Everything posted by Zed Head

-

What Engine Harness is this?

The fine people here can get you close but you won't really know unless you dig in yourself. The EFI harness is almost completely separate from the body harness. It has its own power wires and ground wires. There are connections to the fuel pump relay, which you may or may not need for carbs, and a few other indirect connections which aren't needed to power the car and can be disconnected, like the wires to Pin 1 from the coil (although the wire does need to stay connected to the tach). But, you said you pulled an "engine harness". It's not really clear what that is, the EFI harness is a separate harness and doesn't have a voltage regulator connection. Your best option is to study the wiring diagram and see what you can figure out. A few member of this forum have worked up some nice color diagrams. Here's 1978, and 1976 which is close to 77. 77 might be out there somewhere too. http://www.classiczcars.com/forums/misc-s30/44992-somewhat-color-wiring-diagram-1978-280zs-enjoy.html http://www.classiczcars.com/forums/open-s30-z-discussions/36494-free-full-color-wiring-diagram-1976-280z.html

-

What Engine Harness is this?

The wrecking yards in my area get the year wrong all the time. If they went by the build date, it might be a 78. 78 had the internal regulator.

-

Engine differences about Series 1 S30 Zs?

I think that Kerrigan's quest may be to find out what's true and not true. How do you know? Lots of conjecture out on the internet. For example, all of my comments in this thread about no need for L20A until there was L20B are wrong, if the information in the links in Post #21 are right. Apparently there was an L20, then an L20A, then an L20B. Apparently, according to the internet.

-

Engine differences about Series 1 S30 Zs?

By "cooling setup illustration", do you mean the water jacket outlet on the side of the head? You don't have that?

-

Rear axle peened nut alternative

Many people reuse them. You can tell when you get in to the locking part of the thread, it gets much harder to turn. Other nuts on the car are self-locking also, like the ones on the two long transmission cross-member bolts. But, the FSM recommends a new nut. On the axle, probably best to go new. You can still get them at your dealer, I believe. They even show up on the Nissan data base. $4.98 each. Rear Axle :: 280ZX Parts (S130) 1979-1983 :: Nissan Parts, NISMO and Nissan Accessories - Courtesyparts.com

-

77 280Z Dropping Fuel Pressure once Warm

True, at some time in the 1978 model year they changed the type and location of the relays. But the FSM's shows the same picture and location for 76 and 77. 1977 still used the AFM switch, so would have had the dual relay. And, oddly, for some reason, a 1978 parts car that I bought and dismembered a few years ago (with title and proper build dates for a 78) had the 76/77 style dual relay in the same location. It's actually sitting in front of me right now (I keep various odd parts laying around, for inspiration). If I knew then what I know now I would have messed around with the AFM switch and the oil temperature sender on the 78 car to see which controlled the fuel pump.

-

Engine differences about Series 1 S30 Zs?

Here's another Fairlady topic. More stuff. Fairlady Z ID help - S30 Series - 240z, 260z, 280z - HybridZ

-

Engine differences about Series 1 S30 Zs?

Here's a 72, but the engine's been swapped - 1 tuff z: 1972 Fairlady Z-L project! - S30 Series - 240z, 260z, 280z - HybridZ

-

Engine differences about Series 1 S30 Zs?

Another - Post #6 (looonnggg thread). Again, no engine picture, just the body tag. By the way, could you link to your pictures for comparison? Might as well tie all of the Fairlady's together in one thread. Build your own case. http://www.classiczcars.com/forums/misc-s30/16660-gotta-sell-my-69-fairlady.html

-

Engine differences about Series 1 S30 Zs?

Here's one from this site that would be good to compare to (maybe you've already referenced it). With an A on the body tag. And some comments from your friend Alan T. Post #20 has the picture of the body tag. None of the engine though. Note that the OP does not say it's an L20A engine, he says it's an L20. Implying (to me) that there was no A stamped on the engine. http://www.classiczcars.com/forums/misc-s30/14433-information-about-very-rare-s30.html

-

Engine differences about Series 1 S30 Zs?

Post #4 - Orange, and only a little rust: `76 710 - Project Datto - Ratsun Forums Implies that the format is L20X XXXXXXXXX, not L20 X XXXXXX I would assume that the format would be the same and would only be used when the potential for confusion was realized.

-

Engine differences about Series 1 S30 Zs?

You're good at writing on the margins. I can't tell if you're serious or not. Anyway, an interesting thread for you might be titled "Who has an L20 engine and what is the serial number, and year of car?" You might get a sampling of information that tells something. The picture from the past that you remember would be a start. I take it this is an argument about originality, and maybe value, of your 1971 car? Those arguments are served well by comparison with like articles. There must be others out there. There would be no good reason to mark your engine before the L20B 4 cylinder was planned for production. And, logically, you know it's not an L20B, and it is an L20, therefore it can only be an L20"A". Unless you're trying to find out when Nissan started marking A's and B' on their L20's, if they did. That would be a question that could be answered. Maybe go could out and find out what the 4 cylinder L20B's have stamped on the block.

-

77 280Z Dropping Fuel Pressure once Warm

The EFI relay and the fuel pump relay are combined in to a 1x1x2.5 inch silver box, above the hood latch release handle, under the driver's side dash. And yes, the screws are hard to reach, mine only had one installed when I got my car.

-

Rear axle peened nut alternative

The 280ZX are your basic "deformed thread" lock nuts. They won't harm the studs, they're designed to work with them. You wouldn't re-use the nut, you'd get another and peen it over again. The ZX nut is the best option and won't hurt anything.

-

Engine differences about Series 1 S30 Zs?

I didn't read through all of your other posts but I do see that you might having some "cognitive bias" going on. You're interpreting things to fit what you "know" instead of changing what you know to fit the reality. There's nothing written anywhere that I see about an "A" stamp. Why would you need an A or a B stamped on the engine, all you have to do is count cylinders. So looking for an A stamp seems pointless. The A and B seem to be for documentation and manual purposes. The number on the engine would match the number on the body plate, in the USA market. I don't know if they did that in Japan. Is that where the "mis-matched number" thing comes from? It could just be a replacement motor. From your post farther above it seems like you just have a plain old JDM Fairlady Z with an L20 six cylinder. What's the big deal? The FSM shows it as a stock engine for the car. What are you really looking for? Edit - seriously, I'm just wondering what the fuss is about.

-

Engine differences about Series 1 S30 Zs?

Here's another good source - http://www.nicoclub.com/FSM/Engine-Specific/L20A,%20L24%20&%20L26%20Engines/L20A,%20L24%20&%20L26%20Engines%20EG.PDF I haven't seen any reference to an L20 engine anywhere yet. Only L20A and L20B. Your Wikipedia reference indicates that L20 and L20A are the same engine. So why would there be a difference? Seems like your real question is "where was the L20A engine used?" Again, just trying to help out. The answer to your question seems to be that there are no differences. They are the same engine. The A was added to show that it's the 6 cylinder 2 liter engine versus the 4 cylinder 2 liter enigne.

-

77 280Z Dropping Fuel Pressure once Warm

Yes, take all of the relays and switches (except the defrost switch) and the AFM micro-switch out of the picture, to see what the pump and FPR do when they have a solid 12+ volts like they should. If the system fails, you'll know that the pump and/or FPR and/or tank screen or fuel supply, are faulty. If the system works fine, you can focus on the relays and switches. From there you can break it down even smaller, like FPR versus pump, or AFM switch versus fuel pump relay. The potential sources get reduced until you're left with one.

-

Engine differences about Series 1 S30 Zs?

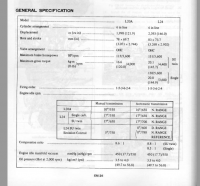

I think I saw some of the responses on your other thread. Some of the irritation might come from the fact that you're not including any of the helpful information from the other replies. You're ignoring what's been said and quoting Wikipedia. Maybe you could put some time in to compiling what you've learned so that people see their help being acknowledged. It seems like you'll keep asking the same question until you get an answer that you're looking for. "Describing differences" is very vague. What is the purpose of your question? Maybe someone can help you get their instead of citing differences. Tom Monroe's How To Rebuild Your Datsun Engine book says that the the L20A is a six cylinder engine that was not sold in the USA. There's a difference. The L20B is a 4 cylinder engine. The 1972 FSM shows an L20A as an option for the 240Z though, which seems odd if it wasn't sold in the USA. Maybe Canada got it. I included a picture of the L20A specs. I collected all of this in 5 minutes with my paper book and the internet. If you could do the same, people could fill in the gaps instead of starting from scratch every time you ask. What do you know and what are your sources. Just trying to help you out. Compile what you know and show it.

-

77 280Z Dropping Fuel Pressure once Warm

The 36 psi with pump only (engine not running) shows that the pump and regulator and relays can work correctly. That is actually normal, and is one of the standard tests of the system. But that's with everything cold. One thing you could try to see if it's electrical is to just hard wire the pump directly to battery power. If it works, then you know that you have an electrical problem. I had an AFM problem once, on the road, and used the back window defroster circuit to run my pump. They're conveniently close (two connections at the top of the window), can handle the current and have a switch (the defrost switch). You can run the wires out of the hatch. Or you can find a way to wire it in at the relay. You're kind of at that point where you need to break the problem in to pieces.

-

77 280Z Dropping Fuel Pressure once Warm

You're getting closer. If you could have measured fuel pressure while it was running well, then when it was not, you would know a lot more. Instead of a direct nipple, a T-fitting might have been better, with the gauge left under the hood in a cool spot while driving. If the problem was the fuel pump relay you would have seen low fuel pressure. But even watching the incorrect number on the bad gauge would help. If it shows 20 psi when it's running well, and 20 psi when it cuts out, then you could reasonably assume that it's not lack of fuel pressure causing the problem. The 40 psi is on the low end for maximum fuel pressure but it's close to the spec. for the bypass on the factory stock Nissan pump. Did you get a brand new Nissan fuel pump or an aftermarket pump? The aftermarket pumps typically will reach 90 psi. The Nissan pumps have an internal bypass that kicks in at 43 - 64 psi. I would T that gauge in between the filter and the rail, and take another drive. Take a note of fuel pressure several times while it's running well, then as soon as it cuts out get another. Proper fuel pressure is critical and you just don't have any good data on what it really is when the problem happens. You have to get good numbers to understand what the system is missing.

-

Has anybody attempted to repair their ECU?

Makes sense. I see also that sccanf's has an extra D315, right below the burned diode. Missing in yours. Looks like a tough puzzle. I wonder if one of the old Nissan diagnostic testers would help with the project.

-

Has anybody attempted to repair their ECU?

You're right, I assumed that the green on the ends was a stripe. There's not enough information in your picture to tell. I wonder if there was enough variation in components that the final parts were chosen based on test results. Add up a bunch of plus tolerances or minuses and maybe the end result is out of product spec. Just a thought. Considering the injector open times are so small, it's incredible that they could build a functional board "solder by number" alone. Who knows.

-

Has anybody attempted to repair their ECU?

Interesting that the resistors in the upper left of your picture are different than the ones in Post #21. I have several ECU's that I've collected. I'm going to open them up and see how things compare, so if anyone wants a picture I can get it. I actually fixed one that had the two (or one of the) main injectors go bad by replacing them with my best guess. The failure symptoms, holding the injectors open, seemed to indicate that and I got lucky. I know very little about electronics.

-

8/70 240z transmission question

Here's another thread on shift kits that I just came across. Not that a shift kit is necessary, just posting because automatic transmission threads are few. I think it's the same guy. DIY Stage III Shift Kit Installation for S30 and S130 Jatco Autos - Drivetrain - HybridZ

-

Car stops pulling at 2500 RPM

Channeling Occam (actually William - I had to look it up) and Einstein and KISS - are you sure that the throttle blade is opening completely? It's called a throttle for a reason.