Everything posted by Zed Head

-

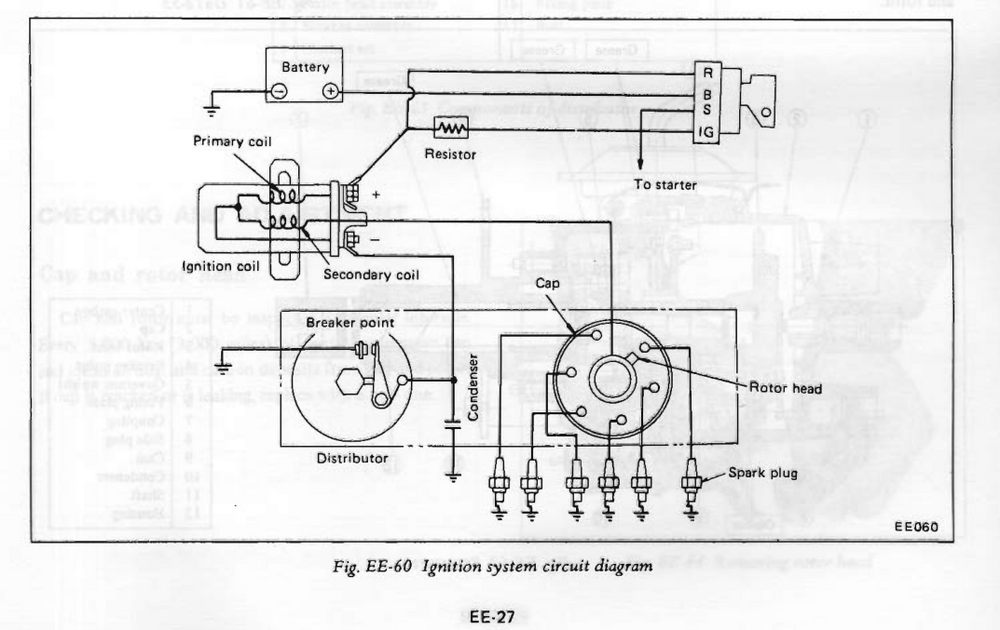

Condenser failure

If there's no spark with power directly to the coil then working on the wires under the dash won't help. Study the diagram and you should see. Did you test for spark from the coil's main output wire? The center wire?

-

Condenser failure

Seems like you might be overwhelmed with ideas. Pumping my own suggestion here, but a simple length of wire will allow you to split the whole system in half. Seems like the cheapest easiest quick and dirty diagnostic. No oscilloscopes nevessary. No offense intended to the scope suggesters. But it seems early for that level of tool. If it doesn't start, focus on everything after the coil positive post. If it does start focus on everything before. Don't forget that you'll have to remove the wire to kill the engine.

-

1976 280Z Fuel Issues Troubleshooting

I found your Ford doppelganger from 2021. https://www.ford-trucks.com/forums/1656335-91-f150-losing-spark-intermittently.html "There is nothing I could find on the Computer that indicated where it came from or what calibration it is for. The only thing it had was a QR code that directed me to a site called "installapart" but the site itself looked closed."

-

Condenser failure

Hot wire it. Run a jumper from the battery positive to the coil positive post. It it starts and rnus then you'll know that the distributor and coil and points are fine, and you can focus on the wiring and tach. Not sure I saw rotor and cap discussed. It might be that spark is being created but it's just not making it to the spark plugs. Hitting Submit even though Yarb has replied. Let's see....

-

Z's on BAT and other places collection

-

Condenser failure

Try bypassing the resistor and see what happens. Jump it end to end or just move the one on the end of the resistor to the Start post. It is bypassed on the Start circuit so you might be right about the bad coil. Maybe the coil is weak and needs full current to create a spark. It will be another clue if it works. Could be a bad coil or it could be a bad ballast resistor. Or put the old ballast back on.

-

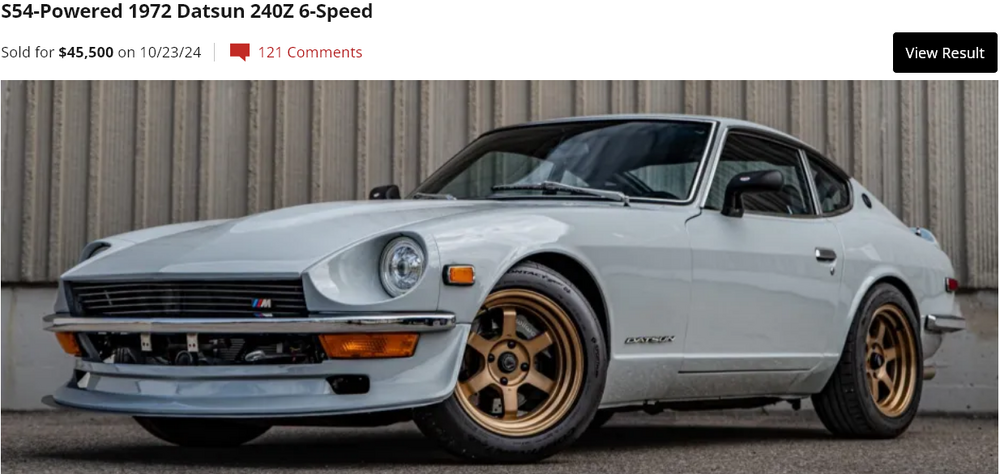

Z's on BAT and other places collection

grannyknot's build car sold. Pretty good money but I thought it would get more. https://bringatrailer.com/listing/1972-datsun-240z-342/

-

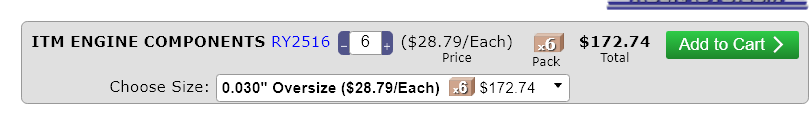

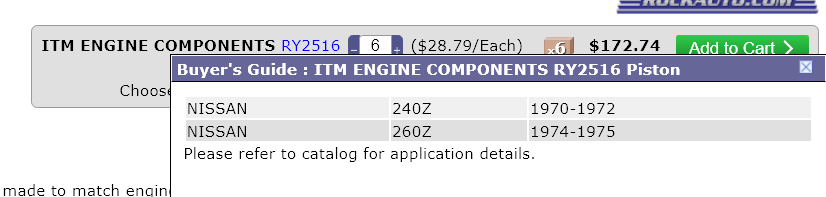

.030 oversize ITMs...for a 2.4

I seem to remember oversize pistons being hard to find a year or two ago. Looks like the supply has been rebuilt. Good news for engine rebuilders.

-

Condenser failure

That's normal if the points are closed. There is a resistance test for the coil. You might try that first. The single spark actually makes sense if the coil has a circuit to ground continuously. When you turn the key on the coil is energized. When you turn the key off it is de-energized and a spark results. It is a clue that you have a short to ground somewhere on the wires after the negative post of the coil, or the points are not opening. Check all of the wires after the negative post, and the points, and the condenser. Make sure that they are connected correctly. A shorted condenser would do it too. You can test the condenser with a meter also. It should have OL, Open Line, infinite resistance on the meter reading. Even though it is connected to ground it does not pass any current. Remember, new does not mean good.

-

.030 oversize ITMs...for a 2.4

How can you tell that they're for an L24? I Googled the number and found this Rockauto listing. Looks like the Facebook guy might be one of those resellers. Easy money! https://www.rockauto.com/en/moreinfo.php?pk=4803141&cc=0&pt=5620 p.s. I can tell where you live, what you've been doing and numerous other things from all of the extra Facebook code in the listing. 😎 Seriously, what is all of that extra stuff for? Makes me wonder. p.s. 2 - the application does come up on the Rockauto page. What would we do without Rockauto?

-

Where To Make Cuts

If it was brazed it might be debrazeable. But you'd probably have to take a chance on destroying the base metal to find out. https://jfdbrazing.com/ten-steps-for-a-successful-brazing-operation/#:~:text=10 – Separating a brazed joint,easy to separate the components.

-

Where To Make Cuts

I asked a whole bunch of questions about type of weld in that same long thread. Posts #102 and on are interesting. Some thought spot weld some thought linear weld. I think consensus was though that they were all ugly welds. Also, some wondering, on my part, if it was welding or brazing. I don't think that MIG was common back then. I think that the end conclusion was that it's a complex joint. I don't that there's a way to make a clean straight cut because there is overlapping metal. You have to sacrifice one or the other side.

-

1976 280Z Fuel Issues Troubleshooting

Not clear what you mean when you list those numbers. The first three pairs are AFM pins. Were you doing the AFM test procedure? Not uncommon to have the plug fall off of the bottom of the AFM, since gravity is pulling on it and the clip sometimes doesn't get clipped in when you reinstall the AFM. It might just be that the AFM plug fell off of the AFM and the bullet connector over the intake manifold for the coolant temperature sensor is unplugged. One big plug and one small one.

-

Condenser failure

I was trying to be humorous but came off as scolding. Sorry about that. I'm sure that cgsheen just got his condensers mixed up. He knows a lot more about electronics than a simple condenser problem would require. Some of it's in his sig. Still waiting for bluez to give us an update...

-

KONI Sports for Classic Z's

I wonder what happened to Joseph and Koni Lee.

-

Condenser failure

Your comment about wrongess is wrong. WRONG! Just kidding. Actually cgsheen's comment was only partially WRONG!. Disconnecting the condenser is a good idea. The points won't "burn" immediately. And the part about grounding (shorting) is RIGHT also. Commenting about somebody's wrongess almost always goes wrong. Like this post probably will. Right?

-

1973 Rebuild

You should sell the file to Vintage Dashes for $100.

-

Condenser failure

Use a meter or test light and determine where you're losing power to the system. If you have power everywhere, check the ground on the other side of the points. Basic electrical system testing, power and ground. Check power with the key at run and start since the ballast resistor has two circuits through it. Spark can be lost by either no power or no ground or constant ground. So, confirm also that the points circuit is complete when they are closed. Also, check that the condenser is not shorted, via testing resistance through it. Apparently, like many new aftermarket parts, condensers are getting poor even new. Sounds difficult but once you start poking around and getting data it's easy.

-

Good deals at the wrecking yard in Sherwood OR

My old hunting ground. The lower yard tends to flood in the winter time, it's by the Tualatin River. 75% off! No idea what's there. October 21th?

-

1976 280Z Fuel Issues Troubleshooting

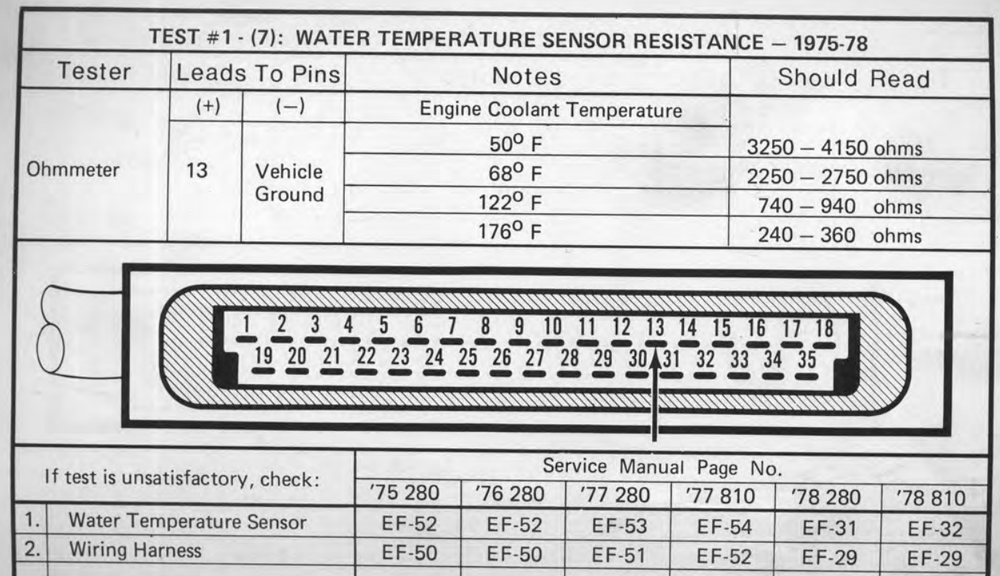

The FSM instruction comes after the test of resistance at Pin 13 at the ECU connector. The assumption is that the temperature circuit is complete and working correctly all the way to the ECU. You need to be sure that the ECU is getting the proper information. Measure resistance at the pins and compare to the table of resistance versus temperature. From the 1981 Guide -

-

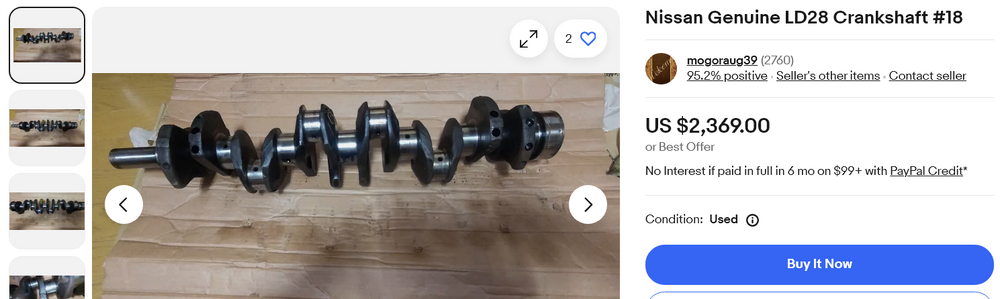

Diesel crank

If I lived in the Denver area I'd probably buy that engine car and resell the crankshaft. Seems worth the effort. Easy money.

-

Diesel crank

You guys probably knew that already. I imagined a question about the veracity of the Copart ad for some reason. Are diesel cranks still a thing?

-

Diesel crank

I might have found a clue. Picture 15 in the BaT listing below. The gas cars don't seem to have anything there. p.s. apparently you can reVIN your car with a label maker in Colorado. https://www.classic.com/veh/1981-datsun-810-maxima-jn1hu01sxbt004519-n3yxe6p/ https://bringatrailer.com/listing/1982-datsun-maxima-2/

-

KONI Sports for Classic Z's

There's a discussion back around page 17 and earlier about the weld bead and the modified nut. Suppsoedly there was a note on the MSA pages about it but I don't see it. You might contact Jospeh or Koni Lee since they were in the conversation. @Joseph@TheZStore @KONI Lee https://www.thezstore.com/product/4296/koni-sport-adjustable-gas-strut-rear-70-8-74-240z-260z-coupe

-

Z's on BAT and other places collection

Some things just cannot be explained. https://bringatrailer.com/listing/1976-chevrolet-c20-pickup-5/