Everything posted by Zed Head

-

Using the EFI Correction Box

It's the same as the common potentiometer installation (isn't a two terminal connection more properly called a rheostat?). Seat of the pants or an air-fuel ratio (AFR) gauge or nose are the ways to measure effect. It changes the response curve across the complete range of conditions, I believe. If you want to change the idle AFR only, it would be be better to use the idle air screw on the side of the AFM. That's the one where a "sniffer" is recommended, by the FSM instructions.

-

Pertronix Burn-Out

Surprising that that is still a problem. Most modern electronic modules are designed to remove this issue. Also surprising that Pertronix doesn't have an add-on solution. Maybe that's where some of the Pertronix failures come from. You could run the output through a GM HEI module and let the HEI control the coil. Module triggering module. The HEI module doesn't put full current through the coil unless the engine is running. It would be kind of goofy but I think that it would work. $25.

-

'73 Rear Stub Axle

If you're on the Oregon side of WA ST. there are a couple of 240Z's in the local salvage yard.

-

11.3 volts

I didn't look at the wiring diagram but if the running lights switch is on the circuit that could be your drop. It's combined with the headlight switch, in the same box on top of the steering column. Does the top of the shell behind the steering well get hot when the lights are on?

-

Help....Z won't start

The relay you bought should work, if that's what you need. The Ford relay is popular because someone that knows a lot used it and described it and likes it. And, apparently, it triggers at a fairly low voltage, which is good. They both work the same way. The test I described will show you if the relay offers anything though. If jumping the solenoid directly to the battery doesn't solve the problem then the relay won't work either.

-

Differential Swap: Should I Use A Lift or Not?

I've always left the mustache bar in, never actually left it attached to the diff, only seen it done that way. Thought it was worth mentioning. As madkaw says, the diff will hang from the two studs in the bar without the nuts, giving time to practice lifting and moving it before bumping it forward it and letting it down. I've also found that the inner half shaft nuts can be removed using a bunch of extensions on a ratchet handle, working from the wheel well, if you rotate the shaft to the right spot. Leave the outer nuts for last so that you can use the wheel to rotate the shaft. Also, the half-shaft flange can be a tight press fit on its locating center. You might need a punch or chisel to knock it loose, on the inner and outer sides both. If you use a chisel to split it, make sure that you don't leave any burrs on the surfaces when you put it back together. In principle, it's pretty simple but there are few spots that you can get stuck at.

-

Help....Z won't start

Sounds like the ignition switch works correctly but the solenoid may not be getting enough current to make and hold the contact. I don't know if there are multiple contacts in the switch or just one that splits though. You could remove the small wire from the starter solenoid and attach a jumper. Take other end of the jumper and touch it to the battery positive post (basically a home-made remote starter). That should activate only the starter solenoid and the starter. That will take all of the wiring and relays out of the picture and focus only on the solenoid and starter. If it works correctly, the problem is somewhere in the wiring and relays/switches. If not the problem is still at the solenoid and starter. Make sure the car's not in gear when you do that, since you won't have a foot on the clutch pedal or know where the shift lever is. People have run over their own feet doing this.

-

I am at my wit's end with these brakes!

Have you checked your flexible lines? The ones that run from the body to the suspension. You might have one about to blow. Expanding when pressure's applied, contracting when released. Might need help to watch while the pedal is pressed.

- FW471B Mystery Switch

-

Gm HEI upgrade on a 78 280Z

When I installed the HEI module on my 76 car, I left all of the wires to the coil and ballast connected. I only disconnected the two trigger wires from the distributor, and the factory module in the cabin. I used two jumper wires directly from the coil posts. A jumper from the coil positive to the B terminal, and a wire from the coil negative terminal to the C terminal. The two wires from the distributor, a green and a red, were connected green to G and red to W. If you have two blue wires from your distributor, you'll probably find that they are spliced to green and red inside the distributor. If you connect them backwards it won't hurt anything but your timing will be retarded and jumpy. If you find that just swap them. I also ran a separate wire from the wide mounting grommet on the HEI module to a verified good ground. If you're positive that the screw through the mounting hole is a good ground that would be unnecessary. Eventually I removed the ballast and made other modifications but that setup worked fine for quite a while. On your 78, you can do the same thing, the absence of the ballast won't matter. It's all about coil power control.

-

!!!Exhaust is burning my eyes

My mistake, thanks for the correction. I wish they had extended the fuel cut to a lower RPM. I think that's a big part of why these cars tend to be gassy smelling. 3200 RPM is pretty high, even 2800 is. Regualr driving gives no fuel cut most of the time. My 95 Pathfinder, apparently, cuts fuel when the throttle is shut at any RPM if moving. They learned. p.s. to my other post - My BCDD and TPS both check out. I think that my AFM is a little bit funky and has an uneven enrichment curve. Not super relevant to the OP's problem. Enough about my car...

-

Final word on spark plugs for L28

A 5 is actually a hotter plug than Nissan recommended. Not sure why NGK would show differently. For many short trips where the engine might not heat up completely a 5 would be good. Extended freeway or constant speed trips (normal driving) a 6 might be better. 7 would be for extended trips with expected high engine temperatures and high loads, or racing.

-

!!!Exhaust is burning my eyes

What RPM are you talking about while decelerating? The ECU also has a fuel cut function, from 3200 to 2800 RPM on the way down. Page EF-12. The BCDD's purpose is HC reduction (EC-5). Not idle control. It's not clear how though, the FSM just says it's for "maintaining manifold vacuum at the proper operating pressure". Maybe to provide extra air to allow proper burning of any fuel injected. Implied by the word "operating" in the FSM description. I'm glad this came up because I've been catching one sharp whiff of unburned fuel right as I stop. Noticeable since it's warm now and the windows are down. Off to check the BCDD... Edit - just realized what that one connector with the plug in it is for, up by the coil. It's the BCDD, and maybe other, "function test connector". Looks like a pain. Edit 2 - the instructions in the FSM for checking the BCDD are confusing. Check resistance and voltage on the same circuit at the same time. Might take more thinking. Edit 3 - I think that instructions in the FSM for the BCDD are incorrect up to 1978 (says that 0 volts is good for everything - incorrect). The 1979 FSM has a whole new test procedure with new diagrams and a chart. That makes sense.

-

Differential Swap: Should I Use A Lift or Not?

Didn't realize they'd go bad so quickly. He didn't give any gory destruction details. I've replaced mine several times using jack stands on the rear only. They're heavy so if you used an auto lift you better be able to maneuver about eighty pounds over your head easily, or have a transmission jack. Doesn't sound like a whole lot but it's an awkward load. On the ground on jack stands you can either bench press it or use a floor jack, balancing carefully. I've always used a floor jack for ease and to stay less greasy, plus it makes it a one man job. There are basically two ways to do it, leave the mustache bar on and it will drop straight down and go straight back up, or wiggle it forward to release the studs from the mustache bar, and reverse that to install.

-

Final word on spark plugs for L28

I think that the bigger gap came when they went to a better ignition system. They got rid of the ballast resistor, changed the coil, and most likely improved the internals of the ignition module to take the higher current. This apparently gave enough juice to open the gap. A guess.

-

Differential Swap: Should I Use A Lift or Not?

Wouldn't it be much easier to just put some fluid in to the diff that's in the car now?

-

PCV Hose Replacement

It might be a multilayer construction. Fluroelastomer on the inside for chemical/oil resistance and cost, silicone on the outside for strength and durability. Multilayer is how fuel line is made, if you get gasoline on the outside of your fuel hose you'll see that it really doesn't like it and will get soft and a little gooey, and bleed black material on to your hands. There was a pretty good discussion on zcar.com about this a month or two ago.

-

emissions fuel check valve

Datsun 280Z Fuel Tank L28E (From Jul.-'76) Nissan Parts, NISMO and Nissan Accessories - Courtesyparts.com

- Compression Test questions

-

Oil sump full of coolant, WHYYY??

Any chance you have a head bolt or two bottoming out? Torque wrench working incorrectly? Dry bolt threads giving high torque wrench readings? Warped head?

-

Crank pully and oil drain plug size confirmation

You got me. I just went out and checked a replacement plug I got at a hardware store and it was 22 mm. I always use my big crescent wrench, so never really knew.

-

Crank pully and oil drain plug size confirmation

One year is not much. But, with the plugs out, you could probably get it to turn with the average length ratchet handle. Or, if you have room, you could put the transmission in to high gear and push the car to turn the engine. 22 seems big. Probably in the 14 to 17 range.

-

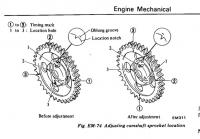

Aligning cam guide to sprocet

You meant half of a millimeter, right? Not half an inch. And the groove should be on the cam shaft retaining plate, matching a notch in the sprocket. The groove doesn't move, but the notch of the sprocket does. Make sure the engine was being turned the correct way when setting TDC. Otherwise you can get slack in the chain and the mark won't be where it would be when the engine is running. "After adjustment" is close to where you want to be.

-

There Goes The Clutch!!

A slipping clutch generates lots of heat, enough to destroy the flywheel. Crawling to the shop while it slips might not be a good idea.

-

I need a brake

Second on checking for pressure build-up. That will narrow it down. Take a piece of hose of the size of the bleeder and run it in to a container to avoid spraying. It seems unlikely that it's mechanical unless your brake pads are so thick that they barely fit between the caliper and rotor and bind when everything expands. Even then, clearance should get looser, not tighter, unless the rotor steel expands more than the caliper steel. I think that you can have pressure build-up in only the front system since the reservoirs are separate. You might just have a bad MC. Maybe it was assembled incorrectly. Maybe there's debris in the return port acting like a check valve.