Everything posted by Zed Head

-

Motivation - or the lack thereof...

Grab a tool, of any kind, open the hood and go loosen one screw, bolt or nut that will need to be removed to fix any one of the problems that you know of. If you find yourself an hour later with most of what you're working on disassembled, keep the car. If you can't even get the motivation to turn one bolt, sell the car.

-

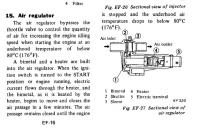

Help me understand the AAR please.

I took your thread title literally, so described how it's supposed to work. The FSM description should help, attached. It shouldn't work like your describing yours as working.

-

Compression Test questions

Yes, it would be from an exhaust valve not opening completely. Pressure pops back through the intake valve in to the manifold. It might not be that at all, hard to tell from the video. You'd probably hear more noise all the time, so maybe not. On a carbureted V8 you'll actually see fumes coming out of the carburetor when it happens. The other possibility is knocking (detonation) from timing too advanced or from low octane gas. Again, just possibilities that sound somewhat like the noise on the video. I don't know what SeaFoam does to the octane rating of gasoline. Timing too advanced could be from a stuck advance plate in the distributor. That might be more sporadic. These are all just guesses. You might just check timing first, rev the engine while checking and make sure it doesn't stay advanced when the throttle is back at idle.

-

Compression Test questions

If you mean that noise that sounds like popping inside the intake manifold, you might check your valve lash settings again. One of them might have loosened up. It sounds like other engines I've heard with a bad cam lobe (common on small block chevys), but in your case maybe just a valve that's not opening completely because the lock nut has backed off and the pivot screwed itself in. Easy to check.

-

Help me understand the AAR please.

The AAR should have power supplied to the internal heater as long as the engine is running. It's on the same circuit as the fuel pump, I believe. So it should only cool down when the engine is not running. If your idle stays high at a light, it's most likely not the AAR causing it.

-

Engine will only run above 4000 RPM. Carbs or timing?

madkaw touches on another possibility, or maybe is referring indirectly. Maybe your timing is just off. Too many posts to go back and see if it's been verified. By the way, my post #64 was in reference to Steve's post #62. Although, it could apply to anyone looking to avoid all of the module and coil resistance matching stuff.

-

Engine will only run above 4000 RPM. Carbs or timing?

A while ago I discovered that GM made an external version of the under-the-cap HEI coil. It's used on a variety of cars and trucks, like the 1977 Nova. It's ugly but it's the coil that the module was designed to use. I've been using it since then with no problems at all and smooth performance. It has a primary resistance of about 0.8 ohms, so probably has a shorter saturation time also, than the 1.0-1.2 ohm Z31 or late 280Z coils. Accel makes a much better looking version. Search Accel remote mount HEI coil to find theirs. Here's an image from RockAuto of the AC Delco brand.

-

retaining clutch springs

Did you change anything? Or did taking apart and putting it back together the same way do the trick? On the clutch, take note of Blue's recent post on counterfeits, especially if you're thinking about EBay. I have an OE-style Rhinopac clutch set and it's very smooth and holds my stock engine and 205-70s just fine. Some people like a grabby clutch so that they can chirp the tires. My old Zoom Perfection OE-style clutch set from NAPA would do that but it also had higher pedal pressure and was grabby when it got hot. By OE I mean not a performance clutch, just stock style.

-

Concerning Engine Serial Numbers

I just went and looked at my 1976 S30 and it's an HLS30... Someone on another forum posted about a 77 HLS30... Did they just get rid of the L for the S130's? Looks like they had it for the S30's. Wonder what happened to wtsawyer?

-

Concerning Engine Serial Numbers

Is that for 1979? The Poster of #13 might have be looking a Japanese market car? Thanks. Edit - Maybe you're just supplying examples of the Japanese Model numbers. Still not a turbo. And I would guess that a left-hand drive car made for the Japanese market would have the L.

-

Concerning Engine Serial Numbers

The GI chapter in the FSM is what makes it confusing. It says that the Model number is part of the what we call the VIN. Model number + serial number = VIN. I'm think that the US market VIN's are different from Japanese market and the FSM didn't get changed to show that. All US cars start as "L" so they left it out, just like all Japanese cars start as "R" so they don't even recognize it with an "R". Forget about the "L" and the Model numbers probably make sense. This is all an aside of course, since the OP can't have a factory-installed turbo even in a 1979 ZX. Unless I'm about to learn something.

-

Concerning Engine Serial Numbers

Good answer. I didn't even really look at the number. Reminds me that I did try to use the FSM once to identify a 1979 by VIN number but couldn't find a number that matched. Which is surprising by the General Information page in the FSM. One of them should have matched, there are so many. I looked in 78, 80 and 81 also. I don't see any HGS... numbers. All of the Model numbers are HLS..., KLS, or GHLS... The L means left-hand drive so maybe they just left it out for the non-Japanese market. It's in all of the FSM's though as a descriptor. You're right though about ZX = S130. Most likely a 78 build date 1979 280ZX. Probably with a transplanted turbo motor. Edit - added the legend

-

Concerning Engine Serial Numbers

Turbos weren't introduced until 1981 so 1978 would have to be a modification or engine transplant. The VINs on these cars don't seem to fit any of the common VIN databases so there's no source of information readily available. And by 1978 Nissan stopped putting the engine serial number on the car's ID plate so there's no way to connect the engine serial number to the car. There's only one good way to get information. Go look. Good luck. Pictures though, would be happily viewed and commented on if you have them.

-

No injector pulse

Here's something that I've seen on my car. I don't completely understand why but I've seen it on two cars and verified it on my 76 (the other was 78 so you're bracketed). If the tachometer is disconnected the ECU won't ground the injectors correctly. The circuit from the negative post is branched, so you'll still see continuity but it just won't work. I assume that the ECU sees two much current or voltage without the tachometer drawing things down. For anyone that wants to verify it, easily, find the lump in the wiring harness under the dash over by the fuse box. That is the resistor that is in-line with the tachometer. Unpeel the tape, remove it, and try to start the engine. I actually knocked mine partially loose while installing a relay, drove in to town, parked for a while and had a no-start when I came back. I remembered that I had just worked in that area, looked on the passenger side floor and the resistor was laying there. Put it back in and it started right up.

-

What is needed for a 1978 PFI 280Z to run?

You can lead a guy to the FSM, but you can't make him open it. Har har hardy har. It's a bread crumb. It's from the Engine Fuel chapter of the 1978 Factory Service Manual (FSM). That thing that we keep mentioning. From XenonsS30. It has smaller, specific wiring diagrams in it also, easier to work with than the the big one, although the big one is worth having also. Not kidding! It will help you out.

-

Compression Test questions

Yes, I meant turn it backwards. I didn't know you were using a remote starter. Doubtful that you'll get it to stop on the spot with that. 12 o'clock is pretty good. I think that the damper bolt is 27 mm. It's difficult to get to though, at least on my car, from the top. Another way to do it is to put the transmission in 5th gear, then nudge the car forward or backward while watching the mark. Probably easiest with the plugs out. You can fine tune the movement by grabbing a tire and turning it. You might have to go forward and backward a few times to get it on the spot since it's easy to go too far.

-

What is needed for a 1978 PFI 280Z to run?

-

Compression Test questions

You're looking in the right spot but it looks like you might have turned things too far. You should set the notch on your damper pulley to zero (where you look to set your ignition timing) to be at TDC. The cam lobes will be up if you're on the compression stroke. Sounds like you're almost there. Back the pulley notch through zero, and down to about the first or second mark (5 or 10 degrees) on the timing marker. Then reverse rotation and move the pulley notch back slowly through 10 and 5 degrees to zero and stop. If you accidentally go past, try again. This will stretch the chain in the direction of rotation, as it would be in operation. The groove should be visible then, close to the V notch in your pictures.

-

retaining clutch springs

Taking the problem to what we called when I was getting educated, "first principles", the slave cylinder should only get pushed all the way out if it is starting from a point close to the end of its cylinder, since it is designed to work with the stroke of the master cylinder. If the slave piston starts from the right spot, the master cylinder can't push it out because it doesn't have the volume (you didn't install a bigger bore master cylinder, did you?). So, for whatever reason, your slave cylinder piston is farther down its bore than it should be. Assuming that nothing is cracking, bent, broken or wearing out, like the clutch fork or collar or pressure plate fingers, then the fix is a longer rod. That will push the slave cylinder piston back up the bore to a new starting spot so that it can get its job done before it pops out. I believe that the only thing determines the piston's resting point, is the tip of the clutch fork, which is determined by the pressure plate fingers pushing back on the collar, pushing on the fork. Can't say what was happening before, but that seems like the best fix. Worst case, you cause some funky wear on the pressure plate and/or collar but you're thinking of replacing them anyway. It's a "can't lose for trying" effort, I think.

-

Engine will only run above 4000 RPM. Carbs or timing?

Just noticed the "new RX7 fuel pump". Maybe you're getting too much fuel pressure to the carbs. I don't know anything about SK/OER carbs. Maybe a defective/sunk float or bad needle valve. Most of your signs point to flooding.

-

Clutch Pedal Soft - Parts Confirmation

What was on the car before and how well did it work? Hard to tell if you've accidentally created a new problem or if you were trying to fix an old one. If it worked before, then something's changed, if not, maybe it was never right.

-

I am at my wit's end with these brakes!

Marty Rogan's post on the racer's trick reminded me that, where air bubbles are concerned, you might be missing something. Others have found that, although the bleed points looked like they were correct, they weren't actually at the very top of the cylinder, where the air bubble is. You might have two choices of up or down, but the "up" is not the "top" where it has to be. Some people have removed the calipers and repositioned them so that the bleed point was definitely at the top, then bled them with the calipers unbolted. You just have to make sure they squeeze on the rotor, or insert a block of wood in to the space. The racer's trick probably works because it squeezes almost all of the fluid out of the cylinder so the bubble gets pressed out even if it's not at the top.

-

Compression Test questions

#3 looks so dry and clean that the injector might not be opening at all. Might be worthwhile to put it back together, start it up, and remove the injector connectors one at a time. Each one should cause a drop in RPM when it's removed. If #3 is "dead" there won't be any change. Then, if you find no change with #3, swap 3 and 4 or 3 and 2 and do the test again. See if the problem stays on injector #3 or follows connector #3. It will tell you if it's the injector or cylinder, versus just the injector connection. If it stays with cylinder #3, and the spark plug has stayed dry, the odds are good that it's an injector problem. If the spark plug comes out wet, it's probably a spark problem.

-

Do I need to remove engine and transmission to check loose clutch withdraw lever?

You can remove the transmission without removing the engine. It's commonly done when swapping transmissions and not too difficult. Make sure that you get the car high enough to slide the transmission out from underneath before you start. It's really a pain to try to raise the car a little more when you have the back of the engine supported with blocks or a jack. I've found that the car's scissor jack is excellent for supporting the back of the engine, it allows you adjust it up or down as needed to get the proper angle. 92 mm is approximately the distance that you want from the surface that the clutch fork rides on the throwout collar to the surface of the fly wheel. Might be difficult to measure from under the car. Might be worth your time to install a new clutch set while you're there.

-

What is needed for a 1978 PFI 280Z to run?

Not sure where intelligence comes in to play for not getting something put back together. Maybe he just found something better to do. You spent $2000 and have a car that that doesn't run! What did you spend the two grand on and what's your goal with the "project"?