Everything posted by Zed Head

-

condenser on coil positive is important.

Is that Buddy Holly's garage?

-

Need to replace Pertronix Flamethrower coil

Describe the rest of the ignition system. Do you have the Pertronix ignition module? Or points? Or something else. That will determine, for the most part, what resistance you need on the primary circuit.

-

83 280ZX accelerating problem

One problem people new to cars have is terminology, not enough words in their brains to convey the message. Reading back through your post I think what you might be describing is a "lean" fuel air mixture. Not enough fuel for the quantity of air entering the engine. It's controlled by the AFM vane position, so will be tied to engine RPM. But, before you go crazy on the AFM, one cheap thing you can try, that might be enough, is to add resistance to the coolant temperature sensor circuit. It's fixed the problem for many of us here, and it's pretty simple. You can either buy a few resistors and wire them in or get a cheap potentiometer (volume control) from Radio Shack and use it as adjustable resistance. The sensor has a bullet connector on each wire coming and going to the ECU. Put a male and female bullet on your resistor, find one of those connections, and slip it in there. If "lean" is the problem, a little bit of extra resistance will have immediate effect. If it does, you can focus on fuel supply - fuel pressure, clogged injectors, bad AFM, etc. At least it wil give you a better focus. And the second "Bible" is really the one you want. It might be available from another web site somewhere, or maybe you can find a way to get it on a thumb drive or something. It covers the ZX's. http://www.xenons130.com/reference.html

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Bought six quarts of 10W-30. For a future break-in.

-

260z won't start!

Crap, I knew something was bothering me when I posted that. I usually point that out myself. The picture I posted is from the wrong FSM. Got 73 stuck in my head, not 74. Forget about points Clomolina. You can still check air gap though. Engine Tuneup chapter. http://www.nicoclub.com/FSM/280z/

-

260z won't start!

The stuff below is wrong for 1974. See the two posts below this one. No the points are under the cap. If you don't know what points are, that's not good. You have much to learn. Anybody who has worked on older cars, will know what points are and how to check them. Newer cars don't have them and many people have never seen a set.

-

260z won't start!

That's not really the best way to check for spark. Put a sparkplug in the wire and place the body of the plug, the threaded metal portion, in contact with the engine, typically the valve cover, where it can be seen. Then crank the engine while watching the plug for spark. Be careful, the engine might start, so put the plug and wire where they won't get damaged if it does. That's one way, there are others. Have you checked the points yet? Examined the inside of the distributor cap? You're jumping around a lot, hoping the engine will start but you should really be going through the basics first to make sure everything is in order. If the PO left the fuel pump disconnected, who knows what else is missing. It may not even have a rotor under the distributor cap.

-

Timing indication

Don't you have the original marks on the pulley? Several. And the pointer. How did you determine TDC? You can get a lot of crankshaft rotation for not much piston movement.

-

83 280ZX won't start, won't fire. Just turns over.

No, it looks like you have the right distributor for the engine management system. No CAS for NA. And the problems you described are all common to old distributors.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

That's cheap, in general, for any oil. Hope it's not a discontinued product price. Thanks for the tip.

-

Rear shock noise

You're in the MSA vendor forum. Not the best one fro fixing problems. The springs will compress when you put the weight of the car on them. They just don't have any preload. Can you give more detail than "Lately I've be hearing a clunking/popping noise"? Noises from the rear have many potential causes.

-

Seattle Area Z Brunch Saturday

I had that same thin stream of fuel shoot out on to the sidewalk when mine finally let go. Mine was squirting from the connections of the three piece rail though. Note on the newer EFI hose. It tends to creep or relax a little bit over time. At least my Gates brand hose did. I think the newer hose is designed for constant tension spring clamps, not the screw type clamps. Might need to retighten the clamps occasionally until it settles in. That's VR-1 oil, right?

-

tranny question

We had a big discussion about this quite a while ago. There's internet stuff that says the numbers mean something but when you compare the numbers with known facts about the transmissions, like year of car they came in, there doesn't appear to be any usable correlation. You can tell a lot just by the gear ratios.

-

Driveshaft play at transmission end. Normal? (see video)

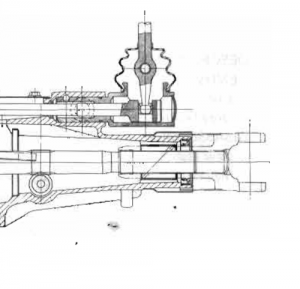

Just a couple of things. Maybe we should go with factory nomenclature. That would be "propeller shaft" for the shaft we're talking about, and "drive shafts" for the two that go the the wheels. Some people use "tail shaft" to talk about the output shaft of the transmission, and tail shaft housing to mean the rear case of the transmission. On the measurements. I measured in exactly the same spots as EuroDat, center to center of the u-joint caps. early 240Z propeller shaft - 21.25" (540 mm) 1976 280Z shaft - 22.3" (566 mm) EuroDat's late 204Z shaft - 22.55" (573 mm) As for room inside the slip yoke for the transmission output shaft, the early shaft, I measured 4 11/16" by sticking a tape measure inside and eyeballing to the end of the slip yoke. 4.6875", 119 mm. Just to give some idea of engagement. But, I'm not sure what hits first, the output shaft inside the yoke, or the nose of the yoke on something inside the transmission. Also added a picture fro the 1976 FSM showing the yoke inside the transmission and what looks like an outline of the bearing. You could easily be only half-engaged in that bearing. It might be wallowed out already, damaged. Edit - also added a much better image from 1973. The best route might be to remove the shaft, examine the inside of the transmission for damage, and get a longer shaft. Might be overloading on data here, but it's fun to review all of this since I spend a bunch of time doing the same for the 71C case swap in the past. Which is still sitting in the garage.

-

Driveshaft play at transmission end. Normal? (see video)

I get 21 1/4" from cap center to cap center on my early, diff-forward shaft. It's not clear what "stock" means, and I don't know what shape the mustache bar was on the diff-forward setup, but it looks like you have the short shaft, when the long one would work. MY 280Z long shaft is a hair over 22 1/4". Looks like you have the short shaft when you could use the long one. I look at the angle of the halfshafts to determine if the diff is forward or not. In the improved vibration resistant setup (the factory modification and what they changed to for later cars) the shafts are perpendicular to the wheels when looking through the wheel well. In the early cars you can see that the shafts are angled forward. Did you try wiggling the yoke around like in your first video? That would answer part of the question. If the play goes away, then a longer shaft might be more stable. EuroDat mentioned tailshaft in his post. I don't know if he meant your transmission, but there are shorter versions of the 71B transmission. from trucks. Maybe you have one of those. Obligatory edit - to be clear, you do have the R180 diff? It hasn't been swapped to the R200.

-

Rocker Revival

Here's an old article. People have wondered about this for a while - https://books.google.com/books?id=CRDEneSREucC&pg=PA144&lpg=PA144&dq=smooth+tappet+surface&source=bl&ots=7Hum0yt51O&sig=DgXG_t_DAzbCNCNPCEvDyp7C-x0&hl=en&sa=X&ei=-AIzVd2fAoO3oQTo2IGwCA&ved=0CCQQ6AEwAQ#v=onepage&q=smooth%20tappet%20surface&f=false

-

Rocker Revival

Asperities are the enemy. Most failures occur during break-in or at startup (no oil film). Broken in engines have much smoother surfaces than new parts and are less likely to fail than new parts. I understand the feeling that roughness holds oil and oil is good, therefore roughness is good, but the counter argument is that oil is there to combat roughness, so smoothness is good. Seems like dealing with the devil. Could certainly use more study. If very rough is bad, and very smooth is bad, then there must be an optimum in the middle. Knowing that magic number could save some parts.

-

My New Z

Odds are good(bad) that you connected the battery backward. Nissan did not use red and black like everyone else did. Follow the cables to be sure which is ground and which is positive. The cross member is actually what the engine is mounted on. Can't be removed without removng the engine too. You can get the oil pan off with everything in place though, it might take a couple of tricks. There are tons of parts for sale from people who decided to just tear the car apart and rebuild it from scratch. One year of looking at boxes of parts and you won't even remember it used to be a car.

-

Driveshaft play at transmission end. Normal? (see video)

Went out and looked at an early 70 shaft and a 76 4 speed trans. with a dust shield and I'd guess that you have 2 1/2 - 3" of engagement, when you could have about 4 - 4 1/2". So, not fully engaged, but not so loose that it would pop out. There is a bushing/bearing inside the transmission though that helps locate the slip yoke. You may or may not be engaged with that. One member here had a worn bearing, different style of transmission though, and it allowed some looseness.

-

Driveshaft play at transmission end. Normal? (see video)

While you're under there you might as well unbolt the flange from the diff and see how much room there is to push in the trans. I'm pretty sure the factory only left about 3/4 - 1". Pretty full engagement. No need for more play because the diff and trans are both locked in to place. The slip yoke barely slips. Actually, it may be that the u-joint got torn up because the propeller shaft tried to come out of the transmission, got cocked and broke the u-joint. The shop might have just reproduced a too-short propeller shaft. Also, it might be too short because you have the later diff location, but the early shaft length. Just throwing out some possibilities.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Here's an interesting web site and an article by a consultant. Doesn't seem to have an axe to grind either way. Put your own search terms in, I had ZDDP in the first link. Lots of good reading (except for the format, it's Powerpoint or giant screen mode...) on all kinds of lubricants, grease oil, synthetic, additives... http://www.lubesngreases.com/search/?zkDo=search&publication=all&query=+zddp http://viewer.zmags.com/publication/20213322#/20213322/48 Obligatory edit. Had the wrong page linked. Also interesting that he's talking about the phosphorous component of ZDDP. And one reason to lower ZDDP is because of the sulfur content. So you can search all three words and find much more stuff. Zinc, phosphorous, or sulfur.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

The diesel oils do/did seem like a good option. But, I've seen some indications that diesel engines are or will be getting more regulated (good!), and may be using catalysts to clean up the emissions, and that the diesel oils are getting reformulated for that reason, just like the car oils did. The problem is that since ZDDP is not called out or spec'ed it could disappear with no obligation from the manufacturers to tell anyone. We'd never no. Might start another thread just to see if anyone has had a stock cam go bad, using plain old motor oil. Still curious. VR-1 and GT Racing oils are cheap enough though that the insurance factor makes sense. VR-1 is even available in the parts stores, no internet gyrations necessary.

-

Driveshaft play at transmission end. Normal? (see video)

It does look like it might be short. I think that the two dust/dirt shields usually overlap almost completely. Did the shop measure or did you, or did they use a factory specification? If they cut it to the early 1970 spec. it might be for the set-forward differential. Do you have the modification to move the diff back? Need more info. If you take a measurement, someone here can verify length. I have one of each style, short and long. Measure from the center of the u-joint caps. In the meantime, you could unbolt the shaft from the differential and push it in to the transmission to get an idea of how much engagement you're not getting. If you raise the back end high enough you might be able to remove it without losing your fluid.

-

Cam Wear?

Started a new thread! Good luck grannyknot. http://www.classiczcars.com/topic/51321-internet-expertise-exemplified-by-a-conversation-about-zinc/

-

Internet Expertise Exemplified By A Conversation About Zinc

Rather than fill grannyknot's thread with more stuff, I figured I'd just reply here to patcon's comment. Just not a fan of people who defend their positions too zealously with little but the internet to support it. From here, #35 - http://www.classiczcars.com/topic/51243-cam-wear/page-2 You have to go back to posts 16 and 17, two pages from Chickenman of links pulled from the internet with commentary, then read my reasonable post 18, then Chickenman's dismissive tone in post 19, to see how it starts...... Deleted some stuff.... Still... tuning out the bad vibes..