Everything posted by Zed Head

-

Darn Tire Jockeys

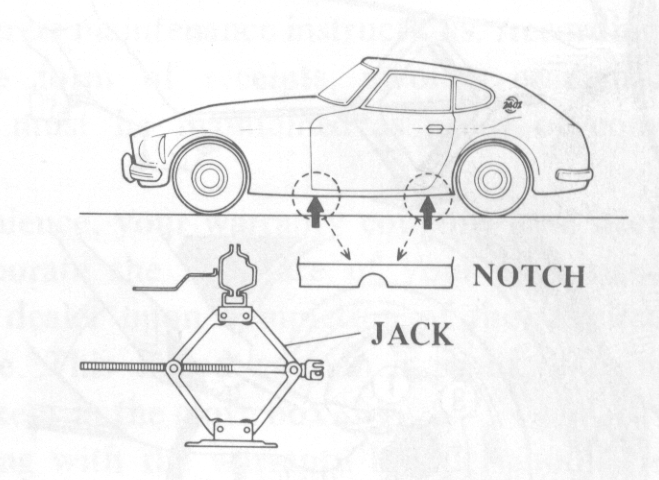

I had thought about making some slotted rubber pucks for the rocker panel seams but at home I just used the diff or the front cross member and the sub frames were dented anyway. I wonder how well a Z would lift using the four points shown in the Owners Manual. Is that not the ugliest drawing of a Z ever? 1973 Owner Manual. Looks like the summer intern did it.

- Charging fun with Zedyone !

- Charging fun with Zedyone !

-

Charging fun with Zedyone !

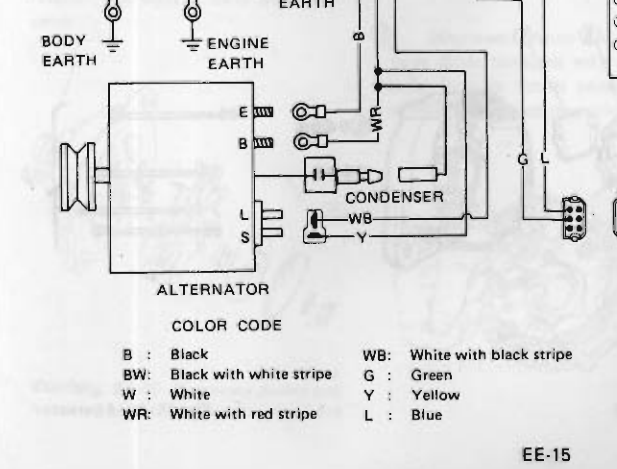

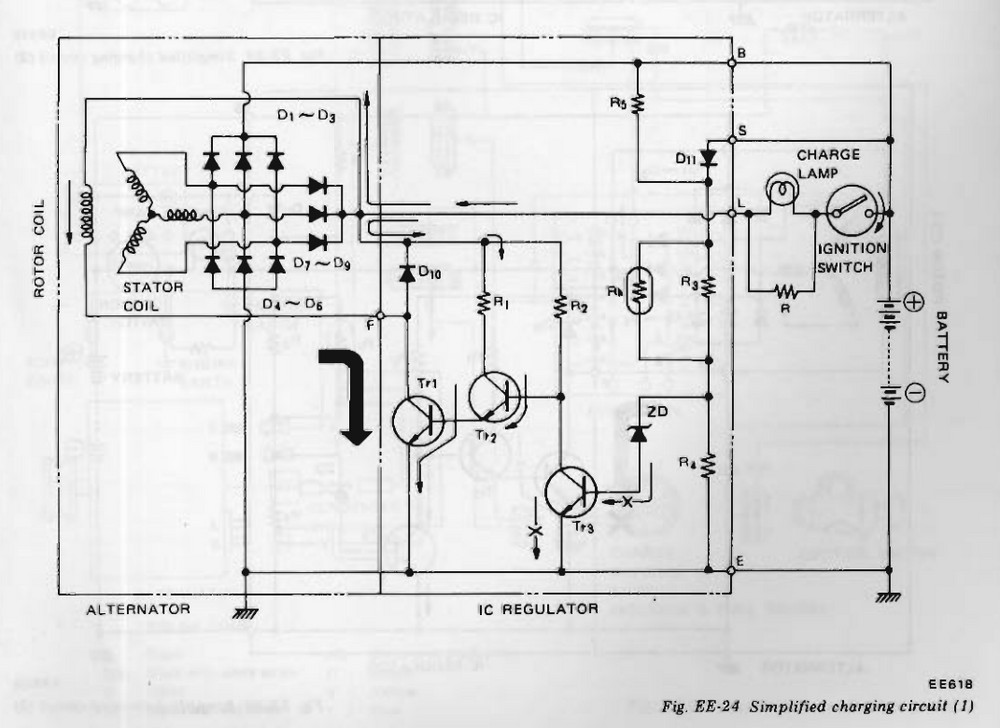

The Dave Irwin adapter converts one of the 71 wires to an "L" wire. Here's a schematic from the 1978 FSM. 1978 was the first year of the internally regulated alternator. Interesting (to me), I just noticed that there is a resistor inline with the charge lamp. In the past I think I've seen discussions about what happens to charging if the lamp burns out. Apparently, nothing. Charging still happens. In your case, when the diode opened, there was no current through the stator coil. No magnetic field was produced so no charging happened.

-

Charging fun with Zedyone !

The other components, the rest of the system overall, could be tested by bypassing the diode. A simple jumper wire or alligator clip could do it. Probably have to kil the engine by pulling the coil wire. Then - how to fix it. What type of diode, how to solder or crimp? Or just buy another from MSA.

-

Putting out the feelers

- Charging fun with Zedyone !

-

Charging fun with Zedyone !

I don't know 1971 but on a 1976 the charge lamp lights when the key is turned on aa a circuit and bulb check. It grounds through the alternator edit- external regulator then turns off when charging exceeds battery voltage. It should be battery voltage with the key on and the plug unplugged.

-

Check out this ATK crate L28 engine on BaT

Thanks, and that is interesting. Google Translate serves its purpose well. Is there a Japanese Wikipedia? Any thoughts on where that "new" N42 casting comes/came from? There is a disconnect between ATK Vege (which seems to be a combined company, looking at the logos and the descriptions) and the KSS that comes up through that Japanese ATK link. 1936 versus 2003. North America versus Japan. From the web pages - https://atkvege.com/about-atkvege/ About ATKVegeATK North America is the largest private label Crate Engine Remanufacturer in North America. Partnered with our sister company, VEGE de Mexico, ATK VEGE has a history of Remanufacturing that dates back to 1936. https://atk.co.jp/company/ name KSS Co., Ltd. Representative President and CEO Keiji Okawa Established August 2003 Capital 3 million yen

- Charging fun with Zedyone !

-

Check out this ATK crate L28 engine on BaT

I think that the poor painting is probably becuase they are rebuilt engines. It's interesting that there is so little on the WORLD WIDE WEB OF DATA about ATK. Not even a Wikipedia blurb. https://atkvege.com/about-atkvege/ https://www.lkqcorp.com/?s=atk https://www.lkqcorp.com/blog/2011/12/14/atk-vege-engines-yamato/

-

Check out this ATK crate L28 engine on BaT

That's good info. The OP was in Lithuania. I wonder if Tony D's explanation was half right except that maybe Nissan produced modified castings for sale to rebuilders or for their own rebuilds. Tony D suggested that the ports were welded and machined but the casting sprue suggests that they were cast that way. I'm no expert but I don't think that you could cast molten aluminum over old castings and get a good bond, besides trying to match properties and the post-machining involved.

-

How vibration free is your 70-71 240Z?

Since you're in experimentation mode and you have fabricating skills, you might remove the factory mount and fab up a new mount that gives the desired angle. It wouldn't need to be super strong or made for permanence if you're only evaluating cruising speed. Keep the strap in place in case of breakage. It could be a solid mount. If the angle is perfect but the vibration is the same, then you can start looking elsewhere. The RTz mount either gives a certain angle with the GM mount, or it gives a range of angles in use with the snubber, as the diff nose moves up and down. The GM version is an actual mount, the snubber version is essentially a solid strap. p.s. have you considered mounting a camera under the car to see what the diff nose is doing while driving? Maybe something is moving. Or, looking back at your pictures of the crossmembers, why don't you just shim the crossmember mount downward with some washers. Perfect the angle, take it for a drive. then you'll know if you should go further.

-

Check out this ATK crate L28 engine on BaT

Somebody called datsunparts bid $2200. There's a business called datsunparts, looks Roadster focused. Might be worth more parted out. Those exhaust ports are weird. Maybe it's a "detuned" L28 for a different model. Maybe the Z's got the good stuff. https://datsunparts.com/

-

1970 Wiring Diagram

Found a picture on BaT. #138 shows a condenser on the back of an alternator. Bring a TrailerNo Reserve: 1972 Datsun 240Z 4-SpeedBid for the chance to own a No Reserve: 1972 Datsun 240Z 4-Speed at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #181,834. Uploading Attachment...

-

Check out this ATK crate L28 engine on BaT

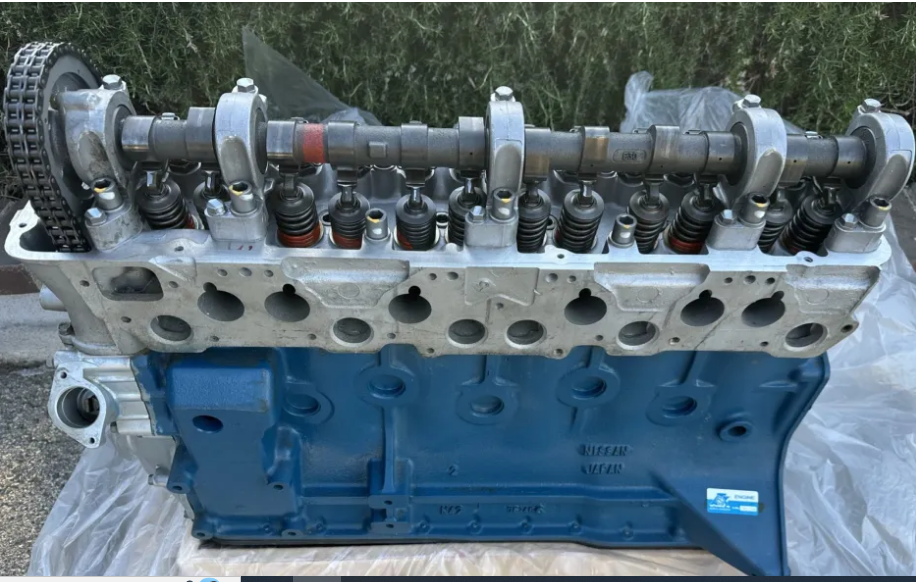

Still in the crate. Has odd exhaust ports. Has anyone seen this before? Also has an odd "temperature sensor bung" that looks like it was welded on. Maybe for use in the 280ZX? N42 heads didn't use the cylinder head temperature sensor. Bring a TrailerNo Reserve: Datsun L28 Crate EngineBid for the chance to own a No Reserve: Datsun L28 Crate Engine at auction with Bring a Trailer, the home of the best vintage and classic cars online. Lot #190,091.

-

How vibration free is your 70-71 240Z?

Do you have a Nissan factory transmission mount to try? Maybe you're fcoused on the wrong member. The T3 mount is the only "non-factory" part.

-

1983 280zx na cranks wont start help

ZCarDepot has been good at sourcing parts. He shows a pickup coil for a ZX. The other parts are hard to find though. I've seen the bushings for sale in the past but not recently. Might be simpler to put in a 240Z distributor with a Pertronix conversion. Or a 280Z with an HEI module. Z Car Depot IncSearch: 38 results found for "distributor"New, used, and OEM repair and replacement parts for Datsun 240Z, 260Z, 280Z, 280ZX, and 510.

-

Wire identification

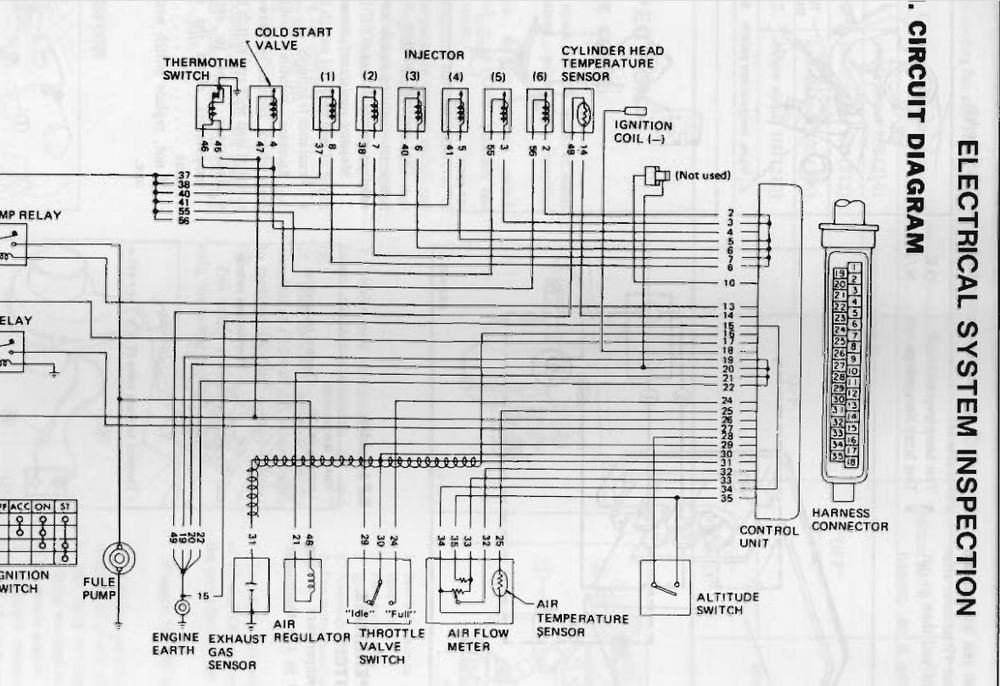

I found an old thread with several of us iin it. I feel kind of dickish reading my old comments. Hopefully I've mellowed. The 6801 has come up before, I'd forgotten about it. I also pulled up the 79 and 83 EFI ECU wiring diagrams and they seem essentially the same. Odd though that the 79 diagram doesn't show the O2 sensor circuit to the ECU. Just interesting that they apparently added the microprocessor to what had been a processor-free system. 1979 Uploading Attachment... 1983 Uploading Attachment...

-

Wire identification

More piling. Sorry, but now that the original question has been answered I'm just following this new thing. Edit - there is a lot in this Hybridz thread. Answers some questions. Way beyond my skill level, couldn't even try to fake it. Just curious. HybridZre-mapping and live tuning L28ET 1982/83 S130 ECCSEdit for latest information; See posts further down for full details on modifying 1982/83 ECCS for re-mapping and live tuning. All information related to reproducing this project can be found on Gi...

-

Wire identification

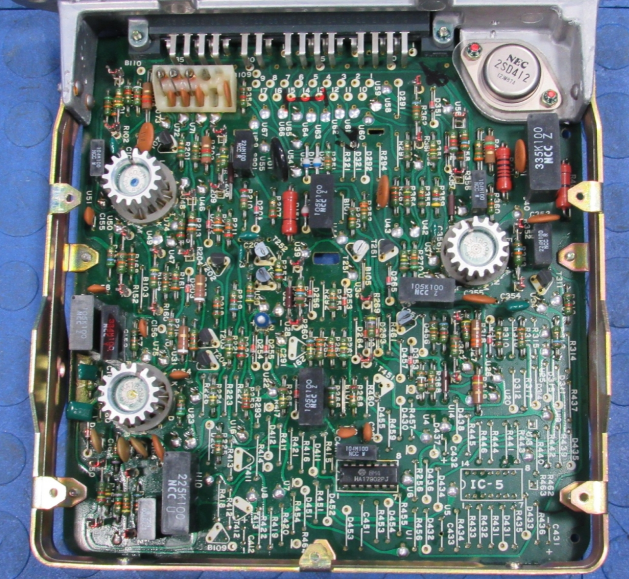

Usual pile on... I found what is supposedly a 1979 280ZX ECU on the internet with some good pictures. I don't see a 6801. Maybe there's an earlier controller in there somewhere? I'm not an electronics guy. The guy has a nice web site. If you click on the picture you can scroll through all of them and blow them up to a good size with another click. https://www.importapart.com/product/79-datsun-280zx-2-8l-l28-ecu-ecm-pcm-engine-computer-a11-616-420-oem-1869/

-

Wire identification

I found an old thread that might have some pictures. Haven't gone all the way through it. Funny though, Nissan uses the word "compute" in describing how the ECU (1978 I think) sets the injector pulse length. It's on page 3, post numbers are gone. Edit there's only a few pictures of early 280Z "ECU"s.

-

Wire identification

But what do you mean by "computer"? Does the controller contain a program? Does it perform computations? Or does it just convert one electrical input in to another? I don't know. I found some interesting things about it. It looks like it does contain programming, I wonder how complex it is. It would be interesting to see some of the code with comments. I assume that the code/program would be considered digital but the inputs and outputs not. https://www.cpushack.com/2017/12/07/cpu-of-the-day-hitachi-hd6801s0pj-automotive-6801/ http://www.bitsavers.org/components/hitachi/_dataBooks/U24_Hitachi_6301_6801_Assembler_Text_Editor_Users_Manual.pdf So, going backward from 1983, do you know when the Hitachi controller was introduced in to the ECU's? I know that the FSM's say that the 1979 and later ECU's cannot be plugged in to 1978 and earlier systems, even though they use the same connector. The pinouts are different, maybe because 1979 and up contain the controller. Does 1979 contain the controller and 1978 does not? Referring to what HS30-H said above, maybe the controller was introduced in to the ECU's also in 1979, along with being used in the ECCS. Only commenting to learn some new stuff. I started watching repair videos for modern vehicles and learned that they have all kinds of modern tech with high speed and low speed communication networks, and numerous "modules" each usually with its own controller, communicating on the networks. I think that even the intrument cluster in my truck has its own controller. Crazy. Always something new to learn...

-

Wire identification

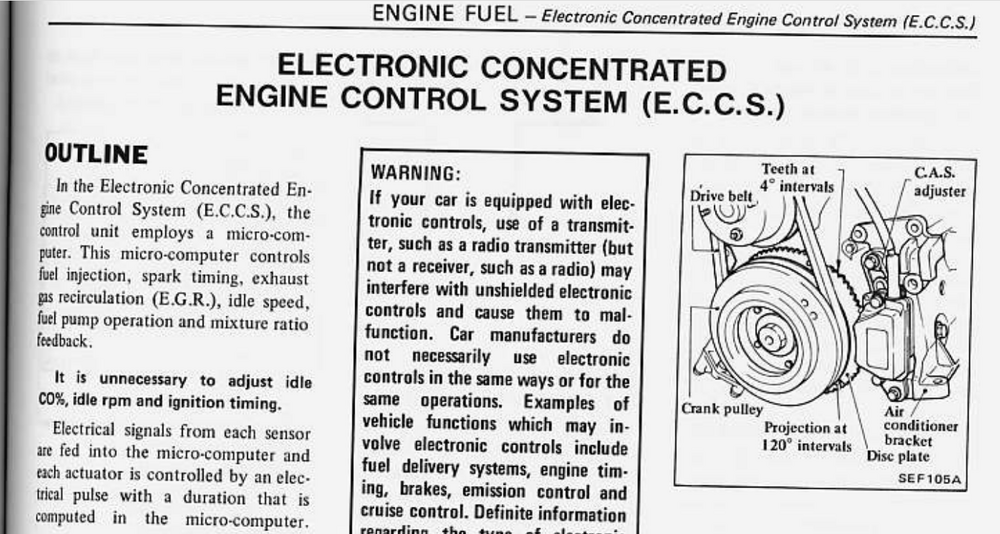

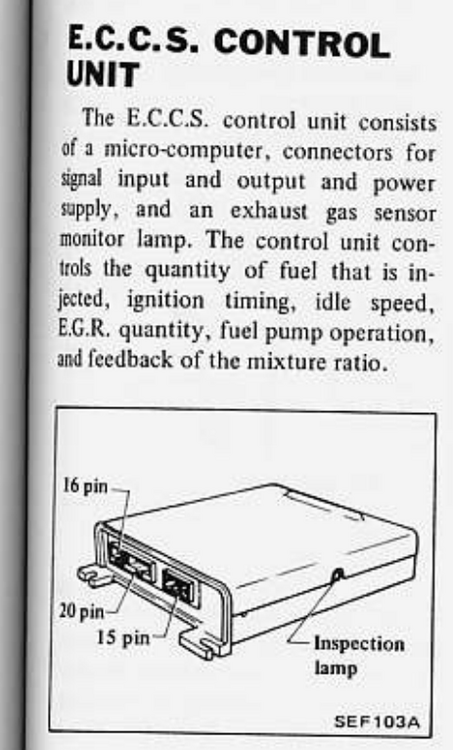

Thanks for the clue. I had looked in the 1982 FSM and found the combined EFI and ECCS descriptions, letters only, but should have started at the beginning. In the first 280ZX use of the ECCS, the 1981 Turbocharged 280ZX, they created an ECCS-only Supplement chapter, where they actually used the words, as defined above. Image below. They do call it a "micro-computer" in their description. I'm still not sure though that it does computing, in today's sense of computing. Besides the fact that it's not digital. (Sorry SteveJ, now that's really pedantic, Just having fun.). But it was still early days for computers, and I think the definition still varies today. From the 1981 Turbo Supplement Engine Fuel chapter -

-

Z's on BAT and other places collection

Not bad. There are still good Z project opportunities popping up out there. https://bringatrailer.com/listing/1972-datsun-240z-357/