Everything posted by Zed Head

-

Charging System Woes....working But Not Working?

Your numbers look normal and don't show any functional problems with the system. Your alternator is just on the weak side. They don't put out their rated current at low RPM, only at high (see attached). Pretty common. A different alternator, same style, might solve the problem. It's kind of a crap shoot unfortunately.

-

Gm Hei Swap No Spark

74 was the first year of electronic. The blue tach wire runs to the ignition module. It's a branched circuit. Stick your head up by the fuse box and make sure the module is unplugged. Could be your problem.

-

Front Cover/dizzy Hold-Down

Do you have a link? The site below is typically known as Arizona Z Car. It's one of my most unfavorite web sites to try to get around in. Maybe there's another out there. http://www.arizonazcar.com/

-

Junkyard Clutch And Flywheel Should I Use It?

I'm down to the odd trim part now, in my searches. For 280Z's. I kind of miss the hunt but the garage is full of spare parts. The first few years I had my car, quite a few Z's went through. Things have gotten sparse lately. I've been to the Tacoma yard and it's not as pleasant as the three Portland PnP's. Plus it's hard to get to. Don't go unless you know they have something you want.

-

Junkyard Clutch And Flywheel Should I Use It?

Wasn't me. I have all of the flywheels I need. Keep an eye out for a 12 mm Ace Hardware wrench. Lost it a couple of years ago. I am net positive on tools found though...

-

Gm Hei Swap No Spark

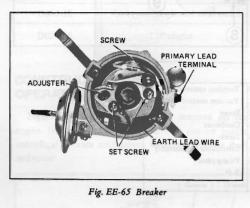

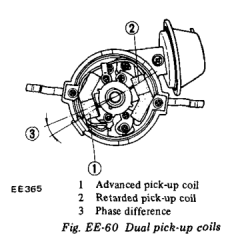

There should be alternating voltage between red and green as you spin the distributor. That's what triggers the module. You won't see much on a meter but you should see some variation. You can also measure resistance of the pickup coil (green to red wires when disconnected) to see if it's in spec. Is the original module still connected under the dash? That might keep current flowing on the coil circuit. Which would keep the coil from sparking. Not sure why it wouldn't do the same with points but maybe you left the blue wire off for the quick points system test. Also see that you didn't mention the rotor. People have been known to forget to install it. I did once. Forgot to say - of course, there's a test procedure in the Factory Service Manual. Engine Electrical chapter, any 280Z FSM.

-

Junkyard Clutch And Flywheel Should I Use It?

For what it's worth, I bought a junkyard flywheel and pressure plate with the intention of using them eventually. I didn't get the disc, it looked like it had grease on it. And I'm using a used flywheel now, that I sanded clean, from a parts car. With a new pressure plate and disc. If the ZX is a 2+2 it's probably a 240mm clutch and flywheel. The clutch discs will swap from 240 up through 280ZX but need to match the pressure plate and flywheel. Coupes use 225mm, 2+2 and Turbo use 240mm. If you decide to do it, get the throwout bearing collar also. It matches the pressure plate height. That would be a complete set, ready to go.

-

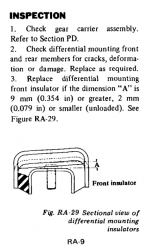

Mustache Bar Bushings... Anything Special I Need To Know?

To Blue's point - it's hard to tell if the diff mount is really in good shape, when it's on the car. The loose rubber is not obvious. I think that the "clunk" is actually the sound of the diff dropping back down on to the crossmember and mount after the loose rubber lets it lift. It doesn't have to lift far to make a noise when it drops back down. The strap doesn't really come in to play. I thought mine was fine, but once I replaced it, I stuck it in a vise and could pry the two pieces apart easily with a big screwdriver. And there's actually a measurement you can make, shown in the Rear Suspension chapter, to help determine if the rubber is worn. Also hard to tell if the u-joints are good without sticking a screwdriver in to the joint and reefing ti around while watching the seams of the seal with a strong light. Twisting the half-shaft by hand won't really do it. They see a lot more when in action.

-

Mustache Bar Bushings... Anything Special I Need To Know?

It's been posted occasionally that one-wheel burnouts are the death of a diff. The hole for the spider gear pinion shafts wallows out. I've seen pictures where the hole is so worn that you can see the ovality and the looseness of the shafts. You might see something if you pop the cover. Kind of confusing that the deeper you go in the diff, the more "pinions" there are...

-

Front Cover/dizzy Hold-Down

Does that part show up on the Arizona Z Car web site or do you have to call them? I tried to find it but the AZC site is kind of a mess. There's someone on another forum looking for one.

-

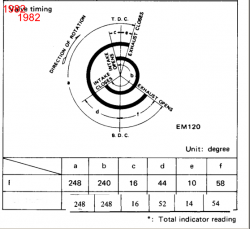

280ZX Distributor Advance Curve Reference

I think that the differences between the two engines might be very small. The change in HP calculation methods really confused any comparisons. But if you look at the specs, it seems like the old style engines should actually have the power edge. The cam specs are a hair better for the N42/N42 engines. The CR is a hair higher for the later ZX engines. 8.8 vs. 83. The intake manifold is smaller on the ZX engines, and so is the throttle body. The cam specs for the old engine should produce more power. Really hard to tell, but it's probably just a few HP either way, with maybe a different shape to the power curves. I have a spare 1981 ZX engine in my garage myself. I bought it because it was in good shape, the price was right, and I thought that it might be a little "better", But after digging in to the details I can't find the better part. Seems a wash. On the other hand, the later ZX's ECU and EFI system could offer potential for a small investment of time. Probably has a more developed fueling algorithm, and it has an O2 sensor feedback for efficiency. Tried to cobble/copy the specs in for 76 v 82. Intake open duration is 8 degrees longer, and stays open 8 degrees later for 1976. Which should allow more charge to enter. But the lifts are the same, I believe, although I can't find the numbers in the 1982 manual. 76 on the bottom. There might be other changes in the F54 block it self that make it more desirable.

-

I Just Pulled A 4.38 Diff

I can't find the man reference usually used but the one I found says that 19 tooth is the white gear for a 3.9. A lot closer to a 4.38 than a yellow, for a Z. 510's and Z's both use the same size tire, I believe http://community.ratsun.net/topic/26704-matching-speedo-gears-after-rear-end-swap/ Post #7 A similar question came up on another forum and someone posted the link below. It will give you an idea of the difference you'll see between the two. It really depends on how you intend to use the car. Nissan designed the systems to allow starting from a stop easily, including hills, and cruise at freeway speeds. Race cars need to accelerate from corners and go fast on the straights. Drag cars need to accelerate and top out in a gear as they hit the lights. Auto-cross: in the powerband with throttle control. Stuff like that. http://webspace.webring.com/people/cz/z_design_studio/

-

I Just Pulled A 4.38 Diff

Don't forget tire size. With a bigger tire the diff will spin slower. A big tire and a 4.38 might spin the propeller shaft at the same speed as a small tire and a 3.36. Yellow is way down at the other end though. Count the teeth to be sure what you have. Maybe it's old white.

-

90 Deg Elbow Fuel Lines

If you do a Google search on the part numbers, you'll get several options here. http://www.carpartsmanual.com/datsuns30/DatsunZIndex/Engine280Z/FuelPumpHose/FromAug-76/tabid/1619/Default.aspx Also look at the post Aug 76 parts, menu on the left. Looks like the same pump but different hose and tube setup. More metal, less rubber. You might also try your local dealer. Surprising what parts they can still get. Also, if you decide to go cheaper and use an aftermarket pump, you can make a loop in the hose to get it to curl around from port to port without kinking.

-

Fuel Volatility

We've had some good discussions about the "vapor lock". The info gathered suggests that the simplest way to cure it is to convert to an aluminum fuel rail. The larger bore of the rail holds enough fuel to cool the injectors via boiling and condensation, with the heat conducted and radiated away by the aluminum. http://www.classiczcars.com/topic/48810-hot-start-issue-with-efi-who-has-it-who-doesnt/ Assuming that you're talking about a 280Z. The 240Z's with carbs and mechanical pump can have a real vapor lock problem.

-

280Zx Dizzy Into 240Z: Need Vacuum Advance Replacement

I was replying to what you said in Post #3. If it is a ZX control, then it won't fit the Z distributors is what I was saying. If my memory is right. I have both styles in the garage and remember noticing that they were different. I could be off but I think I'm not. I'm sure I'll check soon, just to be super-sure. Nissan changed a lot on the ZX distributors, from the Z's. Edit - Hey. I had a bad memory. I was positive that there's one vacuum canister that won't fit another type of distributor. But, I did go out and swap the 280Z and 280ZX vacuum canisters and they fit fine. I feel better now, sorry for the confusion. Carry on... Edit 2 - Must have been the points distributors I was thinking of. For those swapping to electronic, they can't swap the vacuum canister. So 240Z distributors would be off the list.

-

280z cranks, but will not stay running.

I don't think that the test I described is written up in the usual places. And what you're writing doesn't tell much, but does fit a dirty AFM switch. The 10 volts is normal. The starter drops the voltage as it uses amps. You can test the AFM contact switch at the AFM, or at the EFI relay with an ohm-meter, but the easiest most direct test is to take the black cover off of the side of the AFM, or take the inlet hose off, turn the key to On/Run, then move the AFM vane. If you have the cover off and there is power to the AFM contacts you might actually see a tiny spark. The contacts look like a tiny set of distributor points and are actuated by a bent rod when the AFM vane moves. It's very simple. All it takes is a piece of hair or dust to hold the contacts open. Probably why Nissan changed the system. I would do that test. You'll know more than you do now. Forgot to say - I have cleaned the contacts in an AFM with the striking pad from a book of matches. Never did figure out what exactly was blocking it.

- 280Zx Dizzy Into 240Z: Need Vacuum Advance Replacement

-

Mustache Bar Bushings... Anything Special I Need To Know?

If you run a torch over the outside metal around the bushing rubber it will get hot enough to degrade and soften. It can then be pushed out, leaving a few pieces of rubber to scrape away. No need for the smoky fire, although it does look like fun. Much cleaner too.

-

280ZX Distributor Advance Curve Reference

I was wondering about the TSB also. It would be cool to see some official Nissan communications on the subject. It seems odd to use the standard tip on the dished piston and the projected on the flat. Just initial gut feel. They are different heads though, N42 and N47 vs. P79. But if Nissan realized a problem later on, that would be interesting.

-

280z cranks, but will not stay running.

Kind of sounds more like the AFM contacts, if he's only losing power to the pump. If it was the ignition switch he'd lose all power. Details on the "checks" and whether or not this is a new problem on a car that was running or a problem that came with the car would help. The easy way to check the AFM contacts is to turn the key on and move the AFM vane. The pump should get power. If it's quiet, you'll hear it running. I've had my AFM contracts get dirty and kill power to the pump. The engine would only start, run for a few seconds, then die.

-

280Zx Transmission Seal Woes

Looks like Nissan Parts Zone sells bonafide Nissan parts, so I would assume that you're okay. Your other post looked like maybe you just used them for parts numbers. Wasn't clear (to me) where you actually bought them. I posted "just in case". Good luck with it.

-

280Zx Transmission Seal Woes

I thought you might have a comment. I remember you rebuilt yours a year or two ago. How is it working for you?

-

280Zx Transmission Seal Woes

Not to be a downer but the synchros that are commonly available seem to be of questionable quality. Didn't know you were doing a full rebuild or I would have posted the link below. There's a guy on Hybridz who did extensive work on these transmissions, for racing, and destroyed many synchros in the process. I think that he ended up using Nissan factory synchros. I can post the link if you'd like, it's multiple pages. May not change anything but worth reading - http://www.datsunstore.com/transmission-manual-shift-c-202_216_243_271.html?page=2&sort=2a http://www.datsunstore.com/syncro-ring-through-7083-p-1458.html

-

280ZX Distributor Advance Curve Reference

You'll probably want to gap the plugs wider to take advantage of the high energy ignition module. So the -11 is the way to go since it's prebent to .040" gap. P is for projected tip and it's not really clear why Nissan jumped around on that specification. People have their theories but the shape of the combustion chamber is probably what matters most. Can't really go wrong using the factory spec. If your engine used a P tip, use a P tip. New wires are a good idea since you'll have more voltage with the wider plug gap. It's the -11 that's probably giving you problems on the fitment. -11 is prebent for the .040" gap. These would not work with points well but you don't have points any more. I'd use the BPR6ES-11.