Everything posted by Zed Head

-

1978 280z Won't Run Properly Anymore! Any help is Appreciated!

This is always good, in general. Put everything back to where it "drove perfectly". The fact that the idle screw adjustment has no affect is a big clue. Almost sounds like the AFM vane is stuck or something else is blacking the intake system. Air flow is what controls engine speed. Are you missing any shop rags?

-

1978 280z Won't Run Properly Anymore! Any help is Appreciated!

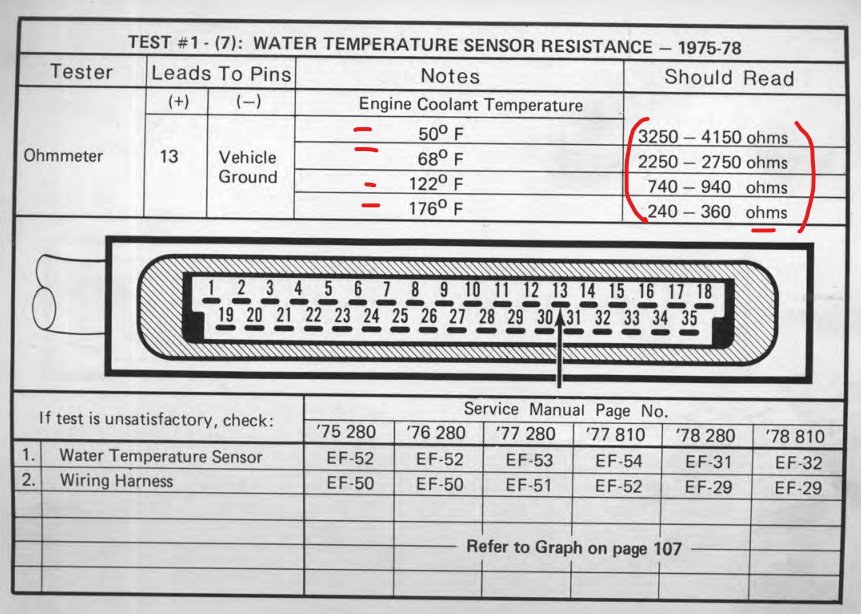

It's probably something to do with fuel or valves. People have had the locknuts come loose on the lash adjustment. Knowing fuel pressure is always good. As far as "testing", you need to show the numbers. So many people try to start out with a couple of easy "tests", but in the end, days or weeks or months later, they almost all have to get the real numbers. Even the FSM gives bad advice with their "N.G" continuity tests. Just go directly to real resistance readings. Make a list. Seriously, it will save a lot of time.

-

1978 280z Won't Run Properly Anymore! Any help is Appreciated!

- Sealing an oil pan

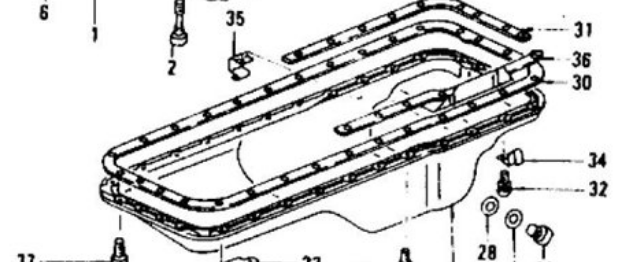

That's a heat shield. It goes behind the exhaust downpipe. Nissan must have seem some cooked gaskets and made that little piece to fix the problem. http://www.carpartsmanual.com/datsun/Z-1969-1978/engine-280z/cylinder-block- Clutch fork throw

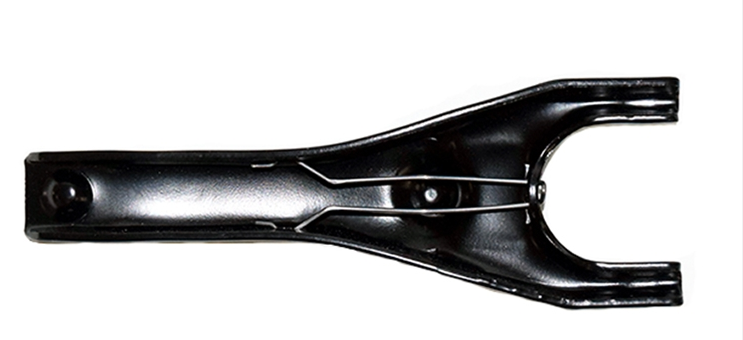

No offense zKars, there's a lot in this thread. But his problem, summarized, is that he has the longest collar he can find and still does not have room behind the fork to get enough fork throw before the fork hits the back of the hole. A longer rod won't help (that sounds wrong somehow...). This is his starting point.- COVID-19

Won't be too many games in New York state. 22 states are on the quarantine list as of now. https://coronavirus.health.ny.gov/covid-19-travel-advisory The travel advisory is effective at 12:01 am on Thursday, June 25, 2020. If you have traveled from within one of the designated states with significant community spread, you must quarantine when you enter New York for 14 days from the last travel within such designated state, provided on the date you enter into New York State that such state met the criteria for requiring such quarantine.- Clutch fork throw

I found an old video about broken noses. You're not the first, by far, to get stuck in a weird transmission problem hole.- Clutch fork throw

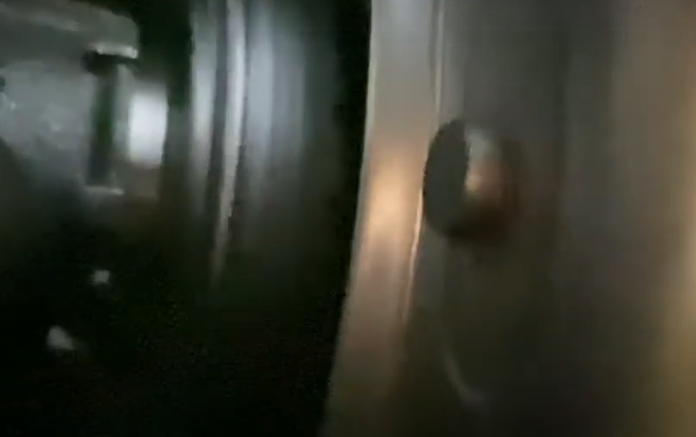

I wrote this yesterday before I realized the 71A thing, then didn't post it. Overall, it seems like something is partially opening your pressure plate, jammed up against it. Either the nose of the transmission, or the sleeve/collar, or a combination. There should be play behind the throwout bearing and sleeve. In other words, the bearing and sleeve should not be contacting the pressure plate fingers or the front of the transmission, at rest. It should have wiggle room between the two. I went back and watched your video and when you move the fork I don't see the bearing/sleeve moving. Only the fork. It looks like something is jamming the bearing/sleeve in to the pressure plate. If you take it apart again make sure that the bearing and sleeve slide all the way back on the nose of the transmission. That friction surface is often overlooked. Even though the bearing/sleeve is held in the fork it's resting on the nose. The noses actually get worn and break after many miles with no lubrication, just from the bearing and sleeve wearing on it. Most old transmissions have a groove worn on the nose. And, following up on EuroDat's last comment, maybe the collar slipped off of the nose as you were installing and is jammed in there, between the end of the nose and the pressure plate. It might be that you just need to get it back on the nose where it can work like it should. I think that is a good possibility. It fits, I think. It's at about :40 in the video. Here's a clip from it, below. Lots of fork movement but no sleeve movement.- Clutch fork throw

The distance from the front of the bellhousing down to the top of the pivot ball would be good to get. If it's the same as a 71B then the 92 mm number should work. The relationship between clutch parts will be the same. After all of this, it might just be that the 71A needs the thick pressure plate. The pivot ball might be deeper, farther away from the engine. p.s. if that is the case, then adding washers to extend the pivot ball would be rational.- Clutch fork throw

Okay, found it, in the very first post. I don't know for sure but the 71A might not work with the 92 mm standard that the 71B does. Either the 71A is different and we've been steering you wrong or the 71A is the same and you still have a problem.- Clutch fork throw

I just realized something that might be the main clue. All of our advice has been for the 71B type transmission. Yours appears to be something else. I don't see the front cover of the 71B. I noticed in some of your other pictures that the transmission was more rounded, didn't have the distinct features that the 71B has. You can probably start over, not sure where though. Identify your transmission. Is it a "monkey motion" 71A type? Sorry I didn't say something sooner, when I noticed the odd roundness. Here's the roundness. I even copied it and reposted.- Rear control arm bush alignment

Doesn't having the offset to the outside leave a gap for that little rubber seal/washer? And keeps the nut off of the outer edge of the control arm. Nissan spent a lot of time avoiding metal to metal contact. If you look at all of the components in the rear you'll see that they're all suspended in rubber, separated from the body. Just an extra view... http://www.carpartsmanual.com/datsun/Z-1969-1978/axle/rear-suspension/69- What's old is new again. Alternator upgrade options

I think that the one wires actually have a couple of jumper wires right on the back of the alternator. Where the L and the B and the S connections are. They're all connected together then one wire is run to the battery and harness. So you don't have a charge light and the loads are farther away from the alternator itself. But it's simple.- Clutch fork throw

Checking back. Curious if you went ahead and installed it. With extra washers and things. I was going to suggest that you could make a lever arm, extension, for the end of the clutch fork to see if the clutch releases with that amount of throw. A piece of pipe with the end hammered flat could be made to slip over the end of the fork and you could work it by hand.- Clutch fork throw

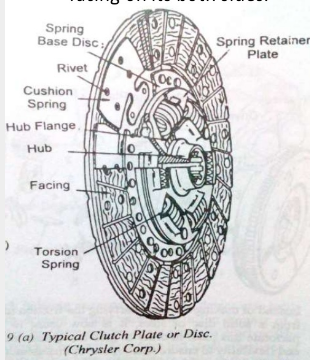

1/2 mm. Now we need to figure out how far the 25 mm of slave travel moves the pressure plate fingers and how that translates to the pressure plate moving. Would be a pretty cool math problem, for high school algebra. Seems like a lot of work now. Don't forget that clutch disc has a wave spring inside that compresses. Can't remember the name of it. Cushion spring? It doesn't seem like it would be the problem. 1/2 mm is less than a groove in the disc. Might be worthwhile to let all of this new info stew inside your brain for a bit. Something might come to you.- Clutch fork throw

If you decide to do this, make sure you use thread sealant on the pivot ball threads. The hole extends in to the oil cavity inside. I had one that leaked and it was a real puzzle to figure out. Never assume that aftermarket parts are correct out of the box. If you have an old disc you could compare. Or take a measurement and maybe somebody will have one out here.- Clutch fork throw

Here's my last one, until I think of another one. I think that it's been mentioned but it's worth reconsidering. Your pressure plate is being held open. Maybe your clutch disc is too thick. This would hold the pressure plate open and move the pressure plate fingers down. Or, and I don't really know if this could have the same effect. The disc is on backwards. If the disc is on backwards it can be pressed on to the flywheel bolts. This might be enough force to make it hold the pressure plate open. It would also engage the transmission with the engine, making it seem like the clutch is engaged, but never allowing you to disengage. Since all of your other work seems right, that seems most likely at this point, to me. Your pressure plate is being held open by something, causing the fingers to be depressed, causing the fork to be out of proper position.- Clutch fork throw

Weird that you can pull it so far forward if it's clipped on. When I messed with mine I was always worried that I'd accidentally pull it out and not be able to get it reclipped. In your video you're moving the fork completely off of the pivot ball. It's normal to be able to move the sleeve back and forth but the fork should stay on the pivot ball. The shaft turning could be light drag. I'd make sure that it's firmly engaged. Put a rag on the output shaft and use some pliers to turn it, against the force of the engine. It just looks like your fork is way too close to get full disengagement. You could even measure that distance between fork and case until the fork bottoms out on the case and see if it is more or less than the slave cylinder stroke. Just looks like you're going to bottom out on the case. Anyway, thanks for the puzzle...- Clutch fork throw

Or, maybe because the holding spring is not in place the fork is slipping off of the throwout sleeve. So maybe that's actually a major thing. That spring on the back of the fork should be set in place, clipped over the pivot ball, at the same time you clip the throwout sleeve under the fork tine springs. All of the those parts are firmly held in place and aligned by the spring clips and the nose of the front cover. I see the edge of the spring in your other pictures but it doesn't seemed to clipped on to the pivot ball. Example from internet -- Clutch fork throw

It still looks wrong. Is it possible that the clutch is already disengaged? Put the transmission in gear and see if you can turn the output shaft. Maybe when you install the transmission you're pushing the throwout bearing in to the pressure plate, disengaging the clutch. That could happen if the nose of the front cover is binding inside the throwout sleeve. Also, and this is minor, but there should be a spring on the back of the fork that holds it on to the pivot ball. It shouldn't be loose like you show in your video. Just another odd thing.- Clutch fork throw

The distance from the friction surface of the flywheel to the back of the engine would tell you something about if the flywheel is thin. Again, somebody will need to get you a proper measurement to compare to.- Clutch fork throw

That's a good one. That should show up at the front of the crankshaft. The damper pulley should be projecting forward. You'd see it in your belts and pulleys, they'd be misaligned, from damper pulley to water pump, etc. Might also see it in the distance from the flywheel edge to the back of the block. That's a more direct measurement but someone will need to verify theirs for you. Never heard of it happening but all of your other numbers seem right. Seems like a crankshaft misalignment would cause other problems too though.- Clutch fork throw

Couple more... Is there a gap between the engine and transmission? That will move the pivot ball back. Picture below. Do you get the same distance with the new fork installed? It's a lot of work putting it all together to check, but it's the last unknown. Maybe that older fork is deformed somehow. It's the actual contact surfaces that matter, you can't really tell from the outer dimensions. The pivot ball could be "sunk" in to its seat on that older fork. The fork "tines" have a lot of wear visible.- Clutch fork throw

I'd use the newer fork myself. The pressure plate and slave cylinder and throwout bearing/sleeve/collar will be designed for the newer fork. The older fork is the one odd piece in your collection of parts. The pivot ball looks in good shape. The one you showed is an odd style I haven't seen before. Might be an aftermarket part. Plus the wear on the old fork will lose a little bit more travel.- Clutch fork throw

One last thing on your pivot ball. Is the washer underneath it? Without the washer it is effectively shorter which would cause some of your problem. You'd lose the thickness of the washer plus the geometry would change slightly. Not much else. Shaving the flywheel would also lose you some, moving the pressure plate away from the pivot ball and throwout bearing. Good luck. - Sealing an oil pan

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.