Everything posted by Zed Head

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

The possibility of a wiring diagram error did pop in it to my head last night (again, I think it's been in there before). I might pop that resistor out and see if Pin #1 still has a path to the coil. We might hit 70 degrees here today. Weird weather. If the resistor is inline with Pin 1, instead of branched, that would explain why no resistor caused no-run. BUT, I discovered the phenomenon when I tried to move my car with the tachometer out. Anyway, one of those puzzles "Ground by wire" would have been more descriptive. My meaning was more that it doesn't depend on a ground through the mounting bolts, although it may also ground there. It's been in the back of my head that it could just be an ECU problem. But, the weird tach behavior is there. I hope a clear answer and solution comes out, even if it's just localizing the issue to one component. Nothing worse that a problem that disappears for no reason.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

I would check the ground wire for the tach first. If the tach is losing ground it would be like disconnecting the tach. If everything looks right though, and you want to try running it without the tachometer, in case the tach is causing the problem, then try grounding the resistor. The fact that you still have spark but the tach stops working seems to show that you're losing that path to ground. Either because the circuit is broken inside the tach, or because the tachometer's ground wire is bad. And I know that the EFI engine won't start without the tach. It might cough a few times from some cold start valve fuel but won't run. I had the resistor fall out on my car once and the engine didn't even pop, but I don't have a CSV. I put the resistor back in and it fired right up. I've repeated the experiment, on purpose, since then. Some people don't believe it, but it's easy to test. Pop the resistor out - no start. Replace - back to normal. Anyway, that's just some background Keep looking at diagrams and testing parts and something will crop up. I know someone who had a corroded fuse that would overheat just from current flow, causing everything to shut off. Sit for a few minutes and it would start right back up. That was a BMW though.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

So here's a possibility - your tachometer might be losing ground, or failing, causing a loss of ground on that wire. From my own experience, the EFI system's will not work if the tachometer is disconnected. So the "trick" i mentioned would be to find the resistor under the dash, disconnect the side that goes to the tach, and connect it directly to ground. I ran an engine in my garage like this with no problems. The resistor is very high resistance so no chance of burning wires. superlen or Captain Obvious or SteveJ might have some thoughts on why the computer needs the tach to work. All I know is that they need it. You might also check the tach's ground. The wiring diagram shows a dedicated ground wire through C1 for 1977. Page BE-31.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

The ECU's pin #1 is on the same wire as the tach signal. I wonder if a bad tach could cause the ECU to stop working right. Or if a bad ECU could cause the tach to stop working even though there's spark. Yes, sometimes you can stuck in a weird place. Have you tried tapping/beating on the side of the ECU when it dies? Others have reported that that has temporarily fixed bad ECU connections. The solder joints crack and lose their connection at the main connector. I know a trick you could try to take the tachometer out of the picture but it might make you uncomfortable.

-

Slipping Clutch.

I thought you might be able to remember the pattern of the bolts, tightening two that were close together or six evenly spaced. Anyway, you can always return it and start again. OReillys will usually bring parts in just to look at. Might be worthwhile to just have them bring both in. Don't forget to drain the new fluid, for reuse, before taking the trans. back out.

-

Slipping Clutch.

One last thing - there are two sizes of clutch, 225 and 240mm. The bolt patterns of the pressure plate assembly are different, and the height. Do you know which you have? Some people use the 240 mm for performance applications. They came stock on 2+2's and the later ZX turbo cars. The visible difference is that the 240 has 6 evenly spaced mounting holes and the 225 has 3 sets of 2 closely spaced holes. The factory fywheels only fit one style each. So if you ordered the clutch for the car model, or the transmission, it could still be wrong. More to worry about.

-

Slipping Clutch.

Look through the link in Post #5. It shows how to take a measurement that will tell you how far off your collar is.

-

Slipping Clutch.

It's happened before. You probably got the collar and bearing with the transmission and the pressure plate and disc separately, right? Bummer. Hopefully the parts didn't take too much heat. Some clutch kits come with a collar included so there's no mismatch possible.

-

Slipping Clutch.

Here's another - http://www.classiczcars.com/topic/44389-l28-is-toasting-my-240z-clutch/page-2 92-95 mm from the fork surface of the collar to the flywheel surface is the key. That puts the end of the fork in the right spot for the slave cylinder and its rod. By the way, when Diseazd says "clutch" I think that he's talking about the whole assembly of pressure plate aka "cover" and clutch disc. The pressure plate and its cover come in different heights, that need different throwout bearing collars.

-

1971 Datsun 240Z - Restoration

Neat. But it looks like an ad for a shop. If it is, the OP should just say so.

-

Only Runs While Throttle Is Wide Open..

Don't wizz off the carb guys! They have the answers! These carbs are not like many, in that they have pistons inside, with damping oil to control their movement, and require exquisite tuning to work correctly. `Seriously, they are different from a USA-type Rochester (for example) carb. If you don;t have the right oil inside you might have problems. Post a new thread with "Problems with SU's " in the title and you'll get some pros to take a look. If you've covered all of the basics, carb problems are likely.

-

Only Runs While Throttle Is Wide Open..

You say "throttle wide open" but later it looks like you mean "throttle pedal pushed to the floor". What's really happening at the carburetors? And what type are they? That might be the key. Also, what do you mean by "shot" with reference to the three plugs? And "turn over" is what the starter does. "Fire" would be descriptive of the engine trying to start. And, although it probably doesn't matter, one person's "good" is another's "maybe bad". If you got numbers, you might as well throw them out there. If you're checking compression with your thumb though, that's a problem. Numbers are always good to look at. Full disclosure - I haven't had a carbureted car since 1995.

-

Making Fusible Links

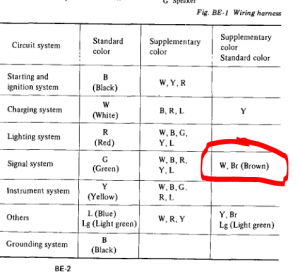

Br means brown. This comes up occasionally. I'm guessing that the early "Brown" Nissan links looked red. Then people went by color, not the letters, some web pages were made, and we're locked in to Red forever.

-

Importance Of Heat Shields

I have some of that foil covered bubble wrap hanging and placed in strategic spots in the engine bay. My HEI module swap was getting kind of hot (I mounted it on the fenderwell, line-of-sight to the exhaust manifold) so I hung some insulation from the edge of the manifold just to test. It works well, reflective and insulating, and the base materials have a temperature rating of about 230 F. It's still there.

-

Gm Hei Module Upgrade

Most of what you describe sounds like a bad tach. But the thing with the clutch pedal sounds like a loose or shorted wire, in the vicinity of the clutch pedal. I don't think that there are any electrical switches at all on a 77 Z, so mechanical movement of something is the only other option. The wire to the tach has a high ohm resistor inline so it could probably be dead-shorted with no fuse-blowing or wire-melting. I'd look around under the dash. Not really sure how the blue wire could be affected but who knows.

-

Gm Hei Module Upgrade

EuroDat supplied one in Post #2 of your other thread. You would just need to extend and connect the red and green wires from inside your distributor to the red and green wires that run to the old TIU by the fusebox. The E12-80 is essentially just the big TIU reduced in size and moved to the distributor body. And even though the inside of the distributors look different the old 77 and the newer ZX type both use the same triggering mechanism. The red and green wires are the key.

-

Fi Ecu Mods And Differences?

All three of these are different, but all three have some similarities. Look at what looks like a screw terminal at the top. Mine and your "modern" unit have the same number of filled spots. Your older one has many more. But mine and your old one have the same heat sink parts (I don't know my parts...). And the circuit boards themselves are all three different. Edit - actually the later lots, mine and yours, have similar circuit boards. But different parts filling the holes. Probably made at various subcontractors to some performance spec. Maybe.

-

Fi Ecu Mods And Differences?

Here's Lot #8107. No clues here. I don't think I've seen any with the shiny new parts yours shows. They all have the circular heat sinks. Maybe yours is a rebuilt unit.

-

Fi Ecu Mods And Differences?

That is interesting, They build to specs. though, maybe the component quality just got better. I have several of those, if I have a later lot number than the first one, I'll open it up and see what's in there. Maybe there's a certain break-point number to look for, to get more modern parts (designed 39 years ago instead of 40). The ECU doesn't control the fuel pump relay, the AFM switch does. Although I think there are some diagrams out there that show some interaction with some ECU pins. But there are also errors in the early ECU wiring diagrams. Pins that don't exist. Somewhere out there is a list of what the various resistors and capacitors do. But the work needed to make changes is difficult. Easier to just add a potentiometer to the coolant temp. circuit. Change the inputs, not the ECU parts.

-

Manual Transmission Oil. What's Best?

The thing about "limited-slip" lube is that it is designed specifically for limited slip clutches. Which may have different needs than synchro rings. They both slip then grab, but that may not be good enough. The only reason I tried the Swepco, which is really an out-of-left-field option, is because jmortensen recommended it, and had lots of experience with it from working in a shop that used it on hundreds or thousands of cars. It was a proven lubricant. Even so, it's still an odd usage, blended with ATF fluid, which is not GL-4 or -5 rated. Anyway, personally, if I was starting from scratch, I wouldn't use anything that didn't say "okay for yellow metal synchros" on the label. That's what everyone should look for, not GL-5. In my opinion. The GL-5 issue is very well known so if a manufacturer doesn't bring it up, they probably haven't tested. Why they would take a chance on causing damage though, doesn't make sense. They should either have a warning or a comforting message.

-

Another Coolant Leak

Has it ever overheated in those miles? The aluminum heads don't like overheating. Depending on your spare parts pile or availability, maybe it's time for another reworked head. Then you'll have a spare to dink around with.

-

Fi Ecu Mods And Differences?

The A11 number tells the application. There are many other A11 numbers. Your three should all work the same. superlen has expertise, as well as Captain Obvious (I think). superlen is/was developing an ECU replacement, more modern and tunable.

-

Manual Transmission Oil. What's Best?

Edit! - no offense to anyone who lives by the "avoid GL-5" rule. I'm just offering a little more background to the issue. If they address the issue, odds are good that it will work fine. Royal Purple is a well-established company. Probably, way back in the past, somebody produced a GL-5 rated high pressure lube that caused synchros to get trashed. From then on, the only identifier that people could tie to the problem was "GL-5". Forevermore, "GL-5 is bad for synchros". This is how out-dated products live on. Wouldn't be surprised (actually I think that I've seen ad copy that does this) if manufacturers of old products helped spread the rumor. I'm using GL-5 rated Swepco 201 right now in my 1980 5 speed. It's been in there for about 20,000 miles at least. Not a single sign of a problem. It's just one of those comfort-level things, and as shown by the Royal Purple product, looking at what the product was designed for. The spec. is just one of many factors. One product can meet several specs. Staying comfortable can be limiting. http://www.royalpurpleindustrial.com/assets/MAX-GEAR-PDS.pdf http://royalpurpleindustrial.com/assets/Max-Gear-product-sheet.pdf http://www.swepcolube.com/products/swepco-201-multi-purpose-gear-lube Here's an old PDF file from Swepco that tells a few things about the confusion. Doesn't seem to be around on the internet anymore. SWEPCO GL4 and 5 TG_199508.pdf

-

Manual Transmission Oil. What's Best?

The sulfur question is more complicated than just GL-4 versus GL-5. There are GL-5 rated lubes out there that work fine with "yellow-metal" synchros. The GL spec. is a performance specification, and doesn't tell anything about how the formulator made the lube hit the spec. number. It's a pretty interesting area if you're in to that kind of thing. But, overall, it's most effective to just go with what has worked for other people. Redline has a great reputation.

-

77 Z Drives For About 10 To 15 Minutes,then Dies.

That's a good question. I think that the ZX module's have current-limiting technology like the HEI modules, which should work with any coil of higher resistance than stock. But I can't find any documentation, and the ZX coils are 0.84 - 1.02 ohms, higher than the HEI's ~0.5 - 0.7 ohms, and higher than the early 280Z's ~ 0.5 ohms. . You might measure yours, since aftermarket parts tend to vary. If you're around 1 ohm, you're probably fine. Note also that the manufacturer's spec their parts to last 10's of thousands of miles. If your coil's not getting hot it's probably not a problem. It's the heat over time that bakes them.