Everything posted by Zed Head

-

Install Engine With Trans, or Engine Then Trans?

I hanged (hung?) a hoist from my garage rafters and rolled the car back and forth. People generally hate to read that but if you know how rafters work it can be safe. Spread the load and know the loads is the key.

-

COVID-19

- COVID-19

Might as well follow this elephant around and see where it goes...- COVID-19

Nah, I said "too serious". Making fun of one man's plight, when 200,000 plus other real people have died because of it just doesn't work. Makes it all seem normal when really it does border on insanity. He'll probably survive, call him healed in a week or two, while another 7,000 - 14,000 citizens have died in the meantime. And, probably, nothing will change. Nothing is changing now.- COVID-19

Too serious. Had a joke here. Wait it out.- COVID-19

Crazy times man, crazy times. I hope we all make it through and get back to at least some form of sustainable madness. More and more of the people in the crowds at the events and parties are testing positive. Russia doesn't need any help at all...- 1977 280z Won’t Start

Worth a shot. Since you know it works when the starter is off the car. These cars really only have the switch in the AFM as a safety system. Or the interlock that iscnetwork is messing with, which you shouldn't have. That's about it. The starter should always work. Several of us have used it to move our cars off the road by putting it in gear and turning the key to Start. Since you're getting a click though, that means the solenoid is getting power. Not clear what's going on with yours. Good luck, keep trying stuff.- 1977 280z Won’t Start

Follow-up thought - take the spark plugs out anyway before trying to get the engine to move, even if you decide not to use penetrating oil. And might as well squirt some oil in there, but just use regular motor oil, it won't contaminate your new oil. No offense to anyone, but there's a pretty big gap around the piston top for the oil to get in. It should not be rusted shut after a few months. Not really an application for penetrating oil, I think. Leave the plugs out when you try to turn the engine. Just did a circle back to oil in the cylinders. Can't see a reason for the engine to be locked up though. Maybe it's just a weak or jammed starter. Are you sure the engine is in neutral?- Install Engine With Trans, or Engine Then Trans?

The bipod, use the bipod. That weird looking knobby thing in the right hand corner. For sharing. There's a lot of pages in that thread. Thanks for the compliment too, I do try.- Install Engine With Trans, or Engine Then Trans?

I think it's 50/50. If you do the transmission separately make sure that you have the car lifted high enough to slide it underneath before you start. Or put it under the car through the engine bay before you install the engine. Otherwise you have to rig up some device to hold the engine in place while you lift the car if you didn't have it high enough. A trick I learned if you do both together (after I had already installed both together, and struggled mightily) is to tie a rope around the tail of the transmission and lift from the inside through the shifter hole to get the cross member installed. Use a piece of wood to roll up the rope to hold it in place. It's very difficult to get underneath the tail and lift when you have the weight of both hanging there. I don't know how much range you have on the load leveler. You might run it through it's range with the engine and transmission to see if it will work before you get it all hanging over the car.- FS5W71B transmission identification (close-ratio vs. wide ratio) - with pictures

I think that "close" actually refers to the spread between first gear and top gear. First on the wide is 3.321, on the close it's 3.062. Top gears are similar, and 4th is always 1.0.- 1977 280z Won’t Start

If you had a head gasket leak you might have a hydraulic lock. Shouldn't be rusted tight though. Are you sure that you don't just have dirty battery terminals? If you move the car while in gear just do it slowly. Use 5th gear and rotate a tire by hand.- 1977 280z Won’t Start

Does the solenoid click when you bride the terminals? The solenoid should still move even if the engine is seized.- FS5W71B transmission identification (close-ratio vs. wide ratio) - with pictures

This is nice work. In the States what you're showing will be true 99.9% of the time. The things dutchz are talking about might be true over there, but I can't think of a case over here where somebody has described what he's talking about unless you get in to the odd truck transmissions. The truck transmissions use a different tail shaft housing. For the Z cars though, that's a great guide.- Bleeding Brakes / Brake Master Cylinder

I read your first post and wanted to reply but didn't have a clue. Those rags and paper towels are common problem sources, form what I've seen. You should keep a count of your paper towels like a surgical team with sponges, and verify all accounted for after a procedure.- 1975 280z 2+2 will not start

Posted at the same moment as zclocks. Re the relay - It should be under the dash by the hood latch release. A 1x1x2 inch silver unit. Hard to get to, two screws hold it in place. If you prop the AFM vane open first you should hear it click when you turn the key on. It's a typical solenoid, powered through the contact switch in the AFM.- 1975 280z 2+2 will not start

No, it only gets power at Start or when the AFM vane is open with the key on. So the other way to test power to the pump is to turn the key on then open the vane in the AFM. You can do that by removing the black cover on the side of the AFM and rotating the counterweight. The black cover is a press fit, usually with a bit of sealant to hold it in place. Just use your fingernails or a screwdriver and pry it straight off. Then you can prop the AFM vane open and use your meter on the pump leads in the back or anywhere on the circuit. Even at the fuel pump relay.- Rear Wheel Bearing Related

They could have written a procedure that made much more sense. If you look at the drawing you can see that the inner race is actually used to "press" in the outer race by applying force through the balls. That's supposed to be bad (potential for "brinelling") but that's how they do it. You can also see that any speck of metal shaving or grime that stops the outer race from fully seating will screw up the relationship between the inner and outer races. The whole point of the torqueing exercise is to get the two races on the same plane so that the balls will be centered in each race. The preload and/or end play measurements are just confirmation that that has happened. So, the best procedure, after you get the seal pounded all the way in, would seem to be to make sure the outer race seat area is perfectly clean and burr-free, then torque the nut to its minimum value. Then take your two measurements and either keep torqueing if they're not right, or stop if they are right, even at the minimum torque value. The whole point of increasing the torque beyond the minimum is to compress the distance piece, drawing the inner races together. Once the races are aligned, the job is done, except for the peening, if you're in the peening camp. I just felt compelled to write that, while it was clear in my head...- Parts for Sale: 4x reproduction Nissan Fairlady Z432 wheels in aluminum

Off-topic, or maybe actually back on topic, did you buy a certain number of rims, or do you place individual orders with the factory? It would be interesting to see a picture of a set of wheels side by side, just to see the final finish quality. Grinding marks, smoothness, etc. On the ground off "Made in XXX" area, it looks like the China part was actually ground off of the core mold, not the wheel after it was made. I assume that these are investment castings, using wax or polystyrene cores? Why did they do that? Seems like they would have ground off more ID marks. Maybe they're not actually made in China? Not that it really matters, just curious. We used to work with Korean companies that oversaw production facilities in China. Manufacturing over there is all inter-connected. Aside from the business practices, and concerns about "ethics" it's still interesting to see somebody working directly with a Chinese factory. Many small business spend a lot of time trying to figure out how to get their products made over there. You can't just call them up and/or go visit. By the way, I took a course in ethics when i was in school and it's an area that can be confusing, and often is. Ethics are not honesty or morality (I'm not implying a lack of either for Mr. Dezart). Ethics are actually determined by organizations or groups of people. There is no universal ethic to be applied to a situation (actually if you Google it people have decided that they know what the "universal code" is. But, if a person doesn't agree to it, it doesn't count. The agreeing is the key part).. Here's an example. Just to add to the discussion. https://www.nspe.org/resources/ethics/code-ethics- Trouble Downshifting to First Gear?

I had a similar problem with a Ford transmission and while I was figuring out a solution I would just match speed and RPM when approaching a light to get in to first and just sit there with the clutch pedal down. You've probably considered it already but just in case. The solution wouldn't apply to your problem, it's a design problem with the Ford (actually Mazda) transmission I think. In that case changing fluids to Pennzoil Synchromesh worked. I've never heard of anyone having your problem though. It seems mechanical, maybe a broken synchro or a jamming ball. One thing you might do right off the bat is to check the fluid level, then drain the fluid. Check the magnet for fragments.- Trouble Downshifting to First Gear?

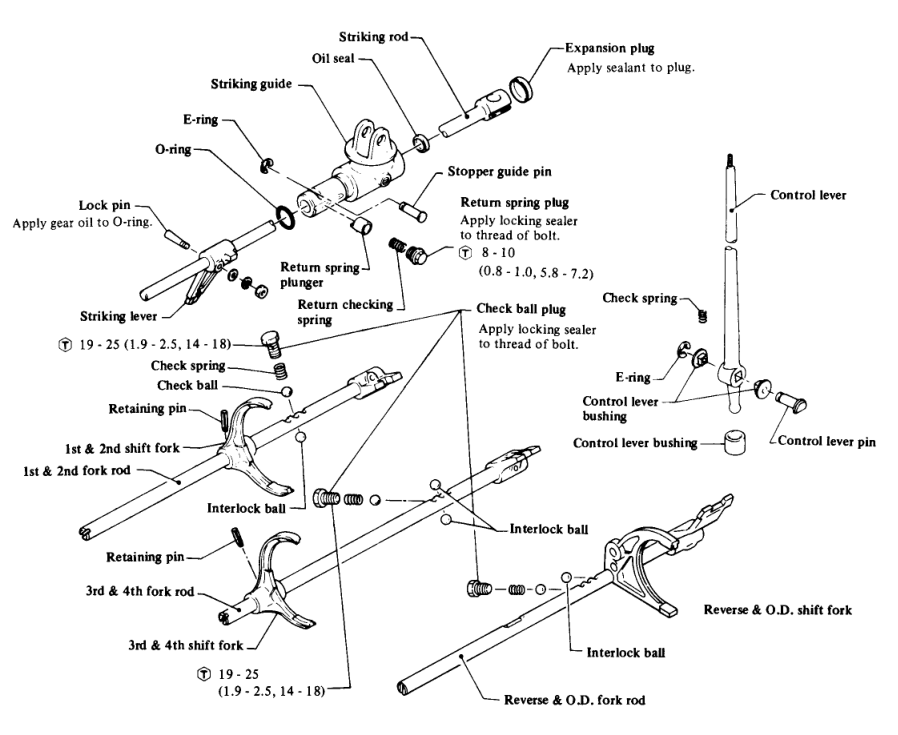

Could be something to do with the check and interlock balls. Balls that are pushed in to notches to keep the gears in the correct place. I think that you can check those without removing the transmission. EuroDat knows more @EuroDat- Trouble Downshifting to First Gear?

Does it grind or does the lever just not move? Also, does it go in to reverse easily? Reverse is the true test of your clutch since it does not have a synchro. Might just be worn bushings on the shift lever, letting things get out of alignment.- 1975 280z 2+2 will not start

Yours is red now. The one that pulls off by hand, no wrenches needed. With it disconnected the starter solenoid will not energize, only the fuel pump, and CSV, etc. The engine won't spin so you'll hear the pump. It's a good way to run the pump and flush out the system with fresh fuel, if you're worried about that. You can also use it to check your fuel pressure, without engine vacuum.- 1975 280z 2+2 will not start

- Rear Wheel Bearing Related

Is this "meta"? Still trying to get a good grasp on that word.. - COVID-19

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.