Everything posted by Zed Head

-

Z's on BAT and other places collection

Somebody bumped the bid on the white 1970. By an odd amount. The guy buys a lot of car so there could be an interesting battle on tomorrow. Does anyone know if a 1970 240Z could have a three groove damper pulley? It has an L28 crankshaft so the damper has been off. The sellers on BaT are interesting because they often don't really know the details but don't want to say "I don't know".

-

Z's on BAT and other places collection

Does anybody want to guess on the final bid then? Will it break 100?

-

Z's on BAT and other places collection

I have to guess then that this auction is for a select crowd that already knows that. I looked through all of the paperwork and the description and don't see Chuck's Frame Shop mentioned anywhere. Seems like it would be worth advertising. There is a Chuck mentioned, findable if a person looks closely, in one of the images. I guess that people in the resto world would know about him. It's a fascinating world. I don't live in it but it's fun to watch.

-

Z's on BAT and other places collection

Are the seller and the restorer the same person? Chuck is Garage44?

-

Z's on BAT and other places collection

Does this really mean that $71,970 was over Reserve? There's still four days left. Probably get no more bids. Posting for entertainment now. These high dollar auctions are usually interesting.

-

Z's on BAT and other places collection

That big bid to $71,970, from a previous bid of $28,500, is still interesting. Like somebody that owns some already wants to be sure the "value" stays high. My cynical view. I don't think that seller understood the point of the question, of unfiltered air in to the newly rebuilt engine. Actually there isn't much discussion about the engine. Normally a Datsun Spirit engine would be a big deal. But it only cost about 8% of the bid value, so far.

-

Z's on BAT and other places collection

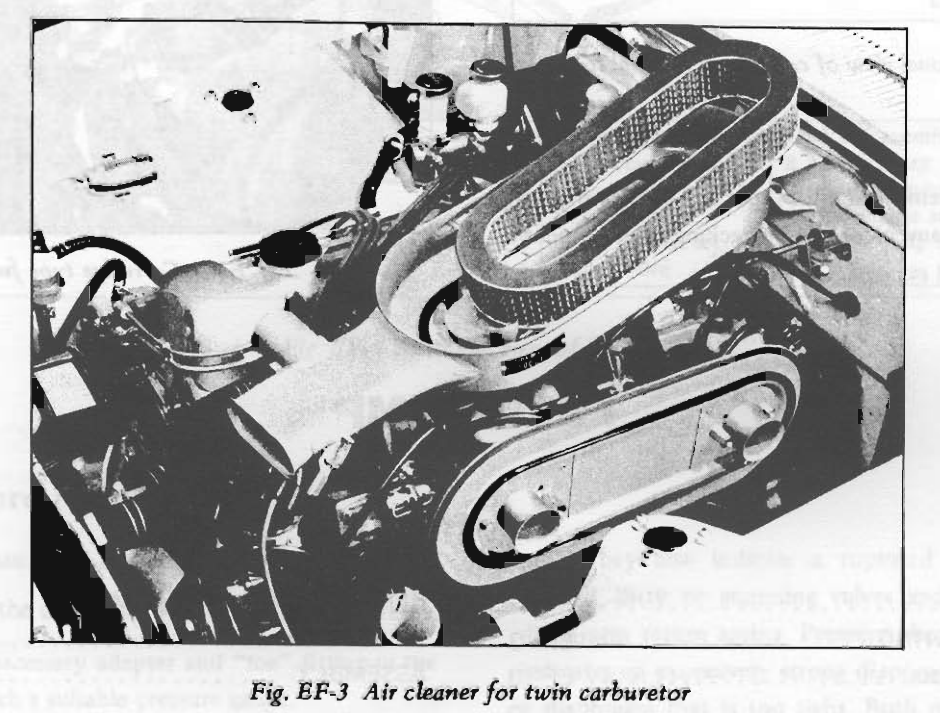

And, is anyone going to get in to the Comments over there and ask about the open port? Who wants to be the bad guy? 😈

-

Z's on BAT and other places collection

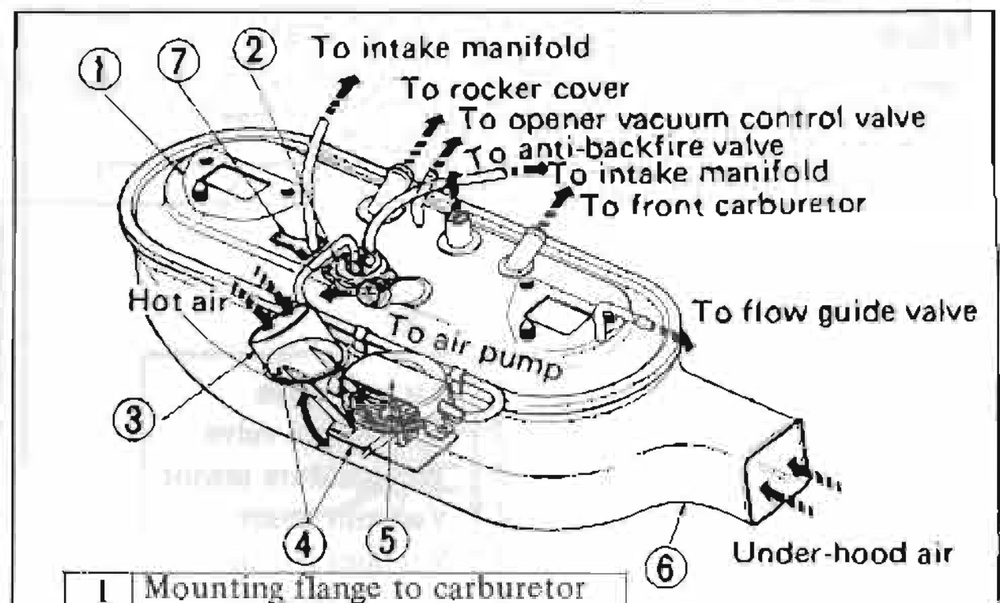

Funny, I wanted to be sure I knew what that port/nipple is called and/or what it's for so I looked through the FSM's and it doesn't show up until 1973. Is that the right air filter housing for a 1970? 1972 1973

-

Z's on BAT and other places collection

This one? The bids seem surprisingly high for so early in the auction. Somebody went directly to a very large number. And the engine is not original, it's been bumped up to L28 size apparently. Although I had always though that the L24 blocks would not take L28 bore size. And it has an E88 head. Looks like one of those interesting auctions. https://bringatrailer.com/listing/1970-datsun-240z-133/#comments-anchor

-

1980 Datsun 280 zx

What are Euro-Top pistons? What did the chambers measure out at? Just curious about compression ratio. You should add a driving video. Good luck.

-

Need full shock absober kit for my 1972 datsun 240z

Mismatched and high miles. Yikes. Why were they removed? What's on the car now?

-

Problems with 240z doors from Resurrected Classics.

So you probably have over 100 potentially disappointed customers out there. Good luck with that. The fact that they were purchased does not mean that they are of good quality. It means that people expected good quality, like these two disappointed individuals did. Besides the possible disagreement on quality, the problem here seems to be the lack of communication. Anyway, these things are not uncommon. At least you have a dialog going now. Good luck.

-

Problems with 240z doors from Resurrected Classics.

It's been documented, with measurements.

-

Problems with 240z doors from Resurrected Classics.

That answers the Summit question. But it looks like you know that the parts are bad but are trying to hold on to the money that you received for the first set of bad parts. It's like the old ads for lifetime replacements. Replace bad with bad. Long-term the remaining question is "are you addressing the poor part quality?" Will anybody buying parts in the future get the same bad parts or will they get new "fixed" parts? You haven't said that the parts are actually good, you've only said that the individuals paid for them and that you'll replace bad with more bad.

-

Problems with 240z doors from Resurrected Classics.

Outsider view - it looks like Resurrected Classics got screwed over by thier supplier and has decided to pass the damage on to their customers instead of eating it as the cost of doing business. But, there is a question about Summit. If the parts were purchased through Summit why not return them through Summit? Summit has more leverage than an individual customer. Give Resurrected Classics the details, but return through Summit. If Summit stops selling the parts, then the responsibility goes back to where it belongs. Companies that get their products from off-shore suppliers really hate to get returns. Probably because they have to eat the cost. Communicating with companies in Asia is very difficult. I got a bad mirror from MSA many years ago, obviously bad, the image looked like a funhouse mirror, and it took some serious persuading to get them to send me a good one. Probably because the bad one could not be fixed, it was garbage. MSA had to but two mirrors to get paid for one. Commenting more from the perspective of how global business works. Many ways to get screwed. I wonder if Alibaba is involved. https://www.alibaba.com/

-

Z's on BAT and other places collection

1970. Bring a TrailerL28-Powered, 24-Years-Owned 1970 Datsun 240Z Series I 5-S...Bid for the chance to own a L28-Powered, 24-Years-Owned 1970 Datsun 240Z Series I 5-Speed at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #193,538.

-

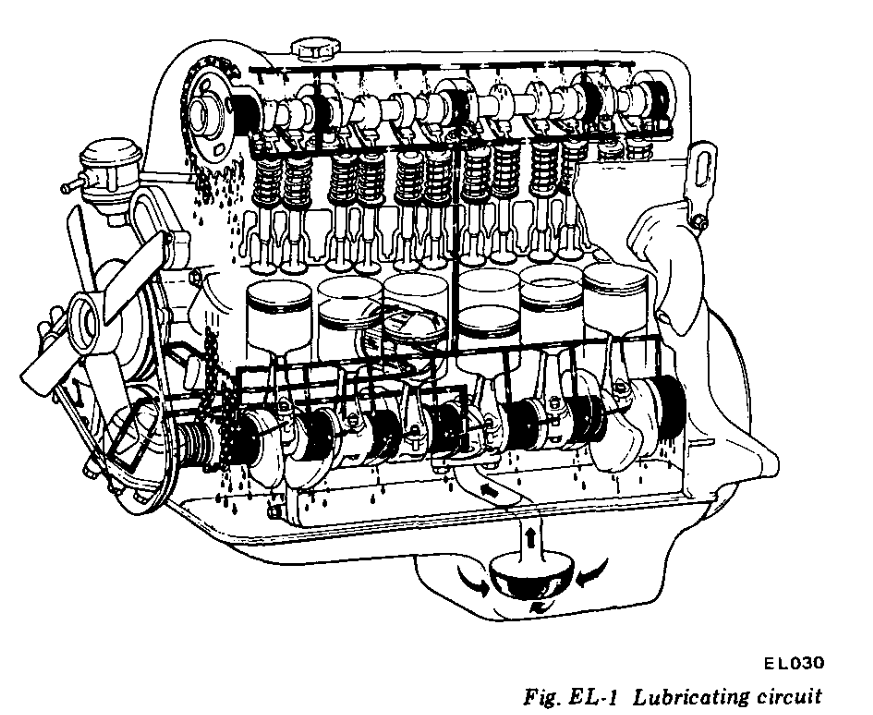

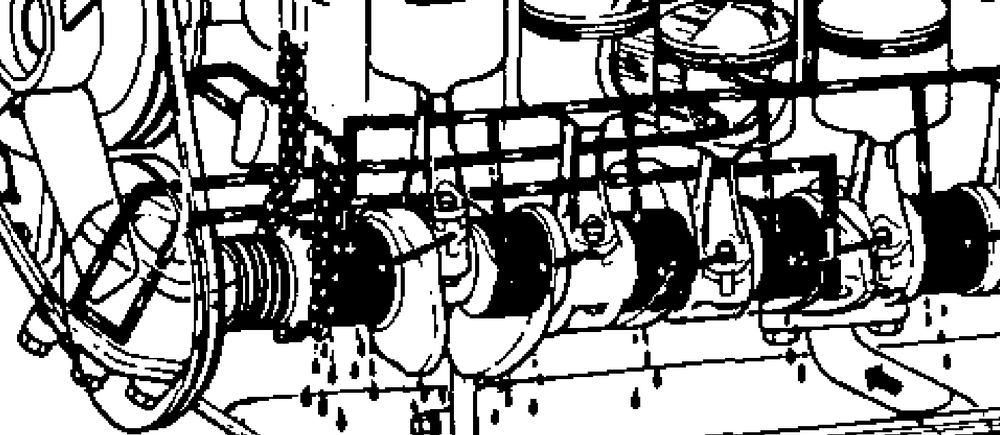

Oil Won't Prime

Pretty sure I remember reading about people using the oil pressure sending hole as a source to prime the whole block with oil (might have been @Captain Obvious , although not obvious). So, if you can rig up a way to push oil in that way it should fill the system. I am not personally familar with that plug, it should be described on the Monroe Rebuild book, but it does look like it matters if it's the one end at the end of the main passage/gallery/galley. If it was left out, the oil would not get very far after it left the pump. There would be no pressure build either. One of those borescopes would be handy.

-

Oil Won't Prime

When you write "won't prime" do you really mean won't pump? Filling it with oil is actually the priming. How do you know it's not pumping? Oil flow to the cam shaft, reading on the gauge, or what? You might remove the oil pressure sending unit and see if oil flows from the hole when you spin the pump. Also, if you packed vaseline on the inlet side of the pump it might have trouble pulling the oil in to pump it. You can only generate atmospheric pressure on the inlet side.

-

Need full shock absober kit for my 1972 datsun 240z

Rockauto has a good reputation and their price is better. Shipping to Spain might be the decider for you. https://www.rockauto.com/en/catalog/nissan,1972,240z,2.4l+l6,1209169,suspension,shock+/+strut,7556 Seems like you should be able to find a supplier over there. KYB EuropeKYB Shock Absorbers - KYB EuropeKYB shock absorbers - world class quality suspension from one of the worlds largest manufacturers of shock absorbers

-

Need full shock absober kit for my 1972 datsun 240z

KYB makes good shocks. I have used them on other vehicles and not been disappointed.

-

Z's on BAT and other places collection

Project potential. Maybe restoration. Bring a TrailerNo Reserve: 1972 Datsun 240Z 4-Speed ProjectBid for the chance to own a No Reserve: 1972 Datsun 240Z 4-Speed Project at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #193,030.

-

Mechanical Fuel Pump Drive (name?)

There's a couple on eBay that might work. Probably all the same. https://www.ebay.com/sch/i.html?_nkw=datsun+eccentric&_sacat=0&_from=R40&_trksid=p2332490.m570.l1313

-

How vibration free is your 70-71 240Z?

Soccer's a gamble. I felt lucky to have made it through the years with none of the major long-term injuries. I did have to do some PT on a knee. My doctor had been a college athlete and had the "suck it up and take some Advil" attitude. So I went in to weekend warrior mode and tried to tough it out. He sent me to PT when I went back a month later and showed him that the thigh on the injured leg was about 2/3 the size of the good one. The PT shop owner used to do the Cleveland Browns football team. Got me straightend up pretty quick but it still wouldn't bend as far as the other one for about three years. And the tough-it-out doctor was afraid of blood. Later, after the knee, he refused to remove the stitches in my chin because the tails were cut too short (forgot to mention the chin. And the broken collar bone.) and there would be blood if he had to dig them out. I had to go to the drug store and buy some tweezers and pointy scissors to dig them out myself. There was blood. Good times.

-

How vibration free is your 70-71 240Z?

Are you a keeper? All of my injuries were ankle, knee, nose, eyebrow, or jaw. And one AC joint. And a groin.

-

Problems with 240z doors from Resurrected Classics.

How did things get so bad, since this last thread? https://www.classiczcars.com/forums/topic/68334-resurrected-classics-continues-to-impress-with-new-fenders-hatches-and-bumpers/