Everything posted by Zed Head

-

Rear Strut housing replacement or not

That's pretty "cool"! Can you take a picture of the page and post it? I assume that it's in English?

-

Rear Strut housing replacement or not

Cooling fins are on the CLSD R200's. The open R200's just have the plain covers.

-

Quaife LSD Installation in R180 - With Questions About Installation Also

Isn't the ring gear located by an interference fit on the center of the carrier? There shouldn't be any play to play with.

-

240Z WILL NOT run right

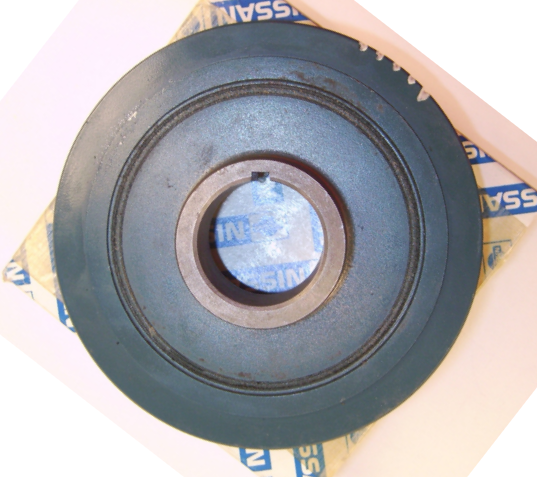

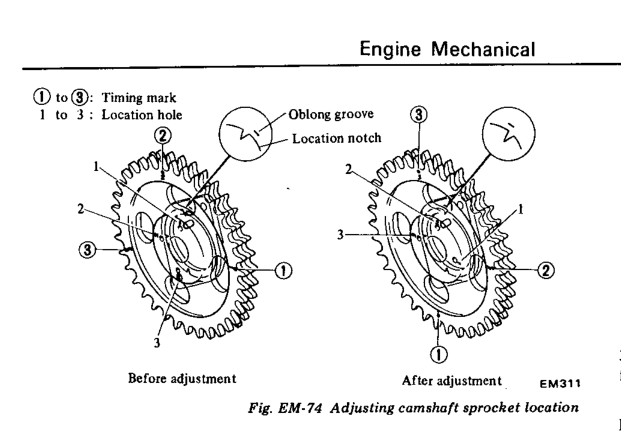

I had the feeling I was missing something obvious. 😟 I had assumed that the purpose of the notch and groove was known. Didn't read the accompanying words. I did get things right on my last suggestion to reset the mark on zero/TDC and see where the notch and groove were.

-

240Z WILL NOT run right

I think that your cam timing might be off by a tooth. If you're careful you can get it right without removing the front cover. You'll need a chain holding tool. Not sure how it would get off a tooth except for previous misassembly or radical chain wear. Also, I think that you can get a really close estimate of TDC using the damper key keyway in the crankshaft. The keyway should be aligned with the top of the block. Since you have the damper off it should be doable. Don't forget that the engine is tilted so up and down are askew. All timing events are relative to the crankshaft and its pistons.

-

240Z WILL NOT run right

It was fun looking around at the different dampers out there on the internet. Seems like your damper is fine. I'd rotate the engine around twice by hand and put that bottom/left side mark on the pointer. Then see how the cam sprocket lines up. If you use the cam sprocket to turn the engine make sure that you turn it backward before checking your marks. So that the slack is removed from the tight side of the chain. That might explain some of the discrepancy in your notch and groove. Ideally, everything is assembled and the engine is turned clockwise via the crankshaft bolt, or the fan belt, looking at it from the front, to keep the tight side of the chain tight. Assume that the TDC/zero mark is the farthest to the left, looking from the front.

-

240Z WILL NOT run right

I found another that doesn't say Euro. It looks about the same. Not sure what's going on here. I'd probably take the time to verify TDC and mark it on the damper pulley. Then use a dial-back light to set timing. https://maseraticompound.com/products/datsun-240z-main-crank-shaft-pulley-with-extra-ac-belt-pulley

-

240Z WILL NOT run right

I found an ad for a "Euro" damper and it looks like yours. Don't know how it's different from State-side. I'll look a little more. https://datnissparts.com/x-euro-crankshaft-damper-pulley-harmonic-balancer-240z-260z-280z-510-all-l-engines-12303-e4100/ Spun the picture in Paint 3D. Yours

-

Cars for Sale: Test ad

If you show the offers it could be an auction site. I offered $1.67.

-

240Z WILL NOT run right

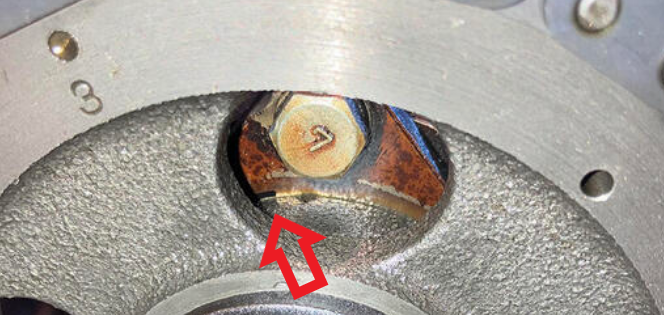

If that's the notch it does look like you have problems. Rotating it to get it aligned would make your damper marks even farther off the pointer. Looks like a bad damper. How about a picture of the face of it? That second pulley has seen some weather. Looks very old. Don't be afraid to really give it a tug to try to pull it apart. It's supposed to be very firmly bound.

-

Rear Strut housing replacement or not

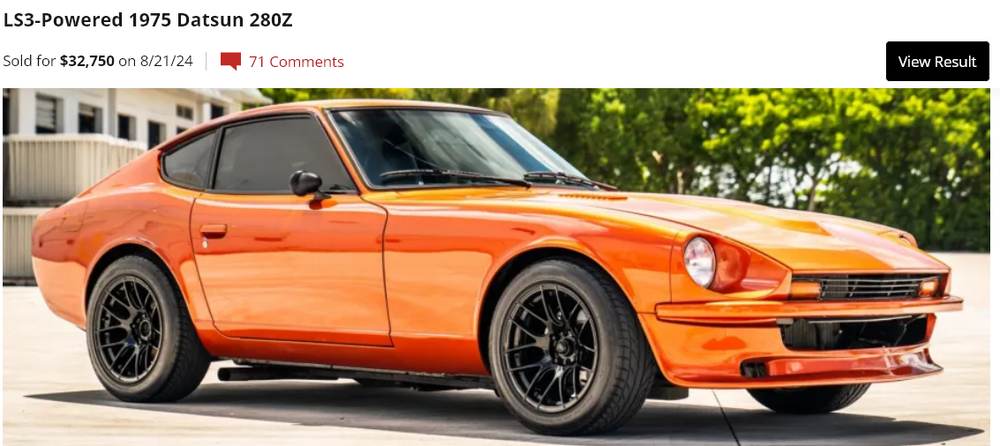

That does sound like the 280Z strut. The strut towers in the body of the 280Z are taller than the 240Z's. I've never heard of anyone doing that swap, seems like there would be very little suspension travel and the springs would be designed for more wight. The back end would be higher. If you look closer you might find more modifications. Cut springs maybe. The shocks might be fully compressed already. I'd guess that you'd be better off resintalling the 240Z suspension. Here's a link to the parts page. Not much interchange. p.s. you can tell an R200 from an R180 by the rectangular block of metal under the drain plug on the cover. https://www.carpartsmanual.com/datsun/Z-1969-1978/axle/rear-suspension Borrowed this from a recent BaT listing.

-

240Z Tach Wiring After 123Ignition Install

The blue wire from the coil (-) terminal supplies the tachometer with the voltage signal. You can leave it connected at the coil, but disconnected at the old igniton module. It's on a branched circuit. You can follow it out on the wiring diagram and see it.

-

L26 Rebuild Original E88 or P79

If money is not a consideration pick the one that looks like the most fun. Better check parts and procedure availablity though. An engine swap would actually be the "fastest" way to get back on the road. Machining and assembly time on the existing engine is going to add up. Good luck.

-

240Z WILL NOT run right

Piston stops in the plug holes. Rotate backward and forward and mark each spot. TDC is halfway between. Moght as well check the notch and groove. Put the groove over the notch and that should be within a few degrees of TDC. Your cam sprocket seems off in the picture. https://www.oreillyauto.com/detail/c/comp-cams/comp-cams-piston-top-dead-center-locator-tool/com0/4795

-

240Z WILL NOT run right

Not clear what happened or what you're asking about. Where is the bolt and washer that holds the damper? Did you just grab the damper and slide it off by hand? Where is the woodruff key?

-

MSA Rear Disc - E Brake

The above still applies. Some time on the back looking at the various cables and moving parts will probably tell the story. Part #4, the equalizer might need some lubrication, along with adjustment of the unlabeled part between 2 and 7.

-

Z's on BAT and other places collection

Not a bad starting point for a Z that looks pretty nice and will probably be up and driving with just a little bit of work. https://bringatrailer.com/listing/1976-datsun-280z-91/#comments-anchor

-

MSA Rear Disc - E Brake

Looks like about 0.1 mm clearance there. Is that finished work or in progress?

-

L26 Rebuild Original E88 or P79

No offense intended, but keeping the matching block with a 260Z probably adds very little value. It's just the way things are. People just don't appreciate the 260's like they do the 240's and 280's. My theory is that it's the shape of the 6 compared to a 4 or an 8. If you really want more power then an L28 swap would probably be the best value for the money. On the other hand, if you just want to see what you can do with an L26 then what you're talking about makes sense. Good luck.

-

MSA Rear Disc - E Brake

What is the mechanism of the parking brake actuation? It's mechanical, right? No hydraulics involved? Should be able to just eyeball the mechanism and see what it's doing.

-

240Z WILL NOT run right

Ignition modules can fail due to heat then come back to life when they cool down. You could take some cooling spray, like Dust-Off Duster, and spray the Pertronix module under the cap in those minutes when it's not restarting. Or take a spare spark plug, pop a plug boot, and check for spark. Wouldn't be a surprise if it was the Pertronix module. Apparently quality dropped dramatically many years ago. There are old posts about it. The Pertronix I's were also sensitive to leaving the key on. It can damage them.

-

280zx dizzy, too much timing advance. How to make it not hurt my engine?

I would measure what really happens rather than hope the table is correct, before taking any actions. You can set the timing to zero, to stay on the indicator, or use a dial-back timing light. Connect the vacuum advance to intake vacuum at idle and get the vacuum advance number. Disconnect the vacuum advance and rev it up to get the centrifugal. The TB vacuum advance hose is ported vacuum and only works when the throttle blade is off-idle.

-

Z's on BAT and other places collection

Here's a good starter Z. Probably get it for a good price. Has some minor accident damage but very little rust. Most of Washington state doesn't use salt. https://bringatrailer.com/listing/1976-datsun-280z-91/

-

Z's on BAT and other places collection

I think it's across the whole classic car market, not just Z's. I follow some of the older muscle cars and other sports cars like the Sunbeams. Many are going RNM. Ya gotta put those speed parts in there! https://bringatrailer.com/listing/1975-datsun-280z-54/

-

New problem - Fuel pressure drops off - 75 280 L Jet, w/ composite injectors, ProtunerZ rail, 3 bar FPR

I had a similar problem with the AFM switch once. There was a hair or a piece of dust or a bug wing stuck on one of the contact points. They looked closed but there was no current through them. I didn't find the actual offending item but the problem disappeared after cleaning the points like you'd clean a set of ignition points. It was a head scratcher for a while. Also had a problem with low idle RPM dropping air flow low enough to shut off the fuel pump. Probably why Nissan switched to the oil pressure/alternator switch later.