Everything posted by Zed Head

-

New guy from Ohio

Using a Z car site for photo hosting doesn't seem right.

-

Tachometer Resistor Value

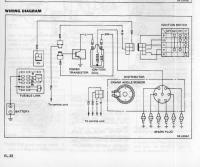

The attached 1983 Electrical diagram suggests that there should only be one blue wire off the coil. Tried to figure out where the tachometer gets its signal but the later FSM's are much worse than the early Z FSM's in describing and illustrating how things work. The turbo motors use a Crank Angle Sensor (CAS) which I would guess also feeds the tachometer. Probably through the ECU.

-

Tachometer Resistor Value

I measured 2.3 kOhms (2,300 ohms, to be clear) on my spare from a 78 280Z. That's on the negative side, between the negative post and the tachometer. In series. I have also used the resistor without the tachometer connected between the negative post and ground, to run an engine on a stand. I think that it might also "condition" the Pin 1 signal to the ECU, since they're all branched off of the same line on a 280Z. Maybe absorbs voltage pulses or something. The ECU seems to need it to work right.

-

no power help!

The fuel pump is not like the motor on an air compressor. It does not stop running when target pressure is reached, it runs all the time when the engine is running. The fuel pressure regulator (FPR) bleeds off excess pressure to maintain target pressure in the fuel rail (the fuel tank is not pressurized). How long did the car sit before you bought it? Old fuel was mentioned in another thread, and that's something you should consider. Some fuel will last for years, other goes bad in less than a year. Give a short summary of the condition of the car when you bought it, a new clue might show up.

-

280ZX distributor control module

I forgot that from the other thread. No vacuum advance. 20 + 17 puts him at 37. He had 30 degrees total in that thread, post #13, but didn't report how it drove. New distributor implies that there's still pinging. Maybe?

-

280ZX distributor control module

What you might want to double-check is the timing advance curves. Later engines were designed for high fuel mileage and emissions so have a lot of vacuum advance. I copied some entries from the Excel chart. The numbers are initial, centrifugal, vacuum, total of all three (high PRM cruising), RPM at which centrifugal is complete, total of initial plus centrifugal (full throttle above indicated RPM). D606-52 17 12 11 40 2000 29 M/A 1970 – 1972 D611-54 7 24 14 45 2830 31 M 1973 D6K82-01 8 17 30 55 2800 25 M/A 1983 Non-Turbo p.s. Mike, we need WYSIWYG! I spent 5 minutes making it look right and formatting disappears when posted.

-

Just bought a 280Z, engine will not run properly. Help!

I just picked out this one thing because it shows that you might need to spend more time in the FSM. There is a lot of information in there and the Engine Fuel chapter is kind of like a college level EFI course book. The way your engine runs after you read it is your grade (kidding, kind of). Since you've been in to some of the engine and EFI parts it would pay you to go back the Engine Fuel chapter and read from page one. Things will make more sense each time you go through, and you'll realize that there are primitive mechanisms that need to work right. In short though, most of the individual pieces need to work correctly, and they all work together to make the engine run right. There are a few items that are for cold start only, but the rest are important. One other key is that all intake air must have passed through the AFM at one time. And the PCV system is connected to the intake system so any leaks there are essentially intake system leaks. To the question I quoted - no the fuel pump should not run all the time. As you noted, the PO has wired it that way. This is a sign that there was probably some other problem that he was trying to fix. Fuel pressure is key. And once you figure out the Engine Fuel chapter, you can do a lot of testing from the ECU connector without removing parts. What the ECU "sees" is most important.

-

Exhaust Heat in Trunk

I seem to recall a heat shield on my 76 280Z between the muffler and the spare tire well. Maybe Nissan realized things get hot back there. I would suggest getting some insulating material to put between the muffler and body metal but you said it's too loud. Seems like a different muffler with better fit would be in order. Two birds...

-

wire off the starter 1978 280z

The big one came off too? You didn't say that. There's one that has the battery positive and alternator charge wire attached and the other supplies power to the starter motor. Sounds like the one that passes power through the solenoid to the motor is off, based on your symptoms. But that wire is almost never removed. Maybe whoever put your starter together wasn't paying attention. A picture would help.

-

1977 280Z with 350 Chevy engine and a paint job

Saw this CL ad and thought - wow, I could add $11,500 of value to my car with a conversion and a paint job. Actually, his interior is probably in better shape than mine. No low-balling!!! 1977 Datsun 280z READ ON!

-

Fast Lift cam

I wonder if they built a roller rocker arm to go with it.

-

wire off the starter 1978 280z

That would be the solenoid wire. If it was touching ground (because it fell off) when you turned the key to Start you would have a direct short. There should be a fuse in the circuit somewhere. Check the wiring diagrams to see where that wire gets its power.

-

Starting a new project...Subaru STI Differential swap into my Z

Depending on the fit, you might use a stack of big washers and the nut to pull the stud in to place. Check the flange fit first though, re madkaw's post. Did you get the studs from your local dealer or Courtesy?

-

wire off the starter 1978 280z

If the end of the wire was grounded you might have blown a fuse when you tried to start, or when the wire came off, depending on which wire it was. Considering the number of wires attached to the starter, "one of the wires" is pretty vague.

-

Original Shocks (struts)?

I don't know that the earlier cars did not come with steel gland nuts, only that my 76 280Z did not. I just offered it as a clue. Even if you plan to drive the car for a while before any more strut work, soaking in penetrating oil is a good idea. Let it work while you drive. Be careful with heat though if you plan to re-use them, since too much could damage a seal. But heat is a great idea if you really need to remove the nut. I love heat for problem nuts and bolts, it has a huge effect.

-

Tachometer Schematic Anywhere???

FastWoman's first ever post? Maybe? Wow. I picked up a wrecking yard tach the other day, because it was there, spares are good to have, and my current tach is not perfect. Took my 76 tach halfway apart to see what's in there, but got stuck on the glued-on PCB's on the housing and decided to re-visit after some web time. And found this old thread. Are there alternative internals for the old coil negative triggered tachs? I have a 78 tach in my 76 because the 76 would hang at high RPM after it got warm. The 78 tach is offset by 200 RPM so not ideal either. The wrecking yard tach might be a 75, it's font is weird and primitive looking. It would be nice to rebuild the 76 tach and put a good, solid and visibly correct unit back in.

-

Rear end sway?

It's good to look around under a Z anyway because the suspension system and unibody are unusual for anyone used to American cars. And read up on bushings before you go crazy buying, there are varying opinions on what to use for what purpose. Polyurethane is not a fix-all solution. Check your half-shaft u-joints while you're underneath, if you have a grease gun have it handy. Your u-joints might have Zerk fittings or might have screw plugs. If you really want to be ready have a Zerk fitting and flat-blade screwdriver with you also.

-

Rear end sway?

Take a look for loose parts, including lug nuts. And "rear end feels like its sliding back and forth while driving" isn't very informative. Could be wandering while in a straight line, could be while cornering, could be while accelerating, braking, etc. Bald tires, bad wheel bearings, over-inflated tires, worn-out bushings (suspension or steering), many possibilities. You have to get under there and see what the state of the situation is.

-

Will a longer duration cam help get rid of ping?

That's a good point. It's difficult to measure advance when it's off the marks. I've estimated mine by setting static to zero and revving the engine. Still have to eyeball/estimate the final few degrees. I regret not spending the extra few dollars for a dial-back light.

-

no power help!

Aaccck. 1978 went to the oil pump switch or alternator power to trigger the pump relay. Each year has it's own little tricks. For 78, removing the small wire at the starter and turning the key to Start might work. Z cars that have sat also have their own little problems. Like the combination and dimmer switches getting tarnished and not passing current. To the OP, how long did the car sit before you got it? Of course, it "ran when parked" but that doesn't matter much.

-

Will a longer duration cam help get rid of ping?

You should have full advance before 3500 RPM. 24 + 10 = 34 total. Are you using projected tip plugs? I've read that because they start the flame closer to the center of the chamber it's like adding 4 degrees of advance. That would put you at 38 total. I think that worn weights and the pins they ride on can let the advance move further than stock. A timing light would tell you what you are getting, but 24 + 5 is still 29 total. The pros would say you should get some dyno tuning to find what you really need. Do you feel like there's more power to be had, or are you looking for cheaper gas? Also, have you measured cylinder pressure? We all talk about CR but it's really the cylinder pressure that matters. That's why the longer duration cam can help, it lowers static cylinder pressure. It will give you a better idea of your starting point for cam changes or head work.

-

no power help!

Don't forget the basic resource - Index of /FSM And, if you're listening for the fuel pump or checking power to the pump when the key is On, that's not how they work.

-

No brakes

Z brakes are generally hard to bleed. What method are you using? Do you have someone helping, one in the seat and one at the bleed screw? I installed speed bleed screws on my rear cylinders so that I could easily push a lot of fluid through the lines. I've also developed a one-man system using a broken shovel handle on the brake pedal. But using vacuum at the wheels, or pressure at the MC reservoir would probably be easier. It can take a lot of time and brake fluid to get it done. Eurodat's implication is right, you need to start with a good methodical step-by-step plan and get each step right. One bad step can allow air back in. And your car looks modified. Even though they worked before, if you have one of the brake "upgrades" on the front or back, that will add a lot of difficulty to the bleeding (ha ha, that's a UK double entendre pun) process.

-

No brakes

Not sure what changing hoses and lines all around means, but did the brakes work before? Is it a factory stock system or modified? No pressure even with pumping or the pedal goes straight to the floor every pump? You've given not much at all to work with. Check the orientation of the bleeder screws on the front calipers.

-

Original Shocks (struts)?

One clue that you might have original is that the factory gland nuts are aluminum,while the aftermarket nuts seem to be stamped/welded steel. A magnet will tell.