Everything posted by Zed Head

-

Silver Mine Motors Review

Personally, I appreciate these kinds of stories. The world is moving toward companies trying to buy and manipulate their reputations, rather than put the work in. I hope though, that you didn't jump the gun on your dealing with Silvermine. He's been on this site I believe, so he might screw you over even worse.

-

Missing Rear Exhaust Manifold Stud

The front stud tends to break also. Wrote a whole nerdy thing about materials and expansion/cooling but it probably boils down to you only get so many cycles (metal fatigue) before the studs break. The ones on the ends move the farthest during a heating and cooling cycle. A good reason to replace the studs if you have the manifolds off.

-

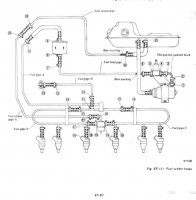

Make a fuel rail

Considering the recent heat pipe cooling theory by Fastwoman on the hot start problem, fins might actually be the way to go. It's a dilemma, since when the engine is running you'll be taking heat to the fuel tank, but when the engine's stopped, you'll be cooling the injectors. Assuming the theory is in play. More work is needed (this is the statement with which almost all research presentations end).

-

Fuel rail questions?

siteunseen's link has all of the relevant information. I assume you''l be using it as a guide? One area I made a mistake on mine that needed fixing, was I left it too long in front. There's only so much space available between the injector and the thermostat housing. I had to grind a corner on mine to get it to fit. I could have recut and retapped but I didn't even know if it was going to work. Future fix. Good luck.

-

Replacing Twice Pipes exhaust! How to go back to stock without buying unnecesary part

I was going to suggest the same, but he's in Panama and I don't know how things work down there. Probably not a muffler shop every five miles like we have here in the States.

-

Fuel rail questions?

You might be looking at the ports on the FPR backward. The center port on the bottom of the FPR is the return port. Fuel is fed in to the rail directly, then the FRP acts as a pressure relief valve, bleeding excess pressure off through that center port. If you have old hoses on the stock 1975 rail they might have longitudinal cracks that will seep or squirt fuel. I had an episode of a tiny three foot stream of fuel squirting out of an old injector hose once. A 1978 rail is solid steel (no connecting rubber hoses like on the 75-77 rails) and will bolt on directly, but it will need the FPR it came with also. Attached a drawing...

-

Modern injectors, new fuel rail - no heat soak problem

Thanks, I sent them both a message, we'll see if they get back. I also posted over on Hybridz to pallnet to see if a person could buy his barbed rail, with the potential for modifying to o-rings later. But, apparently, his o-ring rails have the holes offset so it wouldn't be a straight hole-enlarging operation. Mine are centered with no issues, so it should be doable for anyone building their own rail though. I bought the rossmachineracing scratch and dent rail off eBay. Same as shown in your thread, just saved a few dollars. It only had a few extrusion swirlys as defects, otherwise it was in great shape. He sells the good stuff there also. I'm filling up the forum, break time..... Raw Dash 6 Fuel Rail Sold by The Foot Scratch and Dent | eBay Raw Dash 6 Fuel Rail Extrusion Sold by The Foot RMR 019 | eBay

-

Hot-start issue with EFI - who has it, who doesn't

Here's the link to my other thread. Still collecting information. http://www.classiczcars.com/forums/fuel-injection-s30/52171-modern-injectors-new-fuel-rail-no-heat-soak-problem.html#post455660

-

Pervious owner nightmare thread

Brake calipers on the wrong sides, bleed screw on the bottom. Now I know better. Followed by a brake fluid leak after pressure could be applied, from a scratch in the bore, probably from the dust seal wire, removed when the PO was rebuilding the calipers. Then re-installing them upside down.

-

Windows XP, Windows 7, Windows 8

I've been using 7 now for a little while and have to say that, with an extra one MB of memory, it is much much better than my old XP system. Just Windows 7 and twice the memory (two instead of one MB). Then there's this stuff that I don't have to worry about - Defense, energy, banks hit by Internet Explorer bug - May. 2, 2014

-

Noise diagnosis, and Mustache bar issues.

Did you replace the diff when you found the loose part? I don't know what a "spider gear spacer" is but whatever it is probably came loose because something broke. Or if it just a loose part, thee's probably damage from running that way. Does the ratchet noise follow the rotation of the shafts, or is it a one time sound that only happens when the diff nose moves up and down? Also, I don't think that you can get much movement at all from the front rubber mount, with no load on the diff. Wheels in the air, nothing should visibly move at all, unless you have the parking brake on. If you can see the diff nose moving, your front mount is probably shot. You should probably take the diff and mustache bar out, replace the diff, and check the two studs while everything's out. That's what I would do. It seems unlikely that the body of the car would crack around the mustache bar stud.

-

Replacing Twice Pipes exhaust! How to go back to stock without buying unnecesary part

I don't see any mufflers in the picture. Many people run their cars with no mufflers, you might not have any. The MSA twice-pipe came with mufflers. It might be that installing two simple glass pack mufflers will make it quiet enough.

-

Modern injectors, new fuel rail - no heat soak problem

The time from shutoff to restart really needs to be noted. 5-10 minutes: generally OK, 30 minutes on: generally OK, 10 - 30 minutes: most likely time to have restart issues. Congrats on getting the car running well. I did have ~3 seconds of what felt like the old problem today after a long drive, in hot weather (high 80's), with about a 20 minute stop before restarting. It cleared up right away, but gives the impression that the problem can still be induced, but the threshold is much higher, which should make the problem time window much narrower. On the heat pipe principle: I wonder if someone could build a "worm" (saw the word on a moonshiner shows on the Discovery channel) or distillation coil between the rail and the FPR or the inlet to remove heat. Just seems like a lot of heat to remove through six small injector bodies. Here are few links about heat pipes. I learned the technology from Kona Corp. before they got bought. The second link has a good picture. In our case, no wicking, just gravity. http://www.synventive.com/aboutus/default.aspx?id=44342 Endless-sphere.com ? View topic - Definitive Tests on the Heating and Cooling of Hub Motors I might start an aluminum fuel rail survey over on Hybridz.org to see if there's a trend. pallnet has sold a few barbed rails so they are out there.

-

Gearbox ID

Wow, that's a good catch on the missing bump. I managed to get a picture of my oily 1980 transmission, by sticking a camera under there and taking a bunch of shots. It has the bump. So does my 83, but the 78 stops sharply at the mid-point parting line. You know though, if you look closely, you can see the bump on Werup's picture. It has a slope to it which doesn't really show in Eurodat's picture, which looks almost perpendicular, maybe due to camera angle. The slope is easily visible on my 83 sitting in the garage, and visible in my oily picture. One other thing I notice, which doesn't seem to get mentioned, is that the early transmissions have a double dust shield at the drive shaft yoke. The one on the drive shaft slips in between the aluminum housing and a separate shield on the transmission, with the transmission shield ending up on the outside. On the later transmissions, the driveshaft shield ends up on the outside, they got rid of the shield on the transmission. Edit - went a little crazy and retook some pictures, showing the dust shield and the shifter ears. You can see the short ears on the 4 speed, but long on 78 and 83 5 speeds. I almost went overboard and cleaned the garage for better pictures, but managed to stop myself.

-

Help Please! Ground Control Install - Strut inserts too long?

I think that what you took out are the original damper assemblies. They are essentially the internals of a shock absorber and the strut housing is the outer tube of the shock. I did the same on my 76. The KYB's should have come with their own nut, it's called a gland nut and it's designed to fit the top of the shock. It's also possible that there is some crud down in the bottom of the tube. I think I may also have read about the occasional weld bump down there also, that needs to be dealt with. The KYB's with the KYB gland nuts should work. You don't want to use the old gland nuts with the new KYB's. But with the KYB's you'll be at the same ride height, plus a little extra from the gas charge. Find the KYB gland nuts and try again. That's all there is, the gland nut, the insert, and the strut tube.

-

Modern injectors, new fuel rail - no heat soak problem

I've pondered the heat pipe heat removal process. I figured that it was happening but apparently not removing enough heat. It's a viable explanation though. Maybe Nissan knew that and that's why they describe their cooling fan's purpose as to remove heat from the fuel system, and that's why it blows on the rail. Could also be why several of the manufacturers use some pretty fancy aluminum rails, and some of them are even finned (one side benefit of prowling the wrecking yards is you see a lot of stuff you would never see otherwise). Which I had though would draw heat in from the engine bay, but it's all about differential so engine off maybe fins are good, to dissipate heat to the engine bay surroundings. It works for me, taking heat from the injector body, and fits the two cases so far. Mine and siteunseens. pallnet, the Hybtridz link I referenced above, sells rails with barbs. It could be that simple (Occam and Einstein and all those guys, you know). On the clips - the factory clips usually fit around a round projection (the manufacturers typically use a stamped pipe type hole for the injector). You'd have to design your own but I'm sure it could be figured out.

-

Help Please! Ground Control Install - Strut inserts too long?

What was in there before? Does it have part numbers? To CO's point - some shocks come with a pressed on extension. It might still be in there.

-

Help Please! Ground Control Install - Strut inserts too long?

Yes, you need a shorter shock to run in a sectioned tube. You'll have to search around to find the right numbers, I think that some people run the fronts in the back, then use an MR2 shock for the front. There are probably some good writeups on Hybridz.org. Good luck. By the way, measuring first with the shock in hand is the way to go. As you've found.

-

Help Please! Ground Control Install - Strut inserts too long?

Isn't that the other side of the strut mount, where the ball joint bolts on? Looks normal, I believe. It's the inside of the tube that matters. You might have four rear shocks. The fronts are shorter, by about 3 1/8", for a 280Z. If my measurements on some Tokicos are correct. ~18" for the rears, and 14 7/8" for the fronts.

-

Gearbox ID

The gear shift levers will swap across all 71B transmissions. Even though MSA, for example, sells short shift kits for different year cars. And the ears-on-the-shift-mechanism things is wrong I believe. I have a 76 4 speed, and and a 78 and 83 5 speed in the garage and an 80 in the car. The length of the ears doesn't tell anything. If you want to get closer to knowing what you have, measure the ratio of 5th gear by marking the driveshaft and turning the engine until the driveshaft turns one revolution. Then see how far the crankshaft rotated. The exhaust hanger and the speedo bolt put you in the 80-83 range. I think that the main difference in parts is the 5th gear synchro ring though. If you're not buying a 5th gear synchro ring, parts for the 80-83 5 speed should work. Eurodat knows more and might have some comment. 1980 - .773 1981-83 - .745

-

Modern injectors, new fuel rail - no heat soak problem

The heat pipe theory is a good one. It should work for the standard fuel rail also though, but without the surface area and conductivity of the aluminum rail. Vapors are free to rise in the stock system also, up through the rubber hose to the metal rail. Maybe the aluminum rail is enough to keep the injector bodies below the threshold. Could be why siteunseen's rubber hose/aluminum rail system works. Or, as you suggest, there's just more fuel available to keep the cooling cycle going. If siteunseen didn't have headers, he would have the fuel rail as the single variable experiment. Except for the 707T injectors. There has to be more people out there with the barbed fuel rails, running stock injectors. Maybe another survey is in order. The problem with the problem is that the people who don't have it, don't really know what we're talking about. Little reason to get involved. Maybe the accumulator theory is right, and the accumulator is a just a cooling fluid reservoir. Eventually the minimum work necessary or a set of factors that can control it will be clear, I hope. I think that the o-ring system is only more dangerous because the safety built in to it by the designers has been removed. In a factory stock system, each injector has a clip holding the injector in to the rail. You can pressurize the rial without it being bolted down. If it comes unbolted, no fuel escapes. If pressure is applied to these aftermarket rails, unbolted, the injectors will just pop out.

-

Cam sprocket on #3

Yes. I guess I didn't differentiate between distributor and crankshaft. I get 22 degrees of timing advance beyond the 12 degrees static/initial by the timing light, after ~2500 RPM (a guess from the FSM specs). I have a 78 distributor, but it has 11 degree distributor weights (the FSM says it should have 8.5), or 22 degrees at the crankshaft. Sorry, probably not helping the thinking overload.

-

Cam sprocket on #3

As madkaw says, two different timing scenarios, one cam, one ignition. On the ignition. if you want to get precise or match what you had before, compare the total mechanical advance of the distributors. There should be a number stamped on the weights under the breaker plate. Twice that number is total mechanical advance of the distributor. If you don't want to take the ZX unit apart, you can set the timing to zero at idle, disconnect the vacuum advance, and measure timing while increasing RPM until the mark stops moving. That would be total for the ZX distributor. I have 22 degrees total in my distributor, and I'm set at 12 initial, for 34 total at WOT, for example.

-

Water getting inside car through doors when washing my 240z! What seals i need?

The part number is in Post #6 in the thread I linked in Post #4 above. Do you have Kia dealers down there? They're actually longer than needed. Typically, you fit the 90 degree bend of the weather-strip to the 90 degree bend on the car, then run the rest of the stripping and trim the ends. Edit re jfa below - the range of years are in that other thread also.

-

Modern injectors, new fuel rail - no heat soak problem

Quoting myself. I found an old thread about the 707T's - http://www.classiczcars.com/forums/fuel-injection-s30/45474-fuel-injectors-fj3-fj707t.html