Everything posted by Zed Head

-

280z control arm

-

280z control arm

The Nissan bushing does not move/spin. It flexes. That's why you're supposed to tighten the bolt with the car on the ground.

-

resurrecting a 1977 280Z

Did you measure the stack height of the throwout bearing sleeve on the pressure plate? 92mm +/- a couple.

-

resurrecting a 1977 280Z

I saw your other post, wherever it is, about the pressure plate fit. Had a vague memory of a past thread about it, it's out there somewhere. Just now remembered the details. What I recall is that you can bolt a 240mm pressure plate to a 225 mm flywheel, using just 6 holes of the 9. If you use a 225mm clutch disc you should get 225mm performance but the outer edges of the pressure plate will not contact the disc. It will be like a 225mm clutch. Or you could use a 240mm disc but it would be riding on unsurfaced 225mm flywheel. Not clear what parts you ended up using or if you measured the parts. If I recall your other post, and from the pictures here, you have bolted a 240mm pressure plate to a 225mm flyhweel. Disc size unknown. Anyway...why did you grease the flywheel bolt holes in the crankshaft end? That's bad. You want them clean, and maybe even with some thread locker. Probably okay if you torqued them to spec but not really recommended. As far as balancing, you'll find guys that balance everything as an assembly, because they can and have made race engines. For insurance. But the parts are designed to be mix and match. Everything is balanced separately.

-

1973 Rebuild

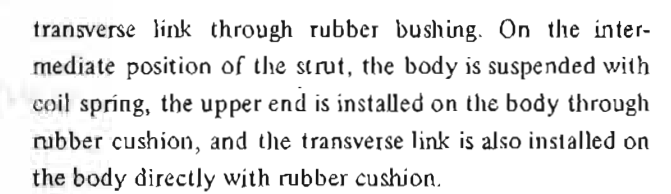

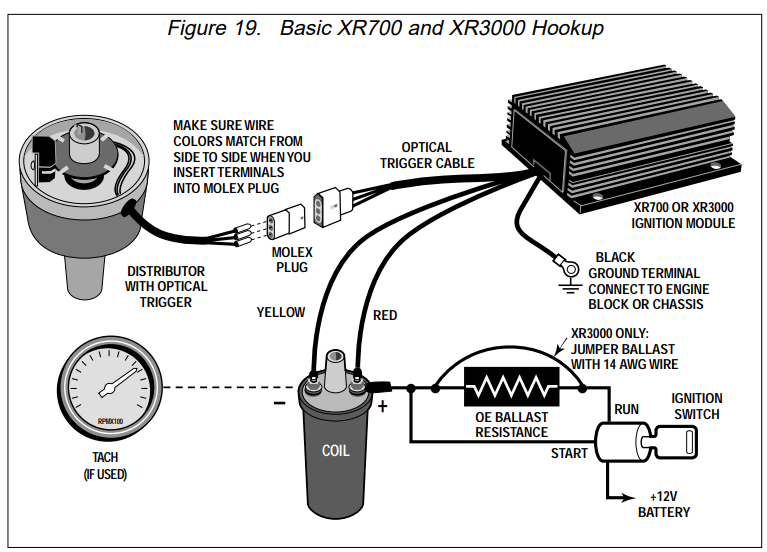

Page 16 here might help if you run in to problems. The Crane systems are electronic, like the ZX modules, and, apparently, people occasionally have problems when they convert from points to electronic. They describe how to adjust the tach. It's the system that the 240Z uses. Pretty sure that others have mentioned the same adjustment in past threads on the forum. It's not obvious. https://static.summitracing.com/global/images/instructions/xr700 instructions.pdf I also uploaded these to the Downloads area -

-

Won't run if tach connect?

Just browsed thorugh the XR700 instructions. There's actually a lot of good basic knowledge in there. A whole section on adjusting the loop for the Smith type current sensing tachs. Pretty cool. But, the part you need is the basic setup diagram. Nowhere in the instructions do they mention a blue tach sense wire. There is a blue in the tach adapter section. but it's a power supply wire. If you're using the tach adapter you have blue connected to the wrong spot. Start over and read the instructions, I'd say. But maybe you don't need the adapter.

-

AFM Loose Arm

-

AFM Loose Arm

Have you looked at the other end of the shaft? Maybe there's a clip missing. That would be a start.

-

AFM Loose Arm

That's not really tuning. It's just messing with things. When you change the tension on the spring you alter the air-fuel ratio curve over the whole of the air flow range. You can't pick a spot and "tune" it in. p.s. the procedure from atlanticz is meant to get the AFM back in spec after people mess with the spring and ruin the AFM performance.

-

AFM Loose Arm

I think I answered the question earlier. If you really believe that there is play that is causing the wiper arm to lose contact with the conductive trace then you'll have to find a way to take it apart. The AFM rebuild guys do it. But they have skills and special tools. There's almost always a way to get things done.

-

Won't run if tach connect?

Probably messing with the make/break circuit to the coil. Have to see how the whole system is wired to know what's really going on.

-

AFM Loose Arm

Might be that there's a problem and you're assuming that it's caused by some wiggle you see in a part. Probably better off to describe the actual problem and see where other people end up as far as the cause. And, p.s., these EFI systems aren't really "tunable". So, not sure what you guys are trying to do . Good luck.

-

AFM Loose Arm

Actually, not sure how this translates to losing contact with the wiper. Not really sure what the problem is. Posting anyway even though there's a reply...

-

AFM Loose Arm

It's worth big money as a core though. Don't throw it away or smash it up.

-

AFM Loose Arm

The vane should be binding up in the housing then. From the pictures it looks they stake the ends of the shaft. Doesn't look like it's meant to be disassembled. You'd have to wing it and get creative. Basically, it sounds trashed otherwise.

-

AFM Loose Arm

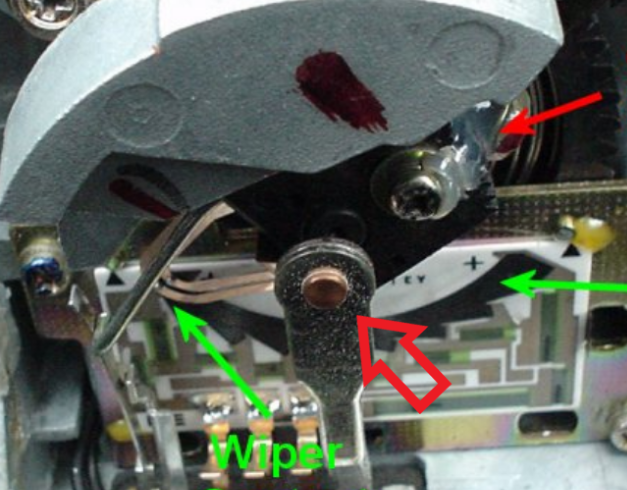

I don't think the AFM would even work if the contact arm is losing contact. Are you sure you're not watching the weight move? It might have play. The vane would probably bind if it was loose on the shaft. A picture or video might help the cause. I see rivets. Here's some links. http://www.atlanticz.ca/zclub/techtips/afm/index.html http://www.atlanticz.ca/zclub/techtips/afm/sizeupgrade/index.html

-

‘77 280z signal fuse keeps blowing up

Actually, it might be a direct short that only happens every few days. Second-guessing myself... Touch the fuse after driving for a while and see how hot it is. Be careful, it might be really hot. That will be a clue if it's a fuse on the edge of melting that finally does after a few days, or if it's a sudden direct short.

-

‘77 280z signal fuse keeps blowing up

The plastic bulb sockets have been known to get hot and deform allowing the electrodes to move and touch things they shouldn't touch. You might pull all of your bulbs and check the sockets. The fact that the fuse lasts a few days suggests that it's not a direct short. It is a current leak to ground or another circuit that is overheating the fuse. See if any filaments are lit up that should not be or that are dimmer than expected. Might be a clue.

-

4 Speed Bell Housing swap to 5 Speed Case : FS5W71B : Reverse Switch Modification

Maybe it's from one of the 4 cylinder NAP? ZAP? ... NAPS-Z twin plug engines. Apparently they were vertical. Did you measure the length? That's another possible difference. Gear ratios might be interesting also. From the cloud. I don't know much, just remember them from the wrecking yard in the small trucks. - https://en.wikipedia.org/wiki/Nissan_NAPS https://en.wikipedia.org/wiki/Nissan_A_engine

-

Question on seat mechanism cover application

carpartsmanual shows that the change is at Jul/Aug 73. So, they might be right. http://www.carpartsmanual.com/datsun/Z-1969-1978/body-260z-280z/2-seater/seat-slide http://www.carpartsmanual.com/datsun/Z-1969-1978/body-240z/seat-slide/type-2-reclining-seat

- Timing Off Runs Bad

-

Timing Off Runs Bad

I forgot who made the universal base plates for the distributors. They're a member. That opens up options. For what it's worth, the brand name "Mallory" doesn't mean much for what you're trying to do. It might have some collection value, if it is an actual Mallory-made product from the past. But really, it's two advance mechanisms and a way to distribute the spark. Many ways to get that done. You might put a set of points back in while you're thinking. Then you can get on with carb tuning. Points work pretty well, they've been around for years.

-

Timing Off Runs Bad

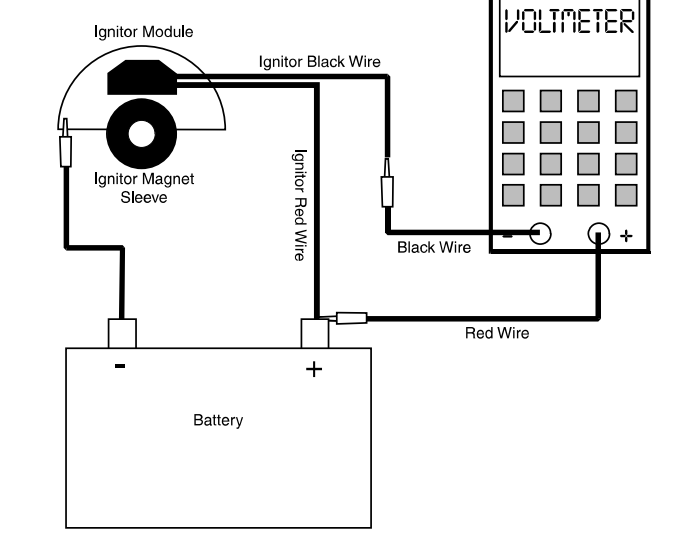

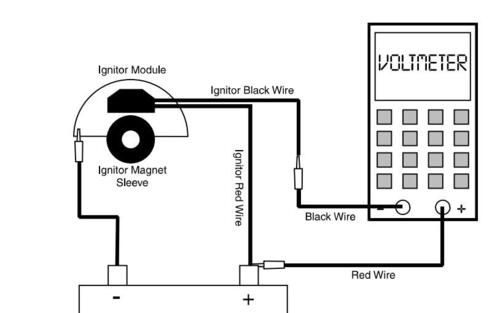

You can see by their diagram that the module grounds through the distributor body and the mounting screws to get to the engine block and complete the circuit . Might be that by loosening all of the various mounting bolts you lost your ground. Attach a wire directly from the distributor body if you want to be sure the module has a good ground. It's actually the most important one for spark strength.

-

Pertronix Ignitor I test methods

-

Timing Off Runs Bad

I found a test method for the module itself on Summit Racing's site. Worth reading... https://static.summitracing.com/global/images/instructions/pnx ignitor i tests.pdf