Everything posted by Zed Head

-

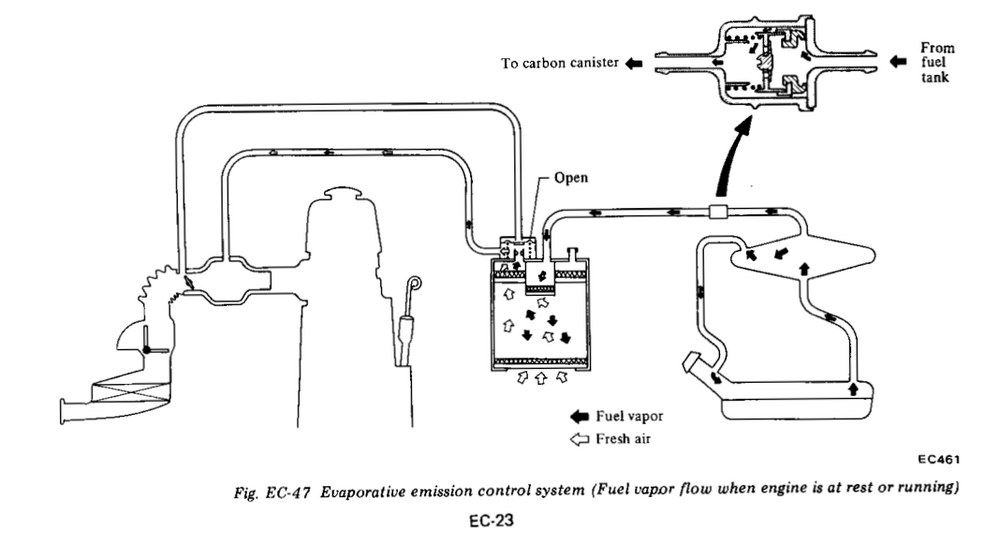

Vapor Tank Question

It's not the canister that holds vacuum it's the cap on the top. The canister is completely open on the bottom. It might be that the canister "charcoal/carbon" in the canister is saturated, coated, or clogged. The basic concpet is that the gasoline vapors enter the pores of the carbonaceous material and stick until they are pulled off by air entering through the bottom. But the material does not last forever. https://www.carparts.com/blog/5-signs-youre-due-for-a-charcoal-canister-replacement/

-

New to me, 280Z...

-

Tach info for 75 280z

That's one reason the 280Z's are great tools for learning about automotive electrical. Everything on them is at the beginning of today's auto electronics. Not trying to double-down on cgsheen's point but the start for modifying the ignition system would be to understand how the one you have works. Again, no offense intended, but if you had done that you would have looked for the "make and break" device that creates spark. The original ignition module. If the coil primary circuit is not broken, no spark will be created. It's fascinating stuff! I've learned a lot by owning and working on a 280Z. Even though I knew quite a bit before I got mine. https://en.wikipedia.org/wiki/Delco_ignition_system

-

1971 HLS30-14938 "Lily" build

I was thinking more like the grinding wheel that you used on the CV end. There's room. Grind away, I say.

-

1971 HLS30-14938 "Lily" build

I'd remove any burrs from the end that needs to slip through the circlip. Maybe even smooth the end of the axle down and reshape it a bit so that it slips through the circlip easier. Add some grease. Once the end gets started it should slide easily until the grooves align and the clip drops in. The axle end is probably jamming the circlip against the back of the groove instead of expanding it.

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

Hope that was it. Here's what mine looked like. I think that the theory is that the insulation breaks down on the coil wiring, causing a weaker magnetic field. A short between wires but not a short directly to ground. Fewer circuits around the core. Can't remember exactly what I was testing or saw with those leads. Should have measured resistance through the coils. But it seemed to be heat-related so hard to reproduce. Probably wouldn't have seen anything. Maybe if I had hit it with a heat gun.

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

I had a similar problem with mine. It was the fuel pump relay portion of the combined EFI/pump relay. I posted about it long ago and posted a picture too. The solenoid coil looked cooked, I took it apart. It was actually a "spare" that had come with the car, that I had put back in to test. I guess that's why it was out. I was able to get home because I had already installed a relay bypass and power control switch under the dash. Because I didn't trust the old electrical stuff.

-

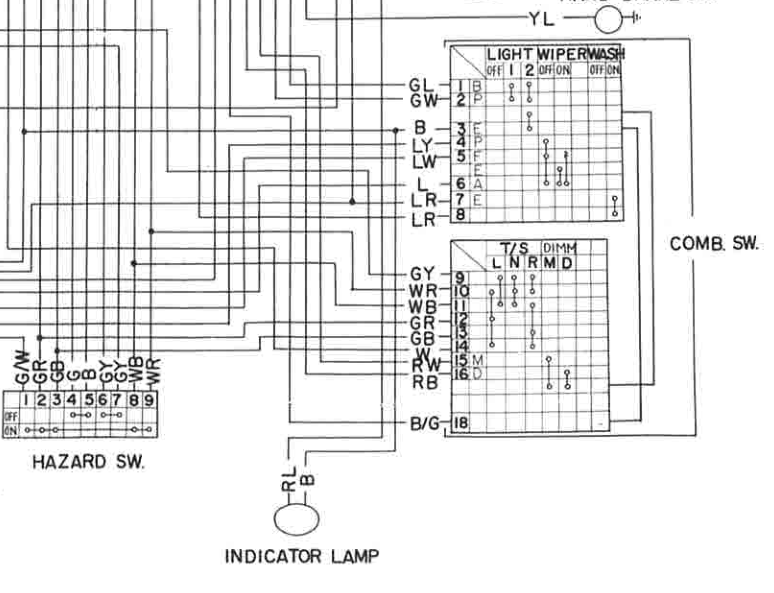

Tach info for 75 280z

Adding to SteveJ's post, re the question above - yes and no. The tachometer is on a branch off of the blue wire to the ignition module. The resistor is in that wire. Reconnect the wire at the coil and disconnect all of the wires at the old ignition module. Megasquirt will probably work but the tachometer might not. But that's a new problem.

-

Sudden Running Lean Issue

Many people switch to the later model spring clip connectors. It's a fun project. If you decide to do it you can get them cheap at any well-stocked salvage yard. 90's GM, Volvo and BMW plus many other brands used them. They're called EV1 style injector connections. Kind of spendy if you buy them new. A piar of crimping pliers and some insulated butt connectors is quick and pretty easy. They look like this -

-

Z's on BAT and other places collection

Another decent driver. 1976 was a good year. Federal model in North Carolina. https://bringatrailer.com/listing/1976-datsun-280z-85/

-

Sudden Running Lean Issue

How did you get the retaining clips in? The plug has to be firmly seated to get the clip in.

-

Signals acting up

-

78 280Z - Finally got it driving - High Idle, will occasionally die (but restart), sound like it has a misfire

Here's another link. They say that there's a fine screen around the pickup area. I've never seen a clear shot of it. https://forums.hybridz.org/topic/96315-por-15-fuel-tank-repair-question/

-

78 280Z - Finally got it driving - High Idle, will occasionally die (but restart), sound like it has a misfire

There is a "can" or cylinder inside the tank, which has the fuel pickup point inside. That's where the crud would be. There is a screen or "sock" at the end of the tube to block particles from passing in to the pump. If your tank has been sealed in the past it might be that some of the sealant has come free. A borescope might tell you something. You can find quite a few pictures around the internet of the inside of the tank but for some reason people rarely take a picture inside the can where the end of the tube is. It's strange. https://atlanticz.ca/zclub/techtips/fuel/gastank/index.htm

-

78 280Z - Finally got it driving - High Idle, will occasionally die (but restart), sound like it has a misfire

Yarb's suggestion is good. You could make it easier and leave the return line alone though and let the gas flow in to the tank, if you just want to test the pump and tank. If it was mine, I'd disconnect the inlet hose from the tank and stick it in to a can of fuel back by the pump and tank. Measure pressure once. You'll know. Super easy. Your symptoms kind of sound like the "crud in the tank" problem. The crud floats around in the tank and gets sucked on to the inlet pipe sock, clogging it. Then when the pump turns off it floats free. Break your problems in to pieces. And yes, page 79. The higher the resistance the more fuel the ECU adds. Corrosion on the connections can cause excess resistance.

-

78 280Z - Finally got it driving - High Idle, will occasionally die (but restart), sound like it has a misfire

You might be getting distracted with all of the different things you're looking at. You said that you were getting 36 psi. That is the correct pressure. Looks like your fuel supply and control system is working right and you were just running out of gas. If you're getting ~36 psi with the vaccum hose removed from the FPR, or engine off, and it drops to about 28 - 32 psi with the engine running then the FPR and pump are working fine. Move on to other things. I'd measure resistance on the water temperature sensor circuit at the ECU connector. The 1980 EFI book is the best resource for doing that type of work. Go to the electrical section.

-

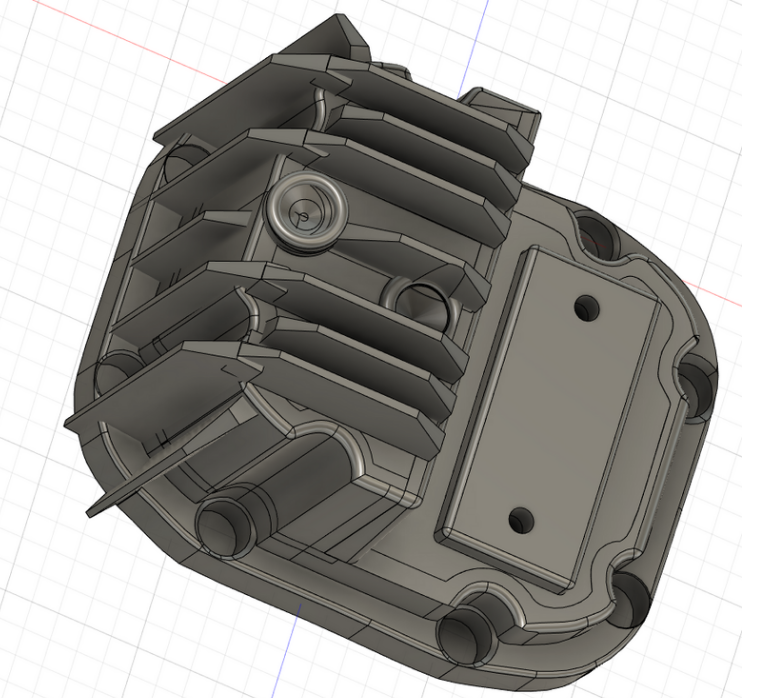

Does an LSD need better cooling?

Did you reproduce the original cover dimensions and just add fins to it? I've not really examined a diff cover, let alone an R180's. The one you show looks a lot different than your modified version in post #16. What happened? The factory covers have quite a bit of internal bracing. Here's a Subaru's.

-

Public Service Announcement

I only see four products on their page. The video is titled LED Turn Signal Kit but it looks like it's about the backlit Z emblem on the quarter panel. I guess they tap into the turn signal circuit with their wiring harness branch and convert the emblem to a turn signal. $150 does seem steep for two bulbs, two sockets, some wire, some sheathing, and four plugs. But they did do the leg work to find the parts. They broke the plastic in the video, and you have to drill a hole. Seems like a lot to get a light in the emblem. Are you saying that you will modify the Amazon part for free and then reship it? Total cost would be the Amazon price plus Amazon shipping cost plus your shipping costs. I tried to figure out what Harmon charges for shipping but you have to put in too much info. https://harmonresto.com/

-

Sudden Running Lean Issue

Seems like you're implying that your fuel filter was clogged. But in Post #36 you said you got 39 psi. ??? I assume that gauge was between the filter and the fuel rail. Might be that you had a vacuum leak at an injector or two and you fixed them when you removed and replaced the injectors. Wahtever it was, good luck with it. On to the next problem...

-

78 280Z - Finally got it driving - High Idle, will occasionally die (but restart), sound like it has a misfire

Does pressure drop immediately when the pump is not running? If pressure drops it might be the FPR. It could have foreign matter holding it open. You can clamp the return line closed with some vise-grips and test pressure again. If it shoots up above 36 then it's not the pump or the supply side. Be careful if you can't see the gauge while you turn the key. A typical aftermarket pump will hit 90 psi. Also, the pump should not be loud. That's a sign that it's working hard to pull fuel in. Could be a clogged pickup tube in the tank. Gather more clues.

-

78 280Z - Finally got it driving - High Idle, will occasionally die (but restart), sound like it has a misfire

Your firing order is correct. One possible reason for no change might be that the timing is very retarded. You need to get a timing light and see where it is. You'll also be able to see if it's changing when you move the distributor.

-

78 280Z - Finally got it driving - High Idle, will occasionally die (but restart), sound like it has a misfire

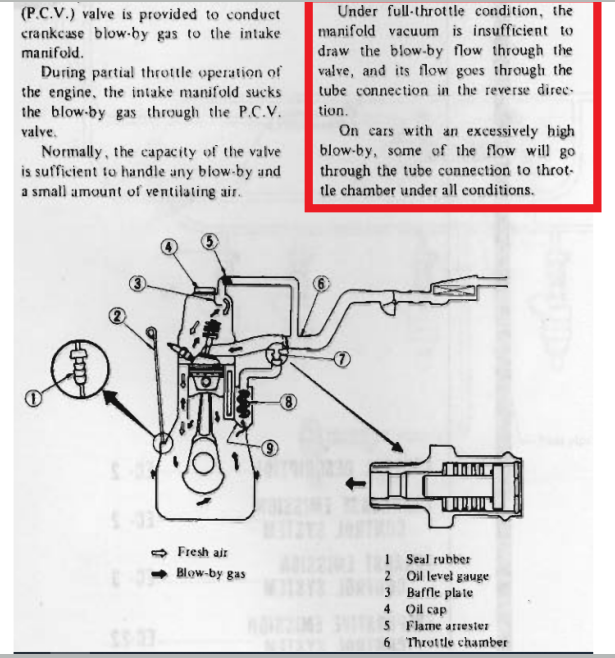

That's the PCV valve, not the BCDD. Yes, the PCV hose from the block to the PV is a specially formed hose. Yarb referred to it above. Small one end, big on the other. When things aren't tuned well the engine will often be non-responsive to tuning efforts. Kind of a vicious cycle, a rabbit hole. The missing and break up at higher PRM are probably due to the massive vacccum leak through the PCV valve under the intake manifold and also through the hole in the block. Air can enter the crankcase through the hole in the side of the block and travel through the engine to the intake manifold. You can either block the two PCV holes, or get the proper hoses connected. The EFI system will not work correctly with a partially intact system. .

-

S30 Public Art - Trivia Quiz of the Day

-

S30 Public Art - Trivia Quiz of the Day

Cosmoline? Protective coating for over water shipping.

-

Repetitive clunking noise from driver side only when in motion. How concerned should I be?

Examples -