Everything posted by Zed Head

-

Mechanical Fuel Pump Drive (name?)

There's a couple on eBay that might work. Probably all the same. https://www.ebay.com/sch/i.html?_nkw=datsun+eccentric&_sacat=0&_from=R40&_trksid=p2332490.m570.l1313

-

How vibration free is your 70-71 240Z?

Soccer's a gamble. I felt lucky to have made it through the years with none of the major long-term injuries. I did have to do some PT on a knee. My doctor had been a college athlete and had the "suck it up and take some Advil" attitude. So I went in to weekend warrior mode and tried to tough it out. He sent me to PT when I went back a month later and showed him that the thigh on the injured leg was about 2/3 the size of the good one. The PT shop owner used to do the Cleveland Browns football team. Got me straightend up pretty quick but it still wouldn't bend as far as the other one for about three years. And the tough-it-out doctor was afraid of blood. Later, after the knee, he refused to remove the stitches in my chin because the tails were cut too short (forgot to mention the chin. And the broken collar bone.) and there would be blood if he had to dig them out. I had to go to the drug store and buy some tweezers and pointy scissors to dig them out myself. There was blood. Good times.

-

How vibration free is your 70-71 240Z?

Are you a keeper? All of my injuries were ankle, knee, nose, eyebrow, or jaw. And one AC joint. And a groin.

-

Problems with 240z doors from Resurrected Classics.

How did things get so bad, since this last thread? https://www.classiczcars.com/forums/topic/68334-resurrected-classics-continues-to-impress-with-new-fenders-hatches-and-bumpers/

-

Problems with 240z doors from Resurrected Classics.

-

Loss of acceleration when hitting gas hard

Here's the link - https://www.atlanticz.ca/zclub/techtips/vacuum/

-

Loss of acceleration when hitting gas hard

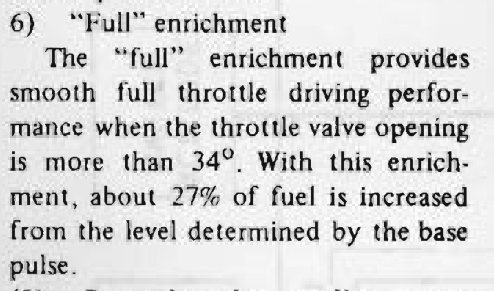

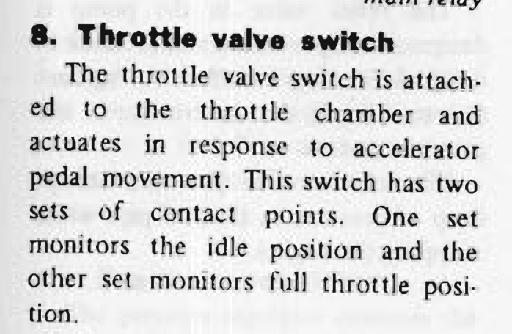

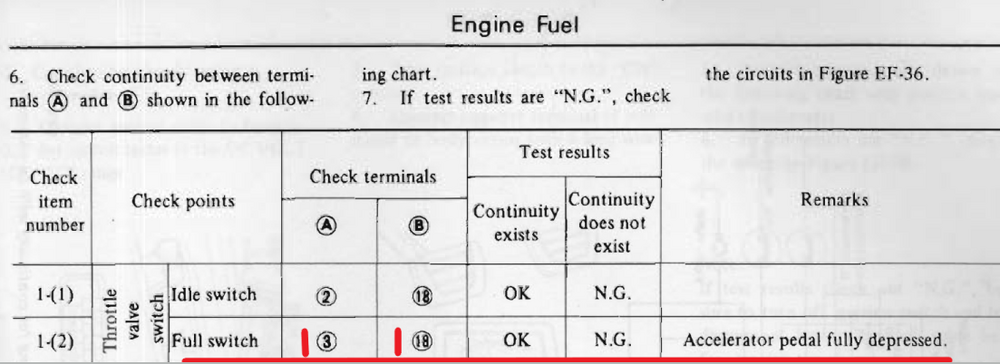

This normal. It also shows (edit) pretty good intake system vacuum. 30 psi or below at idle is normal. Have you adjusted the valves recently? If I had this problem I would check the TVS (aka TPS). Make sure it's working right at open throttle. It's what adds the extra fuel. Your fuel pressure looks good.

-

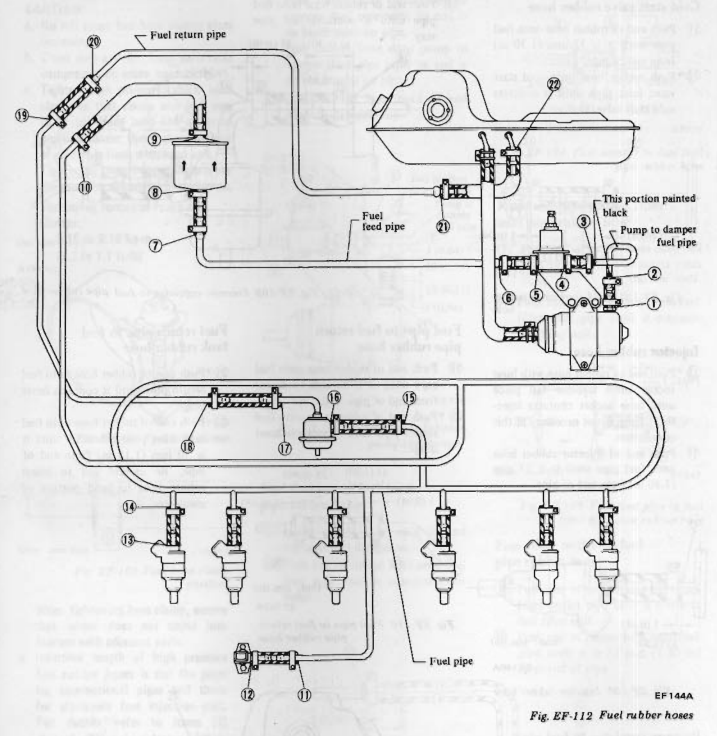

79 280zx Fuel Damper

Try snapping the throttle open and see what pressure does. It's not RPM that causes change it's manifold pressure. If you just ease the throttle open intake vacuum/pressure won't change much. The numbers look good, actually very good, 26 psi indicates very good intake system vacuum.

-

How vibration free is your 70-71 240Z?

How bad was the old one?

-

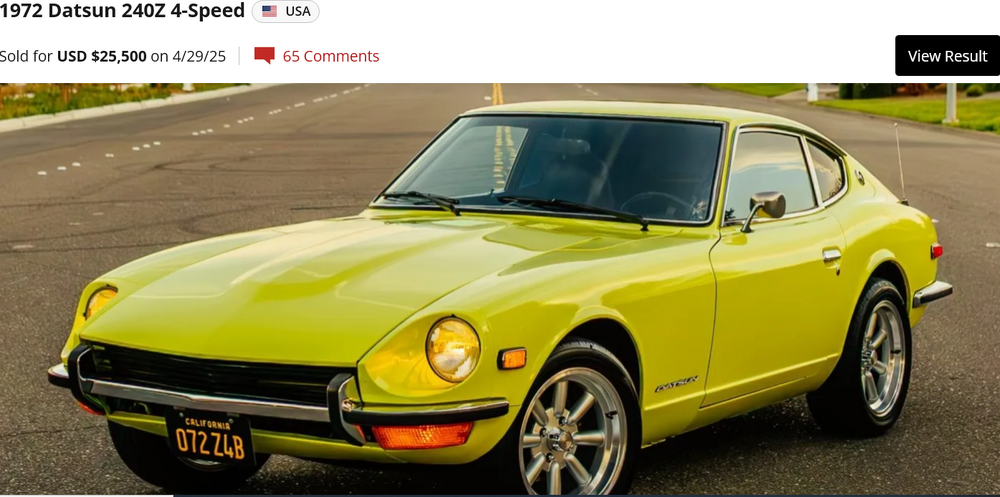

Z's on BAT and other places collection

Here's a Z for somebody looking to get in to the game. Down in Texas, but titled up here. RV camshaft. Whatever that means. https://bringatrailer.com/listing/1978-datsun-280z-176/

-

Rear Inner Wheel Bearing Loose In Hub - What can I do?

What you're saying sounds correct. I've read about the rear hub race surface wearing/wallowing. The guys that race see it more often. Hybridz has some stories. I wonder if there is enough material there to be machined and sleeved. A good machinist might have better ideas. Metal spray or welding, for example.

-

saturday night music thread

Finally figured out who played this song I've been hearing. Need to share. For our Canadian friends...

-

Loss of acceleration when hitting gas hard

Seems unlikely that the engine would use so much fuel when accelerating that fuel pressure would drop. Probably learn what you need to know just blipping the throttle by hand with the hood open. You could connect to the cold start valve hose. It's basically "on the rail" and sees what the injectors see. Don't forget to block the hole in the manifold. Never mind, no need to remove the valve. Just the hose. Good luck.

-

How vibration free is your 70-71 240Z?

Can't tell where the seal is riding in your picture but here is a picture of an old early 240Z shaft I picked up that had a groove from a worn seal, for reference. Gives an indication of factory engagement. The wear pattern in your picture is very weird.

-

How vibration free is your 70-71 240Z?

I'd fix this first. Besides the bushing, the fit of the splines should control play also. Are you sure that you have enough engagement?

-

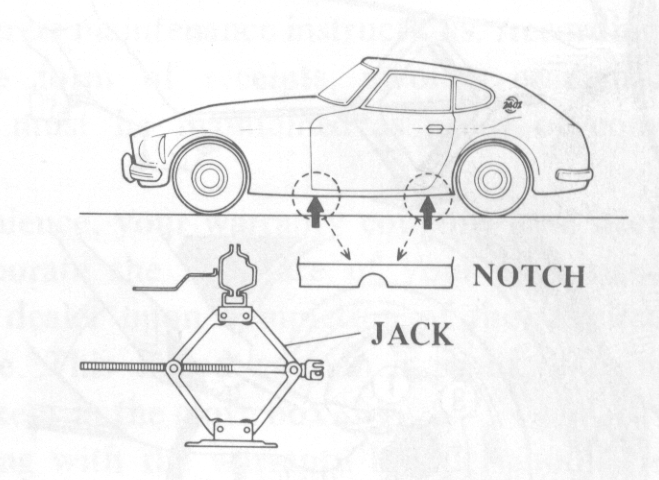

Darn Tire Jockeys

I had thought about making some slotted rubber pucks for the rocker panel seams but at home I just used the diff or the front cross member and the sub frames were dented anyway. I wonder how well a Z would lift using the four points shown in the Owners Manual. Is that not the ugliest drawing of a Z ever? 1973 Owner Manual. Looks like the summer intern did it.

- Charging fun with Zedyone !

- Charging fun with Zedyone !

-

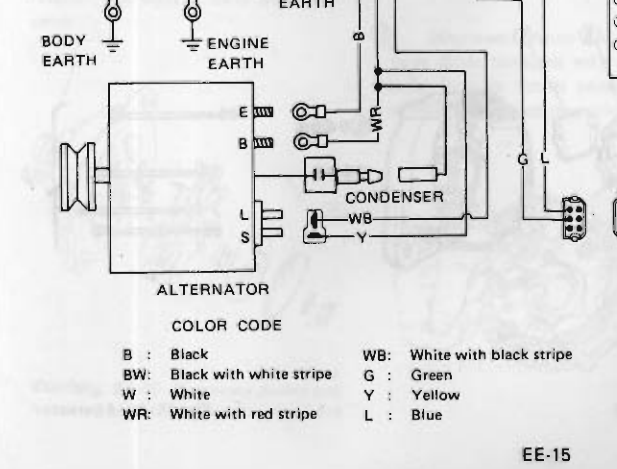

Charging fun with Zedyone !

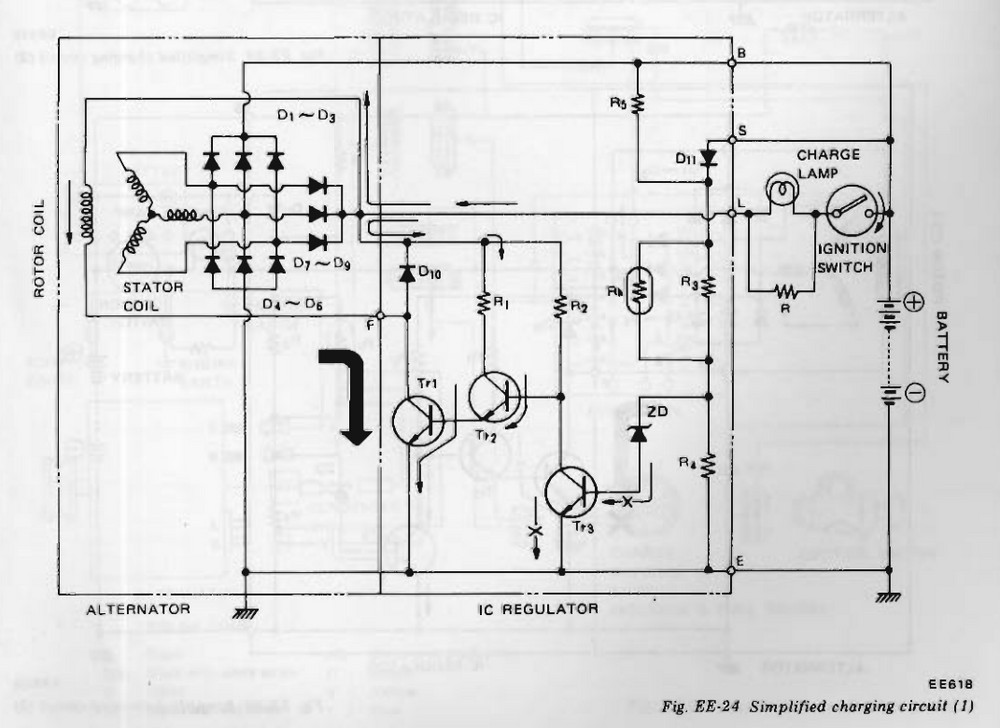

The Dave Irwin adapter converts one of the 71 wires to an "L" wire. Here's a schematic from the 1978 FSM. 1978 was the first year of the internally regulated alternator. Interesting (to me), I just noticed that there is a resistor inline with the charge lamp. In the past I think I've seen discussions about what happens to charging if the lamp burns out. Apparently, nothing. Charging still happens. In your case, when the diode opened, there was no current through the stator coil. No magnetic field was produced so no charging happened.

-

Charging fun with Zedyone !

The other components, the rest of the system overall, could be tested by bypassing the diode. A simple jumper wire or alligator clip could do it. Probably have to kil the engine by pulling the coil wire. Then - how to fix it. What type of diode, how to solder or crimp? Or just buy another from MSA.

-

Putting out the feelers

- Charging fun with Zedyone !

-

Charging fun with Zedyone !

I don't know 1971 but on a 1976 the charge lamp lights when the key is turned on aa a circuit and bulb check. It grounds through the alternator edit- external regulator then turns off when charging exceeds battery voltage. It should be battery voltage with the key on and the plug unplugged.

-

Check out this ATK crate L28 engine on BaT

Thanks, and that is interesting. Google Translate serves its purpose well. Is there a Japanese Wikipedia? Any thoughts on where that "new" N42 casting comes/came from? There is a disconnect between ATK Vege (which seems to be a combined company, looking at the logos and the descriptions) and the KSS that comes up through that Japanese ATK link. 1936 versus 2003. North America versus Japan. From the web pages - https://atkvege.com/about-atkvege/ About ATKVegeATK North America is the largest private label Crate Engine Remanufacturer in North America. Partnered with our sister company, VEGE de Mexico, ATK VEGE has a history of Remanufacturing that dates back to 1936. https://atk.co.jp/company/ name KSS Co., Ltd. Representative President and CEO Keiji Okawa Established August 2003 Capital 3 million yen

- Charging fun with Zedyone !