Everything posted by Zed Head

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Thanks for the update on the springs. I didn't know that they came with a plastic coating. Also didn't know that you could buy them from TireRack. Also didn't know that they were so fragile. Are you saying that this is the second set that failed? At least they're still an option. There was a company that came out with new springs a few years ago but I think that they might have folded already. Can't remember the name but htere was quite a bit of discussion about them back then. Eibachs had a reputation for unpredictable ride heights. Many of the Z's that used them ended up looking like Gassers.

-

73 240z won’t start. Have spark

Watch this from about minute 10:00.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

And, might as well ask since I'm here, are you saying that the Eibach spring or springs broke? Not trying to cause trouble, your writing implies that whatever it is is obvious to you. But you didn't really say what was going on and there's no broken ends shown for the Eibachs. The Eibach looks whole. Might just be me not knowing what I'm looking at but I've seen a few springs. I had some Tokicos in my car and a set of cut down stock springs.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

Still confused. The black Eibach spring is clear. But now you've added another picture of what looks like a remnant of some other spring, intertwined with it. Looks like a single spring plus one. Two springs. What's the brown thing?, is the question.

-

5 speed swap tunnel hole for the shifter

I assume that was the early body style shown in your sig? Maybe that matters. I used the 280Z 4 speed shifter on all of mine, it swaps right in. Never tried the ZX shifter.

-

5 speed swap tunnel hole for the shifter

I'd be surprised if they're not the same basic structure but with different trim for manual versus auto.

-

5 speed swap tunnel hole for the shifter

-

5 speed swap tunnel hole for the shifter

I found this video with a good image of the 280Z shifter hole, below. I don't think that the 280Z's need shifter bending or notching of the body hole. I had a 78, 81, and 83 5 speed in my factory 4 speed 76 280Z and had no conflicts. (I've mentioned that before in other threads.) I think that Grannyknot has worked on many 240Z's where that might be a problem. On the console - are you going to use the automatic console? No idea what that needs. I don't know why Nissan made the hole so big but it looks like you need that front portion of it. It looks like they left the pattern for you in your second picture, just follow the edges.

-

5 speed swap tunnel hole for the shifter

It's pretty easy to install and remove the shifter after the transmission is in. You could do any bending after the installation. Probably metal and console trimming also. Not clear what you're working on so can't comment on what modifications you might need to do. Good luck.

-

4/75 Datsun 280Z; Leaf Green, CA market, 250K miles, Long Term Project 03/2023-

-

Z's on BAT and other places collection

It's already been through BaT before. I almost asked why the guy was selling it if it was the "right" Z. But, not really my business. https://bringatrailer.com/listing/1973-datsun-240z-198/ This 1973 Datsun 240Z is said to have undergone refurbishments in 1985 and 2010, and it was purchased by the seller on BaT in July 2022. lucasphilips (The Seller) This author's likes: 8 Thank you all for viewing. I am offering this 1973 Datsun 240Z after owning it for two years, and getting a ton of enjoyment out of it. I spent about a year searching for the right 240Z. I bought this one because the color is so unique, and the meticulous documentation that came with the car indicated the prior owner had taken proper care of it.

-

73 240z won’t start. Have spark

Set the points gap by getting the points rubbing pad on the peak of one of the distributor cam lobes and setting the gap. Once the points gap is set it does not need to be touched again. You can rotate the engine and the distributor body wherever you want and the points gap will not need to be reset. Then find out where the rotor is pointing with the #1 piston at TDC, compression, +/- 0 to 10 degrees (use the timing mark on the damper pulley). Then set your #1 plug wire at whichever cap terminal the rotor is pointing at. It should be ready to start. If you get all of that done but cannnot use the screw in the pedestal to lock the distributor body down then you'll need to reset the oil pump. But you need to find out where the rotor points at TDC, +/- 0 to 10 degrees, advanced first. Setting points gap. Start at 1:00. https://youtu.be/BC3nmuXdEuI?feature=shared&t=61

-

73 240z won’t start. Have spark

I don't think that the points will open with the rotor between electrodes, if the parts are put together correctly. This is why all three things need to be done at the same time. If the rotor is between plugs it means that you need to rotate the distributor body. I don't think that you actually asked the question about the rotor between plugs. Which might be why no one answered.

-

73 240z won’t start. Have spark

This like the Adam Sandler movie "50 First Dates". Each day is like the one before never occurred. You have one of the three. Do the other two. Side note - I finally discovered how to do a multiquote from multiple pages.

-

73 240z won’t start. Have spark

Here's an old thread with good stuff in it. Excellent picture of lobes-up by Cliff/unseen. Just realized that I have no memory of the ignition timing mark on the damper pulley ever being mentioned by Mr. Vancouver. That's the other indicator of TDC. Get the cam lobes up, rotate the engine until the timing mark is at zero. The adventure is in trouble if TDC compression cannot be found with this information.

-

73 240z won’t start. Have spark

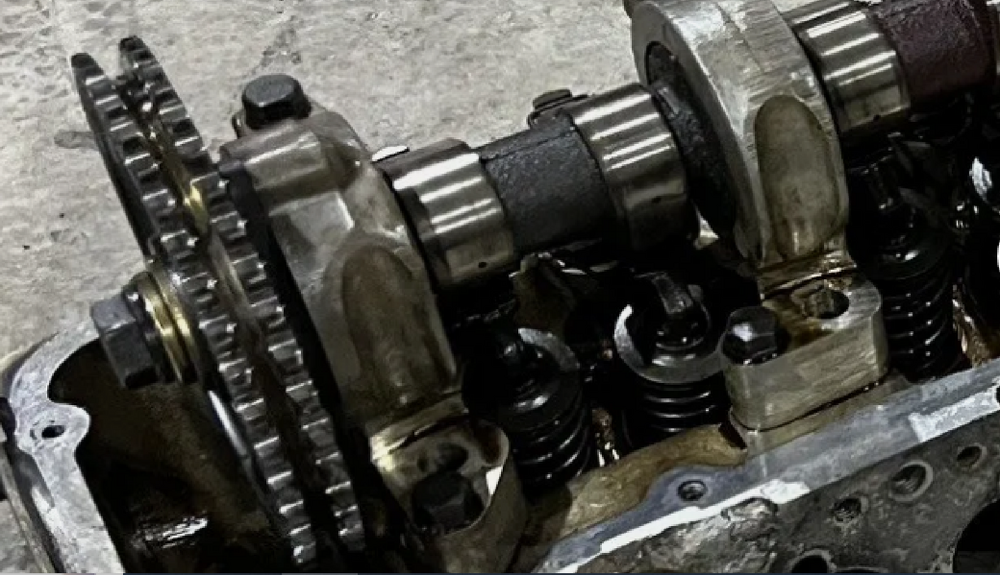

You're right. I thought the other lobe might not be visible behind the timing sprocket but lost track of the actual configuration, even though I had pasted the rusty cam picture earlier. I dug up an eBay picture for reference just now, pasted below. He wore me down, I should have checked. Not sure how two cam lobes sticking up can be misinterpreted. Still, all of the advice given by everybody in all of the numerous posts is good. He just needs to get some of it done. The picture below shows the #1 cam lobes. The piston is not at TDC on compression stroke.

-

73 240z won’t start. Have spark

They look up, so you're on compression stroke. but which spark plug electrode is the distributor rotor pointing at when you are at TDC on #1, and are the points close to opening, either about to open, open, or just closed. You need to get those three things happening at the same time so that spark will be correct for all of the cylinders as the engine turns. Compression stroke on #1, distributor rotor pointing at #1 electrode in the cap, points opening. If you can take a picture like the one above but with the distributor included, one with the cap on, one with the cap off, and with your plug wires identified in the cap that will tell a lot. We need to know where the rotor is pointing when #1 is at TDC on compression. And we need to know that the #1 plug wire is attached wherever it is pointing. And that the points are open. p.s get everything set up with the valve cover and the distributor cap removed. Rotate the engine by hand and watch the parts move. You'll be able to figure out for sure when the points open on the #1 compression stroke and place your dist. cap wires correctly. Then replace the valve cover and try to start.

-

73 240z won’t start. Have spark

Actually it can be off by quite a bit. It would probably start with initial timing set from -5 to 25. A range of 30 degrees. But there's a lot of other things that are unclear. You never answered the question about where you were spraying the starter fluid. You haven't removed a spark plug to see if it was wet. You haven't verified that the timing was close to correct, or if it's even set to the compression stroke. If you're firing on the exhaust stroke as, suggested by several, you probably won't hear a pop because the flame will just shoot out the open exhaust port. You're looking for a simple single answer but there are many things that have to be right at the same time. You need to create a check list then check each item. You got spark, which is something, and you installed different carbs. Lots left.

-

Z's on BAT and other places collection

-

73 240z won’t start. Have spark

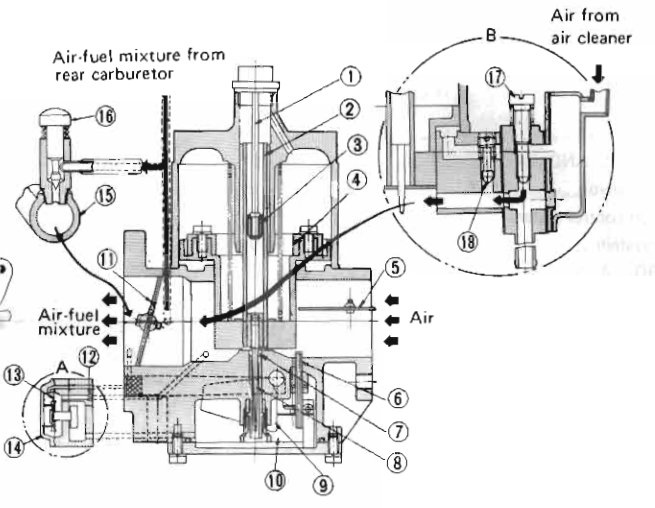

Rotating the distributor body will not affect the points gap. I talked about when the points should be open in Post #11. The points open and close each time the distributor cam lobes go by as described in the video I posted. They open and close about 15,000 times per minute at 5,000 RPM. Rotating the distributor body changes the time that the points open for each cylinder, in relation to the piston position as it moves up and down in the cylinder. Rotating the distributor body is called "setting the timing". The shaft with the lobes stays attached to the camshaft but the points move in relation to the distributor cam lobes because they are attached to the distributor body. Rotate the distributor body as you watch the points and lobes.

-

73 240z won’t start. Have spark

Another.

-

73 240z won’t start. Have spark

This video might help. I copied from the "point" where he talks about the rotating shaft. Watch this video and others from the sidebar.

-

73 240z won’t start. Have spark

The stuff in Post #11 will answer the question about the oil pump. If you do the things and the rotor is pointing the wrong way then you'll know the oil pump is off. Still might not need to change anything. Just get the timing mark and the points opening and the rotor alligned with #1, then put the rest of the wires in. But #11 answers many questions. Do #11 (make sure the cam lobes are up), take pictures, come back. Worst case is the lock down screw won't have a hole to thread in to. Then it can be decided whether or not to reset the oil pump. Progress is slow but it is happening.

-

L28 NA N42 Engine (Block and head)

I wrote a bunch of stuff but will just say instead that idle and pressure tests in the driveway might not be replicating the loss conditions of driving. Loads and temperatures are different.

-

73 240z won’t start. Have spark

For where you're at right now I would do the above. Whenever you try to start the engine and nothing happens you suck raw fuel in to the cylinders. Do the above, pull a spark plug and make sure it's not soaked with gasoline, then try to start it with starting fluid if the plugs are dry. When you spray the fluid in to the carburetors make sure the carbs are open so that the starting fluid can get in to the intake manifolds and cylinders. Also consider the choke.