Everything posted by Zed Head

-

Parts for Sale: Datsun 280zx, A series, L series, 510, 1200 Matchbox distributor breaker plate repair kit.

Can you describe the material and the process used to make it? It looks interesting. I made a time stamp of the video that shows the broken bearing holder. for the impatient people. Good luck, think about doing the 280Z distributors. They have the same problem. Even the points distributors. 240Z repro parts might be a good market.

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

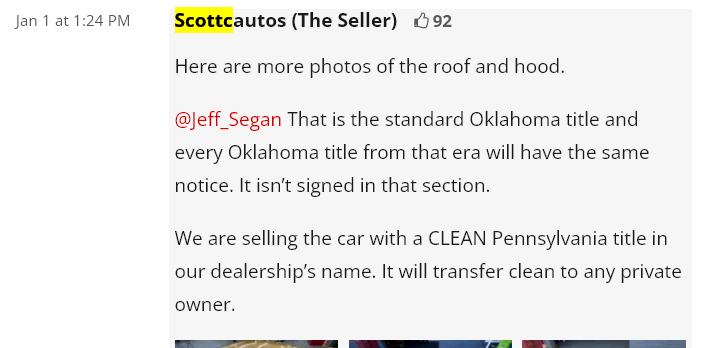

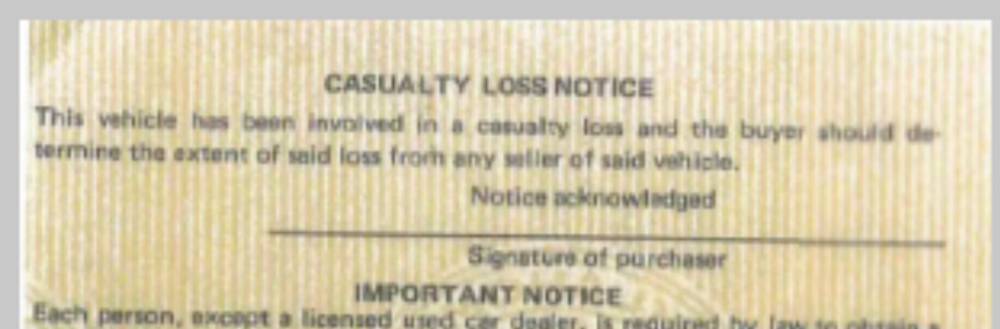

Seems obvious that it got crunched in the front, just by the pictures. The seller is not the owner, it's a sales shop. The guy has to know but he can claim he does not. His "techs" did the work, not him. Plausible deniability. It got to $20,550 but RNM. Does Nissan paint do this, even on a 71? The roof should look the same. It's been crunched and repaired.

-

Dumb dumb dummy!

Tandy Radio Shack?

-

saturday night music thread

Branch from a separate thread...

-

Hybridz.org down?

Anybody know SuperDan? Looks like he did not renew his website certificate. Whatever that means.

- Dumb dumb dummy!

-

Need help finding the best way to install Thermostat Electric Fan Switch on 280z

So you're saying that without the fans it overheats, with the fans it reaches thermostat temperature. Doesn't that mean you should put a 180 thermostat back in and leave the fans on? Do you still have the radiator shroud installed? No offense, but the factory setup should work just fine with your engine. The situation seems overly complicated. Things aren't making sense.

-

Need help finding the best way to install Thermostat Electric Fan Switch on 280z

Are you using a thermostat? Sounds like you either don't have a thermostat or it's stuck open.

-

Hypothetical Power Increase

Pressures can vary depending on the gauge and adapters that are used but those numbers are kind of low. They're about right for a turbo engine. I can't find much about the 260Z E88. I've read about "smog" E88's that have lower CR's. The 240Z E88's had pretty small combustion chambers. Anyway, here's an article with some math and comments about what you could expect. https://www.motortrend.com/how-to/compression-ratio-means-more-power/ Also, the 260Z had a CR of 8.8:1, which is actually on the high end for Z engines. But you have a larger displacement so even with flat-tops you'll end up lower than that. (edited) Big picture - it runs well and makes good power, why mess with it for small gains?

-

Hypothetical Power Increase

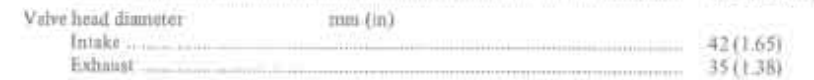

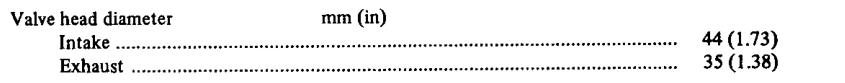

Have you measured cylinder pressures? That will tell you something about the CR. Ideally, combustion chamber volume would have been measured when the port-matching and valve unshrouding was done. Either way, if you did not install bigger valves, an N42 or N47 will be an immediate benefit, due to the higher flow. 2mm bigger intake valve and smaller combustion chambers. Here's the 1974 260Z specs compared to 1976 280Z. Even the text is cleaner and crisper.

-

Hypothetical Power Increase

Calculate the compression ratio. E88's came in several varieties as I understand things. What size valves are in it? You could probably come out ahead just by swapping to an N42 or N47 head, designed for dished pistons. Higher CR and bigger valves.

-

Brake master cylinder identification

I think that it would work just fine. The bores are the same for front and back and the stroke is the same. So performance would be the same. They completely redesigned the internals of the MC besides moving the reservoirs. Might be that they just moved the mass of the larger reservoir and its contents back to where it exerts less leverage on the assembly, for protection against inertial forces and vibration. That would be a typical engineering "perfection" that might happen in a redesign. It started in the front because front brakes = front reservoir, but got moved. There might be better reasons but I can't see them.

-

Pulling My Engine, Need Second Opinion

It can help to remove the spindle pin lock bolt, put a lug nut on the end of the spindle pin, squirt some penetrating fluid in to the lock bolt hole, and spin the pin suing the lug nut. It will spread the lubricant inside and break up the rust that's holding it in.

-

Z's on BAT and other places collection

The roof of the blue one looks like it's salvageable. Might be some 5 speeds in there, three look like 77-78. Struts, strut insulators, manifolds, consoles. He'd probably take $100, I bet.

-

Seating brake line fittings

I had good luck at the local parts store. They typically have a wall loaded with precut, prefitted lines of various makes. Take the old one in, maybe with a wire or string you used to get the unbent length and you can walk out with a piece that just needs a few bends to bolt right in, professionally flared.

-

Z's on BAT and other places collection

I'd like to see one running and driving just to watch it crumble apart. That would be great youtube material, many views probable.

-

Z's on BAT and other places collection

Butterscotch highway cruiser (automatic) with new wheel nuts. https://bringatrailer.com/listing/1971-datsun-240z-202/

-

Seating brake line fittings

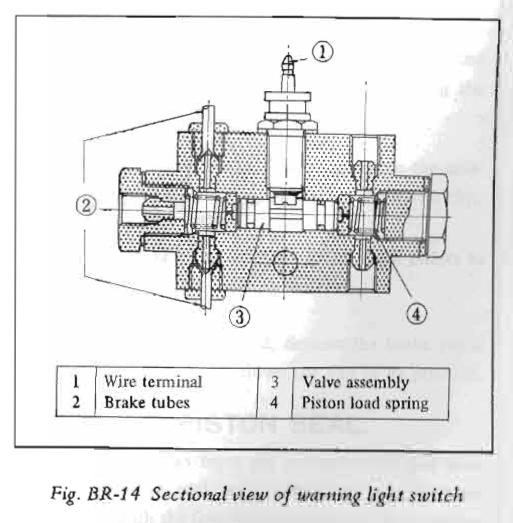

If you have a spare brake part around and a flared tube end it might help you to just pull the threaded portion back and stick the tube in to the hole, just to get a feel for how they seal. The threaded portion's sole purpose is to apply pressure on the bell edges of the flared tube end, pressing it down on to the cone in the middle of the device, whether it's a brake cylinder or a caliper or the pressure differential switch. There are only two surfaces that need to be smooth, clean, and crack-free - a small ring around the inside of the flare, and a small ring where the inside of the flare contacts the cone. You can take a bright light and a magnifying glass and examine them closely and you'll get a good idea beforehand if they're going to seal or not. All it takes is grain of sand, or a metal shaving, to get trapped there and you can have a leak. Or even just a scratch or a crack. Once the fluid gets in to the void at the end of the fitting it can easily leak past the fitting end and out of the hole since the fitting end is designed for force not sealing. The fitting is just a clamping mechanism. Anyway, a bunch of words to say take a close look at the actual fluid sealing surfaces.

-

Seating brake line fittings

-

Bleeding MC

Just do both at the same time. Make sure that the MC is tilted upward at the end so that the bubbles will be forced out. You can do that by leaving the bolts loose or by lifting the front of the car. The MC bleed screws are at the ends of the stroke you want the the bubbles to rise to that area so that they'll push out. Both front and rear are actuated at the same time, because they're in the same bore, so you can just run two hoses up in to the reservoirs and pump away.

-

Brake master cylinder identification

In short, I think that your assumption is correct.

-

Brake master cylinder identification

Interesting how far off the two are, time-wise. Not sure what's going on there. The FSM's I downloaded from this site or others. The 72 FSM files come with a cover image that says 1972. Somebody on the forum will know what's what. Might be that the change happened in 1972. The build date is what you see in the cparpartsmanual data. August/Sept 1971 is the changeover. Maybe the 72 FSM did not keep up.

-

Brake master cylinder identification

The Nissan Factory Service Manual is where I got the images. Choose your source.

-

Brake master cylinder identification