-

KONI Sports for Classic Z's

Zed, we respect that, but we're talking about a custom setup, and it would be 100% the same regardless of whether they use a Koni or any other strut cartridge. There are many different custom mount options and types we've seen, and most of them would require their own separate solution. And on many, like those with rubber at the top, or camber movement, the washer-type solutions wouldn't work at all. We'll talk to those custom mount manufacturers we know about options for their products. For most, simply holding the shaft gently has been successful, since the torque spec needed isn't much. Of course Koni has to stress that if you're not extremely cautious, you can damage the shaft. For instance, many I've read after simply suggest using pliers and a rag, which is strongly not recommended at all, as it is too easy for the teeth to get right through the rag and cause damage. The rubber used should be solid and fairly thick to completely protect the shaft from damage. On many of the custom mount options we've seen, a crows foot would not work as there would be no room to drop it down to where the nut is (like our street camber plates). However on those where the nut stays near the top and is accessible, then yes, that would be a great option, thanks for suggesting it.

-

KONI Sports for Classic Z's

While these Koni's were designed for the stock equipment at the top, Koni is progressive when it comes to performance items, like lowering springs, and custom top mounts, and always try to find a way to make it work, unlike some other companies. If you have chosen to use a custom mount (pillowball, camber plate, etc.), then hopefully these suggestions will help. One of the Koni techs had a chance to respond this morning: "The idea of using an impact is never recommended. Doing so over the strut nut is essentially a guarantee to destroy the strut internals, or at very least the threads. Using a layer of rubber to protect the rod and set of pliers or vice grips is another option but extreme caution also needs to be taken to ensure the rod is not damaged or marred. If using this method it would also be a good item to hold the shaft at the highest point possible near the upper mount. Try to grab at an area on the rod that less likely to pass through the guide seal during normal compression stroke." Other thoughts: jonbill said "make a washer with a D shape hole and bond/weld it in to the top of the top mount." This could be a great idea, depending on what tops you are using, especially if you may need to remove them often for racing or some other reason. For those skilled in welding, you might even take your custom top mounts, and weld a small piece of metal at the opposite of the D shape. But since the torque spec is so light, even a simple bonding as suggested would be enough to hit the necessary torque figure. Using pliers and some form of rubber or protection is a time-honored method. Great suggestions we've heard include what AK260 said (cutting a rubber hose from the valve cover breather/etc.); or using an old serpentine belt from the family sedan; or a good rubber hose section or two. Another option, completely depending on the configuration of the custom mount you are using, might be tools like an oxygen sensor "wrench", if you can find one in a matching size and height that you need. If so, you can use it to torque the nut, and above it either use two nuts to lock the shaft using a wrench, or perhaps the rubber-in-pliers method at the top, not going anywhere near the lower part of the shaft. Many setups won't have room for this option. For all of these, just keep in mind that if you are using a custom mount setup, it is still your responsibility to ensure the shaft isn't damaged, so always use extreme caution.

-

KONI Sports for Classic Z's

Hello JagoBlitz, while Lee is currently unavailable, he did get the Koni engineers to confirm. They said if you are using some coil over or other custom top or replacement for the mounting insulator, which does not have the "D" shape, if it has room for two additional nuts at the top, you can "lock" those together to hold the shaft, and use special wrenches to tighten the nut below them. However we would add that since many or most custom setups won't have enough room for 3 nuts, then jonbill's suggestion is a good one. We also know of some who have used strong hands and gloves to simply "hold" the shaft in place. Many have tried a "protected" pipe wrench, which is not recommended.

-

KONI Sports for Classic Z's

Thank you Kent. By the way you described it, and with the springs you mentioned, I believe you'll be very happy with the range on these cartridges. Be extra cautious in regards to overheating the struts, and if you've not done anything similar before, it might be worth checking with a technician or machine shop who has. The key things are a sharp wheel, level cuts, and cooling it down often. Heat could really screw up what is in that cartridge just a few mm away. Let us know if you have any issues.

-

KONI Sports for Classic Z's

Hello Kent. Those are the correct strut cartridges for a stock 240Z front strut housing/hardware. Unfortunately they are not designed for Ground Control coil over kits. GC sells specific cartridges to fit in their kits, and whatever cartridges they are labeling as "Koni Yellow" are not the same as our Koni Sport (Yellow) struts, so they are either a different type of Koni strut (not Koni Sports), or they are from another application entirely (BZ3038, for instance, were for 280ZX front). Even though they do not section the strut housing to shorten it for lowering the car (assuming that is what you meant), that doesn't mean the whole kit hardware is designed for "stock" 240Z strut cartridges. In addition to the height of the cartridge, the cartridge you need is also dependent on the strength of springs you will be using with the coil over kit. Do you know the springs that are on the second hand kit you purchased? I'm not sure if anybody who has ordered the Ground Control kit can tell you what number of Koni strut cartridge they were sent from GC, but they are not 240Z front Koni Sport Yellows as we sell. If you are not racing this car, and want to use these with your Ground Control front coil over setup, and your measurements indicate that removing part of the "nub" would be enough height, then it is possible, although not recommended, and one would need to be very careful. The warranty would be void for modifications, just like it is for racing applications, so consider carefully if you decide to use these for a custom setup. Here is what a qualified technician said: Again, if this is a race car, or you have a specific level of "race" type performance in mind, Ground Control has strut options designed to match the "race" strength of the springs, AND fit with their specific hardware/camber plates/etc. Let us know what you decide and how we can help.

-

Putting in a replacement L-28

Zed, as far as we're concerned, we always appreciate you looping us in. Thank you for doing so. We'll always try to come up with the best option as far as shipping and delayed items are concerned. With all the supplier issues it has been much more prevalent and difficult than usual these past two years. On more orders than people might think, where we've screwed up and had to reship something, we often end up losing money on those orders. It is part of doing business, but Greg is working hard, every day, to get parts here from literally all over the world to ship out, and we're working on making certain everybody knows all of their shipping options. Thanks again for alerting us. As a side note, James is unfortunately no longer with the company, I'll be asking Mike to remove that account to alleviate confusion.

-

Putting in a replacement L-28

Sorry for taking so long to respond. There is no excuse for what you've reported, all we can offer is our apologies. Getting quality shipping staff has been a struggle for many years. Unfortunately, the pandemic has only made it worse. We're training a new person now, and hope such packing errors are a thing of the past. With millions of possible combinations of parts, training is a long term effort. None of this helps or excuses what we did to you of course, and what you've described should be simple common sense, but it is something we continue to work on. As far as the email contact, I can see the email that we did send on June 15th, in the (failed) attempt to let you know about the 2 items that we hadn't received. If you do ever choose to give us another chance in the future, when you don't see an order confirmation email in your inbox or spam folder, after you place your order, please let us know. As far as the older order you mentioned, your account we have now only goes back to 2020, so we assume we had you at a different address before, and duped your account by accident. If you're willing to help me find that order, please pm me. Sorry again for the inexcusable shipping problems, and thanks for all the orders you've made. Hopefully we'll get a shot to help you in the future.

-

Joseph@TheZStore started following Reproduction E-Brake Cable failure -70-78 Z and Putting in a replacement L-28

-

Putting in a replacement L-28

Sorry to respond so late, and muddy the current thread discussion. Things have been quite overwhelming here, we're trying to dig out. First of all, nice job on the Z so far, and it sounds great! Thank you for your patience with us. The email issues have affected many companies. Places like Yahoo flag a domain as spam, with no explanation, and no recourse. We did send you an email on October 13th (that obviously went to spam or disappeared into cyber-oblivion), that the intake and boot were delayed from the manufacturers, and that we would ship it all together when all items arrived. So our apologies as we should have followed up with you when we didn't see an email reply. Sorry about that. It is definitely something Greg is working on as we get new sales team members up to speed, and hopefully (soon) find a few more, so they aren't overwhelmed all day long. We have also recently been trying to call, in addition to sending emails, which can be tricky as many don't want to be bothered with phone calls. Unfortunately we're still waiting for the other items you ordered. Just call our sales team anytime for the latest we've heard from the manufacturers (side note: Your most recent order left yesterday, just in case you're not getting the tracking emails either. If you didn't, if you can help us out, please check your spam folder and let me know if our emails aren't in there). As far as successfully getting out of our old systems and into new ones where inventory can be shown, that has been the most difficult of all, a long story, and that one is on me. I will say that we have what we hope is a great new company working on things now, and are very hopeful that they can get it all figured out relatively soon. Thank you for all of your orders, kind words, and for having mercy on us.

-

KONI Sports for Classic Z's

I can't speak for the Koni engineers (and I'm certainly not one, lol), but as best as we understand it: The strut insulator does not impact on the Koni sleeve either way it is installed. The insulator impacts on the strut bearing in the front (or the strut spacer in the rear), and they in turn impact on the top of the spring seat. The Koni sleeve sits slightly under the top of the bearing or spacer (otherwise it would grind when you make a turn), and is not impacted. The bump stops were originally bonded to the underside of the spring seat. If you bottom out, the bump stop takes the impact between the strut body (Gland nut) and the upper spring seat, the Koni sleeve is in-between and isn't impacted either way. As far as damage to the bump stop, that is an engineer question for sure, but it *seems* like the only time there is pressure on the bump stop is when it bottoms out, and then all the stress is between the top of the bump stop and the spring seat, and the bottom of the bump stop and the Gland nut. I'll try to get this discussion seen by those engineers to get their corrections/thoughts.

-

KONI Sports for Classic Z's

You are exactly right, sorry about that, I had forgotten all about posting that previously. I blame 2020, lol... Koni made this setup with the sleeve because that is the way they did it back in the early days. So for these struts, they copied that same setup. Koni told us that originally it was done that way as some coil over kits would not work with the diameter of the shaft, and they therefore chose the sleeve design so it could be optional if necessary for custom setups/coil overs/etc. (Koni always tries to think of racers as well as enthusiasts whenever possible). When the image on the left was posted, we had queried Koni and they agreed that was a proper way to set it up, and will work fine that way. When our drafting-talented customer made the image on the right, we queried Koni again about it. They had the engineers (i.e. smart guys) go through it all again, and their final determination was that once the weight of the car is down on the setup, it matters not which direction the sleeve is placed, as it ends up functioning exactly the same while in actual use. So if you install/installed them with the "flange/ledge" at the bottom, all is well. If you install/installed them with the flange/ledge at the top, all is well. The smartest guys in the room determined that it makes no difference. I'm sure people will add their own thoughts, which is part of what forums are great for. In our own non-engineering minds, having it with the ledge at the bottom might hold the bump stop (at least our urethane bump stops, which we recommend with these struts) in a bit more favorable position. At the same time, having the ledge at the top might work better with different bump stops, and to be extremely non-technical, "looks" better and more natural to us, and might make initial installing slightly easier due to the pre-compression height of the parts while installing (possibly useful if you have stubby fingers like I have). But literally, direct from the Koni engineers, when it comes to how the strut assembly functions, the "ledge/flange" part of the sleeve is irrelevant as to position. Both are Koni engineer approved.

-

KONI Sports for Classic Z's

John, let us know when you're back, and we'll go from there for Gland Nut measurements, and/or getting them back here. As far as the ones you used, as long as the ID of the inner opening that seats down on the strut matches extremely close to the top of the KONI, we would assume you'd be ok, but there may be factors we're not thinking of. If there is any movement at all, the damage could grow over time. We'll figure it out.

-

KONI Sports for Classic Z's

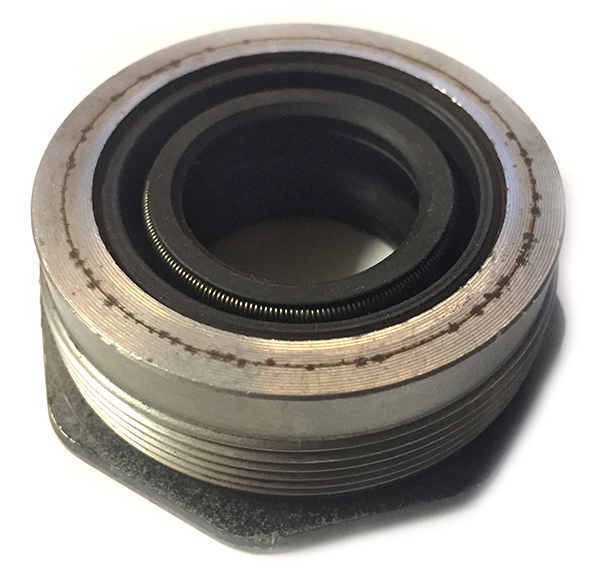

Sorry you’ve had trouble. One manufacturer’s Strut Cartridges should not be used with another manufacturer’s Gland Nuts, so let’s see what we can figure out. Which Gland Nut you used there doesn’t necessarily matter to what we’re trying to figure out here, but to cover all the bases, the one shown in your video is not an original Nissan 280Z Gland Nut. The original nuts had seals to keep the oil fill inside the shaft where the plunger rod was, and it would not fit down properly on top of the strut cartridge body (I was curious to see if we had an original Gland Nut here, and found one, so included images in case others wanted to see them). When manufacturers started making physical strut cartridges to replace the original non-cartridge setup, they all included their own specific Gland Nuts, as they needed to match the shape of the top of the strut body. Just like with Koni, that Gland Nut is the exact inverse of the top of the strut body. Depending on what strut cartridge manufacturer made that Gland Nut, it may or may not be fitting well on top of the Koni strut body; which, if not, could allow strut cartridge movement and damage. The only way that a Gland Nut could slip when tightening would be if they somehow were incorrect nuts (difficult to imagine, but not completely impossible that some random Koni application has Gland Nuts that are nearly identical but just slightly smaller, and were mistakenly put in the box), or if the threads are damaged on one side or the other (which you said the threads weren’t), or there is damage to one part or the other (even stress/wear/cracks/stretching/damage to the strut housing tube itself). Also, in your video the top of the housing seems to be shiny clean as if machined somehow. It may not be relevant, but do you know what was done to the top of the housing tube there? As far as the Gland Nuts you received, if you are able to measure them for us, knowing the exact dimensions and thread pitch/details would help us try to figure it out. Otherwise we could also just get those back here from you and confirm if they are correct. Since the Koni Gland Nut is the exact proper fit for the Koni Strut, then we should see what can be solved so that you can use Gland Nuts that hold the Strut Cartridge in the proper position. Let us know. (the first two images are of an original Nissan Gland Nut (with seal), and the third is the underside of the Koni Gland Nut shaped to fit the top of the Koni cartridge exactly)

-

Reproduction E-Brake Cable failure -70-78 Z

That is the one from Thailand I was referring to in my email discussion with you. Unfortunately he doesn't sell wholesale or bulk. We hope to have some additional options (much less expensive than the actual reproduction version we currently sell) available soon.

-

Reproduction E-Brake Cable failure -70-78 Z

No product failure is ever welcomed, and we will certainly be talking to the manufacturer about this one, and continue to monitor them. We're of course very sorry that both of your products had obvious issues. We have sold over 180 of them since 2016, and these are the first two alerts we know of concerning this issue (possibly 3 assuming the one from Hybrid was the same manufacturer, which is hard to tell for sure, since there have been a few similar options on Ebay over the past couple of years, some of which are no longer around). Hopefully it is not more than 2-3 out of 180 and not indicative of a mass or new problem, we'll certainly look carefully at the next batch we receive. As far as we know the rest of the 180 that were installed are working fine to this day. If other members have had the same issue with this style, please let us know. Certainly Greg and this company have not stayed in business for over 40 years by ignoring reports like this, they are all taken seriously, and again, we'll make sure the manufacturer is aware of it. We do apologize, Madkaw, for the delays. Being severely short-handed for over a year now, Greg himself is having to take care of all the returns, along with a number of other missing staff positions, and we have been quite overwhelmed and behind. Sorry that it took extra time to get everything processed. We're working as hard as we can, and working hard to find more team members at the same time. We of course responded personally to zKars, and are processing his refund now. As a side note, unfortunately James has been on a leave of absence since mid last year, so if you have, or do, try to message him, unfortunately he won't see it. We're also hopeful that James might be able to return at some point.

-

KONI Sports for Classic Z's

Thanks Zed, always appreciate you looping us in. Lee already knew, as Koni has been conversing with this customer directly this week. Lee himself will be in soon with a direct response. James is on a leave of absence, which is why there haven't been any responses from him for a while. Thanks again!

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.

Vendor

Vendor