Everything posted by LeonV

-

Let's show vintage racing pictures. I'll start.

I saw the Frisselle car a few years ago at the historics. I'll have to dig the photo out tonite.

-

215/60 or 225/60 on 14x7

I'll second that one. It's a very good point, let alone the tire rotation factor, although I suppose if one never drives the car hard they'll never tell the difference.

-

New member in NC

You're welcome! Blue has also compiled some fantastic "Tech Tips" over at atlanticz.ca that I'm sure each one of us has used at some point of Z ownership.

-

New member in NC

Invest some time (i.e. a lot of time) in the free FSM. Get it at xenons30.com.

-

Ignition Timing Theory - Port Source vs Manifold Source

No problem. Sounds good to me!

-

l28 + zx 5spd into 70 240z

Ah, the dreaded flat-spot! Enriching your idle circuit will probably mask the low-speed stumble, but you will get worse gas mileage. You shouldn't get popping at high rpm, your main jet must be way out of the range of what your engine needs. If you didn't have these problems beforehand, I'd look elsewhere though. Are you sure you didn't obstruct a fuel line or change something regarding the fuel system? I would check all filters and lines before doing anything else. Maybe you kinked a fuel line upon engine/transmission installation?

-

Ignition Timing Theory - Port Source vs Manifold Source

It's simply because the conditions for knock were right. It might be too low octane, too high intake temperature, engine running too hot, etc. There are many factors that affect when knock occurs, and it just may be that it happens before MBT timing. This is more likely to happen around torque-peak, where cylinder pressures are highest (max. volumetric efficiency).

-

Engine rebuild or not? and to what extent?

I'll second that. Adjust the valves first. Running the engine will increase compression in an engine that hasn't run in a while. I've had an old engine test 90-120 psi, ran it, retested, and got 180-195 across the board.

-

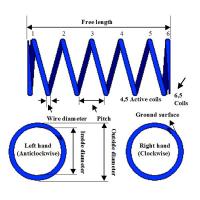

Spring Rate Measurements

Take the total coils and subtract two, if the spring has squared ends (flat top and bottom). If your spring has 9 coils, then the calculation with 7 active coils (197lb) should be close.

-

Gear Reduction Starter v. Standard

No, unless it's in better condition, I suppose. If the current starter is functioning fine, there is no need to replace it.

-

Ignition Timing Theory - Port Source vs Manifold Source

But of course, calculus is the foundation of physics! Yeah, the main topic of the paper wasn't up to snuff but the reason I brought up the paper was to help explain MBT. I think he did a pretty good job of it. There is definitely a window of spark advance where torque doesn't change much, this is evident during dyno tuning. However, as you advance more, you bring yourself closer to the knock limit. That's why when dyno tuning a spark curve, you will see max torque over a certain spark advance range, but set it at the lowest advance needed to hit that mark. It's better to be on the approach to MBT timing rather than overshooting.

-

Ignition Timing Theory - Port Source vs Manifold Source

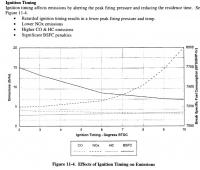

NOx climbs with increasing combustion temperatures. Therefore, in a nutshell, NOx does climb as spark timing is advanced (higher cylinder pressure = higher temp). NOx emissions and EGR are very interesting subjects. I have a summary/explanation posted on HybridZ, it can be found here. NO! Absolutely not! I don't mean to yell, just want to emphasize the point. I'll try to summarize why this is so. Once the mixture is ignited, it burns and releases its energy over a certain period of time. The whole point of having the spark timing advance is for the mixture burn time to match the engine speed. Burn time is essentially constant (depends on AFR, combustion chamber geometry, fuel composition, etc.), but engine speed is variable. Therefore, the burn must start earlier at higher engine speeds. There is an optimal point at each engine speed, where the burn must release a large part of its energy. In relation to crank angle, this is at about 15 degrees ATDC, if I remember right. If you ignite too late, the burn happens late, and your maximum energy is less (piston is dropping = bigger volume = less pressure) since it occurs at a less favorable crank angle, thus you make less power. If you ignite too early, your peak energy release occurs too early, when there is less leverage on the crankshaft (rod almost, if not completely vertical). Your goal when tuning a spark map is to find the "happy point", the technical term being Max Brake Torque (MBT) timing. The knock limit comes into play if your fuel does not match your engine (too low octane, too high compression, high intake temps, or combination thereof). The thing is, the knock limit can stop you before you reach MBT. However, if you reach MBT but have not reached the knock limit, then you can easily over-advance the timing. Therefore, just because you advance to just before the knock limit does not mean that you will be at MBT (the optimal spark advance for that specific engine speed/load). If you are interested in more, here is a great paper I just found on the topic: http://www.vehicular.isy.liu.se/Publications/MSc/06_EX_3809_JM.pdf Another great reference for those truly interested, is "Internal Combustion Engine Fundamentals" by Heywood. This is the ICE bible. You usually need to calibrate those sensors so that you're making sure they don't give false alarms. However, once you reach high enough rpm, these sensors tend to pick up a lot of noise and give false alarms, at least on our solid-rocker adjuster L-series engines.

-

New member in Tucson, AZ with a 1970 240Z

Nice find!

-

Ignition Timing Theory - Port Source vs Manifold Source

Somewhat, you're getting close. The burn is long completed by the time the valve opens but the burn does begin later, thus the maximum combustion temperature occurs later in the power stroke. This gives less time for heat transfer to occur between the end-gas and the cylinder walls, thus the exhaust coming out of the cylinder is hotter but the combustion temperature is cooler (lower cylinder pressure). As spark timing is advanced, exhaust temperature drops leading to a decrease in HC oxidation, thus HC emissions increase. HC are a product of combustion, you're not going to run your engine without HC coming out. However, HC emissions are not highly influenced by spark timing, not nearly as much as NOx emissions. Yes, however, an air pump will catalyze the oxidation of HC. As you can see, that guy is spreading misinformation, at least in the quote you posted as I didn't have a chance to read more. The burn is long done before the valve opens and there is no incomplete combustion to speak of. In fact, retarded timing stabilizes engine running (to a point, obviously), as discussed earlier.

-

Ignition Timing Theory - Port Source vs Manifold Source

I suppose my phrasing was a bit awkward. Retarded timing at idle, and advanced everywhere else has a stabilizing effect on idle speed. But now that I think about it, the effect isn't really there when using a distributor. There could be some dynamics involving how much the throttle must be open under retarded/advanced timing, but I think these are all secondary effects and not really noticeable. It's more beneficial for EFI with programmable spark maps.

-

What classic car is this?

Nice, that's a car from the New Years ("Anti-Football") classic car run I went on! I remember seeing that Alfa (among many others), along with an eye-shattering amount of car porn! Too bad my camera sucks, and I took few pictures because I was going on 2.5hrs of sleep... I'll just leave a few teasers, from our mini-convoy:

-

How to remove the Crank bolt on an Automatic Z with head off?

I've loosened the crank bolt on a block with a method similar to John's. I cut up some extra roll bar padding and put it on top of a cylinder. Then I just put the head back on and tightened 4 used head bolts around that cylinder, not to spec but just tight enough for the head not to be loose. Get a big bar on there and you're done! Of course, this is if you have access to a head and have your old bolts laying around.

-

Ignition Timing Theory - Port Source vs Manifold Source

I agree that there is less NOx emissions at idle than with the engine loaded, but you will see a reduction in NOx through retarded timing. Even if you have a stable idle, retarding the timing will increase exhaust temperatures which then burns up more unburned HC coming from the combustion chamber. At this point, we're getting into the finer details. Point being, for the OP, is that certain emissions will be reduced and off-idle torque will jump making take-offs easier (and stalling harder, unless you let off the throttle).

-

Ignition Timing Theory - Port Source vs Manifold Source

Good question! "Ported vacuum" is used for emissions reduction, among other things. Retarded spark timing reduces peak cylinder pressures, which reduces peak combustion temperatures. This makes for a reduction in NOx emissions, since NOx is dependent on combustion temperature. Conversely, exhaust temperature increases with retarded timing, thus a reduction in unburned HC is also realized. A side-benefit that I see is stall protection. Since the vacuum advance quickly activates as the throttle is cracked open, off idle engine torque is considerably more than at idle. This gives the driver an effective buffer, or aid, in getting the car going from a stop. This can be seen in modern spark maps as well. Also, overly-advanced idle timing is more prone to misfire. Taking a stock '72 240Z, with base timing at 17deg and max vac advance giving another 11deg, that's 28deg of spark advance at idle!

-

popping through the exhaust at 4500 rpm or so.. HELP!

And people say that triples are a pain! As much as I'd like to see the issue resolved, I say just get yourself some Webers or Mikunis already, you won't regret it!

-

Weatherstripping, making sure I got it right.

As far as the spacers, those are for the front crossmember mounting points.

-

What makes the rear wheels sit forward in their wells?

Good point. This is one of the reasons why suspension fasteners must be torqued with the car fully laden. If someone torqued the suspension down with the wheels in the air, problems like this one can arise.

-

240Z California shell bargain!

You lucky guy!

-

240Z California shell bargain!

Yes, it's real. It's CJBrian's from hybridZ. If he was local, that would have been in my garage weeks ago.

-

Front Suspension Advice Request

FWIW, you can get a close approximation that spring's rate with a spring rate calculation. k = Gd4/8nD3 Where, k = spring rate (lb/in) G = Shear Modulus (about 11.5 X 106 lb/in2 for spring steel) d = wire diameter (in) n = # of active coils (total coils - 2) for that spring D = average coil diameter (in) That should get you close.