Everything posted by Zed Head

-

Rhythmic thunking slowing to a stop from right rear

I'd swap the wheels first. Easiest and a possibility.

-

Help ID brake calipers

I'd take a good close look at how well what you have fits together. It has the signs of hack. You might find that you need to start over to make it right.

-

1976 280Z Replacement ECU Issues

p.s. since you only have two bad cylinders it might be worth the time to just replace valve seals on those two. If it was mine I'd probably just do the two intake valves. Why mess with the others that appear to be just fine?

-

1976 280Z Replacement ECU Issues

You'll have to look very carefully through the valve spring. Bright light, magnifying glass, or camera with close-up shot. Here's a shot of an exposed one and link to the guy's video. No idea who it is, found it by Google.

-

1976 280Z Replacement ECU Issues

Four of your plugs look great and two look terrible. The fact that your pressure numbers look good but you're losing oil and have two dirty cylinders suggests that the oil scraper rings in those two cylinders are damaged, or the intake valve seals on those two cylinders aren't working. Valve seals is the easiest place to start. Changing oil won't help. You might be able to see by eye if the intake valve seals on those two cylinders are different than the others. Worth a look. I wouldn't be surprised if the engine is only firing on four or five cylinders. Those plugs are filthy.

-

Help ID brake calipers

Looks like this one, linked below. Those hub wheel flange faces need a cleaning. https://zcardepot.com/collections/brakes/products/toyota-front-brake-caliper-upgrade-vented-rotor

-

Reproduction Gas Cap Seal - Any Experience?

The seller should tell what the material is. Might be fine, can't tell. Here's a different option. https://www.mcmaster.com/products/rubber-gaskets/o-rings-1~/square-profile-oil-resistant-buna-n-o-rings/

-

Question about sealants

Red-Kote seems like a good choice too. Made for sealing gasoline. http://damonq.com/red-kote.html RED-KOTE® Red-Kote is an internal fuel tank liner designed to seal leaks and prevent further rusting. As a sealant, Red-Kote excels at sealing the often hundreds of pin-hole leaks that occur along seams or where straps wrap around the tank. Once in place, Red-Kote forms a very tough, flexible membrane that will never crack or flake as many competitive products do. Red-Kote will not plug lines or cause engine damage when used properly. Future rust will be prevented because condensation will not contact the metal. A partial list of additives that Red-Kote is resistant to includes ethyl alcohol, methyl alcohol, toluene, methyl tertiary butyl ether, isopropyl alcohol and tetraethyl lead. Red-Kote takes approximately eight hours to dry

-

Question about sealants

It would depend on the demands of the application, flexible or rigid, but I would check the specs for fuel resistance specificity. Looks like it's a hot topic, several options popped up with a search. My only real-world experience is sealing a pinhole leak on the bottom of a Pathfinder gas tank with JB Weld's Steel Stick product. It was a defective spot weld. https://siliconesolutions.com/ss-300.html https://www.permatex.com/products/gasketing/gasket-sealants/permatex-permashield-fuel-resistant-gasket-dressing-flange-sealant-2-oz/ https://www.jbweld.com/product/steelstik-epoxy-putty-stick https://www.jbweld.com/projects/gas-tank-repair

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I understand how it went together. I was asking for any future searchers wondering if this will give good results or not. Can't tell. If there's too much play you'll probably get vibration. If it's off-center, the same. It's a good quick "get by for a while" repair though. Might be fine for a long time. It's just much less precise than the Nissan procedure described in the FSM.

-

[2024] What Did You Do To/with Your Z Today?

Can't tell without a video! https://en.wikipedia.org/wiki/Hoon

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

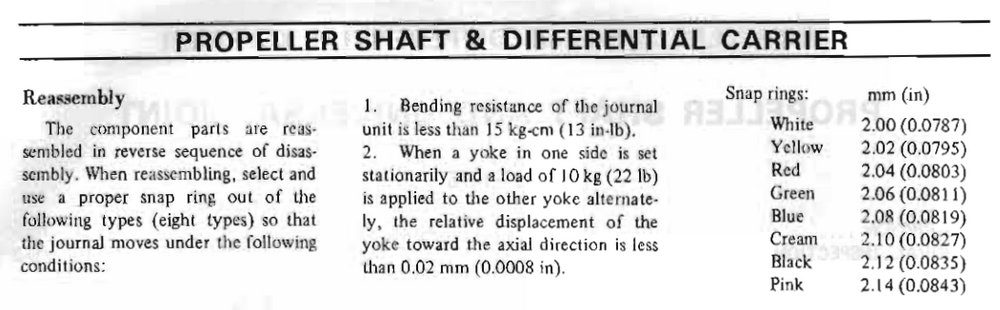

Did you measure the play (axial displacement)? Just wondering. Not much to be done if it's off but it would be interesting to know. These instructions are hard to understand but they can be guessed.

-

Found OE spare key pouch 280z

There's a tool bag in Miscellaneous. https://www.carpartsmanual.com/datsun/Z-1969-1978/miscellaneous

-

Found OE spare key pouch 280z

Let's see the key. Seems odd that the bag wouldn't have the word Nissan on it. The tool bag does. There was a similar post a while back where somebody found a magnetic key box attached to his car and thought it was "factory". Hard to imagine Nissan supplying a device to store an external key on a car. Every thief would know "it's here somewhere!". The YKK seems right though. https://en.wikipedia.org/wiki/YKK

-

Z's on BAT and other places collection

Ouch. The investor's market is taking a hit. Same car, seven years later, somehow with fewer miles (probably the same actually). Looks like the year got corrected also. Maybe that's the missing $19,000. https://bringatrailer.com/listing/1964-sunbeam-tiger/ https://bringatrailer.com/listing/1965-sunbeam-tiger-86/

-

[2024] What Did You Do To/with Your Z Today?

That must be up in the 10:1 CR range, right? Have you calculated it? Flat tops with an N42 head?

-

Series 1 rear brake issues

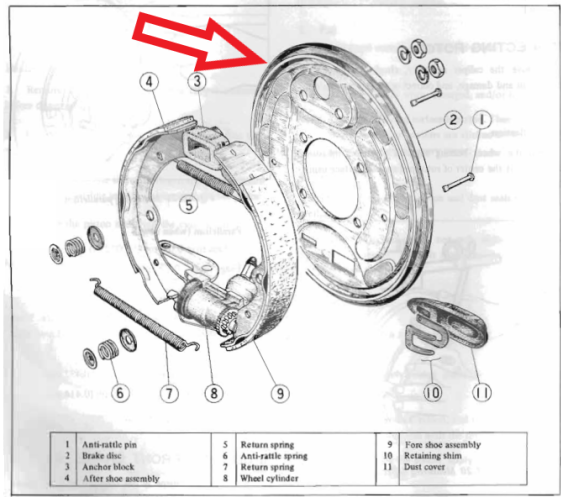

This is the most likely cause. It would be unaffected by the shoe change. Very common. Somebody on the forum just had a similar problem. The drum is a close fit around the perimeter of the backing plate, see red arrow. Any slight bend will cause rubbing, and the plate material is not that strong. The plate itself acts like an amplifier of the sound. Some finesse with a hammer will fix it. Usually you can see a shiny spot where the drum rubs.

-

Series 1 rear brake issues

Piling on - actually, it sounds like the brakes are/were stuck in the applied position. Were the drums hard to remove? You've probably solved it and moved on. Just posting for fun.

-

Series 1 rear brake issues

Just for clarity, and maybe a clue - you said wheels, plural. If that is correct then, of course, the cause is either identical on both sides, or is being transmitted from the differential. Or mabe even the propeller shaft, or coming from the shaft. Are you sure it's coming from the wheels? And how fast are you going when you hear the noise? Could be more a lot more detail to the description. Good luck.

-

Series 1 rear brake issues

Problem fixed? Cause unknown?

-

SpareTire

Get a higher profile. 70 instead of 55. Didn't do the math but there's a lot of room above 55. Just seems more complex than necessary. I understand wanting the same diameter for steering or differential. I think that there are other ways to get there. Since you'll be using tapered lug nuts you'll need to be more aware of thread engagement. You're going to lose 3/8 - 1/2" with a spacer. There's probably enough but it's one more thing...

-

SpareTire

Why not "stretch" a narrower tread on to the rim? It's just s apare. No spacer necessary.

-

1976 280Z Replacement ECU Issues

The topic has come up several times over the years. Put the words below in to Google search and a bunch will come up. site:classiczcars.com valve seal replacement

-

Series 1 rear brake issues

I think that you're going to find a shoe retaining part, or a broken/loose spring inside a drum. The parking (not "E) brake "no longer" works, meaning that it did for a while. Something broke or came loose.

-

Z's on BAT and other places collection

Here's a new offering that might be a fun resto-driver money pit garage project. Probably needs a little bit of work on everything. Has an odd rust pattern. No reserve. California. Gas tank cleaned but says it's not been run since 1991. https://bringatrailer.com/listing/1971-datsun-240z-297/