Everything posted by Zed Head

-

Z Restoration Progam

Did the 11 get new engines? Or rebuilt engines sourced through AER? If they got new engines did Nissan create a new engine serial number tag for the engine bay or leave the old engine number? Each car has its own provenance. Which is part of what Dean Huff is trying to put together for his, I assume. Good luck.

-

Z Restoration Progam

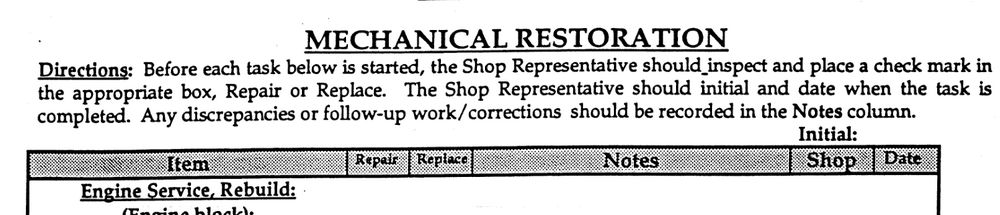

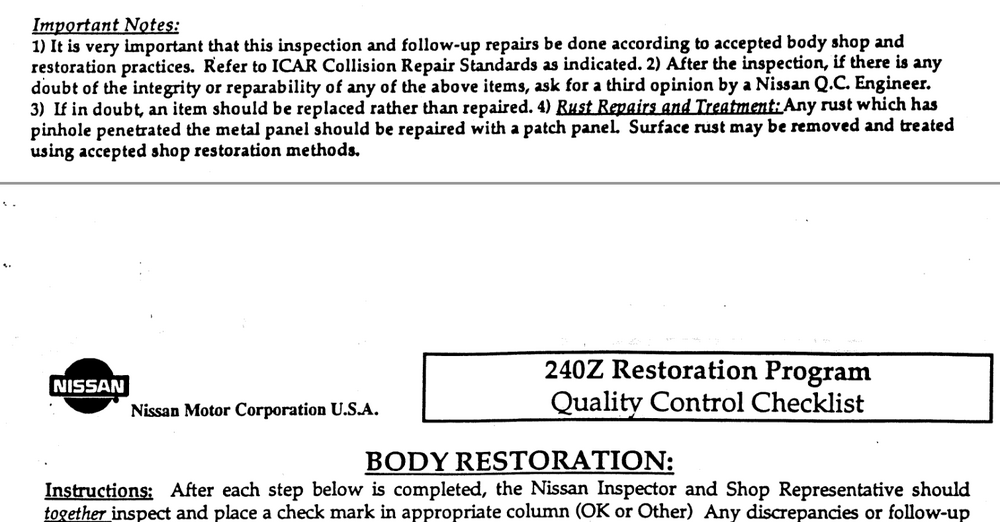

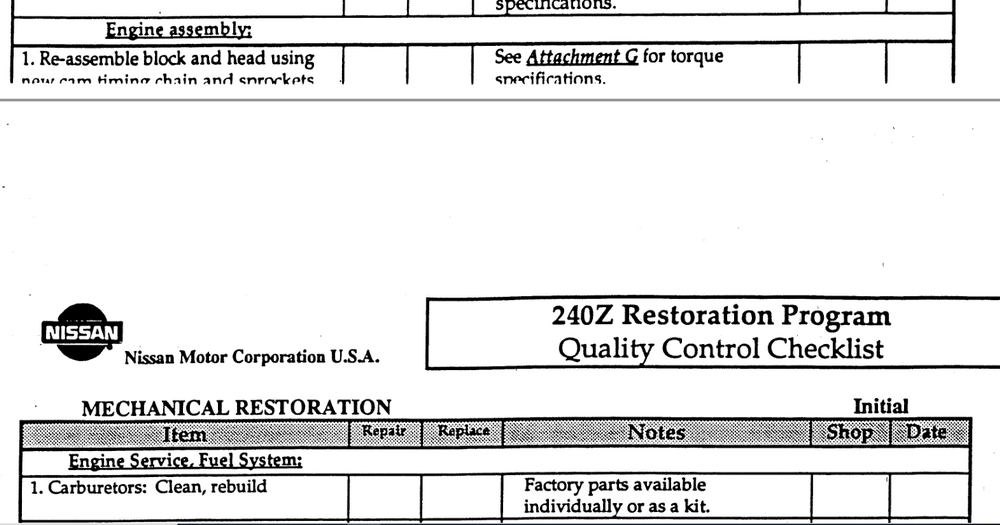

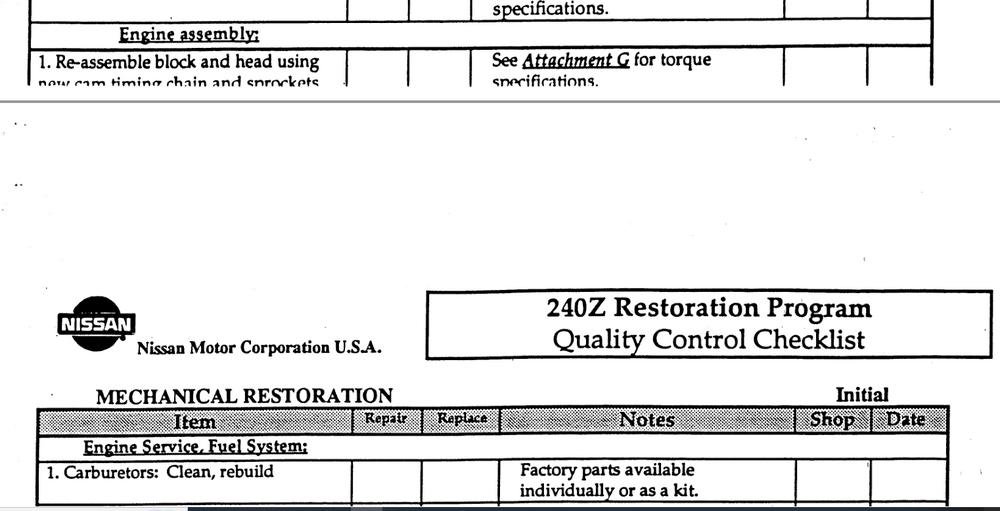

It looks like the engine work was not as well-supervised as the body work. Only the Shop Representative signed off. As opposed to Body Restoration which required a Nissan Rep and a Shop Rep, and a Nissan Q.C. Engineer if there were questions. Still curious about the metal particles, if the engines came fully assembled.

-

It only works if I spray gas into the air intake.

- It only works if I spray gas into the air intake.

- It only works if I spray gas into the air intake.

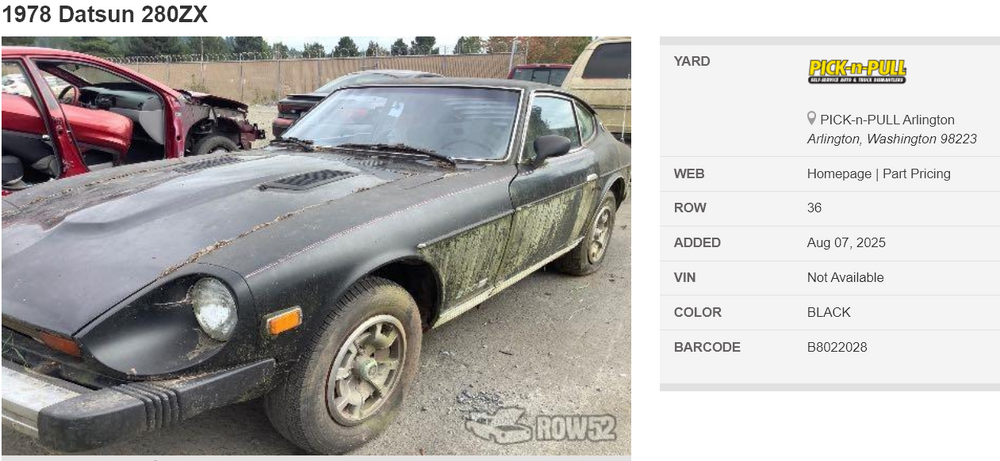

That's a 1978 280Z. The fuel rail and other parts tell the story. Somebody has installed a fuel pump in the engine bay, and it is not connected a to a tank. of the type that don't like to pull fuel. That fuel pump should be moved back to the original area by the fuel tank (if it still works) so that it can self-prime with fuel. Download the FSM if you want to go deeper. https://www.classiczcars.com/files/category/13-280z/- Z Restoration Progam

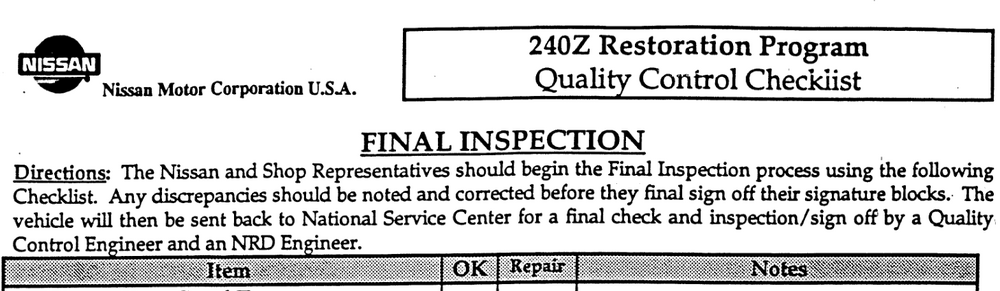

The Checklist document is interesting reading. There's a Nissan rep, and a Shop rep, and a QC Engineer, and an NRD Engineer. Not sure what NRD stands for, have to keep browsing. Also a National Service Center. Not sure where that is either.- Z's on BAT and other places collection

I posted my response above in 26th-Z's Restoration thread. That's a better place for the discussion. Let's see what happens. Click here folks if you want to continue the discussion.- Z Restoration Progam

Attempt to transfer Restoration program discussion over here from the BaT thread. It's an interesting discussion at its core. HS30-H seems to be implying that the engines were not rebuilt by AER, or maybe not all of them were. But he's not offering an alternative, unless he's saying that Nissan engineers worked alongside AER employees or received unassembled parts from AER or somewhere else. Rebuilding requires a machine shop. In 1996 I don't believe that Nissan had any manufacturing facilities in the States. They started assembling cars here in 1993. So, if it wasn't AER who was it? Where were those pictures taken? Seems unlikely that "Nissan engineers" were examining parts in the States. If they were, where did the parts come from? Also interested in where those metal fragments were seen in the AER engines. Under the valve cover? In the oil pan? Why were they seen if the engines arrived complete? Was AER just supplying short blocks and separate heads? The checklist implies that "The Shop" was to assemble the engines (pasted image below). Also implying that multiples machine shops might have been involved, each receiving instructions. Can't tell. These questions can be answered if we avoid the sidetracks. Interesting how Nissan is still using the 240Z in their marketing. First thing you see on their Heritage page. Nissan USANissan History: The Path from Datsun's Inception to TodayUncover the story of Nissan's heritage, including where Nissan started, when Datsun became Nissan, and the key dates that mark Nissan's evolution.- Z's on BAT and other places collection

It's an interesting discussion at its core. HS30-H seems to be implying that the engines were not rebuilt by AER, or maybe not all of them were. But he's not offering an alternative, unless he's saying that Nissan engineers worked alongside AER employees or received unassembled parts from AER or somewhere else. Rebuilding requires a machine shop. In 1996 I don't believe that Nissan had any manufacturing facilities in the States. They started assembling cars here in 1993. So, if it wasn't AER who was it? Where were those pictures taken? Seems unlikely that "Nissan engineers" were examining parts in the States. If they were, where did the parts come from? Also interested in where those metal fragments were seen in the AER engines. Under the valve cover? In the oil pan? Why were they seen if the engines arrived complete? Was AER just supplying short blocks and separate heads? The checklist implies that "The Shop" was to assemble the engines (pasted image below). Also implying that multiples machine shops might have been involved, each receiving instructions. Can't tell. These questions can be answered if we avoid the sidetracks. Interesting how Nissan is still using the 240Z in their marketing. First thing you see on their Heritage page. Nissan USANissan History: The Path from Datsun's Inception to TodayUncover the story of Nissan's heritage, including where Nissan started, when Datsun became Nissan, and the key dates that mark Nissan's evolution.- saturday night music thread

Ignore the women. Just enjoy the sound of the fretless bass. Like a string trombone.- Z's on BAT and other places collection

That document should be downloaded then uploaded to the Resources area before it disappears. I saved a copy. Not sure which category it might belong in. Maybe the Vintage program should be a separate category. https://www.classiczcars.com/files/ or https://www.classiczcars.com/articles/- Z's on BAT and other places collection

I hope this doesn't feel like "doxing" but I found the place you bought the car from. Not that you're hiding it, it's pretty obvious. The ad copy says that it came with Restoration literature. There's a picture of what looks like photocopied pages. Is there anything in there about the engine details? Or is it just vague statements about remanufactured engines? Somehwere out there is some old AER Nissan reman engine paperwork that tells exactly what is done. They were used on more than just the Restoration program cars. I'm here for the puzzle.- Z's on BAT and other places collection

Here's a different AER page. It's from 2002 and "Not secure" so can't tell if it's just an internet artifact or current. http://dealer.aermanufacturing.com/manufac/remeng.html They do have a Contact page though. Might send them an email and see if they have some documents. http://dealer.aermanufacturing.com/contact/index.html- Z's on BAT and other places collection

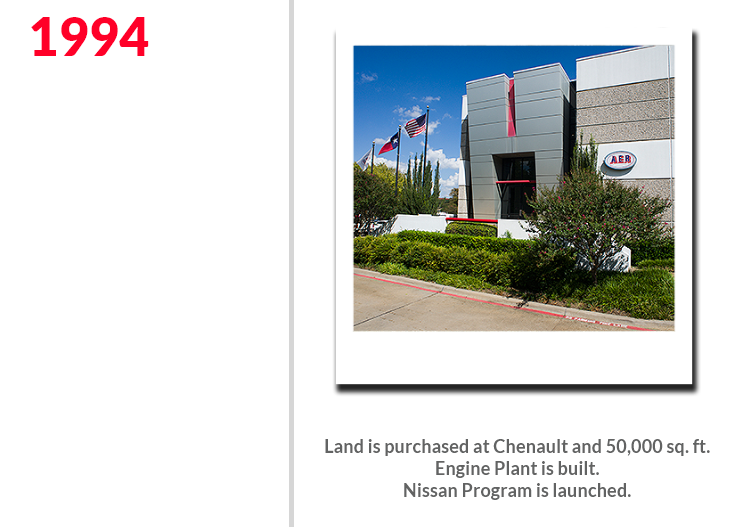

Looks like AER is getting absorbed in to bigger corporation. Contracts with Ford and Stellantis. No contact means on their web page. Documents and old-timers probably disappearing. https://www.aersales.com/company-history/ The History page has some odd references but Nissan did get a mention. I assume that it's for all Nissan remans. So, maybe any Nissan reman documentation would be relevant. Not just the Restoration program.- Z's on BAT and other places collection

Here are two descriptions showing the possibilities. https://gaynors.com/auto-repair/engine-rebuilding/ "Valve seats are replaced with hardened seats..." https://www.budgetenginerebuilders.com/ "Cylinder heads reconditioned with new bronze guide liners, valve springs, valve stem seals, resurface of valves, seats and head gasket surface area..."- Z's on BAT and other places collection

There are different levels though. Sometimes valve seats are checked for wear and just recut, or if they look okay they might just be lapped. Sometimes they are removed and replaced. That's the question at hand. If they were all removed and replaced as part of the rebuild, and the program was done after hardened seats were introduced, then they probably have hardened seats. An old AER document probably has the information.- Z's on BAT and other places collection

I think that the fundamental question is about how much and what kind of work was put in to the engines. Were they completely rebuilt, or were they just evaluated for function like a rebuilt alternator? Is there documentation out there about any engine work? If the valve seats weren't replaced then the new owner is in the same boat as if it was an original 240Z. It would be interesting to see the "work orders" for a Nissan Vintage Restoration Program car. I've only seen anecdotes and old publications about the program, but not the official communications from Nissan.- 1978 280Z at Washington PicknPull

Looks like a ran-when-parked car. Not sure if they would be able to sell it as a complete titleable car. Might be worth an inquiry for somebody. As I recall, they used to sell complete cars for about $1100 dollars. Probably up around $1500 now. The basic scrap value. https://www.row52.com//Vehicle/Index/RNDZRjYMUcAnW9fgxc7OhGt2S- Car runs but rough. Afm ?

Eats, shoots, and leaves? Eats shoots and leaves. Runs, but rough. Runs butt rough. Just kidding. Are there any glue blob marks on the AFM adjustment screws? Match them up if you can find them. Nissan placed a blob of silicone on the wheel after it was set at the factory. What do you mean by "rough"? At idle, during cruising, during acceleration? It's fairly common for the 280Z's to run lean. There's a modification that can be done, described by Blue on his atlanticz pages. He also has an AFM "reset" procedure for AFM's that have been messed with. https://www.atlanticz.ca/zclub/techtips/EFI&fuel.htm- Car won’t crank

as @Zed Head said, pull the spayed ign. Off the terminal and measure the voltage. Black to Gand and red on the spade turn the key to start. I think that he's just answering Yarb's question directly. Seems like you're getting voltage/current to the starter solenoid. Leave the wire off of the spade terminal on the starter and use a jumper wire or a tool like a screwdriver to connect the main battery connection to the spade on the solenoid. You can also run a longer wire directly from the battery positive for convenience. The starter should actuate. If it doesn't then the solenoid contact has probably crapped out. There will be some small sparks and the starter will work correctly otherwise. Make sure the car is in neutral and nobody has their fingers or other things by the fan belt. If you hear a solid click from the solenoid but the starter motor does not spin that's a sign that the starter motor has failed. Yout starter looks pretty crusty. If you try this jumper wire method and everything works then you have a problem with the wire from the ignition switch.- Looking to buy a Harmonic Balancer 240z

Wow. Was it running like that or was during installation? How's the crankshaft surface? I think that new is avaialble. Z Car Depot IncSearch: 11 results found for "damper"New, used, and OEM repair and replacement parts for Datsun 240Z, 260Z, 280Z, 280ZX, and 510.- Kick Your ECU?

I was talking about a different problem. You'll know it if it happens. On the loose pins, if it was mine I might put a slight twist on every male pin in the ECU. Increasing effective width. I'd have to check the contact points to be sure it would work though. On to the next problem. Might as well get ready for the failing ignition module. It's a high probability.- Kick Your ECU?

For the record, I just read that zcar.com thread and see that I might have actually borrowed the transistor replacement idea from ZXPastor. Not sure. I got the replacement transistors at a Fry's Electronics store before they shut down. Cracked solder joints aren't uncommon on the old Datsun electricals. The headlight and running light connections, on the top of the steering column, crack and break also. You might add some relays before those fail. Full lighting circuit current runs through them. They get hot. Will be following to see how things work out. You'll have three ECUs to swap in and out for testing and comparison. Good times.- Kick Your ECU?

Don't overlook that when you have the connector disconnected from the board that the solder joints are probably less-stressed. I didn't see the common cracked solder joint problem mentioned in the thread. For some reason the internet is not picking up the old threads when I search. I only came across one. I've seen the others though.- saturday night music thread

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.