Everything posted by Zed Head

-

What distributor do I have and is my tach broken?

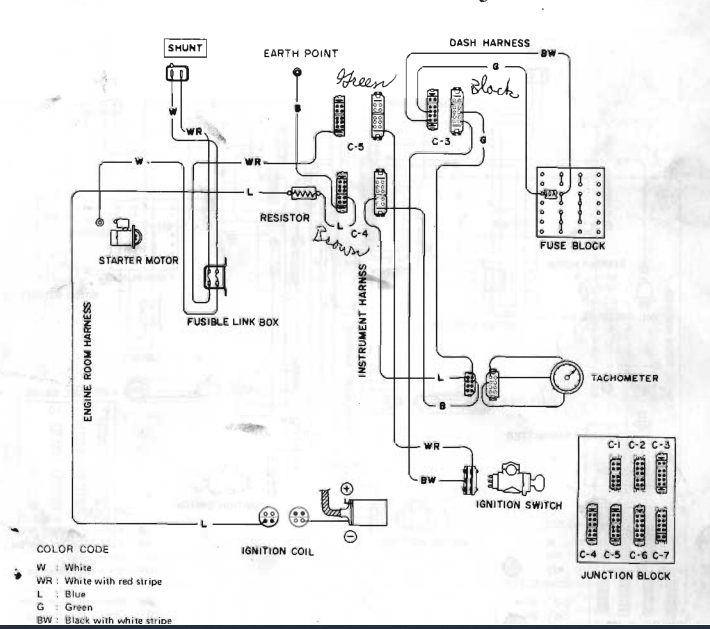

The first electronic ignitions were just points replacements, not "high energy" so they still used the ballast. Your 74 is the first year of electronic in the Z's. Look under the dash by the fuse box and you'll see the space age module. You might burn up the coil or the module if you run without the ballast. You're letting more current through parts that weren't designed for it. The ballast went away in 1978 when they went to a high energy (current limiting) system.

-

Staked Nut and Steering Gear

Your question is all over the internet. Functionally, they are mirror images. Way back when, a smart manufacturing engineer realized that they only needed to make one part, and just flip it. The Z cars were the economical man's sports car. They saved money where they could.

-

What distributor do I have and is my tach broken?

The old tachs do definitely go bad. I put a 78 tach in my 76 after the tach needle started getting stuck when it got hot out. That looks like the magnetic pickup for a stock 260Z ignition system. Looks like you have a stock ignition system. I assume that the engine runs, but the tach needle doesn't move. Does it move at all, ever, when you turn the key on?

-

What distributor do I have and is my tach broken?

Lots of missing information here. Kind of seems like you meant to post a picture. A 260Z probably uses the blue wire from the coil negative terminal to provide the tach signal.

-

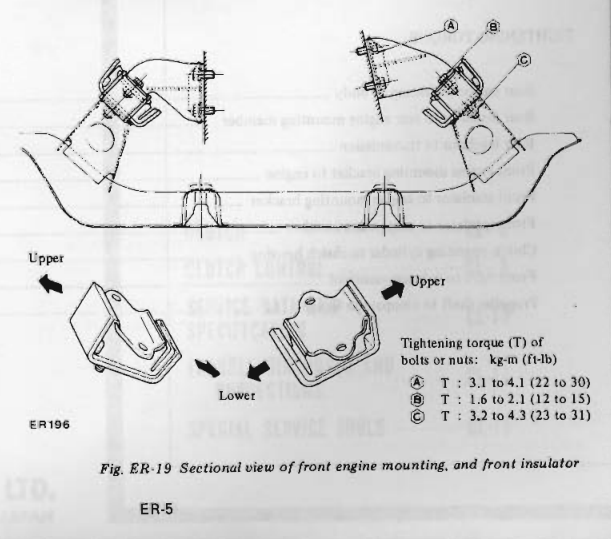

motor mount

-

GMB mechanical fuel pump failures

You could do what zKars wrote about, linked below (meta?, a link to a post in the thread being used to post the link). Pretty clear that it will probably fail. If it were me I'd contact GMB and see if they'll send you one of theirs after they fix the issue.

-

AFM/ Fuel Pump

I just posted this thread link in a different thread and realized that we wee describing here how to use a switch and a relay to complete a circuit that powers another relay, the original fuel pump relay. Might be easier to just use the oil pressure switch to control a relay that controls the pump directly. Just a thought.

-

Where to locate a fuel pump inertia kill switch

The basic concepts in this thread would work on a 260Z also. Using the pump instead of the AFM wiring.

-

Staked Nut and Steering Gear

-

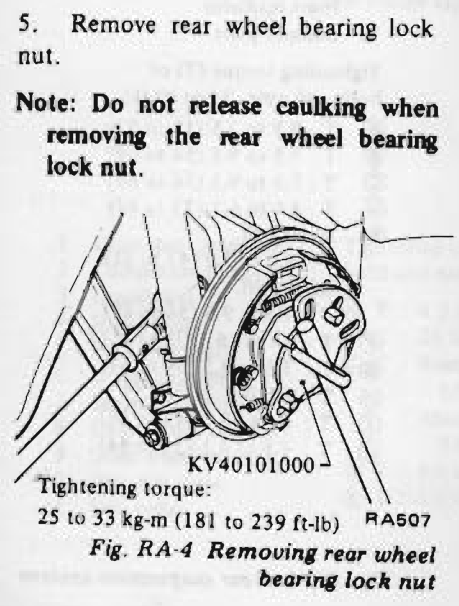

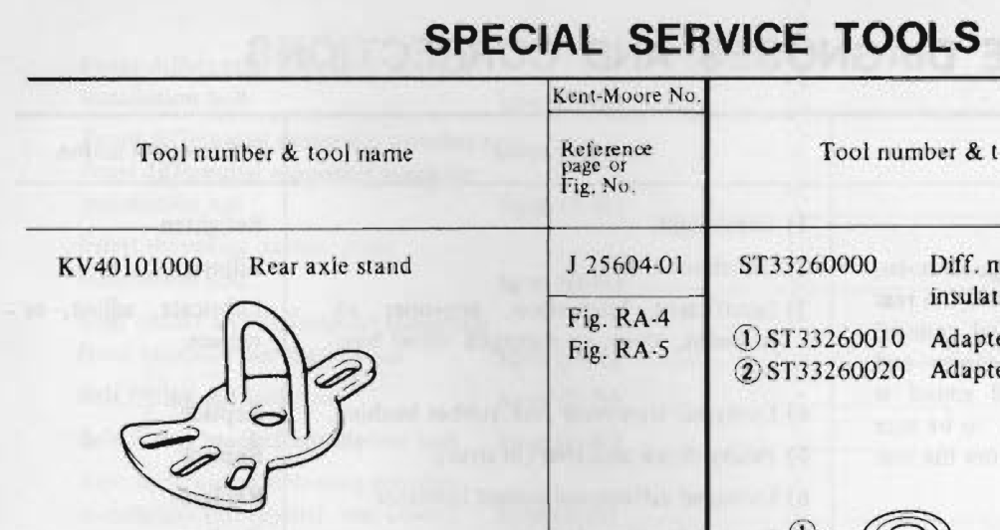

Staked Nut and Steering Gear

An impact driver might do it. Or, if you have some solid metal stock and a drill press you could probably build something to put over the lugs on the other side. A couple of holes and some lug nuts and you'll have the two levers that you need.

-

DHLA 40 question. Running pig rich!

You might check other things before you take it apart. If you didn't hear detonation or rev to 8 grand there's no reason for something to break. Could be something simple like valves getting loose. Rings on one side, valves opening and closing correctly on the other. That's all there is to creating pressure. I'd give it a good inspection and "re-tune" before taking it out.

-

DHLA 40 question. Running pig rich!

"Toast" doesn't sound right. If it's freshly built it seems like the rings just didn't get seated correctly or are wrong for the cylinders. Might just need new rings. Just being positive.

-

What is the theory behind the brake adjustment?

The parking brake adjustment mechanism is designed such that it will not tighten the drums so far that the shoes rub. Pulling the handle moves the shoes, but the adjustment wheel only moves when the shoes get out far enough to get the arm over the next tooth on the wheel. After it goes over the tooth the arm drops back enough, in to the valley between the teeth, to let the shoe fall back slightly. The adjustment arm moves up and down in the valley between the teeth every time you pull the handle until the shoes wear enough to get over the top of the next one. If you have the mechanism working just crank way on the parking brake handle until the handle ends up in the same spot with each pull. Over time you'll notice that the handle pull gets longer then suddenly it will get shorter as you pass over a tooth. I rewrote this a few times, but that's the basics, I think. It's a pretty cool mechanism.

-

Engine Rebuild

I'm not on the notify list, but feel compelled to say that there will be little to no benefit from swapping blocks. Besides that, you'd need new pistons, rings, etc. to fit the "3" overbore (is that mm"). It could get expensive and if the turbo engine is in good shape you're probably best off to leave it alone.

- 280zx 1979 2+2 slick roof restauration

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

Could be I missed it. I sold the car so can't check. How does it seal without the rubber piece? Did you try it?

-

Is this Differential Arrestor Spent?

I've only read about them breaking for the guys that have V8's and abuse them.

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

Nope. I looked closely because I thought that there should be one. Then I thought "what a fine piece of engineering and manufacturing". The reality is that they didn't need one there, as shown by my leak-free cap.

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

2nd edit, actually a post...just curious. I wonder if people could pop their caps and see if they have rubber on there. To CO's last post's point. Just one of those curiosities.

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

Good catch. My Z didn't have one and never had a problem. The surfaces were both flat and sealed perfectly. It was actually a satisfying piece of plastics production. http://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/cylinder-head

-

'75 280Z - Starts and Runs, Shuts Off after 30-60 minutes

No gasket, just plastic. It seals very well.

-

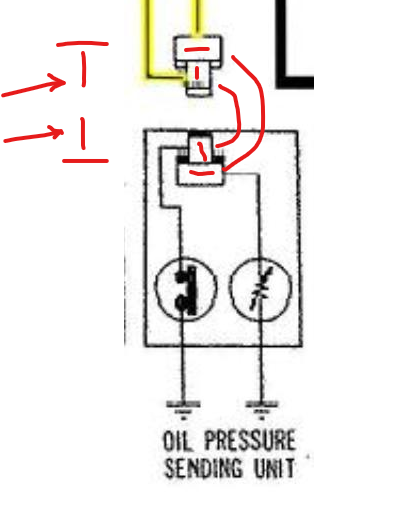

AFM/ Fuel Pump

Vertical would be the up and down part of the "T", the bottom. Horizontal would be the bar across the top. Follow the diagram, jump across the connection to the oil pressure portion.

-

Reaction Disk

Poke it, inside, with a screwdriver. If you feel metal it fell out. If it's rubbery it's still there. As long it's between the rod and the diaphragm seat when assembled it doesn't matter where it started. I don't know why they cal it a "reaction" disc. It should be called a damper or something similar.

-

AFM/ Fuel Pump

Hello @EuroDat I am pretty sure the switch opens when pressure is reached. A person could study the relay system diagram, and get a headache, or just work from the knowledge that if you remove the sender/switch plug (creating an open switch circuit) and turn the key on the pump will run. So you would want to wire up your 2nd relay to be open when power is applied through the key, then close when power is removed as the pressure switch opens. I think that leads to using 87a, normally closed when their is no power through the solenoid. It's a rare case of using the 87a circuit. Key on, the solenoid energizes, the 30 circuit is open, no power to the pump. Engine starts, oil pressure builds, the switch opens, the solenoid deenergizes, 87a is actuated, 30 gets power. I think this is right. The fact that you can pull the oil sender/switch plug and make the pump run is a well-known flaw in the design.

-

Is this L24 a lost cause?

Probably doesn't matter much. You have an L28 in your car because that's the easy way to get more power. The L24 will probably be worth something to somebody some day. The question is whether or not you want to be the keeper of the block. I'd give it away on Craigslist. Some Z head out there will probably take it and make something good from it. I sold my L28 engine for cheap after I replaced it with a better one. I knew I'd never do anything with it. Take the front cover and thermostat housing and other odds and ends that you can use on your L28 and give the rest away.