Everything posted by Zed Head

-

Z's on BAT and other places collection

This seems to be one of those cars with its own fan club. Interesting. A Players Club car. Dilettantes need not apply! "This isn’t a car for dilettantes or dabblers… it’s for connoisseurs and real players…"

-

Z's on BAT and other places collection

It didn't bring anything. Not moving. Isn't this guy a CZCC member? "JDM Car Parts and Restoration founder Tsuguya “Jay” Ataka". There were some small things that might have hurt it, like below, with the TC rod bushing. Small part, its degraded quality impossible to miss. He owns a car parts company. But, the money doesn't seem to be flowing anyway.

-

Z's on BAT and other places collection

-

Z's on BAT and other places collection

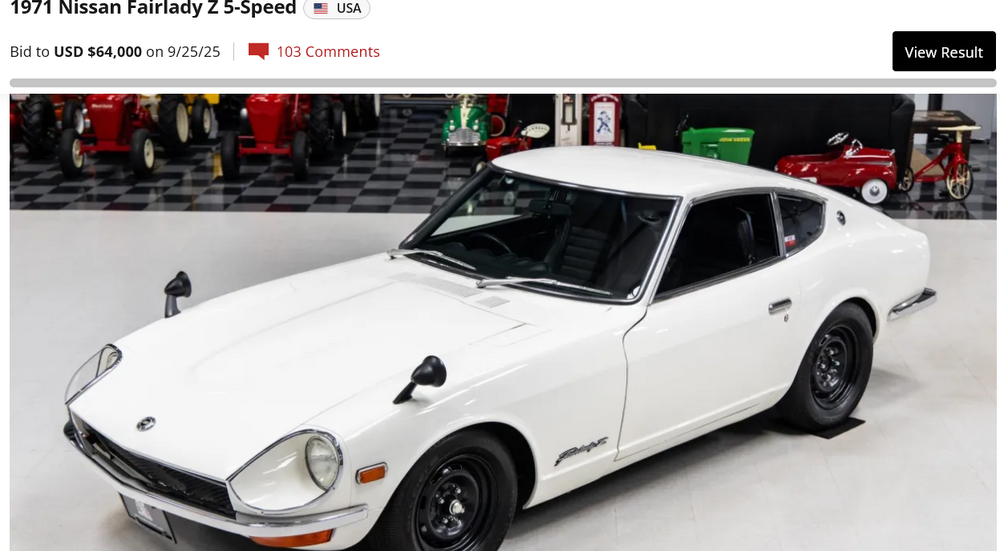

Who is Paul and where is it being sold? That "rarest of the Fairladies" is finishing today. I've noticed many "Bid to"'s though. People are getting tight with their funds, I think. Edit, aside - always funny how the sellers tell people how to use their computers so they don't screw up in the final two minutes. Smart enough to make an extra $100k or more to blow on a collector car, too dumb to know how to get the money spent. "As the listing approaches the end over the next few hours I’d recommend refreshing your screen and having the auction on two devices so it’s in live time." Bring a Trailer1971 Nissan Fairlady Z 5-SpeedBid for the chance to own a 1971 Nissan Fairlady Z 5-Speed at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #211,860.

-

Floor vent rebuild

You guys probably know this but if you're trying to restick an original headliner often the foam backing is so degraded that it fails internally, not at the surface. Just posting for anybody who ends up like I did. I used 3M contact adhesive in a spray can. But the foam was "toasted" (literally) and it sagged again. I never did scrape off the old foam and try again. What I should have done.

-

Fuel Pump Hammer Smack

What year is your car? How about a description? Stock, modified, round tops, flat tops... @Patel Homes

-

Fuel Pump Hammer Smack

@Patel Homes Are you a home building company?

-

saturday night music thread

You forgot the link!

-

saturday night music thread

Bonus Nazareth track -

-

saturday night music thread

Here's another original plus the one that made it big. Apparently these guys are still touring.

-

Inspection light: hot or not?

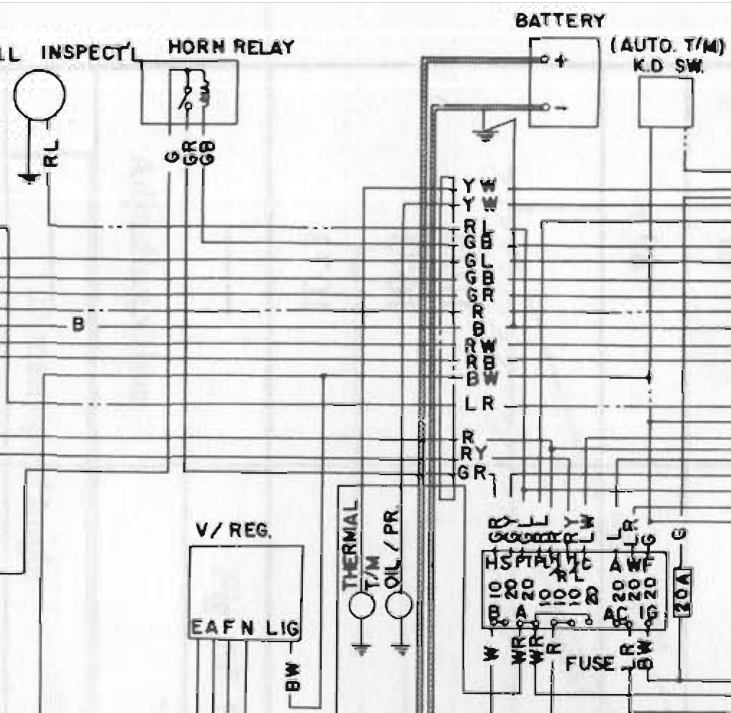

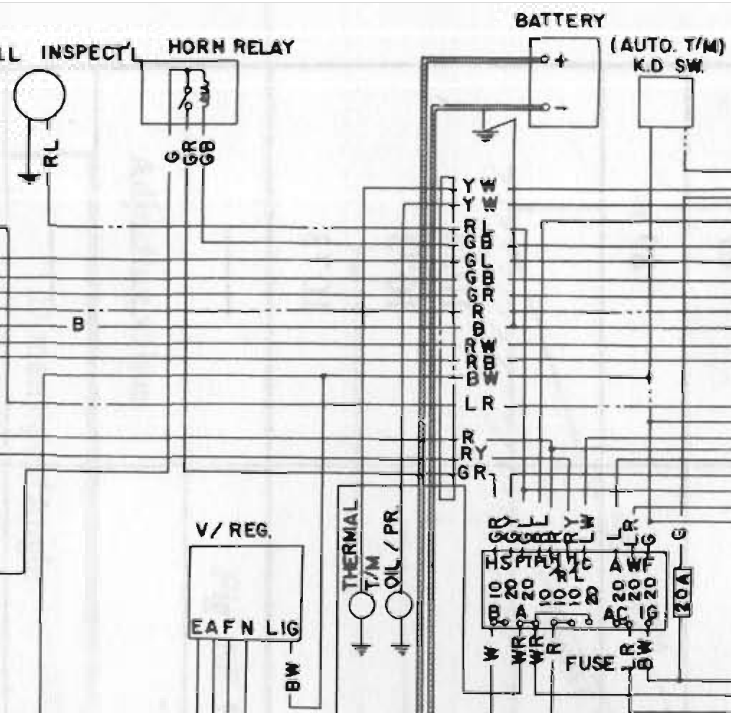

Looks like constant hot by the diagram. It comes directly from the fuse block and has a ground. Not sure what you're working with or if it's together or not (why not just check with a test light or meter?) but if it's apart you can check continuity back to the fuse block, or if it has a fuse in place, check continuity back to the positive battery cable end.

-

Fuel Pump Hammer Smack

I think that the common high pressure electric fuel pump uses steel rollers in a steel cage. I took an old one apart once. There are other designs. The old Z fuel systems are pretty leaky. They let moist air in to the tank. The gas filler cap vacuum relief seals are usually shot. Wouldn't be a surpise if you had condensed water n the tank and the gasoline has dissolved water in it. Gas will hold some water, especially ethanol-containing fuel. If you don't want to drain the tank it might be worthwhile to use some HEET or other dewatering agent. https://www.goldeagle.com/product/iso-heet-fuel-line-antifreeze-injector-cleaner/

-

The OG 240Z - Reanimation Project

Does that help your back or make it worse?

-

getting 1977 280z started

Your clutch master and slave cylinders are probably corroded and have bad seals. If it's been sitting for ten years. Your brake master cylnder also, along with the rear wheel cylinders and maybe the caliper bores. It's just what happens. I would remove the brake master cylinder before trying to use it, before you squirt brake fluid in to the vacuum booster. If you're lucky the brake booster is dry and still usable. Nickels and dimes...

-

getting 1977 280z started

-

getting 1977 280z started

-

getting 1977 280z started

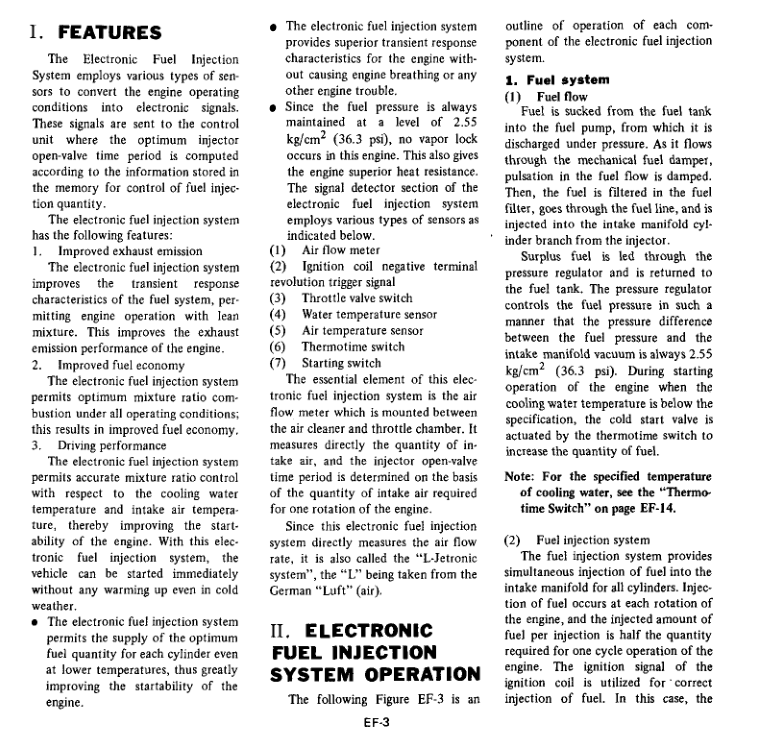

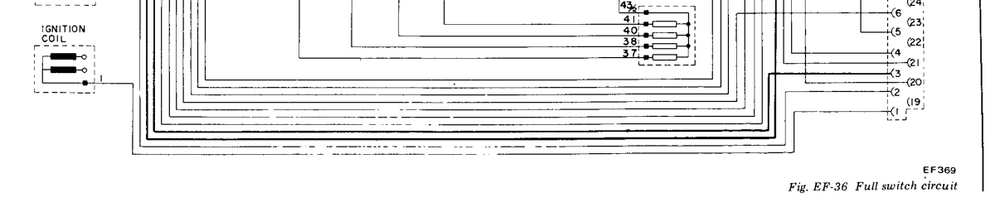

First: The ECU DOES NOT get the "tach signal" - that circuit if for the GAUGE ONLY. It is pointless to look for it. Actually the tachometer and the ECU use the same circuit for the coil discharge signal, from the coil negative terminal. It's branched. One end goes to the ignition module for spark creation, one to the tachometer for the RPM measurement, and one to the ECU pin #1 for injector timing. Every third spark the ECU squirts half the fuel "calculated" to be necessary.

-

getting 1977 280z started

Don't throw the parts away. They have value to somebody.

-

getting 1977 280z started

If you do get the engine running well, replace all of the old fuel lines on the rail and the injectors before too much driving. I smelled gasoline on mine one day while driving and when I opened the hood a tiny stream of gasoline shot by me on to the sidewalk. They dry out and crack lengthwise. The small stuff will eat up a lot of your time but it's worth it once you're done.

-

getting 1977 280z started

Here is a way to test the function of the injectors separately from the ECU. With the ECU connector removed from the ECU, turn the key on. Then short the pins in the ECU connector from the injectors to ground with a quick tap. Each tap should produce a click frm the relevant injector. You'll need a quiet garage or a friend in the engine bay to hear them. Or a long wire.

-

1977 280z ignition/fuel system "neutronics"

How long has it been sitting? What's the back story?

-

getting 1977 280z started

The engine can run off puddled fuel in the intake manifold. If the injectors were opening the engine would continue to run. cgcheen's suggestion about testing with a 9 volt battery was a good one. You can run separate jumper wires if you don't have an EV1 connector. With a 9 volt alkaline battery you don't have to worry about melting wires if you accidentally short them. You'll hear a click when you connect the 9 volts, if they're opening. Also, with 9 volts you can leave the voltage connected while you tap them. You'll have the solenoid pulling them open if you can get them to break loose. Pin 1 at the ECU is the ignition signal that the ECU uses to monitor engine RPM. It's connected to the negative terminal of the coil. It should read battery voltage with the key on. But it also needs a certain type of voltage pulse. There are things that can screw it up. You're making great progress.

-

getting 1977 280z started

I almost made a comment about AI. It's basically a better Google search. But that's about it.

-

getting 1977 280z started

Yarb, the 1980 EFI book is the official Nissan electrical troubleshooting manual. It's basically the FSMs stripped down to the bare essentials and combined in to easy to use charts and instructions.

-

getting 1977 280z started

Besides cgsheen1's suggestion, tapping on the injector bodies will often break them free. In your case though it might take a while to get all six free. The engine will run on three cylinders. Sounds like you don't have any injectors working.