Everything posted by Zed Head

-

Recurring question, no seeming answer...

The 79 FSM says there's a valve, but it's on top of the intake manifold, not in the throttle body, connected to the coolant block (probably the one under the AAR). The thermal vacuum valve. Thermal and vacuum! Could be something. Connect to the throttle body by hoses. Might be worth a look, page EC-8. Maybe there's another port waiting to be blocked. The coolant alone takes a really long time to heat up the AAR. I've had my AAR power disconnected and the high idle lasts forever.

-

Can of Worms Opened...Can I trust Datsunparts LLC for a transmission

There's a lot of "red flag" BS and nonsense in his eBay pitch. We are a professional licensed Datsun Restoration Business. Our parts are backed with a 100% money back satisfaction guarantee. Trust an ebay LICENSED Seller for all your Datsun needs! All engines must be installed by an A.S.E. certified mechanic or other licensed professional shop for warranty to be valid. Buyer responsible of all return shipping cost. SUbject to 10% restocking fee on all returns

-

Recurring question, no seeming answer...

I would like for something that lets air past the throttle body or leaks un-metered air in to the manifold. It only takes a little at idle to get a lot of RPM. BCDD was worth a look. Check power to the AAR also. It should be on as soon as the engine starts, causing the internal heater to start closing the valve. Or you could pinch the AAR hose when the idle is high and see if it drops. A few thoughts. If you can isolate it to one area you can focus. I think that the EGR systems also have some temperature actuated devices. EGR is air in to the intake manifold. Supposed to be closed at idle but would cause an idle RPM increase if it opened. Are you running the 76 intake manifold or 79?

-

HELP! Upgraded alternator in my '75 280z but headlights now won't work.

A thought that might help clarify - the writeups around the internet about wiring up an internally regulated alternator are just focused on two circuits. The L circuit which energizes the alt. windings and the S circuit which the internal regulator uses to regulate. The other wires are typically just left hanging,and un-needed. If a person wanted to they could probably just unplug the external regulator, leave the wires alone and run a switched wire to L and connect S directly to the battery. But none of this probably matters to the headlight problem. There's no reason for your headlights to have stopped working. It's probably just coincidence and while the car sat the dimmer switch lost contact. Shoot some contact cleaner in to the dimmer switch at the base of the turn signal stalk. Although - you never said that the alternator was actually charging, only that the engine runs. the engine will run from battery power alone. So, what is the ammeter doing while the engine runs?

-

HELP! Upgraded alternator in my '75 280z but headlights now won't work.

I think that some of those extra wires are hot. One probably hot all the time (connected to the battery), the other hot when the ignition is on. Better check and insulate. Here's a check that you should do - with everything off, disconnect and reconnect the battery negative post. Look for a spark at the terminal when you connect and listen for a relay click in the cabin. There's a problem with 76 that you may or may not have with 75.

-

HELP! Upgraded alternator in my '75 280z but headlights now won't work.

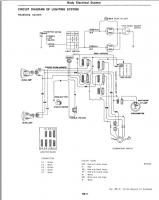

I'm not suggesting that you do the modification in the attached link. But there is a drawing that shows the link. (Two link meanings in one post! - woohoo). I might have the color wrong. Apparently it's the black one, per two posts previous, the FSM drawing. Although black is the high amp link so that doesn't make sense. atlanticz shows black as alternator and ignition relay. So there's confusion. The 75 FSM seems to have mistakes. Either way, worth a check. http://atlanticz.ca/zclub/techtips/fusiblelinks/index.html Edit - black in 75 appears to run many things. They added two more links in 76, splitting the headlights out on to their own. So, overall, my post is only helpful in that it directs you to the FSM. Your 75 would not run if the black link was blown.

-

Rubber caps to block coolant lines - NO !

Bummer. Dorman probably offers a lifetime replacement on those parts that don't work. If you're in a hurry you could loop a section of heater hose from one nipple to the other. Won't look pretty but you'll have the right materials in the right place.

-

Can of Worms Opened...Can I trust Datsunparts LLC for a transmission

I've been watching datsunparts llc over the past few years and it seems like the guy is watching his reputation. But the stories from the past are still there so you know that at heart he's just a guy making money any way that he can. As you noted in your other thread, having a free repair or return policy without paying for return shipping is almost worthless on big heavy parts. zcarsource should have checked your bad transmission before they shipped it. Now you're stuck with the problem. I think that datsunparts will be the same risk. Many of the wrecking yards have a full value replacement policy on their parts. You're still stuck removing and trying parts until you get a winner, but you're only out labor and gas money, instead of big shipping costs, if you can find a local yard.

-

Rubber caps to block coolant lines - NO !

Dorman is an America-based company. Ultimately they are responsible for specifying and controlling product qualities. To hash it over one more time - the off-shore companies just produce to the specs. they're contracted to produce to. This is an American issue entirely. Corporate Info But, all I really wanted to know is what Dorman designed the parts to do. Maybe you're using vacuum line plugs on the cooling system.

-

Rubber caps to block coolant lines - NO !

Do you have the part numbers? For future reference.

-

Reaction Disk

You probably want something in the rubber hardness range, like tire hardness. Pretty vague, but I mean not jelloey and not super hard urethane. I think that the way it works is it distributes the movement from the pedal and booster to the master cylinder. As you push the brake pedal some of the movement is absorbed by the rubber disc. That's why when it's gone, you get the on-off feel. If you go too soft and jelloey, you might get a good feel until the rod bottoms out through the disc then you'll be back to off-on. If you go too hard you'll just get a less-pronounced off-on feel. Just a guess. The weird names that Nissan gives parts have some clues in them though.

-

Recurring question, no seeming answer...

Are you using the 1976 EFI system or 1979? They have significant differences. Also, 76 or 79 (or other) distributor? Which ignition module? 76 has two timing circuits, for example. And the 79 engine might have a few funky temperature actuated vacuum valves on the intake and thermostat housing. I've actually never seen this problem described, with normal - high idle - normal. I've seen normal - low - normal, but not your scenario.

-

Sorry to be Redundent - Help

I rewired the door switch and buzzer to the running light power circuit. A tap from the output side of the light switch through the buzzer and door switch to ground. No more running back to the car to turn the lights off and save the battery. Here in overcast Oregon, with my dull brown paint, I tend to drive with lights on in the daytime. I had to replace the stock buzzer with a Radio Shack unit though. The original was physically damaged for some reason.

-

HELP! Upgraded alternator in my '75 280z but headlights now won't work.

Have you checked the fusible link? The green one that's sitting out in the open in your second picture? So close you could stick it with a meter probe. The headlight circuit wires are all red with stripes or white.

-

Major screw up

When is the last time the engine ran? Puff-puff-puff while cranking might be an intake valve stuck open or an exhaust valve not opening. Or a leak at the manifolds. Are you sure everything is tight?

-

Cam drive and lube

You most likely don't need them. You could have a big leak and still maintain pressure in the bar. Do you mean rotational play around the sprocket bolt center? That would change cam timing, but +/- 1 or 2 degrees probably wouldn't be a huge deal. The adjustment holes are 4 degree increments, so Nissan expects a 4 degree range over the life of one adjustment cycle. The bolt is supposed to supply the clamping force to stop slippage, not the dowel. The dowel's purpose is probably locating the sprocket and stopping it from moving while tightening the bolt. If you want to get fairly exact on cam timing you can line up the notch and groove, then tighten the sprocket bolt.

-

How to test rear defroster glass grid

There's a procedure in the FSM, using resistance measurements. But an easier way might be to just to fog it up and apply battery voltage to the terminals. It's one grid, positive on one tab, negative to the other. Polarity doesn't matter.

-

1978 280z No Power to the Starter

You could also put a little extra twist in the flat rod that connects the cylinder to the electrical portion. Two pairs of pliers will do it. I had the same problem.

-

1978 280z No Power to the Starter

Connect a jumper wire to the small connector on the solenoid (the one that can be pulled off by hand, yellow wire) and hold it to the battery positive post. That should actuate the solenoid, causing its plunger to move, which should then actuate the motor relay and drive the starter gear in to the flywheel. It's what the ignition switch does. It sounds like what you're jumping at the solenoids is just bypassing the solenoid's internal relay. Jumping the solenoid directly from the battery will tell you if the starter is good or bad, then you can focus forward or backward from there.

-

1978 280Z - Just interesting to look at. Why a Z is not an investment.

"78 Datsun 280Z 5spd w/ A/C Comes with tarp and bands to cover leaky area. Apologies if this car is a member's. It's a 78. Even the 240Z classics are't getting close to $10,000.

-

EFI Fuel Pump O-Rings

Way back when I remember seeing seeing general guidelines on sizing o-rings based on the gap they were sealing. They're supposed to compress a certain amount but not fill the gap. The circumference is not meant to stretch much at all, the point is to just gap-filling. The proper word for the purpose is "gland", I believe. So really, you should be measuring the metal parts, not the rubber, to size the ring. Found a few references but there's a ton more out there. You could spend some quality fun time just studying the possibilities. eFunda: Introduction to O-Rings Gland Dimensions http://www.parker.com/literature/ORD%205700%20Parker_O-Ring_Handbook.pdf

-

Coolant sensor question.

There are two types of temperature "sensors" on the Z and ZX thermostat housings. One is typically called a sender and has one connector on it usually a bullet style, using the threads in the housing to ground the circuit. It's used for the temperature gauge. The other has two pins in an EV1 style connector (like the injectors use) and is used by the ECU to know the coolant temperature. You might want a temperature switch instead. Or if the Spal fan has its own temperature measuring circuitry then you'll need to use one that is compatible with it. There are different types among the various car manufacturers and they have different curves. Old Nissan sensor might not be on their list.

-

240z bumpers to 280z brackets

Edit - This stuff, designing and fabricating, is harder than it looks. And there is no real volume to be tapped to speak of for these specific parts, so price elasticity doesn't really apply. Take the pictures and your car in to a shop and see what they would charge. Who knows.

-

240z bumpers to 280z brackets

Someone took the time to figure out the proper dimensions, put them to paper, get them fabricated or did them themselves, and is offering the results of their work. Try it yourself and come back with your price. Maybe you'll make a few dollars.

-

Just ordered my Rebello 3.0, now what

That seems a little bit vague and general. If you have the 260Z distributor it's set up for carbs, if you have a ZX distributor with the side module it might have a high advance vacuum system designed for emissions engines. If you have one of the 280Z distributors there are essentially two sets of advance curves, high vacuum, low centrifugal for the EGR systems and vice-versa for the earlier non-EGR. Just saying, it seems like there could be more attention there. It's all part of the fun though.