Everything posted by Zed Head

-

Sudden no-spark situation

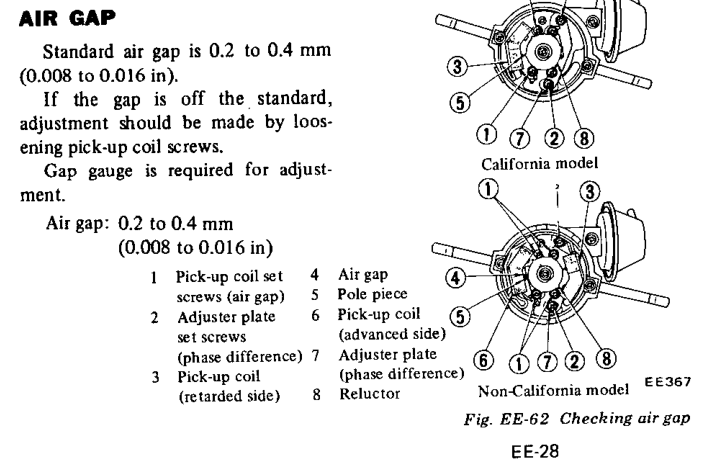

I use the middle number for ranges like those. So, 0.3mm. If there's wear on the shaft or bushing you don't want to be too close.

-

window defrost grid

I bought a defrost fan from OReilly, replaced the cigarette lighter terminal with two spade connectors and connected it to the power circuit for the grid. It was kind of noisy but it worked. The grid is better of course but if you want something to use in the meantime, the fan's only about $20. The defrost grid is on a 20 amp circuit, so lots of juice there. https://www.oreillyauto.com/detail/b/custom-accessories-3126/accessories-16449/winter-accessories-16523/defroster-defogger-23801/5aa88c03919b/custom-accessories-defroster/48701/5981244

-

Sudden no-spark situation

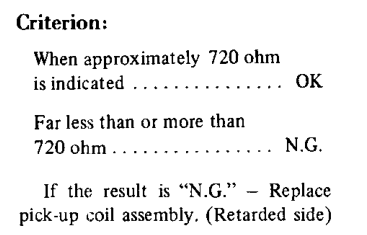

Should work fine. I think that Nissan just didn't set a clear tolerance on that 720 number. Approximately and far is too vague. Edit - actually they were vague for the ZX's also. The ZX uses a different type of coil so the spec is different.

-

Piston ID

If it's a race engine it's good odds that it's high compression. The guy used the pistons to raise CR instead of shaving the head maybe. So, if you want to use it you might have to use high octane race fuel, or "detune" it to avoid detonation. Retarded timing, run it rich, cam timing, etc. Doesn't really look like a drop it in and go engine. Measure and calculate combustion chamber volume to start. Or, since you have it apart, just buy pistons that will give you the CR you want for a street engine.

-

Sudden no-spark situation

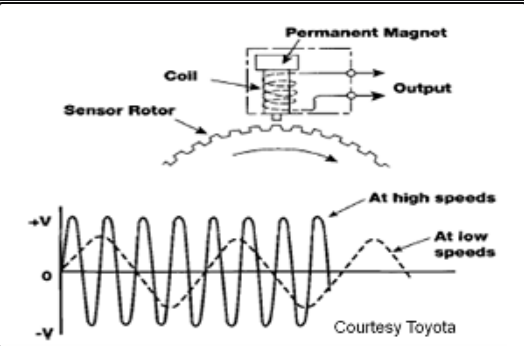

That exposure is normal, but the wear on it is not. It's the pole of the magnet, the piece that the coil is wound around, I think. Don't forget that the grinding of the wheel on that piece will cause heat too. But, overall, if you got no continuity, you got no sine wave, and the ignition module won't produce no spark. It ain't gonna work. Might as well take the distributor out and disassemble it to see where the wear is. In a prior thread that I can't find somebody had a worn shaft and we talked about Redi-Sleeves and other ways to fix it. You might not be able to find a rebuilt unit but there are places that offer rebuild services. You send yours in and they fix it and send it back. Look at RockAuto. OReilly says that they have them https://www.oreillyauto.com/shop/b/ignition---tune-up-16776/distributor-12503/8c7c95368caf/1978/nissan/280z?q=distributor

-

1977 280z prepup for smog check

I'd start with the Google machine. Seriously. I know that they get clogged if they see a lot of fuel over time, but don't really know if the materials inside change over time. Do you know what your regions emissions tests entail? Some states have different rules for different regions. In Oregon all I needed to pass was idle emissions. But even just that was difficult.

-

1977 280z prepup for smog check

The place to start is to tune the engine to Nissan FSM specs. Set timing, valve lash, etc. exactly as Nissan says. If you have a catalytic converter make sure it's in good shape. With the factory stock EFI system there's not much that you can do except get it as close to what the factory sent out the door as possible. The 280Z's were designed to pass emissions. Everything about the tuneup procedure is to get them emissions testing ready.

-

Transmission experts please help

And, on the Porsche synchros, there are several discussions about steel baulk rings in the early 5 speed Nissan transmissions. Another side thread. JMortensen said he used to work for a shop that used Swepco 201 for those in the Porsche transmissions, and a blend of Swepco and ATF for the "brass" Nissan rings. I used the blend on an old 5 speed ZX transmission that had problems with Redline and it fixed it. It's spendy but good stuff. Most Porsche racing shops will have a 50 gallon drum of it in the shop. That's where I got mine. https://www.classiczcars.com/forums/topic/19361-gearbox-oils/ https://www.classiczcars.com/forums/topic/19261-early-5-speed/

-

Transmission experts please help

Apparently Pennzoil developed the "synchromesh" formulation for GM. So if you can find Pennzoil Synchromesh, it's the same formulation, as the internet seems to show. But, for whatever reason, maybe because a copyright wasn't acquired or not enforced or because GM let the formulation data out, there is a "synchromesh" for several other brands of oil. And a "Synchromax". https://www.amsoil.com/search/?text=synchromesh&timezoneOffset=420 https://www.valvoline.com/our-products/grease-gear-oil/synchromesh-mtf https://www.pennzoil.com/en_us/products/other-oils-fluids-fuel/manual-transmission-fluids-axle-oils/synchromesh-manual-transmission-fluid.html https://www.royalpurple.com/product/synchromax-manual-transmission-fluid/

-

Piston ID

Where's the head? Is it a stock camshaft? Regrind, aftermarket? Has it had work done?

-

Sudden no-spark situation

ZX distributors. 123 ignition. Someone probably has a used one. If it's the bushing in the body that's worn you might just get a body and swap your parts in to it.

-

Sudden no-spark situation

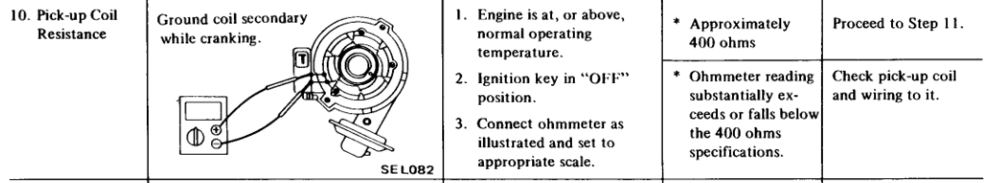

If you're not getting continuity then a/the wire(s) in the pickup coil probably broke from the vibration of the reluctor wheel beating on it at high RPM. There's more than just a magnet in there. I don't know the construction of the Nissan unit but here's a typical diagram from the interwebs. Not my forte...

-

Sudden no-spark situation

-

Sudden no-spark situation

That looks worn out. I don't think I've seen one that bad before. I think that some people have devised ways to repair that bushing surface but it takes some work and proper tools.

-

Sudden no-spark situation

Could be. Supposed to be continuity and a certain resistance. It's in Engine Electrical and the "Bible". The breaker plate moves the wires to the pickup coil and sometimes they fatigue and break or short out.

-

Help. Ignition switch or something else?

Should say "Problem disappeared.". They do that sometimes. Your solution didn't match the symptoms. That's where the extra commentary is coming from. You might be back. Good luck.

-

My 280Z cranks but doesn't stay running once started

Here's an old thread about problems with the ignition switch. Test at the ballast and coil first like SteveJ says, if there's no power there, work your way back.

-

Help. Ignition switch or something else?

Are the battery terminal clamps tight? Sure sounds like a connection opening up due to heat from high current across a loose and or dirty connection. The ignition relays on the 280Z's were put in a spot that gets wet if there's a leak. Same reason, different location. Current heat.

-

Piston ID

Might just be OEM Datsun pistons. Not uncommon for old cylinder walls to show little wear. Apparently the blocks are made from pretty tough metal. Are there any markings on the bottom of the piston tops? https://maseraticompound.com/products/datsun-240z-pistons-rods-bearings-and-rings http://datnissparts.com/x-1973-240z-l24-oe-oversize-cast-pistons-1-0mm-040-84-0mm-12010-h2716-set-of-6-also-fits-l26-l16/

-

Transmission experts please help

Clutch issues show up more in reverse because it has no synchronizer. So, if reverse is fine, then worn clutch is less likely. You can have one worn synchro and fluid will make the difference. But, your problem seems odd in that you say it happens when downshifting. I assume it's fine while upshifting? And why are you being aggressive in downshifting? You do mean the shift from 3rd down to 2nd, right? 3rd gear is usually the first synchro to wear out also. If the fluid change doesn't work and you decide to take the transmission out, save the fluid, It won't be ruined from just a few miles in a worn transmission. It will be fine to use after a rebuild.

-

Transmission experts please help

The right fluid can add thousands of miles to a worn transmission. Redline, Synchromesh, etc. Plain old Valvoline 80-90W isn't good enough.

-

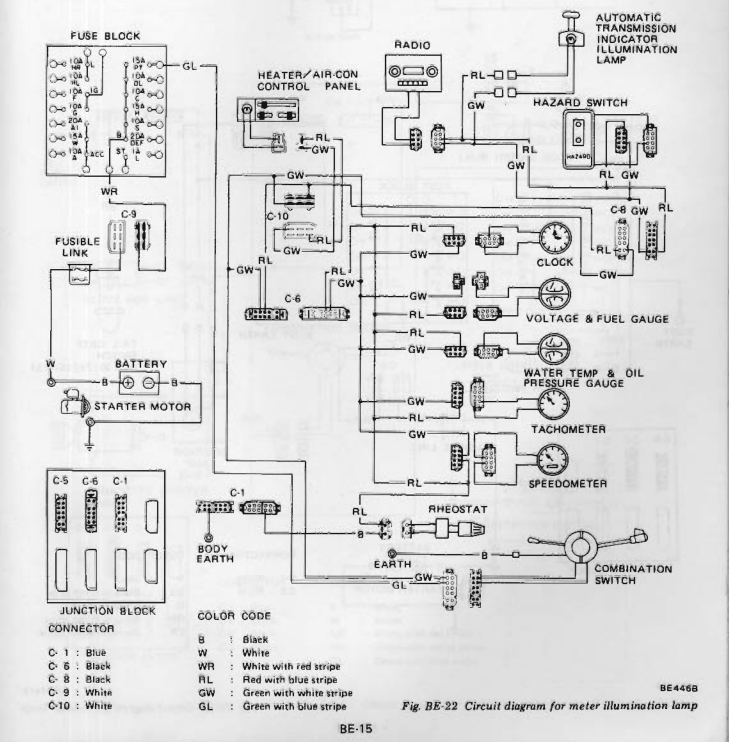

Tach gauge indicator lights dead?

-

Tach gauge indicator lights dead?

-

KONI Sports for Classic Z's

Can you get a picture of the shoulder, just for fun? I assume that it is visible.

-

Tach gauge indicator lights dead?

Check for voltage at the plugs if you're not sure (I love my multimeter). Check the ground circuit from the bulb mount metal to body ground. Can't remember if those bulbs use a single electrode and a mounting ground or if they are two electrode, with a ground wire. Grounds are the hidden circuit killer in the old Z's. And, if you replaced the bulbs recently, some of the new bulbs from the big aftermarket guys are actually too big to fit. They'll go in but then work loose over time. On the dash cap, if you have some Mylar sheet, like for making transparencies, you can slide it between the gauge edge and the cap edge to make a ramp to slide the gauge out. Add a little lubricant of some kind to help. Armor All, for example.