Everything posted by Zed Head

-

Help! Cold start valve has no place to connect to fuel rail

Me? I ran out of words... Had to reload.

-

Help! Cold start valve has no place to connect to fuel rail

I think that 77 might have still used the N42 head and intake. The N47 change was mid 77 and/or 78. I don't really see a patch in that picture but it might be there. It's possible that Nissan made a variation for later L6's, like the L24E. Who knows. The 76 parts would work to get the CSV back in action. You might try driving up to Mount Rainier for a night though to see if you really need it. Make sure that you use EFI rated hose to connect the rail together.

-

Cam Chain Tensioner Mystery...

Might as well be the Debby Downer, but you would expect some damage to happen as it got levered out of the hole. Either to the tensioner parts or to the cylinder it sat in. Unless you're going to try to rig up a way to reinsert it from the top, with magnets and tape and skinny rods you'll be taking the front cover off, so you'll want to inspect the hole carefully. Should be able to poke around in the oil pan more easily then for the tensioner. And I wonder if your timing chain didn't jump a tooth or two. In this case, it's easy to imagine. Might explain why it isn't running quite right. There's a 79 ZX in the Arlington yard that you might be able to scavenge from. Row52 | 1979 Datsun 280Z

-

Flat spot under light throttle application.

So the comments about the needles and the damper oil are about richening the fuel-air mixture, right? On an EFI engine with a potentiometer on the coolant temperature circuit you would just turn the knob to add resistance, leading to more fuel, if you had this problem. Of course, that would add fuel everywhere. Anyway, if it sings under WOT and idles and revs fine, it's not likely a spark problem. Timing looks about right too, doesn't it? So, change needles to a set that add fuel at part-throttle? Just trying to learn a little carb stuff.

-

Hot-start issue with EFI - who has it, who doesn't

Thanks for the addition to the thread. The math seems to be leading to the conclusion that the typical Pallnet style aluminum rail (AN -6 size bore), with stock heat shielding, could solve the hot start problem alone. Heat dissipation is the key. Just summarizing, for anyone looking for the simplest, and probably cheapest overall solution. You can get the rails with barbs, and could even get an extra port for the CSV, keeping all of the stock functions and most of the parts. Headers and/or new injectors are probably not necessary to get rid of the problem.

-

Help! Cold start valve has no place to connect to fuel rail

1977 was still using the multi-piece rail with fuel hose to connect the pieces. Solid would be 1978 Z or 79-83 ZX. Your description of the regulator says 78 or ZX also. It's been known for people to braze a patch over the CSV hole after they cut off the tube. It's described in a few posts around the internet. The CSV is probably overkill fuel enrichment for anybody not living in Canada or the northernmost states of the USA. You might need it for a few days in the wintertime in Cashmere but worst-case you'll probably just need a few extra revolutions of the engine before it starts. The piping that you're missing is generally in the way,and the CSV injector is one more place to have a leak, that's why many people remove it. I cut mine off and capped the stub with a 5/16" compression fitting, when I had a stock rail. So now you can have it figured out and still leave it off. Best of both...

-

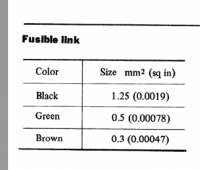

260z fusible link to maxifuse upgrade question

The fusible link versus amp rating topic pops up occasionally. Somewhere along the line, either Nissan made a mistake in their manuals or a translation error in color versus rating has occurred, or in what color Nissan was really referring to in their manuals. The cars were supposed to come with brown links, not read. And Brown is the smallest gauge, therefore the smallest rating. So if Green is 40, the Brown must be less than 40. Copied the page from the FSM. Apologies to anyone who's tired of hearing this. My logical brain just can't let it go... Edit - and just to make it more confusing, MSA now has a diagram for the links on their site. But they use a brown color to show where their red links go. They chickened out! http://www.thezstore.com/page/TZS/PROD/12-4336 And just to round things out, the atlanticz site shows the red as 0.69^2, but the FSM's say 0.3^2. So are the MSA links 0.69 or 0.3? Regardless of color, it's a confusion. http://www.atlanticz.ca/zclub/techtips/fusiblelinks/

-

Recommended High Quality Themostat Housing for 1972 Datsun 240z

Both MSA and the eBay seller are re-selling factory Nissan parts. In other words, all three are the same part. MSA's mark-up is much more reasonable, and customer service probably better. Not to take a sale from MSA, but it is a small sale, you could probably get this directly from a Nissan dealer.

-

280z Door Lock Elbow

Not really sure what this is? Is it described somewhere else? How does the coat hanger differ from what you removed? My locks have the same cold versus hot problem. Cold weather makes everything hard to move.

-

Buying a 240z. input needed?

It has a battery in it so maybe it will turn over. Might be worthwhile to take your own battery and some tools so that you don't get the last minute "darn it the battery's dead" excuse for not checking electrical and engine condition. A locked up engine, or weird noises, are good for negotiating. Good to know in any case. But, on the other hand, sometimes not being able to hear the engine turn over is a better tool for talking price down. Depends on how important an engine is to you on if you want to know or not. The pictures look good but I always wonder when they only show one side. There doesn't seem to be any reason not to show the passenger side also.

-

Almost a poll? How many of you check the classifieds routinely?

I almost never look at the Classifieds. I like the Hybridz.org method also. I use What's New? to see what's happening too.

-

My car rides like Poo :(

The Vogtland springs seem like a possibility. Not stock, but only one inch+ lower. Here's a fairly recent thread on them. You'll have to click through some links to other forums and web sites to get a good view of where they're at. Looks like they just worked some bugs out of the ordering process. Edit - here's a more direct link http://forums.hybridz.org/topic/117631-new-s30-shock-and-spring-option/page-2#entry1118171

-

My car rides like Poo :(

55 is a pretty low profile on your tires. You're probably going to have to choose between looks and ride quality.

-

Hot-start issue with EFI - who has it, who doesn't

So the summary might be that you had one instance of the car not starting at all, and whatever the problem was went away? But since then it's been starting fine. You are essentially all stock, including injectors, except for headers. So, headers might be a simple one component solution to the problem. Possibly due to reduced heat-holding mass by the injector bodies. Thanks for reporting back. Things will get clear, piece-by-piece. At least there will be a few potential solution paths to try for anyone that can't stand it anymore. For the record, my 14mm, o-ring, 1990, high impedance 4 hole valve injectors on a straight-shot aluminum fuel rail haven't had a problem and it's been up in the 90's and high 80's on a regular basis here. Odds are it's just the aluminum rail and its extra fuel volume dissipating heat, as the fuel vaporizes from the injectors and recools in the rail (Fastwoman's heat-pipe theory).

-

Installing new battery turns into fryer fire

The battery was installed correctly and things worked right before you removed the battery and put a new one in, so odds are you connected the new one backward. I have seen batteries with the positive and negative terminals reversed. If you didn't match the - sign on the battery with the cable that connects to a starter mounting bolt, and the + sign with the cable that connects to the starter solenoid (where the other wires also connect) then you probably just got your poles switched. Find the + and the - on the battery top and make sure that they're connected correctly.

-

My car rides like Poo :(

I've never heard of adjustable Tokico's that weren't Illuminas. Have you adjusted them down to the softest setting? That would be the first thing to do. Do you have low profile tires? Tire sidewall is the first line of shock absorption. Old stiff tires could be a factor also. Poly bushings probably would make for a harsher ride, especially if the small ones at the wheel side of the control arm were done. But I have poly on the inside, rubber on the outside, with 205-70-14 tires and my ride is not harsh, but firm. That's a 280Z with cut springs in the front and Tokico springs in the back, with KYB shocks.

-

Chev V8 Intake Theory and Routing?

From my past, limited, experience with small block chevys (actually V8's in general), I remember that many dual plane manifolds don't completely separate each side I think it might be to moderate the pressure pulses or to make both sides available at high flow rates. Anyway, I don't think the sides of the carburetor are completely isolated. Some of the aftermarket manifold actually have a slot cut at the top of the divider. You can find pictures on the web. Plus, at idle, much of the fuel air mixture is just hanging around waiting for the next intake cycle, so if the sides are connected you would get some blending. Of course, if you have a tunnel ram manifold, I think it's just one big hole under the carburetor. Does he have headers? The chevy exhaust manifolds were pretty bad. When I replaced stock manifolds with headers, the idle smoothed out considerably. I don't know anything about Edelbrock carbs. Actually, not much about any carbs.

-

Dead cylinder #3! Ignition or Fuel?

This car was running last year right? The 9 years is previous. Isn't this somebody else on Jenny's account? Still Jenny's car though. Kind of confusing on what's going on here. Anyway, on your noise/vibration from the console area - that's about where the propeller shaft u-joint is, along with the slip-yoke to the transmission. You might check the yoke for play when you're under there, grab it and shake, and the u-joint also. You'll need to pry that one around with a screwdriver to see if it's loose. Look for signs of rust and dryness. And when draining the fluid, level puts the drain plug at the bottom I believe. And puts the fill plug at the right spot. No real need to tilt the front or back independently. And the fluid will expand a lot when hot or warm, so don't be surprised if a bunch comes out if you remove the fill plug first. Which is always a good idea, just to be sure that you'll be able to refill it, before you drain the fluid.

-

Looking for servo diaphgram

Call this place, or send a message (see the About US or Contact Us links at the lower left of the front page). Oliver is the owner, he can find one or tell you where to get one. Z Specialties Online Store - If we don't have it in stock, we can get it!

-

Fighting Transmission to get in Gear

Re ksbeta's probem - The part about the force required at the base of the shifter and the fact that the problem followed the shifter is interesting. If the problem is hydraulic or clutch related you should have grinding in reverse since it has no synchros. Reverse requires complete disengagement of the transmission from the engine, while the forward gears can use the synchros to do some work. Have you checked the three plastic bushings of the shift lever? Especially the bottom one, maybe it's split and opening up or just not seating right in the pocket for the shifter mechanism. Seems like there's a shifter problem, which it looks like you suspect also.

-

unmolested original 280zx 11/80 build date

Just found the thread below that says it's the differential ID. RC39 is a 3.9 ratio R200. I can't find it supported in the FSM anywhere, but I've read that Nissan typically produced Service bulletins in addition to FSM's. Good to know though if you're looking for a certain ratio. Identifying Your S12 *Last Update 22/12/07* - S12 Pinned Information - S12Silvia.com Community

-

clutch slave keeps blowing apart

Did this problem just pop up out of nowhere after years and many miles on the same clutch?

-

Help with yogurt cup test please...

I think that we were looking for low voltage or bad control, leading to slower/lower opening times, and a lean mix. Bad connections, high resistance, bad transistors, etc. Something that ties 1 and 2 together. Of course, it might just be an artifact of something else going on. Since the engine is running, I would do the old ear to screwdriver test. It's a Nissan standard. Quality of the click is the key.

-

Help with yogurt cup test please...

I fixed a dent in my hood using a block of 2x4 as a backer and a finishing hammer. Mine was pretty small though. The metal on these cars is pretty think and malleable. You might be surprised. On the banks of 4 and 2, I think that the original EFI might have been designed for a four cylinder engine and when they added two more cylinders they just added one more circuit to control the two new ones. The power supply is two leads I believe, one is crimped to four resistors in a package, and the other is ganged in to two. If you look down behind the clutch master cylinder you'll see the two packages (each big rectangular metal piece actually has a set of round ceramic resistors inside). Maybe you have a bad crimp. It's a tight fit but the resistor pack can be removed for testing, or tested in place. There's a test in the FSM, page EF-56 for 1976. 78's the same. It's been discussed also, that the transistors in the ECU might control them in batches of two and four. I think that superlen or Steve J or Captain Obvious might know for sure. So if you had one transistor go bad it might only affect two injectors or four. The wiring diagram does show 5 and 6 as together but who knows what they did in the ECU. Injectors are built to a spec. so I can't imagine that the flow rates would be far off. Especially for an EFI system that doesn't have any self-trimming functions. For what it's worth, my cylinder #1 plug has always been much cleaner and whiter than the others. Even with a different engine. I've wondered about it. Maybe cylinder 1 gets more air or runs hotter. Good luck, hope it's something simple. Forgot to say also, the injector harness runs to the middle of the intake so if somebody flipped it when putting it back on, then 1 and 2 would be where 5 and 6 used to be. Just a thought.

-

Old cars - VanDerBrink auctions

Interesting auction site. Many cars, many cheap. No Z's found as of yet. https://vanderbrinkauction.proxibid.com/asp/AuctionsByCompany.asp?ahid=1530 https://vanderbrinkauction.proxibid.com/asp/LotDetail.asp?ahid=1530&aid=76974&lid=20744282&title=1969-Pontiac-GTO-Judge https://vanderbrinkauction.proxibid.com/asp/LotDetail.asp?ahid=1530&aid=76974&lid=20744361&title=1971-Dodge-Challenger