Everything posted by Zed Head

-

Lighting Problem

Check the fusible links. One of them is for the headlights but may also power the running lights. Or, if you have a voltmeter, check for power at the fusebox at the headlight fuse. If you have power at the fusebox then your combo switch is working but the dimmer switch might have problems (not grounding). If you don't have power at the fusebox, then check for power at the fusible link. It might still have a label on the side that says "HL".

-

Replacement Alternator Question

Seems like the test results are on the old alternator, not the new one, right? Hard to tell. The regulator regulates, the alternator charges, so yes, you can get high voltage from a bad regulator. The extra wire might be for the "P" terminal. Some later cars apparently use it for a 6 volt supply or something like that. There would be a "P" cast in to the housing wherever the wire attaches to the alternator. Your 78 car wouldn't use it. On the "15", the voltmeter's in the car aren't very accurate. Use a meter under the hood. 14.8 +/- a couple of tenths is normal, with the RPM up a few hundred above idle speed. All of these alternators typically put out barely enough voltage to run everything at idle speed. The best way to make sure everything is right is to measure at the battery or alternator terminals with a good voltmeter, revving the engine until voltage stops rising to make sure the regulator is regulating. There were probably instructions in the box the alt came in.

-

What to buy? 1972 240Z vs 1977 280Z

I thought the engine might still be in the car. Yes, the starter mounts to the transmission. Probably an N47 head if you have a white exhaust port. And that must mean the manifolds are off. So you could look for deposits on the intake valves or oil leaking down from the guides. White is good on an exhaust liner, that means it wasn't overloaded with fuel and oil deposits and was staying clean as designed. Too bad you couldn't take and post some pictures so the experienced eyes out here could take a look.

-

'73 AMP gauge conversion issue

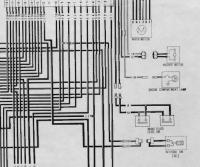

Watched your video and the first thing I noticed was the white gauge faces. So it's been taken apart and re-assembled. At least the needle moves. There is an adjustment screw in the back of the voltmeter (not ammeter) that will set the starting point for the needle. I would guess that somebody turned that screw (a lot) when they were taking the gauge apart. I set mine to sit at 12.6 volts with the engine off by trial and error. Plug the gauge in and note the reading, unplug it and turn the screw, repeat. I notice that your fuel gauge doesn't seem to work either. Gauge wiring is shown in the FSM's Body Electrical chapters.

-

What to buy? 1972 240Z vs 1977 280Z

I would say those numbers are pretty meaningless, but at least give hope. Probably not bad for wrench speed RPM. Can't you borrow a car battery and jump it? You could even disconnect the starter from the car and jump the starter directly. You can tell a lot by looking if you know what to look for. How did things look? Broken manifold studs, sludge under the valve cover, spark plugs from the L28 (this time), etc. They can tell you something about how the engine ran before the car was parked.

-

What to buy? 1972 240Z vs 1977 280Z

Oil fouling is a bad sign. Valve seals or rings could be bad. You won't have much time to tinker with the old 240Z engine if you're trying to get the L28 to stop smoking or just run right. You might keep looking. My old L28 had bad valve seals and would only run well after a high RPM run to burn off the crud. Otherwise it just ran "okay". The cylinder pressure numbers were great, you couldn't tell the seals were bad by that test.

-

Lighting Problem

List the order in which you did all of the things in Post #1. Can't tell when you replaced the fuses, before or after the starter change, for example. Did you disconnect the battery before the starter change or try to get by with being very careful? Also, why did you change the starter? Maybe it wasn't the problem.

-

no fuel gauge

downloadthemanualandcheckthewiringdiagramherehttp://www.nicoclub.com/FSM/ When you get to a computer. The files are probably too big for your phone. Using the internet from a phone is difficult.

-

Differential Advice, Please

Here's a link to the new seller of axles for the Subaru diff swap. Johnc, a forum member here, developed it over on hybridz.org and it's pretty popular. Tranny & Rear Diff Parts For what it's worth, I noticed the difference between a 3.54 and a 3.9 in my 76 Z with a later ZX 5 speed (3.062 first gear ratio). It really depends on your driving style. If you're a clutch-slipper, you might not notice, but if you're a clutch-saver you probably will.

-

Noobie here needs Fuel pump help!

It sounds like your timing marks are not aligned with the #1 piston being at top center on the compression stroke. That's what you should check next. The timing flashes aren't worth anything if the marks aren't correct. If I was in your shoes I would pull the valve cover, rotate the engine until the #1 cylinder cam lobes come up (compression stroke), and stop when the timing mark on the damper pulley is at zero on the indicator. Then see how close the timing sprocket notch is to the oblong groove on the camshaft retaining plate. If they are aligned, you could assume that the timing mark is within about 8 degree of correct. Whatever the reason that the timing flashes that you're seeing are not working with the marks and indicator, a new distributor will have the same issue. I've also seen my timing light pick up the next wire over's pulses. But your problem sounds more like a bad damper or screwed up timing marks. OR, considering that it's not your car and have no idea what's been done to the engine, and this statement, "Good news is he says it has the bottom end from an 81 so higher Compression.", it might just be that somebody has built an old-school 12:1 CR "race" engine and it will never run with standard timing. Overall, it might just be time to check the basics of the engine; cylinder pressure, confirm correct timing marks, check camshaft timing (notch and groove), etc., to see how much farther you can go.

-

Noobie here needs Fuel pump help!

I've always thought of "static" as meaning no advance mechanisms in play. Basically idle timing. Maybe I misunderstand the terminology. Anyway, if the car runs and you have the timing light connected to the #1 cylinder wire and you're getting a steady light just in the wrong place, it won't matter which distributor you have installed. The timing light just tells you when the spark happens in relation to cylinder position. The engine will run the same way at idle with any distributor and module that's producing spark. These engines will run, sounding like tractor engines, if the spark plug wires are installed in reverse rotation order. Backward. Worth a double check. They probably like different timing in reverse also. At least it's running well enough to know that you have a timing problem. You've made it quite a way from "fuel pump help".

-

Noobie here needs Fuel pump help!

Is this the Z Car Source distributor? Good to know for future customers. They're going to give a refund, right? As far as timing, if the engine is running you should be able to set static timing. The vacuum advance should be on ported vacuum and the idle speed should be below the start of centrifugal advance so nothing should be changing at idle. If you had bad springs and an advance weight flopping around you might get jumpy timing though. You'd have to pop the breaker plate out to see that. On the ZX distributor swap - it is simple to do but if your customer wants to retain the car's original functionality you'll need to stick with the stock ignition module and distributor. 1976 Federal models have two pickups in the distributor and two circuits in the module, to bump timing up when the engine is cold. I don't have it on mine anymore and barely notice a difference but it can result in about a minute of lower than normal idle speed while warming up.

-

1973 240Z "240Z head on 280Z block gives realistic estimated 230 HP"

Amusing CL ad in the Seattle area. $22,000. I have a "280z block", all I need is a "240z head". one of a kind 1973 Datsun240z From the ad - Garaged since 1990 when I bought it, fully restored 1973 240z. Simply put, 280z block, 240z head, balanced, lightened flywheel, Nismo headers with Flomaster exhaust, 5 speed transmission, 411 gears. Realistic estimated horsepower of 230. Only flaws are one crack in the dash, air dam has paint chip in it and some very, barely noticeable, dust in one small area of the paint that came out of the door jam when repainted. This is a car that is in the top 1% of its kind and I will only talk to serious buyers. This has been my baby for 23 years and I have over $30,000 into it. reply to this posting through craigslist

-

GM HEI Module Install

Thanks for the story. I had looked at those coils, since they look identical to the others, but found that resistance was typically 0 - 0.1 ohms, compared to 0.7 for the "right" coil. Even though the 4-pin module has current limiting circuitry it didn't seem like a good idea. Better to use the balanced system as it was designed. I can see how you would get burned though, on appearance. Those later coils are typically used with the 7-pin modules that rely on the computer to control timing and current flow. I can understand the "hated that it's not running". 1979 specs. about 0.40" plug gap so Nissan probably has similar high-energy technology in their module. Spark potential is probably just as strong. The main reason to go GM HEI is that it's cheaper, and allows you to keep your distributor timing curves. It's also fun to experiment.

-

Starting a new project...Subaru STI Differential swap into my Z

If the clutch disc is not perfectly centered the nose of the main shaft will sometimes not slide easily in to the pilot bushing. That's the last part, along with the dowels in the engine block, that mate when installing. I've had loose, poor quality clutch alignment tools that would let the disc drop down when tightening the pressure plate. You need the tightest alignment tool you can get, and hold it up perpendicular with the back of the engine while tightening the plate bolts. Spend a lot of time getting that perfect before lifting the transmission up. I've also found that the scissor jack that comes with the cars is great for holding up the back of the engine. You can adjust the angle of the engine on-the-fly as you get everything aligned. Sometimes it's easier to adjust the engine than the transmission.

-

Clogged fuel inlet on '78 gas tank

Only adding this so you can be sure about what lines you're looking at. Seems like the return line would be a straight shot back in to the tank. Maybe use an actual drill bit instead of a piece of speedo cable. Worth a shot before you cut a hole.

-

76 280z ECM?

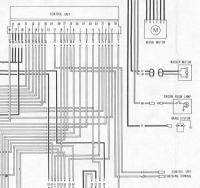

The altimeter wires must be there somewhere for CA models, but the wiring diagram says the white hanging wires are Control Unit Checking Terminals. I should have found this a long time ago, considering all of the time I've spent staring at the 1976 wiring diagram. BUT. Looking at the 1978 diagram I see that there is an altitude switch. But its wires are black. The white checking terminal wires seem to be gone in 1978. I don't see them on the diagram or on a spare 78 harness that I have. One more interesting thing. I've seen it suggested that one could put a switch on those altimeter wires and use it to get a lean tune. Maybe for highway cruising gas mileage.

-

Newbie needs help with build - Springs...

Reading your two posts one thing stands out - you're building a car for you to look at and your wife to drive. Seems like a recipe for dis-satisfaction on both sides. Your wife's idea of comfort is probably different than yours. What do you two drive now? That's what the new ride will be compared to. Hopefully it's an old pickup truck. Don't forget that the lower you go,the more things will drag underneath. My car is not really very low and I still drag the frame rail on certain speed bumps if I'm not careful. p.s. To Eurodat - I cut my springs front and back for about a one inch drop and it did not really make the ride that much stiffer. I figured it was worth a shot and if it didn't work I would get some lowering springs. But the ride was kind of soft to begin with so the cutting just made it better. Plus the lowering had a big effect on handling. I'm actually now running cut stock front springs and Tokico rear springs with KYB shocks. It's a nice ride, in my opinion, but my other car is a 95 Pathfinder.

-

Newbie needs help with build - Springs...

I've seen it suggested, and it seems reasonable, that tire choice can have the biggest effect on smooth road (small bump) ride harshness. The tire sidewalls act as shock absorbers. Next in line would be the shock absorber since its response rate is what lets the wheel move instead of the car body. Then spring rate, since a stiffer spring will also move the body along with the wheel. The opinion that "coil-overs" cause a harsh ride probably comes from the impression people get when they change three things at one time. Typically, low profile tires, high rate springs (because total shock travel is usually reduced), and "performance" shocks are all done at the same time. Add them all up and you get a harsh ride. And, the Z cars all come from the factory with coil-over-spring struts (aka coil-overs). What people call "coil-overs" are actually just adjustable spring perches for use with coil-over-spring struts. Typically they also section, or shorten,the strut housing so that they can lower the spring perch and use a shorter shock absorber. A person could add adjustable spring perches, keep the stock springs, and lower the car an inch or so and probably be fine. So you really need to decide what you're trying to do, and take in to account the condition of the roads the car will be driven on. The right tires could give smooth ride on a lowered car if the roads are in good condition. On the other hand, pot-holes and sharp bumps will give a harsh ride on a car with racing shocks set to a high damping rate (Illuminas on 5 for example). That's what I've learned over the years. It's the combination of parts that will determine the ride quality, not just "coil-overs" versus stock. And don't forget bump-stops if you lower the car.

-

Just wow.

There's an interesting thread on Hybridz about that. Someone's car showed up at a car show under RockyAuto's name. The impression given at the show, whether intended or not, was that RockyAuto had built it, even though they had actually bought it. It was essentially unchanged at the show, but there was no indication that it came from somewhere else. Maybe they used to build cars, but they seem to have spread in to buying and selling, and using the RockyAuto name to help sell. Fairly typical brand name over substance business practice.

-

Thinking about selling my BABY:(

Misleading title. I thought you were trying to raise money to buy a Z.

-

Signature picture size and viewing

Does anyone know a good way get a big view of the signature pictures? Many users have what look like nice views of their cars but the images are tiny. All you really see is red Z, blue Z, brown Z.

-

bumper swap

There are a couple or more people on the forum who have discharged the 5 mph shock absorbers and pushed the big bumpers in. They're the same size but they don't stick out as far. I haven't seen a good picture though so can't say what it looks like.

-

1972 240Z - Classic form

Came across this video this morning. Shows what an old 240Z can be if it can make it through the years without wearing out or being modified. I think they call cars like these survivors. I'm not selling or advertising. This guy posts a lot of videos of his highly modified 240Z over on Hybridz.

-

Air Flow Meter

I'm just trying to help you get focused. I can tell from your thread that you're thinking about five things at one time and not sure about any of them. Kind of paralyzed with too many possibilities. The test with the starting fluid lets you eliminate, for the most part, the ignition system. Now you can focus on why the injectors aren't spraying fuel while the engine is turning and spark is being created. Have you confirmed that Pin #1 at the ECU connector has continuity to the negative post of the coil? You haven't given enough detail to tell if you've actually done the specific tests to determine that the ECU has what it needs to open the injectors. And, no offense intended, your questions about whether the water temp switch or the AFM can stop the injectors from squirting shows that you may not fully understand what makes the injectors squirt. Even though you've read all of the right stuff. Hence my specific questions, and comment about how you just need a few more numbers to get there. I still have things on my car that would never have been put there if I knew then what I know now. It takes a while for everything to soak in.