Everything posted by Zed Head

-

My Distributor Timing Is Horrible

Oh. So you do want to pull timing. In that case, the easiest thing to do might be to find a set of weights (and springs maybe) that have smaller numbers on them, and swap them for what you have. The numbers stamped on the weights are the max. distributor timing, which is doubled to give crankshaft timing. So if you have 24 degrees advance, the weights should be stamped with 12's. The notches in weights determine how far they move. The springs determine when things start to happen and how fast it finishes. I'd get some 1978 280Z parts, they typically have 9 or 9.5 weights. 18 or 19 total, so 33 or 34 with 15 initial. Somebody would probably mail you a set for a few dollars from an old toasted distributor. Specs. are in the FSM's, pick what you want and put some feelers out.

-

Engine Head Plug Sizes

Just one of those lucky cases where thread sizes overlap. Be careful, since you're not getting full, proper, thread contact. You could damage the aluminum head. Actually, those threads may not be metric. But they would still be British. McMaster Carr has BSPT. 1/2" pipe plugs too. http://www.mcmaster.com/#aluminum-british-standard-thread-pipe-fittings/=whyvyg

-

Choices

Have you looked around for an N42 or N47 head? Might be the quickest, easiest way to get to the 75-79 L28 performance level. Someone might trade you for one of those other three heads.

-

Stolen 240Z

That's a good idea about the local news. They're running a story in my area right now about a 57 Chevy that got stolen. They're also running stories like this - http://www.kptv.com/story/28626948/missing-pink-chickens-dyed-birds-show-up-on-portland-waterfront?autostart=true

-

Engine Head Plug Sizes

Not sure what you plan to do with 1/2" but the threads are metric. You can also connect the return hose to the supply line and put a kink in it, or clamp it. It doesn't need to be completely blocked, just mostly.

-

Engine Head Plug Sizes

Might be available - http://www.courtesyparts.com/plug-p-237513.html http://www.carpartsmanual.com/datsuns30/DatsunZIndex/Engine280Z/CylinderBlock/tabid/1598/Default.aspx (17)

-

Afm Spring Adjustment - Bothersome Thoughts

Pondering how to make stone softer...

-

Afm Spring Adjustment - Bothersome Thoughts

The flow bench would probably tell the story. Three runs; stock setting, loose spring, tight spring, with voltage readings. He must need a diversion by now.

-

Water Pump Replacement (And Fan Clutch?)

The pulley charge might be big money for an unnecessary detail. Might be worth asking what the change is. You might find a used pulley or be able to make the old one work. On the fan clutch, are you sure the old one is bad? They don't seem to fail much. You might be more bulletproof and cheaper using inexact parts and adding a fan shroud.

-

Engine Head Plug Sizes

If you have extra engine blocks, the block drain plug (under the intake manifold) is the same size as the head elbow. Here's another possibility, depending on why you're blocking it - the vacuum water **** (rooster) blocks water flow. You can leave the head hose connected and disconnect the vacuum supply. That's one, the return line still needs a solution. But you could loop the heater hose return line around under the dash, both sides to the vacuum water **** (rooster), which is closed. Just getting creative, only works if you have the water **** (rooster). Watercokc, watercock, water ****.

- Water Pump Replacement (And Fan Clutch?)

-

Another MSD problem.

Tach adapter for tach. Pin 18 to trigger injectors. FSM. Engine Fuel system.

-

Another MSD problem.

Blue wire. Pin 18 (assuming 79 system).

- Another MSD problem.

-

My Distributor Timing Is Horrible

I read a really interesting thread from long ago by a guy who tuned his car by butt-dyno and advancing timing until pinging started. Then he got it on a real dyno and found at that he was actually leaving power behind because the ping zone was not the max power zone. He had too much advance. You might be spending time on something that won't get you much. And as madkaw notes, "total timing sucks" really isn't accurate enough to act on.

-

Another MSD problem.

Start a new thread and fill the first post with complete sentences. Yes?

-

Google Image Search Experiment

Didn't work well. Google thinks it's a transmission part.

-

Google Image Search Experiment

-

I'm About Done With The %**&ing Efi

Those are diagnostic wires, apparently. The wiring diagram says "Control Unit Checking Terminal". I can feel the frustration in this thread but I still don't see any measurement of actual mileage, and can't see any problem based on the information supplied. If gas mileage was not raised as an issue, a person could look at all of the measurements, pictures and part descriptions and would say "congratulations, your engine is running as well as it ever will". I just can't see anything to fix. The plugs in Post #78 look fine, except for two that look rich. But the others will probably go too lean if you make changes to overall engine tune. If you could get to flat land, fill your tank, drive a 100 or mile miles, refill and calculate mileage, that would be a good "calibration" check against the rest of the world. You're up in the mountains, climbing some hills, and might have unrealistic expectations.

-

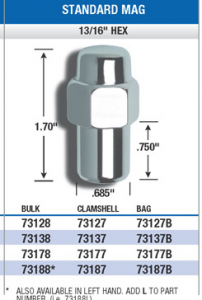

Anyone Have Any Spare Lug Nuts?

-

Anyone Have Any Spare Lug Nuts?

I had a hard time finding nuts for my mags also. Finally found them at either a Baxter or an Oreilly's. Gorrila nuts. Looks like you might be able to get them on Amazon. I'm not positive on size, or thread, but Amazon says 73127 fits. Due diligence. http://www.gorilla-auto.com/lug-nuts-page-09 http://www.amazon.com/Gorilla-Automotive-73127-Standard-Thread/dp/B002801QO4

-

I'm About Done With The %**&ing Efi

Thought of this a few days ago - maybe you have the wrong speedo gear in your transmission. Are you really getting a calculated 10 mpg, or just saying "wow it's on E already"? No offense, but 10 is a nice round number. The gauge hits E after about 12 gallons from Full. Also, I don't think you've mentioned your driving style on these bad mpg trips. If you're climbing a lot of hills and goosing it often, you could easily burn some extra fuel. It's a performance engine, designed to burn fuel if asked. Your plugs don't look like 10 mpg plugs, as noted. I took another look at your post 44 numbers and they look just like my old setup (except for the TPS NG) with stock injectors, that typically got 18-20 mpg. That's mostly flat land, but with goosing.

-

My Distributor Timing Is Horrible

"Pulling" timing usually means retarding. But you said that you're pinging in the "4th gear test". I remember timing a 400 Pontiac engine by the punch-it-at-low RPM-in-a-higher-gear-test. But that was a big torquey low-mid RPM usage engine in a big heavy car. Even back then I thought it was not a good way to do things but I was just a dummy back then (no offense). I don't think that you can tune for power with that kind of method on these smaller engines, designed for high RPM power. One way to verify mechanical advance is tune turn the initial timing back to zero with the engine running, disconnect the vacuum advance, then rev the engine up until the timing stops advancing. The mark should stay on the indicator or be within a couple of degrees. I've only see up to 11 on advance weights (maybe it was a Spinal Tap car). On the .080". The ignition system can probably do it, but the problem with big gaps is that the spark takes the easiest path. .080" is hard to jump so you can get sparks grounding in places they shouldn't, through your wires or dirt in the cap, and other lower resistance paths. Plus .080 with a dense charge in the cylinder will be where it's most likely to miss. You don't really need more .040 or .045". You haven't mentioned anything else about the engine either. Higher CR will make it more likely to ping.

-

I'm About Done With The %**&ing Efi

Here's something I just went through to pass emissions in Oregon. I have non-stock injectors that flow a little higher than stock and I failed my first time through. I tried my usual tuning tricks and failed two more times. CO was high,which means too much fuel for the oxygen supplied. So I dropped my fuel pressure by a few psi (I have an adjustable FPR) and turned the idle air bypass on the AFM out until I heard a change in idle quality. I had intended to lean things out until I got a lean miss, then dial it back up, but didn't get that far. But I did notice a distinct change in idle quality at a certain point, beyond which not much happened. So I left it there, went back and passed. My point is, I guess, that you could dial that AFM spring wheel tighter until you hit that idle change point, and try that. I just posted a thought on the spring in another thread, that I think is right, but I may be off. Since fuel is mostly low air flow at high RPM, the spring adjustment could be a big part of your mpg problem. I think that adding a resistor in parallel with the coolant circuit will change the slope of the curve and might really make things weird. It would make every temperature lower resistance (leaner), but have very dramatic effect at low temperature, where resistance should be very high, and little at high temperature where resistance is very low. Could get confusing. It might barely run cold because things look hot. You could put it on a switch maybe and only put it in-circuit when the engine warmed up.

-

Afm Spring Adjustment - Bothersome Thoughts

I haven't been able to really define what it is about adjusting the spring of the AFM that bothers me. But I think I've narrowed to down to one thing - preload. Preload affects when the vane starts to move due to air flow and should be an exact number, matched to the idle air bypass in the AFM and the throttle blade idle air bypass. Any adjustment of the AFM spring wheel will affect that three way relationship. That's probably why the factory glues the wheel down when they've adjusted it. But preload does not affect spring rate so once the vane starts moving the change in injector time versus vane position goes to the original design goals. If you tighten the spring, the engine gets extra air before the vane moves and enrichment starts. But it's only a certain amount of low flow air. So you'll be leaner at the low air flow than at high air flow. If you loosen the spring you'll get extra enrichment at low air flow, but the effect will diminish at higher air flow. So you'll be richer at low air flow but little effect at high air flow. The spring is a spiral spring with essentially constant spring rate over the range of movement in the application. So, unlike the potentiometer on the coolant temperature sensor modification, the AFM spring adjustment really only has significant effect at low air flow conditions. The potentiometer affects the full range of conditions. Springs are weird things that are pretty simple until you try to figure out how to use them.