Everything posted by Zed Head

-

280z water **** removal sequence

The system pressure will equalize without opening the valves, there's coolant on both sides. If you start the engine and let it get to temperature you'll generate pressure. The main concern would be that if there is a leak, it will be hot coolant instead of cold.

-

Vacuum S line 280z

They can be switched. There's no mechanism inside the tank. The check valve is important though. Be careful with the hoses, they are an odd size and tend to split because they're so old. I spent a lot of time fixing mine, as they kept splitting at the ends, then the check valve went bad. Overall, it was a pain keeping everything working right.

-

280z water **** removal sequence

I'm the one that reported my car(s) would not start with the tachometer disconnected. Actually, if I recall right, it was two cars, my 76 and a 78 parts car that had a good engine. The 76 phenomenon went away after I changed to an HEI ignition module. So, it seems to be a thing only with the factory ignition system. So, basically, if you try to start it without the dash installed and it doesn't start, don't freak out. You might just be the confirmation case. Good luck. One other thing to be aware of is stray wire ends that might be powered with the key on.

-

280z DASHBOARD REMOVAL / UPGRADE

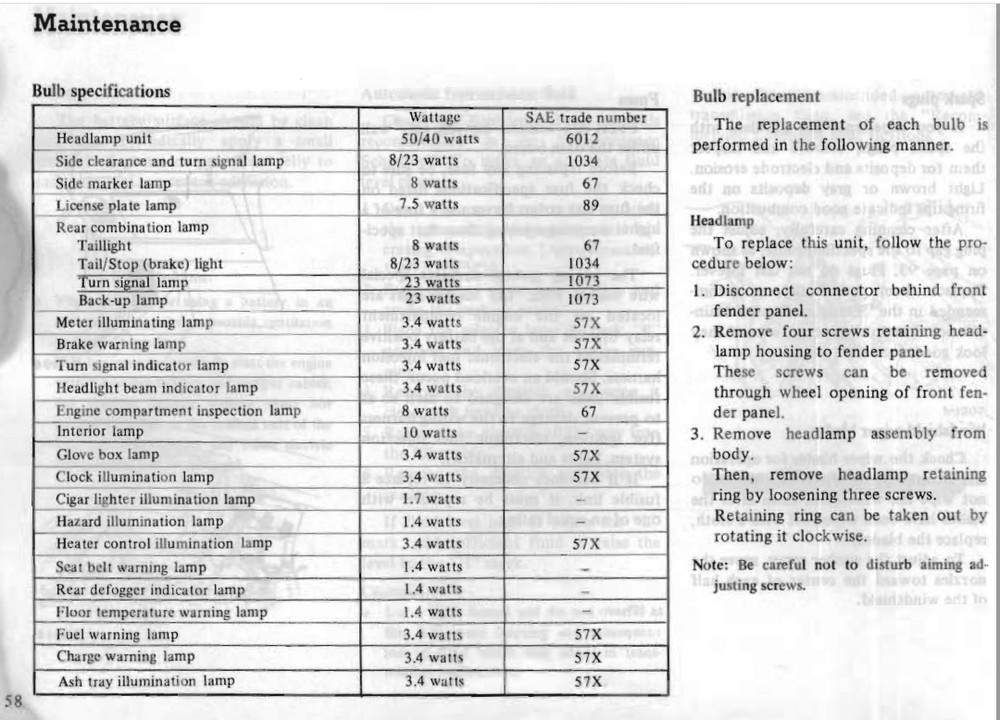

Just for fun, here are the bulb specs from the Owners Manual. Can you show a good picture of the type label on one of your bulbs? Just curious. Today's 57's seem to be slightly larger than yesterday's and don't fit the space very well. I don't think that 57X is available if I recall correctly, except for NOS eBay stuff.

-

280z water **** removal sequence

This old thread might be helpful. It has links to other useful threads also.

-

1970 Wiring Diagram

Here's something from waaayyy back.

-

240z Pre-Wired Driving Lights?

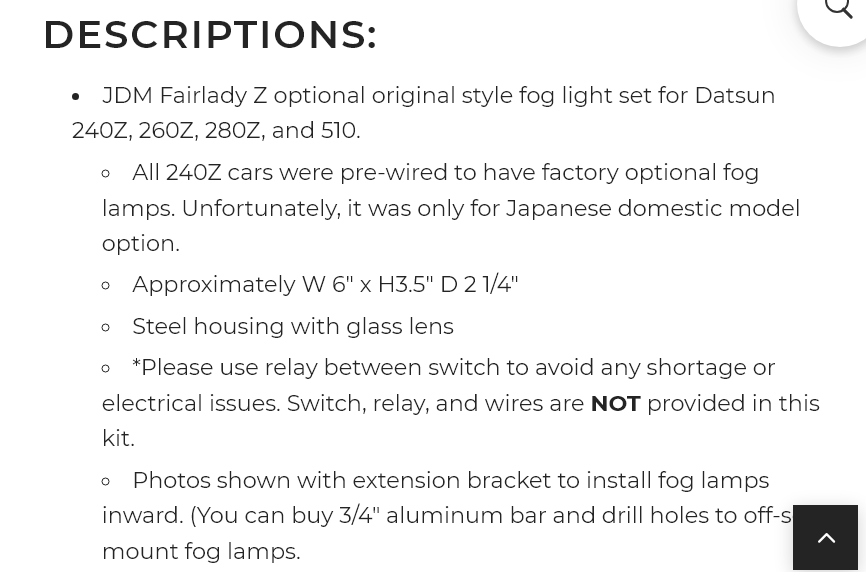

Resurrection!!! https://jdm-car-parts.com/products/original-style-fog-lamp-set-for-jdm-fairlady-z-datsun-240z-260z-280z-510-roadster?srsltid=AfmBOoq9Z4T801ioQzmLJnAbk5VItXD-5LYHbUtRaHKJH_TFZvNyk7Os

-

1970 Wiring Diagram

Here's a different guy that says the fog lamp option was Japan market only. So if that's correct then Nissan was basically cutting costs by not producing non-Japan market dashes. They just left the spot open with no option for non-Japan market customers to fill it with anything. Unless they got creative, with something like an F knob. https://jdm-car-parts.com/products/original-style-fog-lamp-set-for-jdm-fairlady-z-datsun-240z-260z-280z-510-roadster?srsltid=AfmBOoq9Z4T801ioQzmLJnAbk5VItXD-5LYHbUtRaHKJH_TFZvNyk7Os

-

1970 Wiring Diagram

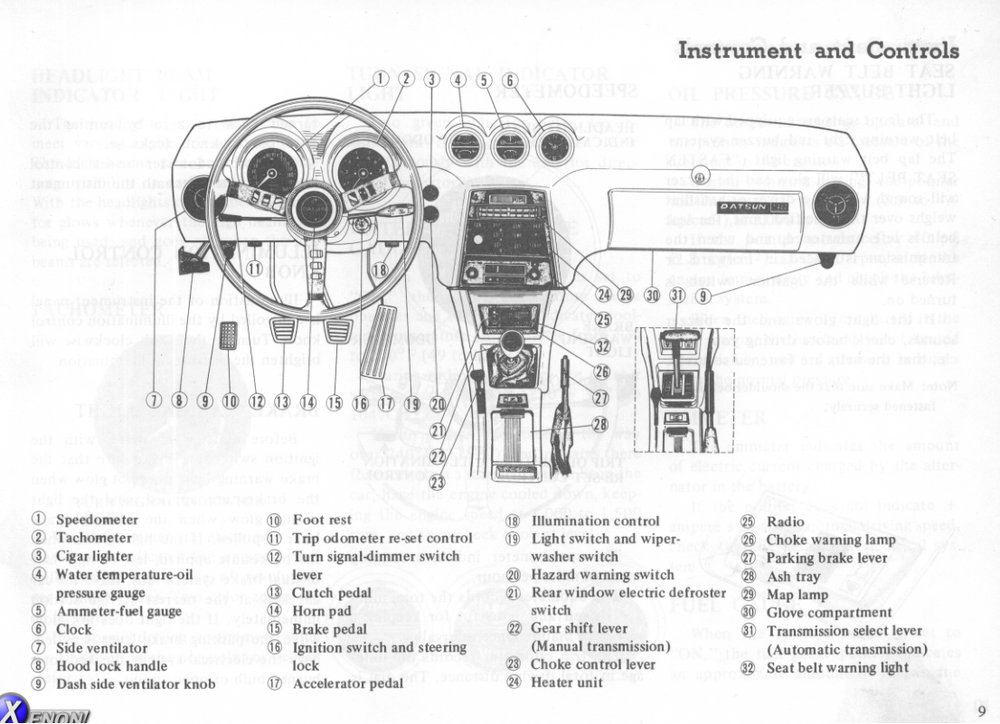

There's an empty hole in 1971, then there's a Nissan factory labeled cigar lighter in 1973 in the exact same spot. About as far from bizarre as a logical person could get, I think. It would have made more sense if there was an optional cigar lighter. Maybe there is, the wiring is probably the same as for the fog lamps. They should have put that information in the Owners Manual, instead of just showing an empty hole. Beside that, do you have any documentation describing the optional fog lamp switch? And the fog lamps, which, of course, would need installation also. That would add a lot to the discussion. Much more interesting than a single comment in a forum. The details and official documentation. They could have gussied up the hole a bit. At least by 73 they had a molded-in spot for the four-way sticker. https://bringatrailer.com/listing/1971-datsun-240z-276/

-

1970 Wiring Diagram

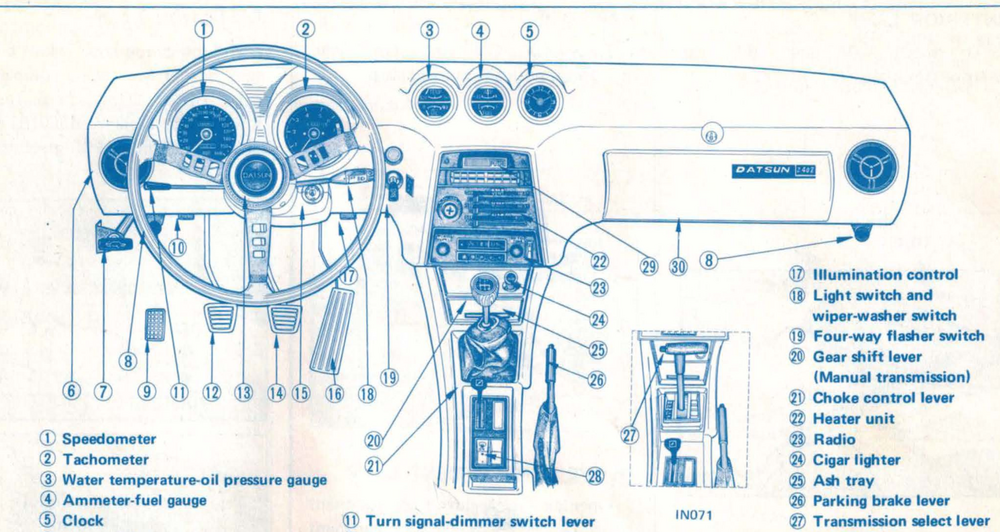

I got curious about the "F" knob when I saw this and looked around my favorite place, BaT, to see what was "supposed" to be there. But I only looked at 70's and 71's. Then this new car came up , a 73, and it has a "cigar lighter" there. I looked in the Owners Manuals and see the drawing of the spot with no label in 71 and the labeled spot in 73. Kind of looks like Nissan was planning to put a lighter there but didn't get it done until 72 or 73. I just got the 73 Owners Manual from Xenonzcar. That site is still alive. https://bringatrailer.com/listing/1972-datsun-240z-354/ #107 1971 OM 1973 OM

-

Transmission Swap and other things

Ron Tyler from HybridZ designed the mount after a day of breaking mounts on his V8 modified Z, if I recall correctly. He posted the dimensions on the site and others have started producing them. I think on the 240Z's you might have to move some fuel lines, Can't remember clearly. But generally, once you get under there and start taking out the old mounts that hold the bolts that hold the strap it will be more obvious how the mount goes in. You have to choose between using a bumper or using the GM transmission mount to complete the setup.

-

Tank to pump hose routing

What temperature? Philadelphia fuel versus Dallas fuel. Ethanol level (it varies). Engine specs? Ignition timing, miles, etc. There are many variables. If a press of the CSV button or reinstalling the thermotime switch produces a good start why modify? Probably worthwhile to compare the variables as a starting point for further discussion. This thread started as "something changed after a fuel line blew".

-

Tank to pump hose routing

Don't overlook also that the old 1970's injectors squirt a solid stream of fuel. Today's injectors are designed to spread the stream for better vaporization. Also, batch fire injection shoots the stream at the back of closed valves on two cylinders, and somewhere between opening and closing intake valves on the others. It was high tech in the 70's but it's pretty crude today. Better injectors, higher fuel pressures, and sequential fuel injection all help starting, emissions, and efficiency. The hard starting without the CSV actually means that your system is very clean. No leaking injectors and clean injector tips. You are about at the point where it's time to start modifying. Megasquirt, Haltech, etc.

-

Tank to pump hose routing

I meant normal in general. from what you described above. I just listened to the video and that sounds normal too. There's just not enough vaporized fuel for all of the cylinders to fire consistently. Cold fuel is being squirted almost directly in to the cylinders. Much of it just gets pushed right out the exhaust valve without fully vaporizing and burning. When the CSV squirts, the stream and puddle of fuel sits upstream in the intake manifold with all of the incoming air rushing over it picking up vapors. Incomplete combustion of fuel in cold weather is a problem so well-defined that the fuel suppliers produce two different grades of fuel - winter blend and summer blend, with different vaporization profiles. https://www.gasbuddy.com/go/summer-blend-and-winter-blend-gasoline

-

Tank to pump hose routing

Sounds like normal behavior. Right?

-

Tank to pump hose routing

Maybe you had a leaking fuel injector. An inadvertent cold start enrichment.

-

Tank to pump hose routing

-

Tank to pump hose routing

I'm not sure what real struggle means. But I did remove the CSV from my engine when I switched to a 280ZX fuel rail (the 280ZX CSV is in a different location) and it was harder to start in the cold weather. My remedy was to hit Start for a few engine revolutions, then wait about 15 seconds for the liquid fuel that had been squirted to vaporize. Nissan put the CSV on for a reason. Hard cold starting. Maybe you should just reconnect it.

-

1971 HLS30-14938 "Lily" build

-

Restoration of BringaTrailer 240z - HLS30-35883

I don't think that they are heat-treated to be "springy". I remember straightening the bends out of the ones that I had. They definitely make a difference. I tried the various treatments and greases but only reinstallng the straightened/flattened shims solved the problem.

-

Tank to pump hose routing

Don't nix up starting and running. If it runs well, with no weak cylinders, that's a sign that the injectors are fine. The cold start valve and the ECU are involved in starting, along with residual fuel pressure in the fuel rail. Leaking FPR's are a common cause of hard starting. Today's aftermarket FPR's are of poor quality and tend to bleed off pressure pretty quickly. Have you watched the pressure bleed down after shut-down? Generally, the rail should maintain about 15 psi for hours. If pressure leaks down to zero within an hour you'll have hard starting, since the rail will be empty of fuel when you restart.

-

Gasoline vapor sniffer device

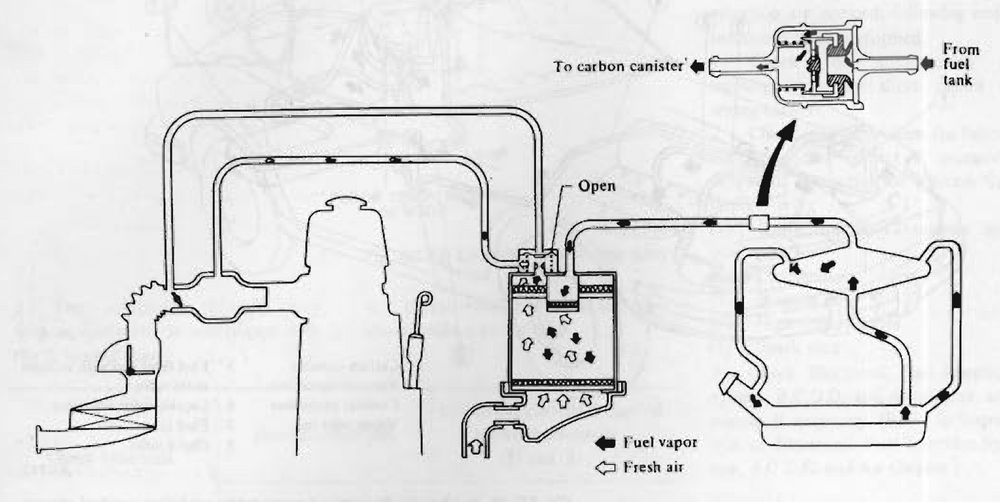

The FSM has a drawing, below. It's not clear how you're using this vapor detector device. I think that the most common source of gasoline smell, that's hidden, is the bottom of the charcoal canister. The carbon/charcoal gets clogged over time and does not absorb all fo the vapor. The bottom of the canister is open to the atmosphere. That's where I'd be looking, after I tightened all fo the clamps.

-

Gasoline vapor sniffer device

What type of hose are you using? I had found that the Gates hose I got at O'Reilly's loosened up and need the clamps retightened. Surprising since the hose is advertised for it's vapor control. I think that the material "creeps" under pressure. Probably needs a constant tension clamp to work best. https://www.gates.com/us/en/fluid-power/engine-hose/fuel-line-hose.p.4219-000000-000003.html

-

Impossible Oil Leak?

I was referring to c. cats original concern, with his 1978 valve cover. The thread has expanded in to the past..

-

Impossible Oil Leak?

ZCD has them. Cheap. No idea of quality. https://zcardepot.com/products/oil-cap-gasket-seal-240z-260z-280z-280zx?_pos=7&_sid=5b8d04292&_ss=r