Everything posted by Zed Head

-

Z's on BAT and other places collection

It's a no reserve have fun big bumper last year 280Z driver. Not a 71 collector model restoration worthy investement. Don't get too carried away in the critiques. It's for the guy who wants a drivable hobby car. Or a quick flip. Buy it, get it running, keep another Z on the streets, make a few bucks.

-

Z's on BAT and other places collection

Here's a good basic 280Z for somebody that wants to get in to the Z world and drive one without spending too much. Lots of nickels and dimes waiting to be spent but it should be pretty easy to get back in to good running shape. Might even make a good "will it run and drive XX miles" video. https://bringatrailer.com/listing/1978-datsun-280z-158/

-

Used Aluminum Brake Drums

Measurement of the inside diameter and pictures of the surfaces will tell the story. There's a limit, it's marked on the drum itself. Borrowed this from an eBay ad. He wants a lot but didn't provide the critical information. A shop won't turn a drum beyond the limit.

-

D Washers for fenders

I actually did check all of the washer part numbers on the internet. None of them came up as the "D" washer shape. Who knows. Maybe they were only "D" on the assembly line, and normal as a replacement part https://www.nissanpartsdeal.com/parts/nissan-washer~08915-43610.html

-

D Washers for fenders

I'm really just here for the puzzle. Can't find them on carpartsmanual but they do seem to be a thing. https://bringatrailer.com/listing/1970-datsun-240z-112/

-

D Washers for fenders

Where would a "D" washer be used on a fender? I didn't even know what one was so I got on the Google. And there are several shapes/types that are apparently called D washers. Maybe add some description? https://www.google.com/search?q=d+washer

-

Trans Input Shaft Housing Sealing

And don't forget to run the clutch disc up and down the main shaft to be sure it moves freely.

-

Trans Input Shaft Housing Sealing

Might as well pile on with more stuff. How does the nose look, where the throwout bearing rides? They do wear, but you have the cast iron cover so it's probably fine.

-

Trans Input Shaft Housing Sealing

If you have a new shaft seal installed then just clean surfaces and a new gasket should do it. Here's an odd thing I ran across once though - the clutch fork pivot pin threads leaked fluid. It took me a while to figure out the fluid ran down the fork and off the end of it to the ground. A weird leak. If you had that out, or even if you didn't, I would use some thread sealer on the threads. The lock washer is not a sealing washer. Also, don't forget the countershaft bearing shim.

-

75 280Z - Updating fuel feed & return lines in the engine bay

I was just properly defining the words. You can't have a good debate if people use the wrong words.

-

Injector pulse is evading me...1978 280Z

Thanks for the follow-up. These weird problems need examples. Good luck with the project, you're at the right Z forum.

-

Injector pulse is evading me...1978 280Z

I discovered this exact problem on a completely stock 1978 parts car. It would not actuate the injectors if the tachometer was disconnected. Apparently, some 280Z's will and some won't. I confirmed it a few different times on the 78 and my 1976 car. You'll find people that say theirs starts just fine without the tach and others like me who say it won't. After I switched to a different ignition system it didn't matter if the tach was connected or not it always started. So it seems like the ECU is very sensitive to what's happening on Pin 1. Short answer - you're probably right and it will probably start right up if you connect the tachometer. It's probably not the ECU. You did all of the right testing too. Good luck. . . .

-

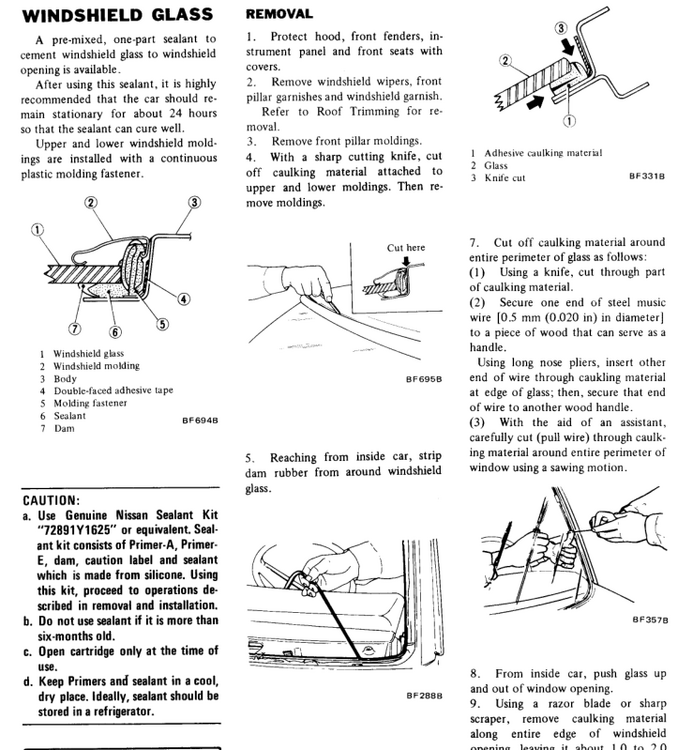

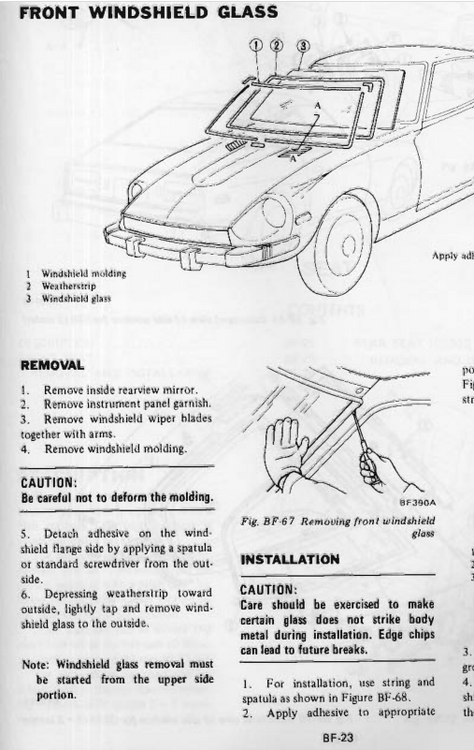

79 280zx windshield trim removal

Yes. As stated.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

If the goal is to just get a few seconds of power to the pump when the key is turned on you could tap in to the pump power wire anywhere. It runs down the outside of the floor under the carpet on the passenger side on the 76's. You could even backprobe the plug, there's a connection there. That's what I did to power the brake warning check lamp relay.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

Here's some expensive examples. Is the goal cheap, effective, or both? https://www.delcity.net/productsearch?search=time+delay+relay&x=0&y=0&it=

-

79 280zx windshield trim removal

I was showing that the 280Z instructions are different. I didn't look at the ZX instructions. Looks a lot more complex.

-

79 280zx windshield trim removal

I was incorrect. Apparently Nissan says the molding is removable separately. I must have seen comments from the internet instead. I'm sure it's much easier with newer still flexible rubber. Here's 1978. "Be careful not to deform the molding". They knew.

-

79 280zx windshield trim removal

I don't know much about it, but I do remember painfully prying out my metal trim to try to get under the edge of the rubber seal to seal a leak (it didn't work). Then realizing later, after reading various accounts, that you're supposed to cut the old seal out and the trim comes with it. In other words, the metal trim is only meant to be installed with new rubber. The system is not designed for non-destructive disassembly.

-

75 280Z Hands -Free Fuel Pump Primer Circuit?

It should. Most do. The old original FPR's are known to leak down. It just takes a little bit of rust at the seat surfaces.

-

running lean '76 280z

If the AAR closes to the same spot consistently, but idle speed varies, then the problem is not in the AAR. My AAR worked correctly, and idle speed was consistent after warm-up. In the end, I was lucky enough to experience an engine with everything working correctly. But I also went through the phase of looking for alternative solutions. The factory parts will give consistent cold start and warm-up to a properly idling and performing engine, if they are working as they were meant to work.

-

running lean '76 280z

An AAR that works correctly is pretty satisfying. It just works. Your varying idle speed might be due to one of your other problems, not the AAR. If you apply 12 volts to the AAR pins and it doesn't close completely, it's broke.

-

running lean '76 280z

A ball valve with a cable would work. It would be, in essence, an idle speed control. https://www.homedepot.com/p/Apollo-3-4-in-Brass-Insert-Poly-Ball-Valve-POLYV34/300850934

-

Voltage Regulator - Should I adjust it??

Check the shipping on that eBay item. $20.

-

Voltage Regulator - Should I adjust it??

I've not seen that brand name before. Interesting. https://www.ftonline.co/product-category/electrical-parts/voltage-regulators/ https://www.ebay.com/itm/234598216098?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=MOJzyVjhShe&sssrc=2047675&ssuid=bBzFtXzvTQO&widget_ver=artemis&media=COPY

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

What brand was the bad one?