Everything posted by Zed Head

-

resurrecting a 1977 280Z

Once the pressure is set the gauge can come off. No real need for a permanent gauge.

-

resurrecting a 1977 280Z

These look decent. Holley has been collecting brands and rebuilding their reputation so quality is probably fair. A selection of psi ranges. You would want the second one, I think. https://www.summitracing.com/search/part-type/fuel-pressure-regulators/product-line/holley-fuel-pressure-regulators?SortBy=Default&SortOrder=Ascending

-

resurrecting a 1977 280Z

I wouldn't use it. A decent gauge, those hose clamps, and pieces of hose would cost over $25. It's universal because they can change the ad copy to fit any application. 140 psi. "adjusts oil flow"? "ideal weight"? Not good... Fuel Pressure Regulator Kit: Prevent stalling, flooding, and other drivability problems by making sure your carbs are getting the right amount of fuel pressure with MOJTBE products. Adjust Capacity: This Aluminum Fuel Pressure Regulator Kit is adjustable from 0 to 140 PSI maximum fuel pump capacity. Optimally adjusts oil flow to meet your car's fuel pressure requirements. Materials: Premium aluminum construction for ideal weight and superior durability. Package Includes: 1x Fuel Pressure Regulator, 2x Hoses, 1x Accessories. NOTE: Not Legal in the state of California & New York, Not complies with C.A.R.B. regulations, Not for sale in the states of CA and NY. No instruction or direction included in the package, Professional installation is highly recommended.

-

resurrecting a 1977 280Z

That's an odd one. Looks like it has a vacuum reference port, which a carburetor would not need. But a 10 psi gauge which is way lower than any EFI system. Post the link, can't even tell what brand it is. Looks like eBay.

-

How to Install Universal Joints in Axles Properly - Using OEM U-Joints

It might also be that they were putting in the extra effort to perfect the installation. "Blueprinting" the u-joint and shaft with extra care.

-

How to Install Universal Joints in Axles Properly - Using OEM U-Joints

You're agreeing?

-

How to Install Universal Joints in Axles Properly - Using OEM U-Joints

It's hard to imagine that Nissan would have a had a fixture that aligns the companion flange or transmission shaft with the future center line of the propeller or drive shaft, so that a worker could choose the proper snap ring thickness, while measuring play. More likely that they had a set of go/no-go gauges and sorted the shaft yokes by the width between the ears and assigned them a snap-ring color. The area between the areas would have been cut with the center of the yoke as the reference point. I think that somebody rebuilt that u-joint in the past and just used the wrong color or was colorblind, or didn't care.

-

How to Install Universal Joints in Axles Properly - Using OEM U-Joints

Looks like one of those conflicting instructions areas. They say "don't change anything" but if you do change them so that certain conditions are met. Kind of like wheel bearing instructions - rotational torque or axial play? You have a dilemma.

-

How is Grahame Suckling's radiator doing?

Putting the image on the front page where people will click it kind of creates a cycle. I guess that explains it. Once it's on top it stays on top. Just wondering what the purpose was. Random images would be more interesting. Something new every day.

-

How is Grahame Suckling's radiator doing?

-

Original water pump?

How about a picture of the impeller? The other side.

-

Referral link

This does not appear to be the case. Never knew about that feature, never sent an email or shared anything, or posted anything associated with my CZCC screen name. Don't of any of the mainstream social media things. Maybe @Route66 could share how they got the referral link. Welcome to the forum Route66! How did you hear about it? Supply details...

-

Referral link

Who knows... https://www.classiczcars.com/profile/45020-route66/

-

Referral link

I wonder what else is getting sent out from "Zed Head" at CZCC.com. Weird. I'll check out this Route66 person. Bet there's a web link in the profile.

-

Front Inner wheel bearing seal

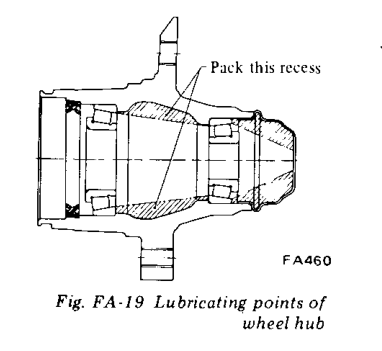

The seal has a seat in the rotor. The inner bearing will be pressed against the outer bearing race after installation so there will be no wobble. It will be wobbly while it's off the spindle but not once it's installed. Here are some pictures from the FSM. There's a gap.

-

technoversions tachmatch voltage booster

Funny, I forgot completely about the typical low output alternator problem. I've never heard of it affecting tachometer operation though. Maybe the combination of parts causes it. You can get 60 amp external regulator alternators. I think that the 280Z's all had them, until 1978 when they went to the internal system. Might give a little bit more current/voltage at low PRM. Thanks for the compliment. I appreciate a good puzzle.

-

Z's on BAT and other places collection

-

Referral link

-

technoversions tachmatch voltage booster

Seems like what you really need to do is move the power supply source for the fan. The tachometer and MSD aren't the source of the problem. It's the power supply to the tachometer and/or the fan.

-

technoversions tachmatch voltage booster

It would depend on current flowing through the transistor, the one in the drawing (if that's what it is). It's that meditation law. Oooohhhmmm...

-

technoversions tachmatch voltage booster

The MSD tach wire bypasses the multiple sparks. That's the reason they have it on the MSD component. Not sure what you mean by blue wire taped up by the coil. How is the MSD tach wire connected to the tachometer? If you could draw out your circuit and post it somebody might have some ideas.

-

technoversions tachmatch voltage booster

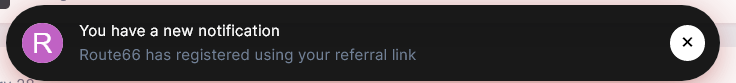

If it was mine I would measure resistance to ground through the blue wire that heads back to the tachometer. Since you have disconnected the original TIU the tachometer should be the only thing on the circuit. Not sure what it should be but it might show something. Do it with the key on and off. 12 volts. Power is supplied to the positive side of the coil, 12 volts, it passes through the coil and up the blue wire, through the 2.2 Kohm resistor and on to the tachometer. As shown in the drawing. The ignition module turns the 12 volts off and on. That's what the tachometer is designed to see - a 12 volt off-on (aka square wave) signal. The MSD tachometer wire (gray wire) is supposed to produce a square wave that looks like the one created by the ignition module.

-

technoversions tachmatch voltage booster

I had a weird situation on my 76 where the tachometer would not work correctly unless I connected a capacitor, actually a simple RF suppressing "condenser" from an alternator, to the coil negative circuit. That was after I converted to a GM HEI module ignition system. I don't understand why it worked but I confirmed it later when the connection broke and the tach went wonky again. The needle would just sit and quiver at the low end of the scale. I was doing the same thing you're doing, just guessing based on my own limited knowledge. My working word was "noise". Anyway, just for viewing pleasure, here is the FSM schematic of the tachometer in a 260Z. I assume that the square with the line through it represents a switch, probably a transistor, that is actuated by the square wave from the coil negative terminal. You can see that the tachometer just passes current with each pulse from the coil.

-

technoversions tachmatch voltage booster

Still not clear why you decided to start putting resistance in the MSD tach output circuit. The circuit already has a 2.1 Kohm resistor in it. The tachometer is designed to be on the end of a 12 volt line from the coil negative terminal. It can't be passing much current because it would cause the coil field to stay energized if it did. Maybe your tach is damaged and your efforts are finding a way to make it work.

-

Starter with some extra in/outlet? What is this!!???