Everything posted by Zed Head

-

Does an LSD need better cooling?

The $40 seems really low if they're building a hard mold. Hard to believe. I'd guess that they could 3D print the part and cast plaster around it. Then they'd have to worry about draft. It does seem an interesting place. https://lancasteronline.com/opinion/editorials/atf-investigation-of-lancaster-county-amish-farmer-highlights-the-importance-of-gun-regulation-editorial/article_b519cf3e-8096-11ec-ae18-b7900627a47f.html

-

1971 240Z, engine won't idle smoothly after fill up...

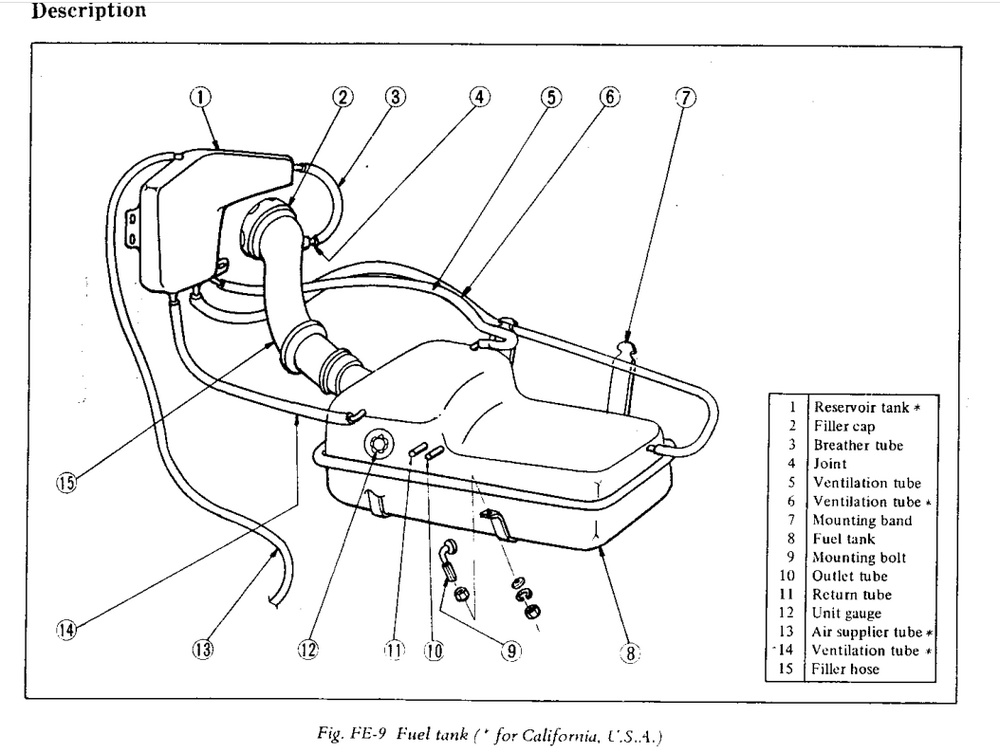

I'd check the air supplier tube and/or the gas cap. And the breather tube. (Edit - actually all of the ventilation tubes. There seem to be many. Must be important.) I see that siteunseen has just replied. Same thought... . . .

-

Does an LSD need better cooling?

I wonder how much heat is transmitted to the mustache bar? A thought. Also, what is air flow like around the diff? Nissan's finned diffs put the fins on the bottom where the air flow is. I wonder if anyone ducts air to the diff, like they do for brakes. It's an interesting topic to think about, especially with a low budget. Have fun.

-

Does an LSD need better cooling?

Have you thought about gluing cooling fins on to the cover you have? Today's adhesives are very strong and can be conductive. https://www.3m.com/3M/en_US/p/d/b00006335/

-

Does an LSD need better cooling?

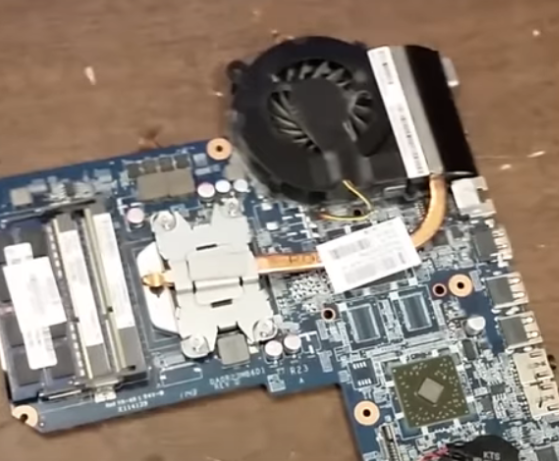

How about remote cooling? Like they use in laptops to cool the main processor. Borrowed this from a Youtube video.

-

What are these things and are they still needed?

You are right. https://en.wikipedia.org/wiki/Delco_ignition_system

-

Does an LSD need better cooling?

Looks like you added fins inside the cover. Here's an interesting video from a guy who has a bunch more on the topic on his Youtube channel. He's selling parts of course, but he does raise some interesting points.

-

Z's on BAT and other places collection

Once an insult shows up the rest doesn't matter. That's what it boils down to, for me. Maybe it's a cultural thing. We have different values. You seem to be saying that a person who contributes to a discussion gains the right to insult other people in a discussion. The more they contribute, the more insults they're allowed. That's just not how I work. You're focused on the punch. I'm saying that the turd is still right there where everybody can see it. The punch is ruined. Stop defecating in the punch bowl please. It's pretty simple. It just takes a small amount of self-control. Read your post before clicking "Submit Reply". Remove the insults. I have written whole paragraphs myself but not posted them. I knew that they would not advance the discussion, or add to the forum, whichever one I was participating in. It takes some objectivity though. It can be difficult. Good luck. There's really not much more to say on this matter.

-

Does an LSD need better cooling?

In sand-casting the sand is the mold. It just brushes off. The core, or form, is what might be molded, for high production parts, but they're not building a mold for $40. Almost has to be 3D printed. Interesting project, but getting all the way to a usable part will take many steps. Good luck.

-

Does an LSD need better cooling?

Who will be doing the machining? Have you estimated the total cost to completion? Subaru still uses the R180 and there are a bunch of custom covers out there. I'm not sure if the mounting stud dimensions are the same, can't remember. I think that they are. https://www.flatironstuning.com/rcm-r180-differential-cover https://www.machinedspeed.com/product/custom-hi-capacity-r180-differential-cover https://www.importimageracing.com/products/r180-rdf-asf-machine-r180-billet-rear-differential-cover-subaru-sti-2004-2021

-

Does an LSD need better cooling?

I wonder if $40 gets you the good aluminum. The Z cover is a loaded structure, not just an oil holder-inner. Not sure that old beer cans will do the job. Better ask. Diff cooling is a popular topic. These words in Google will find a bunch. site:hybridz.org differential cooling Here's a good one. https://forums.hybridz.org/topic/133692-r200-differential-cooler-pump-and-plumbing/

-

Does an LSD need better cooling?

The low cost of the 3D printers probably opens up a lot more opportunity for casting. Used to be, I think, that you'd need a CNC machine to cut a form. The upfront costs were very high. Hard to keep up. I saw a guy make actual usable durable robust electrical parts with his printer. The "work" was mostly calculating and using CAD to make the computer file. Kind of disappointing, no handling of hard metal tools and setting up the machine to cut the piece. Life just keeps getting physically easier. Jeff Berk, does that family shop have a web site? Would be interesting to browse.

-

Does an LSD need better cooling?

More fins is a good idea. https://www.z1offroad.com/nismo/nismo/nismo-rear-differential-cover-upgrade-r200-p-2339.html I wonder if they're using a 3D printing/additive manufacturing/stereolithography tool to create a wax form. Lost wax casting. Probably a lot easier to make the form with the new printers. Zip it out, pack it, pour it, send it. https://en.wikipedia.org/wiki/Lost-wax_casting#:~:text=Lost-wax casting – also called,cast from an original sculpture.

-

Z's on BAT and other places collection

Insulting people on a friendly forum is appropriate? C'mon. When do insults ever really cause somebody to change their views? And your Swift quote could be pointed at HS30. Kind of funny. The sad part of it all is that the insults are like the turd in the punch bowl. Once the turd goes in the whole bowl is ruined. Nobody wants to drink that punch. When I see that HS30 has joned a conversation (he never starts one) I know how it will go and how it will end. It's just who he is, by his internet persona. And, despite your half page, I don't know more about who HS30 is. Overall, your reply kind of helps make my point. A small group of people who value his opinions, for reasons unknown. I came across a funny article this morning. That might be his voice... https://www.theguardian.com/society/2024/feb/23/you-shouldnt-be-doing-that-female-pro-golfer-films-mansplainer-at-driving-range

-

1971 HLS30-14938 "Lily" build

Do you have some axles? They're hard to find. People have reported that the aftermarket replacement axles are longer than the factory units and bind. I think that those adapters might cause binding also. The only adapters that seem to work are the ones that use the original axle flange as the mating surface and build the adapter around it. Something to be aware of. If you have adjustable control arms you can always widen the track. Here's a thread about it, with a picture pulled out. https://forums.hybridz.org/topic/128943-z31t-axle-swap-can-fit/#comment-1204163

-

Z's on BAT and other places collection

A not-bad 78 is up, no reserve. Big bumper delete. Looks like it might have had a diff swap in the past, it has a yellow mustache bar and an R180. Could be a fun daily driver. https://bringatrailer.com/listing/1978-datsun-280z-160/

-

Need R200 Differential Advice

I sent him a message last night with your info above copied in to it. He replied "Thanks! I'll get in touch."

-

Z's on BAT and other places collection

To clarify - I appreciate Carl's rational on-point posts. You know who he is, he describes his history, and replies with the facts as he understands them. He has contributed to the Z car world with his web site and his respectful participation in conversations on the various forums. He makes a new person want to "join the club". I don't really know who HS30 is. Apparently his name is Alan (or Allan). He seems to have a small circle of people who respect his opinion but does not give much reason for anyone new to the field to do the same. He seems to assume that people should already know who he is. Can't really tell why his words should mean anything. He's just a loud voice on the forum. He makes a new person wonder "do I really want to be a part of this?". Carl adds, HS30 subtracts. I appreciate Carl's efforts but sometimes it's best to move on to more productive endeavors.

-

Z's on BAT and other places collection

You can start your own new thread and link to the various posts here. You have that power. Frankly, I'm starting to feel embarassed for you guys. The "Flat-Earth Society" insult is an obvious sign that the discussion has degraded. There are no winners when things get this bad. Why not just stop posting? At least if you start a new thread we can all use the Ignore function of the forum so we don't have to see it.

-

Need R200 Differential Advice

Glad to help, and good luck. Hybridz is not very actively moderated. Not sure how fast they move or what the rules are for messaging. I can drop the guy a message and send him over here if you don't get through.

-

Z's on BAT and other places collection

-

Need R200 Differential Advice

Just saw this on Hybridz. More expensive than a wrecking yard but cheaper than some places. Has the ratio, apparently. https://forums.hybridz.org/topic/133338-r200-370-open-and-z32-5-speed/#comment-1241777

-

Dave W 1971/240Z rebuild

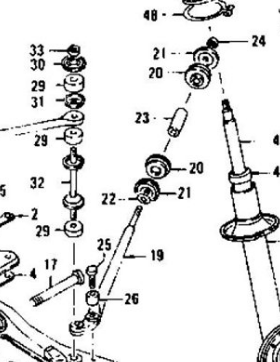

There's a metal sleeve that the nut seats on. Threads showing is determined by the sleeve. https://www.carpartsmanual.com/datsun/Z-1969-1978/axle/front-suspension Part 23.

-

Need R200 Differential Advice

The bolt size problem is well-discussed on other forums. In principle, the clamping force of the bolts does not depend on the space around them, and the ring gear should never move on the carrier once clamped down. But people still use sleeves to take up the extra space. I can't remember which has which but it sounds like you're saying that your carrier has 12mm holes. By the words in the various discussions you should be able to use a ring gear with 10mm bolts. Put these words in to Google and a bunch of Hybridz threads will come up. You'll find links to sleeves/spacers if you want to go that route. The diff shop might have some opinions too, I'd guess. site:hybridz.org 10mm 12mm differential carrier

-

Need R200 Differential Advice

Search your local Craigslist and Facebook Marketplace. Probably have to buy a complete used diff. Maybe even a beat up parts car.