Everything posted by Zed Head

-

'90 240SX FS5W71C swap into '75 280z

Here's another one - DSC04293JPGThumbnail1jpg id 266482 | Motortopia That bearing is difficult to remove. I had to rig up a cheap two prong gear puller with a clamp to get in to the small space available. Don't forget to put the transmission in to gear when assembling. It's possible to get it stuck in two gears at the same time when the bellhousing/fron case is pushed over the shift rods.

-

Radiator cooling capacity is dropping

Don't forget head gasket and bad gauge as potential causes. Stuck thermostat is a good possibility. If you've been using modern antifreeze formulations with clean water it would be odd for the radiator to get fouled.

-

U-joint for driveshaft

Here's a good link for u-joints, with dimensions. https://www.powertrainindustries.com/catalogs_type.htm?type=UJoints&PHPSESSID=1i4gudsrcok13lt4mf660vloa3 How are you going to retain the new u-joint, since the old one was staked in? If it's not centered perfectly you'll have vibration and without proper retention it could move. Here's a thread, with info on a shop up here in the Portland area. I think that they shorten also. 280z (datsun / nissan) non replaceable ujoint replacement where to go to fix for just $103 in 30 minuets - S30 Series - 240z, 260z, 280z - HybridZ Don't forget that the early 1970 drive shaft is the correct length and will swap right in. Jon Mortensen had one for sale, he might still have it. It's already rebuilt and he wasn't asking much.

-

Front brake problems

One thing that people have done to isolate a problem is to convert one of the fittings in to a plug. For example, take an old fitting with a piece of metal brake line, cut the line short, then bend it and crimp it so it won't leak. Then take that plug and block off various parts of the system. Block the fronts and see if the rears are solid, and vice-versa. Block one caliper, block the other, see if there's a difference. Block the proportioning valves, etc. You can even build two plugs and block the ports from the master cylinder to see if the MC is the problem. Have to say though that you haven't really given a good description of what the pedal is doing. Is it high or low, will it pump up, does it drop if you just hold constant pressure on it... etc. Al I see is soft pedal (what does that mean?), air bubbles in the reservoir, and the rear brakes "work great" (no details on what "great" means). Plus you said the rears work great, but you're reporting bubbles in the rear reservoir. The solution is in the details, but you have to provide those. Good luck.

-

Bayline 8.2.14 By Historic J

I've never heard of Historic J or this event. The picture of a very high stack of containers doesn't tell much at all. Are you a freight handling company?

-

Hot-start issue with EFI - who has it, who doesn't

Welcome to the club and thanks for adding. Fuel quality has been discussed here and there. Unfortunately, most of us have to live with whatever is in the local station's tanks. So far, people with Standard FJ707T injectors, aluminum fuel rails and headers, Standard FJ3 injectors with headers (Post #84), and me with Bosch 0280 150 901 injectors, aluminum fuel rail, and stock manifolds, seem to have eliminated our hot start problems. Although it's not clear if rcb's issue will come back in the winter-time. Here's a really interesting presentation from Lawrence Livermore National Laboratory showing how ethanol affects vapor pressure, but also showing that gasoline can be different in different areas of the country. That's one more thing that gets the discussions messed up, one guy says I have these parts and no problem, another says I have the same parts and have the issue every day. But they're talking about different petroleum distillations, and different ethanol percentages. It's worse now than in the past because modern cars are designed to adjust for the variation. http://www-erd.llnl.gov/ethanol/proceed/autoupd.pdf

-

I'm Bringing Back Tha Twin Stacks ^_^ !

Glad you made it back Wing. The things being reported didn't fit. I figured something out of control was going on. Good luck.

-

Fuel injector replacements

Here's a trick I learned from a machinist I used to work for, a way to keep swarf out of critical areas. Turn the part upside down.

-

GM HEI Module - odds and ends

Assuming the same settings and drill speed, maybe the modified reluctor gives a higher voltage at low RPM. Four divisions for the Z, five and a half for the ZX. Can't tell what the settings are on your scope. Thanks for doing that and posting the results. No clear answer though on why the guy from Hybridz had problems with the HEI module on a ZX distributor. Maybe he had a bad module or had it wired backward. I found a four pin Bosch module that apparently passes 7 amps. But you can get that with an Accel high performance module. Also found that many of the Toyota people are using the GM module when theirs break, 'cause it's cheaper and works just as well.

-

GM HEI Module - odds and ends

Found an alternative to Pertronix for the points guys - Electronic Ignition Module Kit K2543

-

distributor issue

They used dual point or dual electronic pickup distributors in the manual transmission cars also. Nissan wasn't 100% clear about why, some say it was for emissions, but Nissan described sit in Engine Fuel. It actually advances timing about 6 degrees when cold (at least in 1976 it did), which raises idle speed. Good that you're looking at it before you have problems. What you really want to do though is take the distributor out, disassemble it, and make sure the vacuum advance breaker plate mechanism works correctly. Most of them, even in the 80's ZX's, are rusted and bound up. This can cause your timing to get stuck in the wrong place, or react slowly, leaving it advanced when it should be retarded. If you only have the wires for one set of points you can just leave the other set in and run it. If your engine isn't running right, it's probably not because of the extra set of points.

-

freeing corroded tube in tube...ideas sought

Is the outer tube steel? I've had the thought that Naval Jelly (phosphoric acid solution gel) might be worth a try to break a rusted bolt free. When steel or iron rusts, it grows in size. If the Naval Jelly breaks the rust back down maybe it will loosen up. Never tried it but it seems logical. To me.

-

distributor issue

The distributor specs. are in the Factory Service Manual. But there's really no reason the engine shouldn't run smoothly with either. I looked and it seems that the distributors are actually the same but the initial timing setting is different. How do you know that you have an "automatic" distributor? p.s. Texting (with the e.e.cummings writing style) isn't really popular on this forum. Classiczcars.com likes classic writing style.

-

GM HEI Module - odds and ends

Found a 4 pin Honda module with dwell control - Honda OE# 30120-PA6-921, 30120-PB1-006 Ignition Module Compare to another with ECU (ECM) control - Honda OE# 06302-PT2-000, 06302-PT2-A00 Ignition Module One could spend a lot of time exploring 1980's ignition systems. Lot of odd stuff out there.

-

GM HEI Module - odds and ends

Oops. Makes sense, of course. I've even played out in thought the tooth passing the pickup point. Missed that. So the extra metal in front of the tooth on the ZX reluctor. That might get the voltage back above zero sooner maybe? You have your Z trace centered peak to peak and the trace between the peaks looks even top to bottom and side to side. If so, I'd guess the ZX trace might be a little asymmetric. Don't know. You're not going to hook up a coil and measure dwell times and output are you? I'm going to see if I can find out more about the Toyota module. I'm obsessed now.

-

E-88 head swapping

Seems like an N42 or N47 L28 head would be a good choice. It already has the bigger valves and essentially the same combustion chamber size. Isn't it about where you end up after modifying the E88?

-

Too many problems to list...

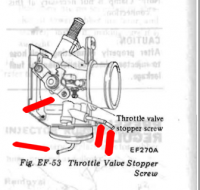

Here's a picture of where the spring would attach to pull the throttle closed. I bought several at a hardware store and tried a few until one felt right. Also added a line to show where you might have hidden vacuum leaks. each one of those tubes will leak when the throttle is opened but wil be closed when the throttle is closed. They should all have a hose attached (ideal stock configuration) or be sealed (in the meantime).

-

Too many problems to list...

Is this while idling? The small details can have a big impact with these engines. Vacuum leaks are a big problem. You can't really do any tuning at all if youhave vacuum leaks. Also, just the simple basics like getting your ignition timing right, and adjusting valve lash are important. Basic steps before you get carried away. People have spent lots of effort on the wrong things, then found that something basic wasn't set right. There's am Engine Tuneup chapter in the FSM. Do the steps in order and you'll be way ahead.

-

Too many problems to list...

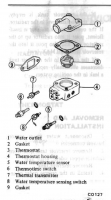

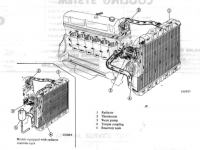

As I said, he was either BS'ing you by grabbing a loose screw and turning it or you mistook the one he actually turned for that one. Attached a picture showing the screw position that I think we're talking about. Also noticed that your radiator does not appear to be stock. Could be too small for the engine but certainly a sign of a past cooling problem. These pictures are from the Cooling chapter. An example of what you'll find in the books. The digital FSM's are one of the great benefits of owning these cars. You don't have to try to communicate with the parts store guys. Looks like you have a challenge. Keep posting, everybody loves a good puzzle. Edit - just noticed that you seem to have an electric fan, guessing by the shroud. Another not really necessary "performance" item. If the fan isn't coming on you'll have over-heating problems at slow or no speed.

-

Too many problems to list...

I put an arrow on your picture. That bolt has nothing to do with any of that. Maybe he was pointing at another? But, there is no adjustment that will, normally, make the engine idle better, but cause a power loss. That would only be the case if things were messed up. Your best bet is to assume the guy you bought it from was a BS'er or didn't know what he was doing. The taped up intake hose, the shiny new oil filler cap, red plug wires, painted air box, 4" exhaust tip - all things that cause pause. Describe one problem at a time and people here can walk you through some of them. I would focus on over-heating first. One overheat can blow your head-gasket and/or warp the head. That's a major expense, and a fairly difficult DIY job. Back to watching Holland beat up on Brazil....

-

Too many problems to list...

There should be a spring under the throttle body (at the end of that linkage) that closes the throttle blade. It might be missing, they break sometimes. It's hard to see, it's underneath. If you haven't yet, open the Engine Fuel chapter from EuroDat's link in Post #2 and look through it. You'll get a better idea of how things work. You've got some study ahead of you though. If you have a multimeter be ready to break it out and start probing. Here's another good link for the FSM's if you don't have an unzipping program. Index of /FSM/280z

-

Too many problems to list...

That is a very important tube (aka hose). It needs to be leak-free.

-

Too many problems to list...

All I see is a loose bolt on the thermostat housing. ???

-

Too many problems to list...

The guys there said they didn't know squat about a ZX - this is very common. t all I noticed out of whack visibly was the throttle stick thingy doesn't want to turn back to naught after a good pushing, - no idea what this means the screw on the motor that alters the idle was ALL the way down. - this is a sign of a vacuum leak. Maybe. there is no motor to alter the idle on the stock engine It's running very hot and popping and bogging down if I lay on the gas or switch gears at anything over 4k rpm. - popping and bogging is a sing of a vacuum leak How many belts should be coming off the front of the motor? I see two pulleys but only have one belt - the engine may have had an AC compressor in the past. why but I do have to almost entirely manually turn the wheel in low gears or low speeds - no power steering. It's good for you. Could the massive exhaust tip it has on it be a problem? It's a 4 inch I believe. - not directly, but it is a sign of "tuner madness". What can I do to keep it from overheating even with fresh water/ coolant in it - more details will help. If it overheats while driving donw the road that is most likely a radiator or water flow (pump, blocked channels, etc.) problem. If it only overheats when stopped, that is a fan clutch problem sign. the.aftermarket rear end - explain. How bout some pictures of all this mess?

-

Too many problems to list...

Everything connected to the intake manifold has to be sealed from the outside air. In other words, all air must pass through the air flow meter (air flow module was pretty close). This includes the crankcase, meaning the oil filler cap, the dipstick tube, all of the little vacuum lines, even the brake booster, all need to be working properly and sealed up. Keep that in mind and it might help you get started. The PO might have "tuned" the engine to run with vacuum leaks. That could be a problem. One way to tell if you have leaks is to pull a small hose fromthe intake manifold, or unscrew the oil filler cap. If the idle speed increases that's good. If nothing happens, not so good. If you take the oil filler cap completely off the engine should die. The belt flying off would normally be from a wobbling pulley. Better check all three, the alternator, the water pump, and the crankshaft damper. Don't run without the belt because it drives the water pump. The engine will overheat, and that is very very bad for these engines. Very very.