Everything posted by Zed Head

-

Voltage Regulator - Should I adjust it??

Check the shipping on that eBay item. $20.

-

Voltage Regulator - Should I adjust it??

I've not seen that brand name before. Interesting. https://www.ftonline.co/product-category/electrical-parts/voltage-regulators/ https://www.ebay.com/itm/234598216098?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=MOJzyVjhShe&sssrc=2047675&ssuid=bBzFtXzvTQO&widget_ver=artemis&media=COPY

-

Fitting a HEI Module in Transistor Ignition Unit 1977 280Z

What brand was the bad one?

-

Mismatched calipers and rotors

The page you linked says the rotor only works with the Stage 4 kit. The Stage 4 kit page says that the calipers are huge. Can't tell what brand they are but that looks like the cause of your problem. Description - Stage 4 drilled, slotted and vented rotor. This rotor is zinc plated to prevent rusting. 10.8 inches in diameter. 22mm thickness. Only work with stage 4 front brake kit. https://www.silverminemotors.com/products/stage-4-front-big-brake-upgrade-kit-240z-260z-280z This brake kit comes with the following parts: 1. Enormous 4 piston calipers (43mm pistons)

-

Half shaft rebuild. What could require that?

The half-shaft rebuild would involve the ball bearings and their races. I found an older thread about. It should be in the Knowledge Base section. @Mike

-

Modern injectors, new fuel rail - no heat soak problem

You can find the same discussions on Hybridz.org. You're in that theory versus practice conundrum zone. The theory can be correct, but not matter in practice.

-

75 280Z - Updating fuel feed & return lines in the engine bay

Not clear what you're saying, you showed a hole and an o-ring, and implied that hole was meant to be an ORB design. The Protrunerz site doesn't clearly say say it's an ORB hole. You're assuming it's an ORB hole. That's the part that needs defining. Looking at the ORB-8 at the end of the rail it's hard to imagine they'd forget to perform that operation on that hole. But, who knows, maybe that's what happened. I'm just here for the words... I did find some other images though that imply it's supposed to be ORB. But even they look a bit off. Seems like the fitting is not seated. Anyway, there are many ways. Carry on.

-

75 280Z - Updating fuel feed & return lines in the engine bay

My first instinct when I saw the hole was maybe it's a tapered pipe thread. Following up on that, you could easily make it one. They seal just fine with a bit of thread sealant.

-

75 280Z - Updating fuel feed & return lines in the engine bay

Edit - actually I can't tell what the Protunerz site is saying. It's not clear. "6AN orb Fuel gauge port"? See below. Which is it? I don't have much experience with AN threads fittings but the internet says it's a tapered thread flared fitting. The Proturnerz site says that's a 6AN hole, if it's the hole you're using. They mixed ORB with AN. Easy to see a mix-up. Full disclosure - I didn't even know what ORB was until just now. Thank you internet... https://protunerz.com/collections/fuel-rails/products/datsun-l-series-fuel-rail https://en.wikipedia.org/wiki/AN_thread https://hosebox.com/insights/orb-fittings-explained-selection-setup/ CNC Anodized BILLET Fuel Rail with outer ORB-8 Thread, 6AN orb Fuel gauge port /cold start/pressure sensor.

-

75 280Z - Updating fuel feed & return lines in the engine bay

The "dead" part of the deadhead is the non-moving fuel in the rail. Dead flow. If the fuel doesn't pass through the rail, in one end and out the other, then it's a deadhead system.

-

75 280Z - Updating fuel feed & return lines in the engine bay

Just an observation. The pros and cons of return style versus deadheading is a popular topic. https://www.bing.com/search?q=return+style+versus+deadheading

-

Half shaft rebuild. What could require that?

Run them through their range of motion and see how they feel. I had one from a parts car that had been rear-ended and it must have damaged the half shaft. It would bind in its travel. I took it apart but did not see any visible damage. On the u-joints, the factory joints have caps in the Zerk fitting holes. Remove cap, install Zerk, squirt grease. Check the seals.

-

Modern injectors, new fuel rail - no heat soak problem

Aren't we comparing about 16 + 6, to 16? 22 to 16. I just pulled those numbers from memory, the more precise numbers are out there somewhere. . .

-

Modern injectors, new fuel rail - no heat soak problem

Leaner with the new injectors or with and without the resistors, same injectors? I think that you'd need to do a one-to-one comparison as far conditions to really know. Engine temperature, air temperature, etc. With and without resistors. Otherwise it's just conjecture.

-

Window glass alignment in the channel

I wonder if Rain-X might help. Just because of how it works. Leaving a fine film of water repellent molecules on the surface.

-

Timing Chain Tensioner Extended too much?

With no load from a pump do you think the eccentric will really have much effect? The weight of the sprocket is far greater than that tiny cylinder of steel, placed near the center of mass. I tend to leave well enough alone. Just a counterpoint...

-

Modern injectors, new fuel rail - no heat soak problem

I did. When I first put the system together I left the resistors in place as I tested it. Then I removed them and jumped the wires, just because. Then I think that I put them back just in case a future owner wanted to swap back to the original setup. I thought about the possibility of low current causing delayed opening times but decided that the EFI system is so crude that it probably didn't matter. It's a semi-batch fire system with no O2 sensor trimming. It just squirts a gob of fuel every rotation to all cylinders at the same time. But, with your AFR gauge you could easily run a simple test. Extra resistance won't hurt the ECU. Worst case you see some leaning at idle, where injector open duration is lowest and delayed opening time might have an impact.

-

75 280Z - Updating fuel feed & return lines in the engine bay

I thought the same. That won't help the hot start problem, might even make it worse since the vapors can't be purged except through the injectors.

-

Modern injectors, new fuel rail - no heat soak problem

-

Modern injectors, new fuel rail - no heat soak problem

I've mentioned this before also, somewhere. You can take an old Bosch/VW/Porsche adjustable regulator and drill a hole through the center of the adjusting screw to add a vacuum reference hose. There was an old VW dune buggy article about it on the web. Notice the 001 number. Might be the first adjustable from Bosch as they got in to L-Jet. Still available. Spendy, unless eBay. It holds pressure too. https://www.pelicanparts.com/More_Info/0280160001.htm?pn=0-280-160-001-INT https://www.ebay.com/itm/115896285815?mkcid=16&mkevt=1&mkrid=711-127632-2357-0&ssspo=JXCBKhvJSD2&sssrc=2047675&ssuid=bBzFtXzvTQO&widget_ver=artemis&media=COPY

-

Modern injectors, new fuel rail - no heat soak problem

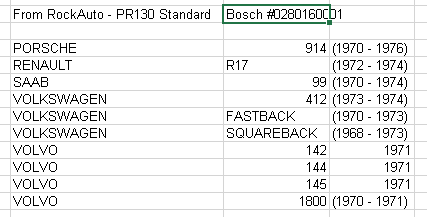

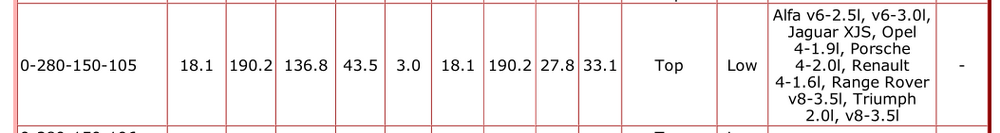

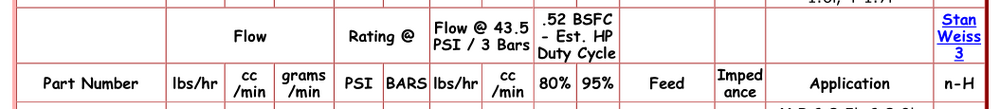

Here is a GM injector I ID'ed in the past as possible. I pulled the data from various sources and stuck it in a spreadsheet. I got a new computer and Microsoft is holding the spreadsheet functions hostage so all I can do is an image for now. A person really needs an adjustable regulator to get things dialed in. Since you have to lean things out. https://www.rockauto.com/en/catalog/buick,1989,electra,3.8l+231cid+v6,1017414,fuel+&+air,fuel+injector,6224

-

Modern injectors, new fuel rail - no heat soak problem

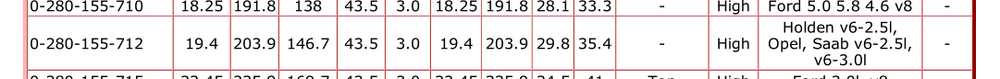

Here's a link to a table I had found a while ago. The original web page seems down but the table exists in various forms. 028-150-105 seems to be the standard Bosch original form replacement for the Nissan analog. In those early days they gave different part numbers based on hose length. I think that up to -112 are the same basic injector. It downloads a pdf file. Those 712's are high impedance. You'll want to remove the dropping resistors, I'd guess. Although I ran high impedance on my engine and they worked fine either way. Looks like you might be a hair rich with those. Good luck. https://alfaclubvic.org.au/forum/index.php?action=dlattach;topic=13145.0;attach=28987 and https://www.google.com/search?q=stanweiss+injector

-

Timing Chain Tensioner Extended too much?

- Timing Chain Tensioner Extended too much?

Just noticed that CO covered what I was talking about. Missed it in the flurry of posts. I'd measure the head thickness (you can do that while it's installed) then do the math on the the headgasket and see what should be. Meanwhile, order new timing gear - sprockets, guides and tensioner. All three can have wear.- 280zx turbo ECU with side mounted potentiometer

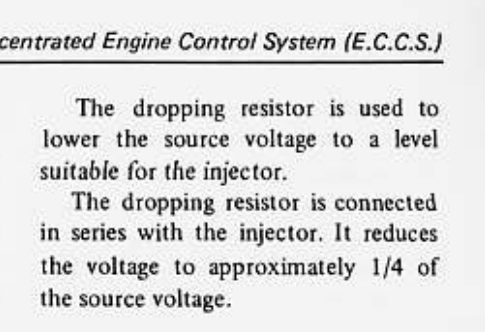

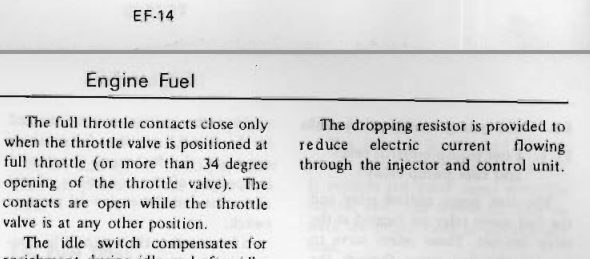

On the 280Z EFI engines Nissan stopped using the dropping resistors in 1982, for both EFI and ECCS engines, according to the FSM's. The FSM mentions current and voltage protection, but the injector solenoid coil is essentially the same as any relay coil. Seems like protection would be more for the ECU. Of course, current and voltage are related. A resistor won't lower voltage unless there is current. So, in terms of "breakdown" voltage, it seems to be a wash. Must be a current issue. But the injectors are cooled by gasoline. Just some random ramblings... 1981 Turbo Supplement 1978 EFI. Current and ECU - - Timing Chain Tensioner Extended too much?

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.