Everything posted by Zed Head

-

Annoying/frustrating No Start Condition

There's something about the formats and layouts of the various forums that affects the replies, I think. The zcar.com forum tends to make a person cranky. It's primitive and clunky and dull,and leads to irritated responses. Hybridz seems more serious and, like serious people do, leads to simple questions being ignored. This forum is just generally pleasing to use and look at and has that affect on the replies. It will be disappointing though when Davidz1911 comes back with another problem. I'm going to guess that the AFM plug was loose and the engine was only getting idle speed fuel from the ECU.

-

Annoying/frustrating No Start Condition

What did you find? You might be back in two days. We like to know the details, otherwise it's like watching a movie with no ending. Plus, it will help out the guy or gal with a similar problem, in the future.

-

Annoying/frustrating No Start Condition

Your symptoms sound like a loss of fuel pressure. Fuel flow is one thing, correct pressure is another. You need to measure pressure while the problem happens. Stick a gauge on and watch. Fuel pump motors and relays can get hot as current flows and stop working correctly. I've had a fuel pump that did that as have others here. The pump created pressure for about 5 minutes then it slowly died away as the motor stopped spinning. I thought your post looked familiar. You've changed some things but no big deal. Pretty sure I didn't call you an idiot on the other thread, it took me a while myself to figure out the Z's EFI system. The key is actually measuring things. Corroded-looking connections can be fine and clean ones can be bad. You'll waste a lot of time and probably create new problems "fixing" things because they look bad. Best to measure and confirm first.

-

Annoying/frustrating No Start Condition

EGR could be sticking. That would lean out the mixture (actually not "lean" but "charge-deficient"). Try turning up the idle speed screw to see if you can keep it running while you diagnose things. By the way, you described a "won't stay running" condition, not a "won't start".

- 1976 280Z Restoration Project

-

'72 240Z Rebuild

Seems like one of the reasons that people like to work with Rebello or DatsunSpirit is because the owners share what they know and the customer learns something when it's all done. Your guys seem more like the old, classic, "leave it there and we'll call you when we're done" kind of guys. Guys that always come in at the top end of the quote range and call you with "problems" found requiring more work. I think the descriptive word is sketchy. On notching the block, a general trick that I learned from a machinist is to turn the block upside down. The grinding or filing chips will fall away from the cylinders. That's if you're planning to leave the block assembled.

-

'72 240Z Rebuild

Saw this on zcar. They're standard bore so if you go over not much use. But might be useful if the bores are good but pistons not. http://www.zcar.com/forum/19-sale-parts-accessories/367049-nos-piston-wrist-pin-set-l24-flat-top-240z.html Tried to learn what "Ttt" means but all the internet came up with is "third tier toilet". Not sure why he says that... Also, just because it's interesting - http://www.art-piston.co.jp/en/profile.htm

-

E88 Head With N42 Components And Cam.

The rocker arms generally follow the cam and the individual lobes. On the towers, the thought seems to be that if you can move things around to where the cam spins freely you're good. That's what I've seen described. Otherwise, you'd have to get a new set of cam towers when you bought a new cam.

-

E88 Head With N42 Components And Cam.

Those are good points. The one about the cam turning freely and align-boring is one of those areas where Nissan and the rest of the world seem to disagree. Nissan would have you replace the whole head, but there's much written about tapping the cam towers when installing to get them adjusted so the cam will turn freely. People swap towers all the time apparently.

-

E88 Head With N42 Components And Cam.

It should be fine. The oil flow is controlled by a restrictor in the head gasket, not the passages in the block or head or towers, and the size is the same for spray bar and internally oiled cams. And the oil pumps are the same also, old versus new. So the same quantity of oil is flowing to the cam towers. From there, oil flow and pressure is controlled by either the holes in the spray bar, or the holes in the camshaft. But they both start with the same amount.

-

Where Did The Classified Ads Go?

Tapatalk is associated with your phone, It's an app. It's not necessary. What happens when you click "no" to the question?

-

Rocker Geometry Woes

Yeah, it is interesting, The guy that makes them has been around for quite a while and seems to know what he's doing. But Nissan used to make a one-piece arm, with a chrome-plated rubbing pad, and they switched to the brazed on pad made of more wear-resistant material. So even if the loads are handled fine you have to wonder about longevity.

-

Rocker Geometry Woes

Could spend more - http://www.zccjdm.com/catalog.php/azcarbum/pd2120660

-

240Z Aftermarket Itm Pistons Issues

Not to pick on your builder but he could mock things up with your old gasket, or no gasket and some math, and some clay or soldering wire, and actually measure the clearance. Most of us get disturbed because we don't have the experience or the tools but this should not be a big deal. If he came to you and said "the new pistons are only .015" from the head and that's a problem" that would make sense since there are general guidelines/thoughts on that clearance. But the consternation over .007", right off the bat, seems odd. Either you're not getting the complete message or he's getting disturbed over something he shouldn't be. Anyway, it's all part of the game.

-

280Zx Matchbox On A 76 280Z Dizzy

Once you get started you'll find that it's really not too hard to get the wires right. Even with a complete diagram, you should always check your wires with a meter or test light, just to be sure. It's a bad feeling to watch smoke rising or see sparks when you decided to just take a chance and trust somebody else's write-up or memory..

-

240Z Aftermarket Itm Pistons Issues

Disturbing. Their web catalog of services says that they work on 81-83 L28's, which all have a pop-up of ~.020". He shouldn't have been surprised and should have compared to the old pistons right away. Not really clear what the problem is. If the new ITM's are just a hair off the old, what's to be right pissed off about?

-

240Z Aftermarket Itm Pistons Issues

That is ever so much clearer. Kidding. Kind of. Seriously, you need numbers. Really though, your engine builder should be familiar with this and know how to deal with it if he's experienced with the engines. Nissan pistons are all essentially the same except for flat-top versus dished. Did he say it was a problem or just mention it in passing?

-

240Z E31 Head Gasket Options

If there is nothing special about the sealing edges of the water passages in the gasket, I would just drill the newer gasket to match the older. Clamp the gasket between two blocks of wood. It's a common method to prevent tearing or chipping of sensitive material. Or carve the holes out with an exacto knife. Not as hard as it seems, if there's no metal layer.

-

240Z Aftermarket Itm Pistons Issues

Which is old and which is ITM? You don't really say which is which. There's much written about L28's and piston pop-up of about .022" but I can't find much on L24's. BRAAP measured a bunch of L28's with flat-tops. Post #19. http://forums.hybridz.org/topic/58127-best-way-to-achieve-piston-to-head-clearance/

-

240Z E31 Head Gasket Options

I usually ask a bunch of questions to learn from, then go with the opinion of the expert. In your case, if you choose and things go wrong, the builder can say "told you so". If you go with his choice and things go wrong, he ll be more likely to make it right. Good luck.

-

240Z E31 Head Gasket Options

What do you mean by "quality"? Just curious. I would rather use an ugly gasket on that does the job best, than a shiny smooth one that has problems. Just saying, once it's buried under the head they all look the same. Head gasket discussions are always interesting. Who is your engine builder? Is he experienced with these engines or just engines in general? p.s. It's champing, not chomping.

-

240Z E31 Head Gasket Options

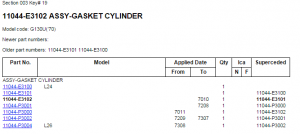

Here's some interesting stuff. Follow the supercession path and you end up at - 11044-E3102 (I think). I'm guessing the P3... numbers are E88, maybe. Courtesy Nissan shows potential - http://www.courtesyparts.com/gasket-cyl-p-239863.html Of course, there's an assumption that only the gasket changed, not the head. And with Nissan, you might still get a different part when you order it. By the way, the Stone gasket seems to be one of the cheaper gaskets out on the internet. If you trust RockAuto and Beck Arnley, there's a $62 HG on the Rockauto site, with the Beck Arnley history behind it. They seem to know what they're doing. Also, on "graphite" material. I think that's meaningless. True graphite would be useless as a gasket material. I think people call anything that looks like it's fibrous, and is black, "graphite". I posted a link to Oliver's ZSpecialties site. Personally, I would go with the opinion of somebody who's rebuilt a lot of engines, if you can get it from them. They're the ones who get complained to when the HG fails. Maybe Eiji would be worth a call, or Rebello.

-

280Zx Matchbox On A 76 280Z Dizzy

The brown is from the other pickup coil. Just insulate the end so it doesn't generate random sparks. Edit - forgot to say, you'll lose the 6 degrees of vacuum advance from the water temperature switch activation. That's another wire that will need to be insulated, I think it's powered with the key. What all of the wires and the extra pickup coil do is described in the Engine Electrical chapter. I did something similar a while ago. Wired a 1978 plug on to the 1976 connection terminal strip so that so that I could use a 1978 module. It's doable. Locate red and green, insulate and set aside the brown, determine which one is hot with the key on (it's connected to coil positive), and figure out which is coil negative (pretty sure it's blue). The colors at the coil and distributor are the same as at the module.

-

280Zx Matchbox On A 76 280Z Dizzy

You never really said why you want to do this. Are you missing the stock unit or do you think it's not working right? Here's the link from EuroDat's work with the GM HEI module. Same idea, 4 connections and ground the metal base. http://www.classiczcars.com/topic/49588-fitting-a-hei-module-in-transistor-ignition-unit-1977-280z/ You'll probably have some extra wires down there from the other magnetic pickup coil. And you'll need to figure out which wire is power and which is to coil negative. Engine Electrical chapter should help. Or just use a meter.

-

280Zx Matchbox On A 76 280Z Dizzy

It's not dead, it just links to the originators web page. Looks like he moved some things. It used to be there. Regardless, everybody knows that wiring diagrams are in the FSM. The wires at the ignition module are red and green though. Stick your head under the passenger dash and look. With Steve J's post you have everything you need. Don't forget to make good contact between the metal back of the E12-80 module and ground. That's where the current through the coil ends up.