Everything posted by Zed Head

-

Vapor Tank Question

I thought the topic was fuel smell in the engine bay. There are exposed lines in the cabin behind the plastic, vents and filler plus the tank. That's a whole different problem. This link is about 240Z's but the 280Z's are very similar. Pull the plastic and explore. https://www.zhome.com/Racing/FuelTankVaporLineMod/FuelTankVaporMod.htm

-

Vapor Tank Question

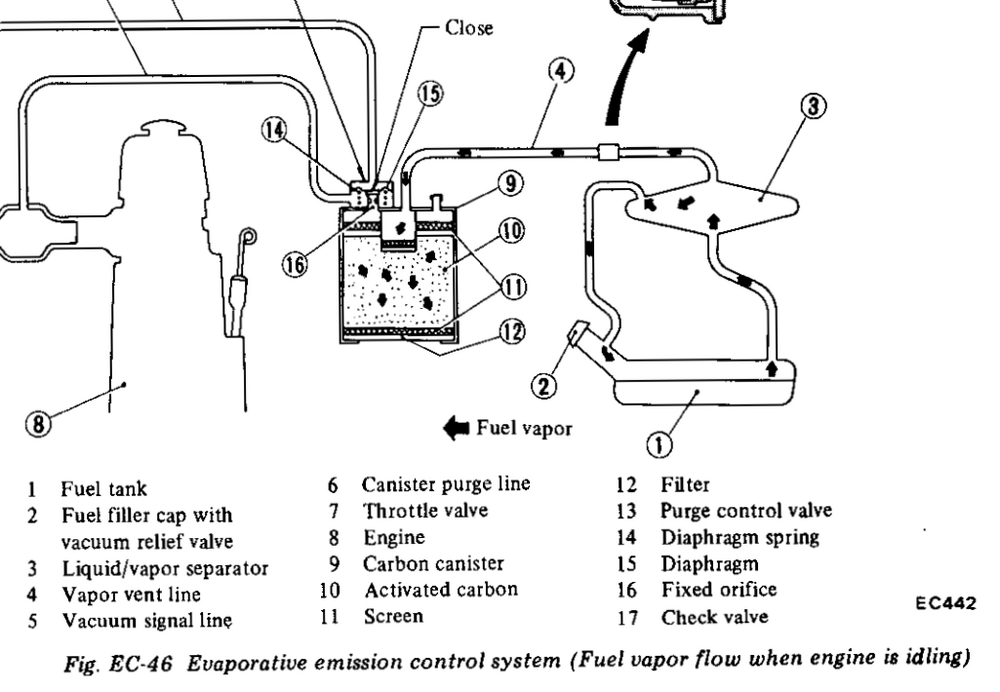

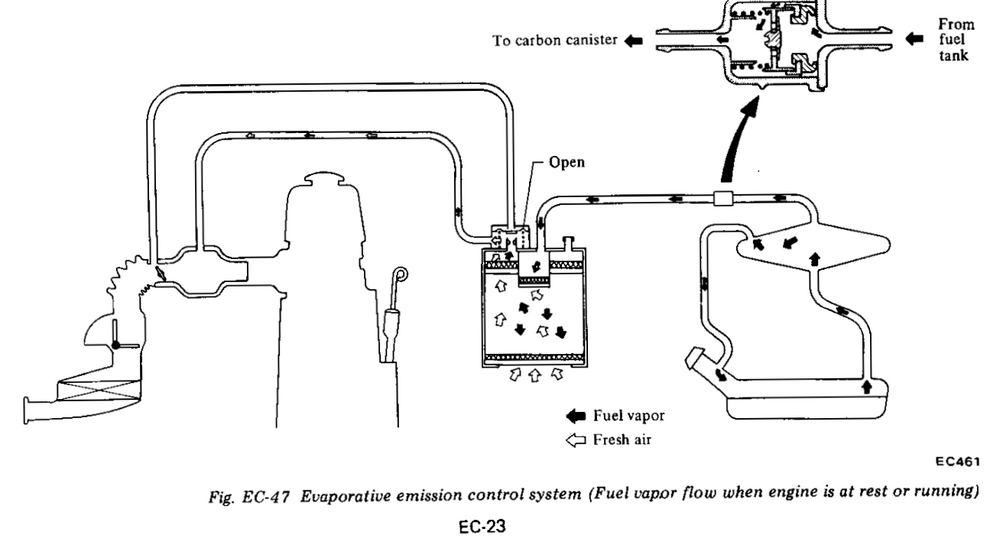

I understand what you wrote the first time about bypassing the canister. If you're smelling gas it means that the carbon/charcoal media in the canister is either saturated with fuel or it is cracked and not absorbing the vapors properly. You're trying to redesign the system but what you really need is just new canister material and a properly functioning control valve. You said that your control vlalve doesn't work. You might be able to fix yours by opening the purge valve in the cap, drill it or remove the return spring, and using a separate vaccum control vlalve on the purge line. Welcome to the world of old cars and NLA parts. Your best bet to get rid of the fuel smell is to get the system back to working like it was designed to work. A salvage yard canister from a newer car and a vacuum control valve would do it, I think. They show a spring inside the cap. It must be a pull spring, not a push spring. That's what keeps the purge valve closed when there's no vacuum. Anyway, notice also that there's a "fixed orifice". Meaning small, so that air flow is low. You could probably remove the cap and connect the purge line directly to the orifice with a vacuum control valve in-line. Also, activated carbon is the more technical term than charcoal. Your carbon has probably lost its activation.

-

Vapor Tank Question

Here's another that you might actually find in a wrecking yard. 2005 Chevy Impala. Actually any Chevy around that year might have one. The hardest part might be finding out where they put it on the car. https://www.rockauto.com/en/catalog/chevrolet,2005,impala,3.8l+v6,1431102,exhaust+&+emission,vapor+canister,5180

-

Sat for two days, now won't start/run.

Any screw in the vicinity will probably be a match, they're not special. Look around under the dash and try a few.

-

Vapor Tank Question

Having the purge hose connected all the time creates a vacuum leak at idle where it will have more impact. The system is designed to give precise mixtture control at idle speed. If you connect directly to the tank you'll have a vacuum leak through the gas cap. It's vented so that the tank is never under vacuum. It would be an odd vacuum leak though since it will be pulling gas fumes in with the ait. Hard to say if it would cause a rich mixture or a lean mixture. This is page 7 and I don't know if you still have the original charcoal canister or a new one. The material in the canister does get clogged over time and can also solidify and crack I would guess, leaving open passages back to the tank instead of filtering/capturing the fumes. Might be that you just need a new(er) canister. They all work the same so you could just grab a complete canister with control valve on top from a newer car. That's what I would do. I looked around for a new TB controlled system on Rockauto but didn't find one. But there's probably one out there somewhere. You could also get a new canister for a solenoid controlled system then use a vacuum control valve to control the flow. Edited for a better option. Ports clearly ID'ed. Tank, purge, air. https://www.rockauto.com/en/catalog/chevrolet,2002,corvette,5.7l+v8,1380024,exhaust+&+emission,vapor+canister,5180 https://www.rockauto.com/en/moreinfo.php?pk=940007&cc=1380024&pt=5180&jsn=10999 https://www.rockauto.com/en/moreinfo.php?pk=814069&cc=1120903&pt=4980&jsn=1979&optionchoice=0-0-1-1

-

Sat for two days, now won't start/run.

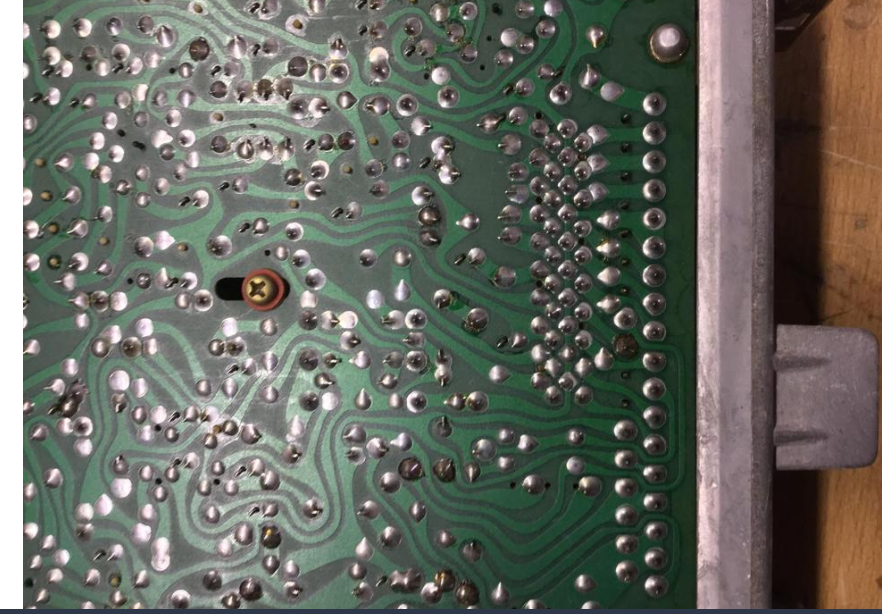

I can't find a good thread about reflowing the solder joints, even though I said there were threads on the forum about it. If you have a good eye and/or a magnifying glass you might be bale to see the cracked joints. Apparently they are on the line of 35 pins where the connector connects. This thread has a lot of good info and pictures, in general. The line of solder spots on the right -

-

Vapor Tank Question

Vapors are pushed in to the charcoal canister from the tank. Like when you fill it with cold fuel and the fuel warms up in the sun. The vacuum hose from the intake manifold pulls air through the charcoal canister, pulling the fuel vapors from the charcoal as the air passes by. The bottom of the canister is open, so there's no way for the intake system vacuum to pull on the hose back to the tank. The Nissan engineers created a pretty good pictorial description, although they shouldnt have said "at rest" since they show the vapors flowing to the manifold. That only happens when running.

-

Sat for two days, now won't start/run.

Your symptoms match how the ECU's fail. You might try banging on it. Many people have used that as a diagnostic method, there are stories on this forum about it. Apparently the solder joints crack at the main connection and banging on it brings them back to life. It it works it's a clue. Fist or foot, it's worth a shot.

-

Sat for two days, now won't start/run.

Check the fuel pressure regulator vacuum hose for raw gas. Maybe the diaphragm ruptured and the engine is sucking in excess fuel. Running super rich.

-

KAAZ R180 LSD fit problem

Does it have the new cover on it yet?

-

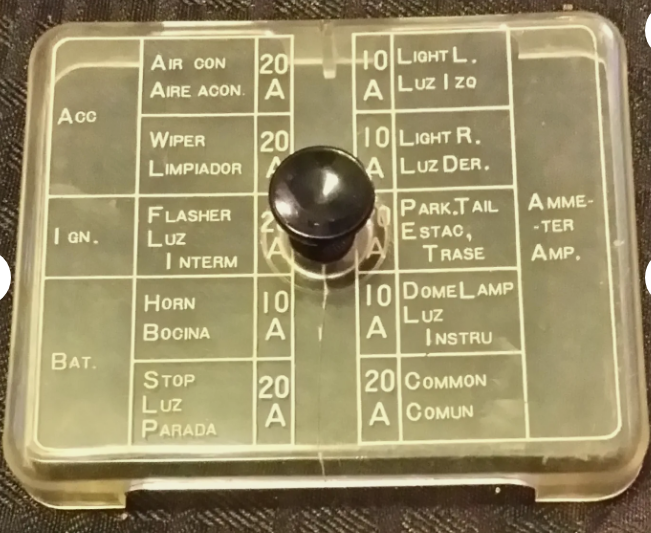

no headlights

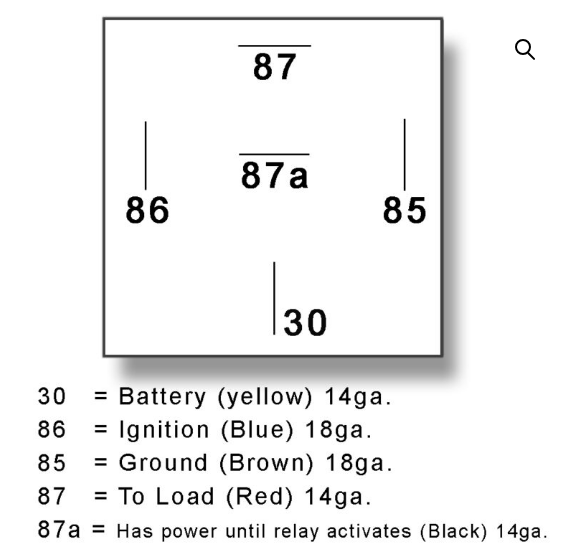

What about the pin for pin 30 on the relay? Might just be a bad connection at the battery supply. https://www.thezstore.com/product/3861/headlight-relay-upgrade-harness-70-73-240z

-

no headlights

No offense but I'm going to guess that you don't feel comfortable doing electrical system diagnosis. There really should be several voltage measurement reports here. At the headlight switch (input and exit), at the fuses (left and right), at the headlight sockets, etc. And at the relay socket pins before you replaced the relays. That's the way to do it, you shouldn't pull or replace anyhting until you've taken a measurement or probed with a test light. You've pulled fuses and replaced parts but haven't reported any actual measurements. I'd start at the headlight fuses. They're easy to get to and you can go forward or backward from there. Measure from each side of the fuse to ground with the headlight switch on.

-

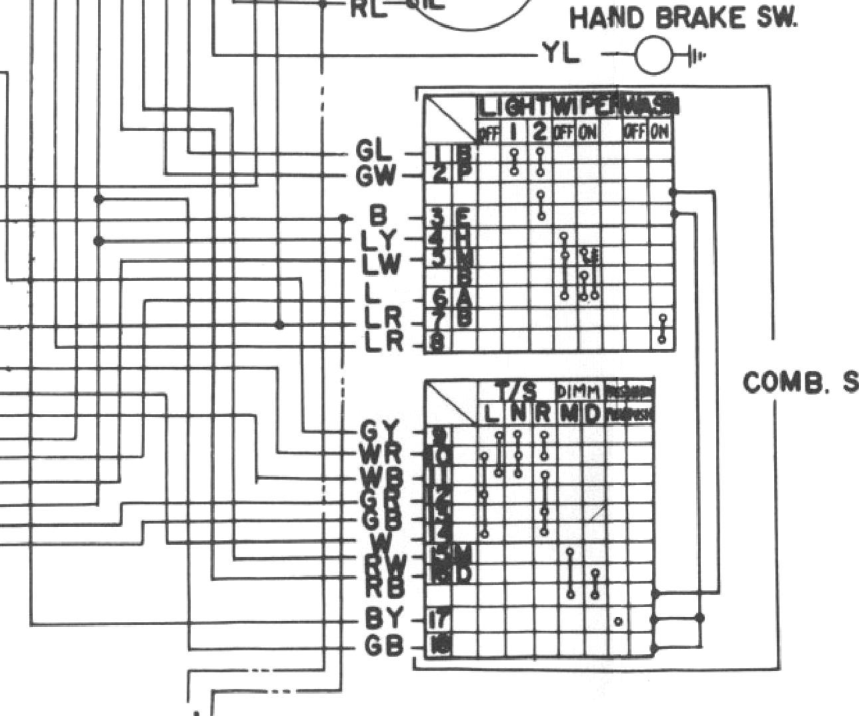

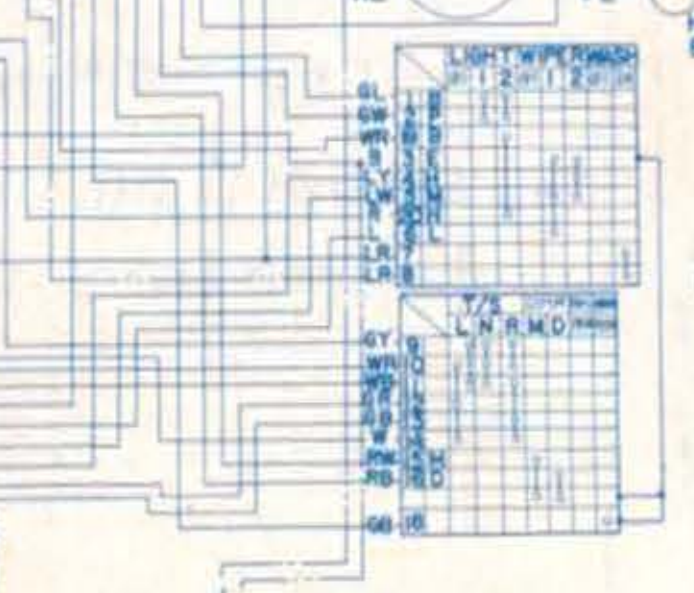

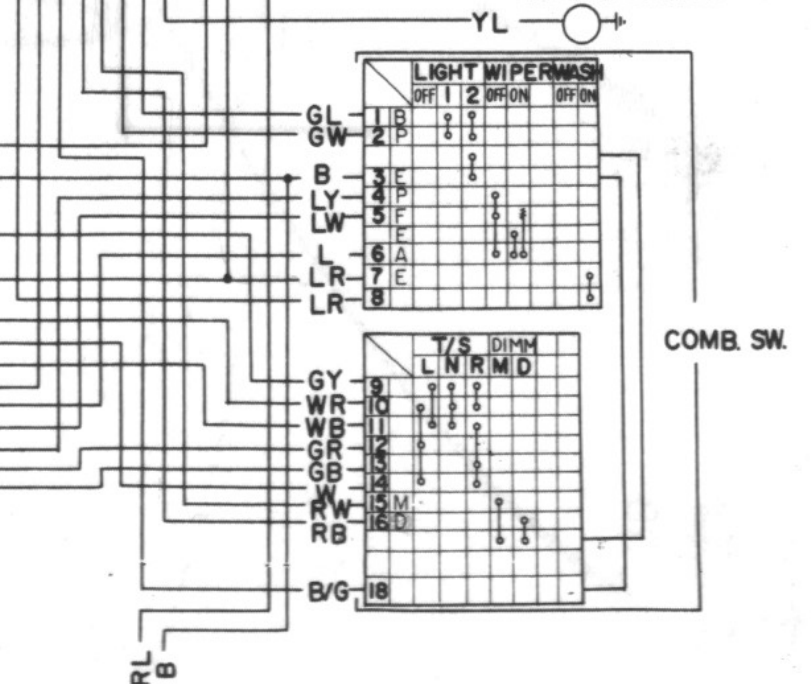

no headlights

240Z's didn't come with headlight relays. More to your Z than it came with from the factory? Sorry to muddy up your thread. I got spoiled on my 280Z. You could follow the diagram easily. From power source to ground. I can't get a grasp on those 240Z diagrams.

-

no headlights

Here's the clearer version from cgsheen's source. And a link to the Supplement he mentioned, where the graphic below came from. I had it, just picked the wrong source from my computer. It's here on CZCC also. Edit - actually I see that the Supplement has the empty block under position 2. Looks like a typo. But the two images together should be useful. Good luck. Edit 2 - never mind I see how the empty block works. Still confusing to me though. RB and RW head through the Dimmer circuit and back through the Combo switch, if B is black for ground. It looks like the Combo switch is after the Dimmer circuit to complete the ground. Different. Anyway, I have no incentive to solve the puzzle. Double good luck! https://www.classiczcars.com/files/category/11-240z/

-

no headlights

-

no headlights

Not sure what you mean by "mating connector" or how you are checking for voltage. I was going to suggest checking the wiring diagram but it's pretty confusing. Nissan did some weird wiring stuff before they got to the 280Z. But if you do decide to take a look it's on the last few pages of the Owners Manual. There are some odd freestanding diagrams out on the internet that have missing links, like open blocks on the headlight circuit. The Owners Manual seems to have a complete diagram. Page 37. https://www.classiczcars.com/files/category/17-owner-manuals/

-

Looks good for $11K

San Jose is a ways away from Bend.

-

HLS30-00684

How did it behave when you jacked it up to put it on the stands? Was it flimsy or solid? The rockers, I believe, are the major longitudinal body stiffeners. You know more, of course, but overall stiffness tells a lot about potential. Was that a muffler hanger holding the "roll bars"? And a piece of strap steel for the seat belt? What does "inspection" entail in your area? How much needs to be done to pass? Just curious. It might be possible to get it past inspection but avoiding involvement with a future disaster is reason enough to say no.

-

Fan Hits Radiator

Well then, no offense intended, sometimes we overlook the obvious, the simple thing to do would be to compare the parts on the front of both engines. Get out the ruler or tape measure. Or, any chance you got the engine mount brackets on the wrong sides? People do it sometimes but I don't know if it moves the engine forward. It does cause it to tilt the wrong way.

-

Looks good for $11K

Who wants to message the guy about leaving a deposit?

-

Fan Hits Radiator

Did the 240Z have anything in it when you bought it? Looked at your old posts and can't find any details. Could be an engine swap, could be a salvage car that didn't have anything. Details about the L28 might help too.

-

Conflicting info on Voltage Regulator delete wiring

Where are you seeing two options for 1977? The writeup that you pulled from is specific to 1977. His other comments are his best guesses for other years. I'd follow his first set of instructions. https://atlanticz.ca/zclub/techtips/alternatorswap/index.html The table that you pasted might be from zcarcreations if I remember right (not positive). That scheme will give you problems with your brake light. Follow the atlanticZ instructions and you should be fine. For 1977. p.s. when you copy from other web sites it helps a lot to post the link. Good luck.

-

Looks good for $11K

I thought that CL had a way to report scams but I guess not. So, what exactly is the scam? Not clear how the scammers make money from fake ads. I do remember the old "selling but not in town" scam where they asked you to wire money. But this one looks local. What's the latest scam technique?

-

75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

This page might help on the speedo gear. https://www.thezstore.com/category/1005/speedometer-pinion-parts

-

KAAZ R180 LSD fit problem

That's a bummer. Here's a Hybridz thread that might be helpful. Note also the part about the ring gear size. Two different sizes for R180's. Better check. https://forums.hybridz.org/topic/49194-differential-cv-lsd-hp-torque-r160-r180-r200-r230-diff-mount/