Everything posted by Zed Head

-

73 240 su flat top to round top swap

- 73 240 su flat top to round top swap

Retap the fitting for NPT. ...- 73 240 su flat top to round top swap

I mentioned that earlier but it got no response. He might find an NPT that is close. People do for the oil pressure sender port. He could even put the fitting back in and use a hose and bolt. Or thread the inside of the tube and use an NPT plug, it looks pretty thick. Or take the fitting in and get a compression fitting. He'd have to cut the flare off of the end. That's what I emant earlier about "mechanicing". Just pick a path and make it work. Could also focus on getting the engine to run with no cooling. If it's a lost cause there's no point in worrying about the cooling system. Many ways to move forward.- 73 240 su flat top to round top swap

Take the fitting that you removed to Ace Hardware and ask somebody to match the threads with a brass plug. I can't tell if it's straight thread or tapered but the right person at Ace should know. Get some thread sealant too. https://www.acehardware.com/search?query=brass pipe plugs https://www.acehardware.com/search?query=pipe thread sealant- 75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

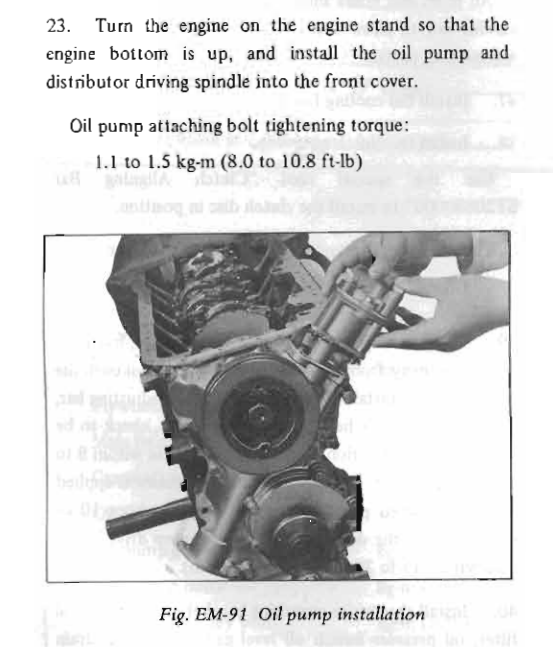

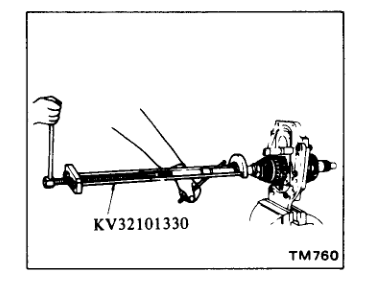

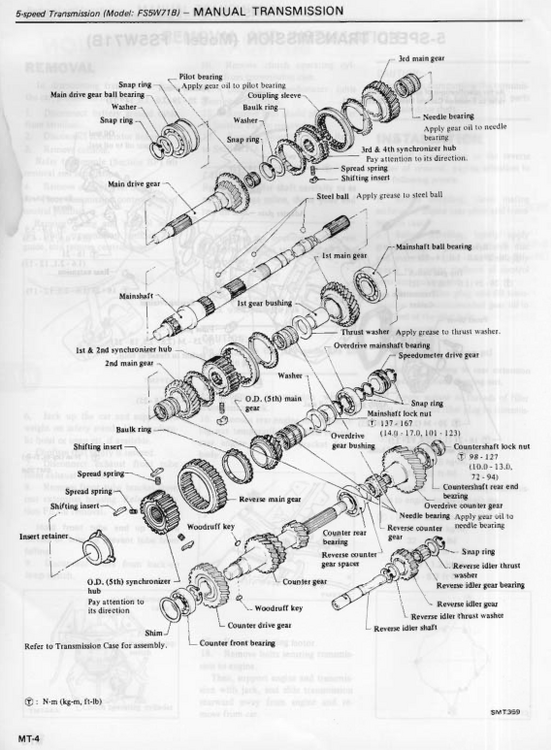

I've had a few apart for small things but have not replaced the adapter plate bearings. From what I've read the hardest part is getting the gears or bearings off of the long tail shaft. But people have made their own tools from pipes and other odd things. I think it's this illustration. You can always tear in to it until you get stuck then put it back together.- 75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

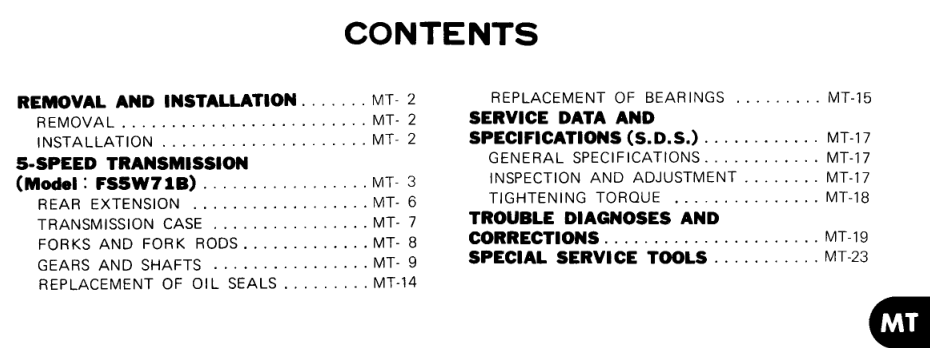

I'd use this one. Should be a Manual Transmission chapter inside. A sample. There's even a specific bearings section.- 75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

There's a guy on Hybridz who really got deep in to rebuidling and improving these transmissions. It's entertaining and I think he covers many of the basics of rebuilding. It starts out slow and simple but gets pretty complex by the end. https://forums.hybridz.org/topic/110792-high-rpm-shifting-dynamics/- 75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

Probably not a "requirement". Dave WM rebuilt one with completely destroyed adapter plate bearings (the center plate) and it worked fine when finished. It was still working even with the bad bearings. The parts seem to be very durable and able to take lots of abuse. Dave's thread might also be pretty descriptive as far as rebuilding. @Dave WM Otherwise, hate to do it to you but ... the FSM has a very thorough rebuild procedure laid out.- 75 280Z - 5 speed swap from 81 280ZX - any catches I should be aware of?

I think that the shift lever issue is a 240Z thing. I had a 78, 81, and 83 5 speed in my 76 at various times. All used the original 4 speed shifter with no problems. Also, I think that Dave WM is talkng about the 225mm versus the 240mm clutches. Different bolt patterns. The clutch collar needs to match the pressure plate height. 92mm. The fork pivot is in the same position on all except the very early 4 speeds.- 73 240z how to find plug order on dizzy

Isn't this question self-answered? If you're looking and you can't see them then it's hard. There's only eight small screws holding the valve cover on. It would be a good idea to see how things look anyway considering the rest of the engine bay. Take the cover off. Pour some oil on the camshaft lobes. https://www.atlanticz.ca/zclub/techtips/cam/index.htm- 73 240 su flat top to round top swap

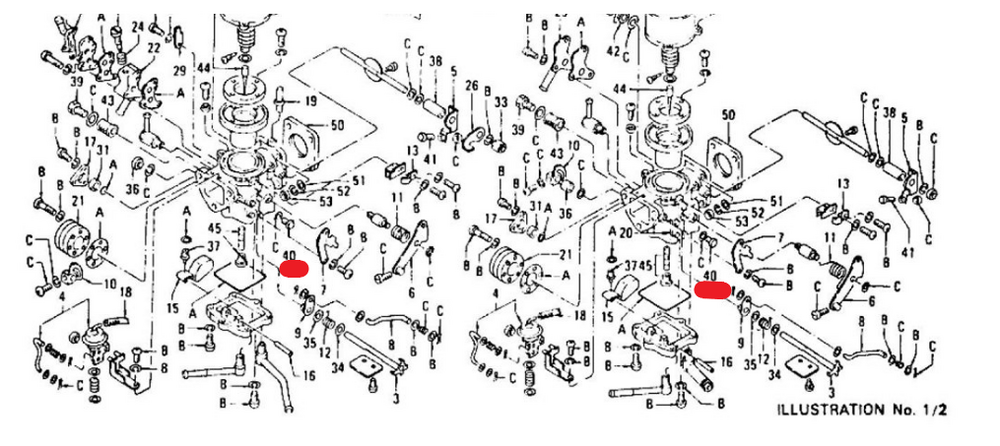

There is no how-to guide on blocking coolant lines. Mechanic's ingenuity is required. The piece of hose and a bolt is a roadside fix. Temporary and unreliable. (Oops, site posted at the same time. No offense intended Cliff! Double oops. Cliff fixed it at the end (I don't read good). We are in agreement.) Follow whatever line you're trying to block back to its source. Choose the approariate blockage method. Here are some samples. These are pretty good. You'll need to measure. https://www.mcmaster.com/products/compression-fittings/shape~cap-and-plug/ These are good if there's a fitting. BSPT is the thread type. https://www.mcmaster.com/products/plugs/pipe-plugs~/?s=brass+plugs+bspt For the carb lines you could just bypass the carbs. Just connect the two ends together. You'll lose some cooling power since the fluid won't be passing through the radiator. I'm not 100% on inlet and outlet but I think that it's these two ends. Maybe somebody will correct me if I'm wrong.- 73 240 su flat top to round top swap

- 73 240 su flat top to round top swap

- 73 240 su flat top to round top swap

"Driving" will require a working clutch and brakes. They take a lot of work once they get corroded and crusty. That car has obviously been sitting for many many years. You might eventually get to hear the engine run but it will probably take much more time and effort before you feel it moving under its own power. Have you pushed the clutch pedal down yet? I'm assuming it's not an automatic. Besides that, you'll probably want a gas tank that holds fuel and a pump that pumps it. Have you looked inside the tank yet?- 73 240 su flat top to round top swap

Actually you removed the carbs and intake manifolds. Maybe that's where the earlier confusion came from. In the picture I posted above it showed the intake manifolds still attached to the engine. Yes, the nuts underneath the manifolds are hard to get to. The more pictures you post the nastier the whole situation looks. What is your end goal? You have a ton of work ahead of you if you want to drive it.- 73 240 su flat top to round top swap

Here's some stuff that might be helpful/inflammatory. https://www.ztherapy.com/technical_stuff/spotterguides/zcar/240spotter.htm "When installing or removing the carbs from your manifold, all the nuts need to be loosened up before trying to remove them. There is no clearance on the bottom of the carb to remove one of the nuts. Sliding the body out a bit will allow the nuts to be removed. "- 73 240 su flat top to round top swap

Yo yo yo dude, the mounting holes are in the same spot on the manifold. Nut on a stud, hex head screw, whatever. Put an open end wrench on it and turn it. Counterclockwise. Just like the guy in the video. Word.- 73 240 su flat top to round top swap

Actually he does show nut removal later. Not much to it though. A wrench, some contortions.- 73 240 su flat top to round top swap

Are you asking how to use a socket on an extension, or a wrench? That's what mechanicing is all about, choosing the tools to get the job done. This guy put a whole Youtube video guide together and apparently the nuts are so easy to remove it's not worth showing. 7:45 they're there, 7:50 they're not.- 71z but L28 engine, could someone tell me what I have?

Most likely a 1975 or 1976 280Z engine. Originally an EFI engine. 5521 is pretty low, I'm going to guess 1975. People often swap the carbs over and install them in their 240Z's. Sometimes they use the 280Z tranmsission and differential also. What type of carburetors does it have? You'll be competing with Shawninvancouver for carb advice. 25-30 years means the gas tank and fuel system are probably rusted and gunked up. Some work involved there. Somewhere here on the forum or out on the internet there is a basic guide for getting an old car back on the road. Can't remember the title of the thread. Ways to prepare the engine to get the most life out of it after it runs again. The cylinders tend to rust even sitting inside, just due to condensation. Check out the Resources area - https://www.classiczcars.com/files/- SU flat top bowl drain screw

Looks like I was wrong. It's on the side. Probably down by the bottom. So it will work correctly. After the old gas is drained, what next?- SU flat top bowl drain screw

The law of gravity suggests that any opening on the bottom will drain the bowls. Also known as chambers. Look underneath.- 73 240 su flat top to round top swap

Weird how I have the urge to post. But then change my mind. So far, the car has only made a few sparks. Carb swapping is far in the future. This is unknown -- 73 240 No spark

Unlikely. No offense intended. Electrical connections, firing order, and timing apply to electronic distributors too.- water pump 280z

Other stuff can make noise up there. Worth checking before you start breaking bolts. - 73 240 su flat top to round top swap

Important Information

By using this site, you agree to our Privacy Policy and Guidelines. We have placed cookies on your device to help make this website better. You can adjust your cookie settings, otherwise we'll assume you're okay to continue.