process from my own experience because they are taller than they are wide.

-

"How To" grease rack & pinion

I never knew if this idea had any merit but when I had my previous 240z 30 years ago I pulled back the boots and applied a coating of grease all over the metal under the boot including that serrated gear thing. I turned the wheel all the way one way, put grease on anything exposed under the boot and then turned the wheel all the way the other way and put grease on any freshly exposed metal under the other boot. I didn't have an FSM back then though it doesn't mention that idea I don't think.

-

Make your own Z model

That looks good! Here is another one. Well now I see it has a copyright notice. Don't know how that applies here. S30 paper model instructions | Import Bible - Automotive Apparel/Car Shirts

-

Part number for a 240z wind shield wiper motor needed! Please Help!

The fiche I have doesn't show a separate P/N for the relay, looks like they want you to buy a new wiper motor as an assembly that includes the relay that is attached to the motor. How do you know the relay went bad? What year Z did you get your motor out of? Your profile shows you own a 1969 so that is the year Z you have?

-

Weak return to center spring

EuroDat, Thank you for the information and the thread link. Now that I know the return to center is supposed to be stronger pulling out of 5th I can make the spring stronger. 5th/reverse doesn't have much return to center force now so making it stronger shouldn't hurt anything theoretically. Mike

-

Weak return to center spring

Replacing the spring and plunger didn't make any real difference on the weak return to center which might not be surprising I imagine given that the measurements of the old and new springs and plungers are very similar. Measurements (note length of old spring fully compressed): Closeup of both old and new springs and plungers: Plunger view from spring: Old spring being measured just to validate my caliper reading (38.84MM): There seems to be a "detent bias" on my car so that the return to center force is much greater pulling out of the 5th/reverse slot and letting go of the shifter as opposed to pulling out of the 1st/2nd slot and letting go. My 5 SPD DD doesn't have that bias, both return to center forces are the same. I don't know if the bias on my Z is indicative of wear on the shift rod. That doesn't seem likely to me, maybe the transmission return to center was like this from the factory due to the shift rod detent being ground differently on one side of center compared to the other? Captain Obvious does your car have that same return to center bias? It might be possible to cut the spring in half and then to place a metal cylinder or cut off bolt where the missing half of the spring was to increase the spring rate and thereby the force the spring is putting on the shift rod detent if the length of the cylinder is selected properly. Cutting the spring in half would still allow putting the spring/plunger back in with the fingers as long as the cylinder isn't too long. The stock spring is already fairly compressed so care would be needed to make sure the spring didn't get completely squished so it would run out of "compression travel". Minimum compression travel would be the thickness of the "ridge" on the plunger that contacts the shift rod. Maybe an even stouter spring is needed. Anyone have insights on this? I only got 1 spring and 1 plunger as opposed to the fiche showing QTY of 10 and 5 respectively though looking at the baggies they came in the plunger baggy was originally marked for a QTY of 5 which someone marked out and replaced with a "1". The white sticker in the plunger baggy picture was on top of the more yellow colored sticker. The spring baggy looks like it is 30 years old but shows a QTY of 1. Plunger baggy, white sticker was on top of yellow sticker as I received it: Spring and Plunger baggies: Plunger baggy large white sticker with QTY 5 marked out with marks a lot: (Picture taken by backlighting with the sun)

-

Racing Decals from the 70s

-

240z alternator upgrade (instructions w/ pictures)

Terrific writeup. Great pictures too. Is the 280ZX alternator the best to use to switch to an internal regulator or is there another more widely used alternator (possibly a cheaper GM or whatever) that will work? I have read going with a GM alternator requires a bracket modification. Mike

-

I spy a z!

Saw a blue 260Z pulling into the same gas station I was in. Went over and spoke with the lady driving it. She looked at her car and said I should have sold this car 8 years ago but it is so much fun driving it. She uses the same Z mechanic I do; that is when I don't do my own work. She said she is going to get it repainted and that the current paint job lasted 8 years. She doesn't have a garage.

-

Choke turn off remonder light

The low tech approach. Will last forever too.

-

Choke turn off remonder light

I don't know if this idea is worth pursuing but I would like to have a blinking LED to remind me to pull the choke off when the car is warmed up. For those who have worked with electronic circuits (I gather some here have) what is the easiest way to do this? I was thinking about connecting an op amp up as a comparator with one input going to the thermostat and the other input wire going to an adjustable resistor so that when a certain resistance is reached the LED that is one of those blinking types is turned on. Where can the LED be hidden so it can't normally be seen? I would assume a switch connected to the choke control would be needed to turn off power to the op amp to stop the LED from blinking when the choke is pulled off. Is there an easier way? Now if I could just edit the word remonder to read reminder.

-

ebrake switch retainer

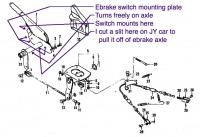

Thank you harlest! In the unlikely event someone else would run across this thread here is a drawing I shamelessly copied from a post by Arne showing the switch plate my car was missing and the slit I cut at the bottom of the junkyard car switch plate so I could slide it over the ebrake "axle" to remove it. It feels quite solid in spite of the slit as it is held on by two bolts.

-

Drinks to take on the Road

Hopefully the driver behind will just think his windshield washer malfunctioned.

-

Drinks to take on the Road

I remember a story about a relief hose that went through the floorboards but you wouldn't want to do that in a z as it would encourage corrosion and detract from the stock appearance.