Everything posted by Zed Head

-

Cam Wear?

You're just not seeing the point. The "Critical Break-In Process" that the cam guys talk about is not the same as what's needed for use after break-in. I'm not re-inventing anything, I'm questioning unsupported dogma. As far as proven facts, I'd have to see some facts. Not just talk about some other "expert's" opinion. What a lot of other guys, or other engine builders or other people in general do, is just other stuff..

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Here's some ad copy from Comp Cams just to illustrate. Everything in the ad implies that you only need it for break-in. "The critical break-in process". http://www.compperformancegroupstores.com/store/merchant.mvc?Store_Code=CC&Screen=PROD&Product_Code=159 It is kind of amusing though that the break-in additive is an "extreme pressure additive". Like the stuff they put in GL-5 oils. One of the other lubricant issues that has some "can't hurt" concepts behind it.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

How did you break in the engine rebuild and was this a new cam, reground cam, or used stock cam? How many miles before damage and what kind of damage? "Appears" is the operative word. I'm trying to find out what's really needed. No offense. It's in the details somewhere. I saw the guys on Fast 'n' Loud destroy a cam in a rebuilt engine, supposedly because they used cheap oil and a zinc additive. It was a push rod engine. They got it rebuilt and used the "special break-in oil with zinc already in it" (Brad Penn?, couldn't tell) and went on their merry way. The car probably has 10 miles on it by now, and who knows, may have destroyed its cam again. Anyway, I see three regular oils with no major issues, two "can't hurts", a break-in plus a few oil changes, and a destroyed cam shaft (reason unclear), so far. Not judging or drawing a conclusion just collecting stories.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

Do they recommend it forever or for break-in and you just kept using it? Just to be clear. I get the "extra insurance" or "can't go wrong" inclination, I'm just really curious about the true need. In your case, you have a performance cam, maybe ground from Isky chosen material, not a regrind from Nissan metal? Does the Isky cam use stock springs or their own? Trying to get the details. Thanks for adding.

-

Zinc Additives, Cam Shaft Or Rocker Wear, And Mileage - A Poll

I'm on about mile # 30,000 of my old 1978 stock 280Z engine and have never used a zinc additive or special oil on this engine. Just common oils, like Quaker State and Pennzoil 10-40W. I think that my engine has about 150,000 miles on it. No problems or signs of excessive wear. If you have the time, please post some details on how many miles are on your engine, how many miles you've driven it since oils changed, and if you've had any cam shaft wear. Just trying to collect more real data on the zinc issue. Maybe I should be running Rotella.

-

Cam Wear?

Impressions are, by their nature, not incorrect. They are the result of what the person has experienced. Anyway, I've seen all of the writing on why people with old cars need to buy expensive oil. My point is that many, many, many of us don't use zinc additives on our old cars, and our cams and rockers are fine after many,. many, many miles. And, in addition, I've seen many accounts of people who used zinc additives during break-in, on essentially stock systems and still wiped their cams and rockers. When you collect all of the real world accounts, not just the theory, and do the math, reality doesn't match the theory. A poll would be interesting, to see how many people are running common oil on the their stock engines, and for how many miles. Compared to a poll of how many people have wiped a new cam lobe and/or rocker pad, while using zinc additives. If you wanted precise numbers.

-

Clutch Slave Cylinder Stainless Steel Hose Doesnt Fit

Pummeling this horse in to glue - here's a shot of the Beck Arnley hose. I noticed in the MSA link that that's an Earl's hose. They have a good rep, but times may have changed.

-

Clutch Slave Cylinder Stainless Steel Hose Doesnt Fit

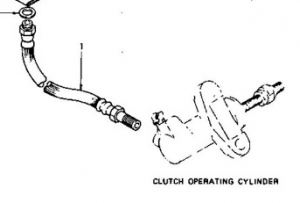

IF I was in a hurry or didn't want to bother with MSA, I'd cut and grind the end, then clean it up and use a new crush washer. But I have a grinder, and a vise and a few other tools. When I was looking for a replacement clutch hose like that but rubber, just an inexpensive one, and wasn't in a hurry, I found that essentially all of the rubber hoses at all of the auto parts stores and all over the internet, are the same hose and come from one place. So I bought one locally and it was not great quality and took a few tries with a new washer and probably overtorqueing to get it to seal. It's one of those odd low-volume parts. And, if you look in the manual, and various sources, the factory didn't seem to use a crush washer. So you may have a hose for the factory style cylinder that won't fit well on aftermarket slaves.

-

Cam Wear?

My impression has been the zinc additives are necessary for break-in, to build up a smooth case-hardened wear surface, but the cams and rocker arms do fine with today's common no-zinc oils after a proper break-in. I've been using common oil for ~30,000 miles on my current high mileage stock engine, from a 78 280Z, and did the same with my old 76 engine for about 25,000 miles. I did use 5 quarts of Rotella once on the 76 engine because it was on sale. Most of the cam problems happen with new or reground cams, shortly after break-in. Often, it's with the zinc-additives. There seems to be a general problem with the way cams and rockers are ground today. Makes you think that there's a bad specification out there that everybody is using, or the factory cams have a subtle profile to them that is important for long life. Like the fact that lash is typically higher one side of a lobe than the other. Maybe the grinders, cam or rockers, are grinding to a shape that applies to much pressure on a certain spot.

-

Clutch Slave Cylinder Stainless Steel Hose Doesnt Fit

Stainless steel braided clutch hoses aren't a factory item so you could argue that the hos is not "correct". But the slave cylinder is an aftermarket replica, so it is also "incorrect". MSA probably sourced a hose from a hose supplier based on diameter, thread size, and sealing surface. But not length of threaded area. You could cut the extra off and use it or send it back. MSA may or may not appreciate being told that they sources a part that doesn't fit correctly. Could also be that their supplier switched suppliers and supplied MSA with a part that doesn't work anymore. Basically, somebody left a spec. of the spec. sheet. It happens. Or, it's possible that they think or maybe it actually does, seal(s) at the bottom of the hole. I don't think its destined to seal that way though. I remember having issues getting my hose and slave cylinder to seal well. Flat on flat is a difficult pair to seal. I would just call MSA and tell them the hose fitting is too long. It's probably happened before.

-

Speedo Removal

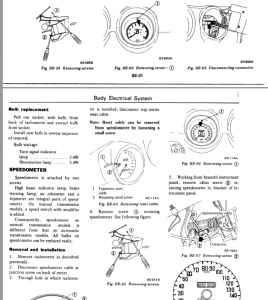

The 280Z's don't use the wingnut. There's one screw in the top of the ring in front of the lens, and one in the mounting bracket, dead center behind and underneath. Plus, at least on my 76, there is a bunch of clutter around the back of the gauges. Not much room at all. Good suggestion, but wrong car.

-

Speedo Removal

It's actually described that way in the FSM. Remove tachometer in order to remove speedometer.

-

Get The Data Right! Argggggh

To be rigorous, you'd have to know the individual part tolerances, and do a geometric dimensioning and tolerancing calculation to know the range of "pop-ups" possible. You could have a combination of +'s and -'s that are in spec. and give what yours shows.

-

Cam Wear?

On the orifices - don't forget the front one that feeds the chain oiler. Nobody ever talks about that one. If it got reamed out for some reason, it could unbalance the oil supply,

-

Cam Wear?

I was drawing the correlation between dribbling and cam wear. Seems like you might want to balance the hole outputs first, see where you're at, then estimate how extra oil you need to get a small squirt from each hole. One way to balance flow would be to close up the holes that squirt far to increase bar pressure and drive more oil out of the weak holes. You could probably peen the edges in with a small drift.

-

Cam Wear?

Does #5 dribble or squirt?

-

Accurate Head Gasket Measurements

I assume that you want the fire ring thickness. I have an old 76 HG, that I'm pretty sure is the original. Don't know if it has any ID numbers on it though.

-

Anyone Close To Lynwood Washington Or Redding Ca

How big is the part?

-

77 280Z Losing Pressure When Pressing Throttle

Sorry REAP, but your communication skills have diminished dramatically from your first post; misspellings, punctuation, grammar, odd phrases like "no response to throttle acceleration". The throttle doesn't accelerate. I can't figure out what you're trying to say. Seriously, I know you're on a phone somewhere texting, hopefully not while driving, but your posts don't make sense anymore. Put time in to the message and you'll probably figure things out before posting. I've solved a lot of problems just by trying to describe them. Feel free to replace the AFM, but you're probably wasting money. You can spend time on testing, or time AND money on replacing parts. The first is cheaper and more effective.

-

77 280Z Losing Pressure When Pressing Throttle

The AFM would not affect just two injectors. Don't get drawn in to replacing parts before doing the testing work. Since the car is new to you, one thing that will help you greatly is to just examine all of the critical parts of the engine, the AFM, the distributor, the injectors, manifolds, etc., recording part numbers, and making sure everything is connected correctly and intact. One reason people sell their cars is because they messed things up so bad that they can't figure them out any more. Then they sell the car, still messed up. Make sure the injectors have the right part numbers, and are the correct color for an NA engine. I picked up a wrecking yard engine that had a mixed set of wrong injectors. People get desperate when their engines don't run tight and do crazy things. The Engine Fuel chapter of the FSM has a series of simple tests you can run to figure out what's wrong. The lack of acceleration and the backfiring could be the AFM, or fuel pressure, or clogged injectors (maybe four are clogged and the PO made everything rich to compensate), or timing, or crossfire between plug wires, incorrect firing order.....many possibilities. http://www.nicoclub.com/FSM/280z/

-

'72 240Z Rebuild

Does it actually come from MSA, in California, or somewhere else? Return address? I wonder if MSA doesn't contract this out and maybe they don't know what's happening. You should send that picture to them so they know. Doesn't seem like their style. Looks like crap.

-

77 280Z Losing Pressure When Pressing Throttle

Your description is hard to figure. It sounds like the engine still runs, and for some reason you decided to look at the spark plugs and saw that two were wet. Describe how the engine runs, in general. Does it have a miss? Do cylinders 3 and 6 not work, you're running on four? Need a more general idea of what you're trying to fix. I can't tell what "lose pressure when the throttle is opened" means.

-

Speedo Removal

I had a half cap and got mine out using the various tricks. Still took the cap off just to see what was under, and because the gauge removal was such a pain. Replacing lights, tach going bad, etc. Luckily my cracks are still in the "added character' stage and not hideous. In my opinion. Fits with the paint and the small rust holes in the door bottoms too. The car is is very fun to drive but not steal-worthy. Doesn't help you get it out but might help make a decision. Is the cap tightly glued on? Maybe you can take it off, do your work, and replace it. Mine came off relatively easily, the silicone adhesive the PO used wasn't very strong, didn't adhere well and he didn't use a ton. Got lucky.

-

Anyone Have A Torque Plate For Sale?

These guys have them - http://www.bhjproducts.com/bhj_nav/nav_honePlate.php I think that they cost a lot.

-

Anyone Have A Torque Plate For Sale?

I've wondered they're not used on the head. Cam swaps, tower alignment, valve guides, stuff like that.